This section delves into the intricate assembly of a high-performance machine, essential for those who seek to maintain or repair their equipment effectively. With numerous interconnected elements, each part plays a crucial role in the overall functionality. A clear understanding of the arrangement can greatly enhance maintenance efficiency, ensuring longevity and optimal operation.

Exploring the internal framework of this machinery reveals a complex network where each component must be understood in detail. Identifying the right elements within this setup can be the key to troubleshooting or enhancing performance. Such knowledge allows for a smoother workflow when handling maintenance tasks, making it easier to pinpoint and address issues.

The comprehensive breakdown provided here will guide you through each essential segment of the equipment’s structure. From the internal mechanisms to the exterior framework, the focus is on helping users comprehend how these elements interact to achieve the desired output. This insight is invaluable for anyone looking to optimize the machine’s use or undertake repair tasks with confidence.

Overview of Key Components in Vermeer BC1000XL

This section highlights the critical elements that ensure smooth operation and reliability of the equipment. Each component plays a vital role, contributing to the overall efficiency and functionality of the machine, helping to handle various tasks effectively.

Engine Assembly and Drive System

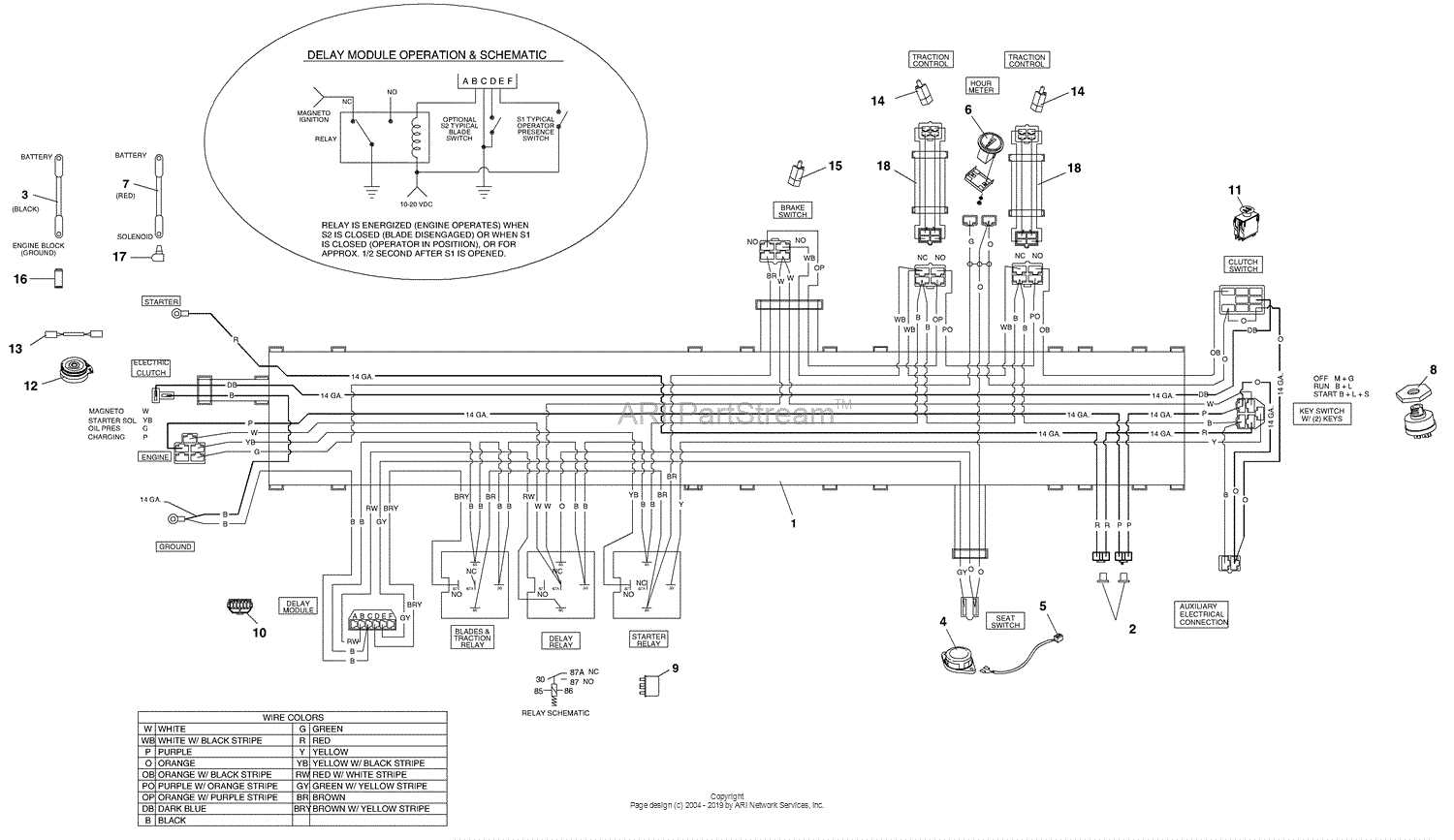

The power unit drives the entire system, providing the necessary force for processing. This segment includes a robust motor that offers consistent energy output, paired with a transmission that ensures seamless power delivery. Together, they maintain the machine’s performance under different working conditions, allowing for effective handling of challenging materials.

Cutting Mechanism and Feed System

The processing unit is at the core of the material handling capability. It includes a precision cutting assembly and an advanced feed mechanism, designed to manage materials of various sizes. This arrangement ensures smooth flow and effective reduction of materials, optimizing productivity.

| Component | Description | ||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

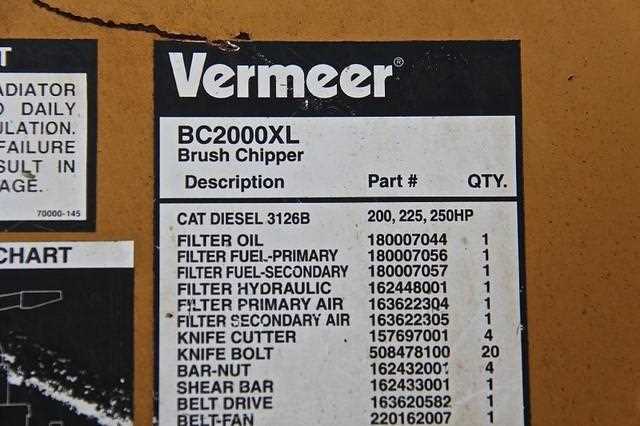

| Power Source | Common Maintenance Parts for BC1000XL

Regular upkeep of this machine is essential to ensure its longevity and optimal performance. Certain components are more likely to require attention due to their frequent use and exposure to wear and tear. By addressing these key elements, users can maintain efficiency and avoid potential downtime. Filters and Fluids

Changing air filters, oil filters, and ensuring proper fluid levels are crucial for the smooth functioning of the equipment. Clean filters prevent contaminants from entering the engine, while fresh fluids like oil and coolant help reduce friction and prevent overheating. Routine checks and replacements can help extend the lifespan of the motor and other internal systems. Cutting Components

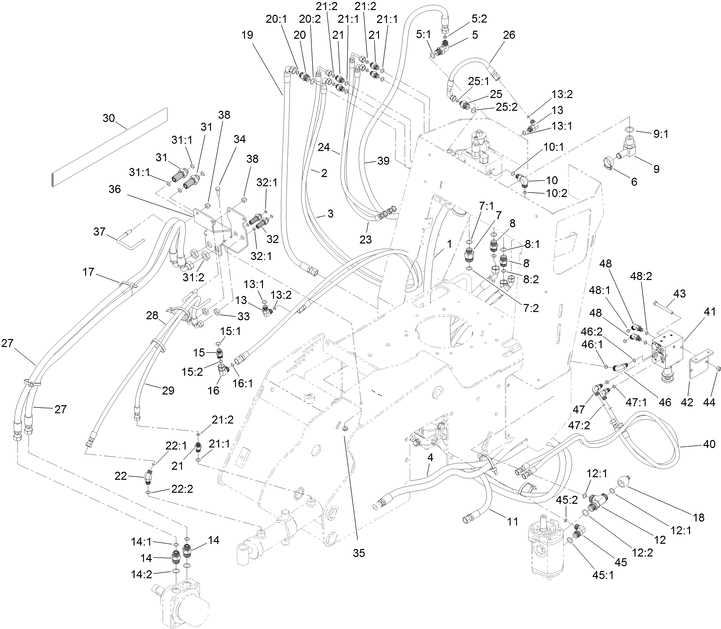

The cutting edges and knives are vital for processing material effectively. Over time, these edges can become dull or damaged, impacting overall efficiency. Regular inspection and sharpening or replacing these Understanding the Chipper’s Drive SystemThe drive mechanism plays a crucial role in the efficient operation of a wood processing machine, ensuring that all components work in sync for optimal performance. This system transforms the power generated by the engine into the movement needed to feed and process material, making it an essential part of the equipment’s functionality. Key Components include a series of belts, pulleys, and shafts that work together to transfer energy. Each element is designed to manage specific aspects of force and rotation, allowing for smooth transmission and reducing wear and tear. The interaction between these elements determines the machine’s overall efficiency. The transmission process begins with power delivery from the engine, which is then directed through the drive belts. These belts connect to pulleys, guiding the movement and controlling the rotational speed. The pulleys help adjust the force, ensuring that the rotational speed is balanced for consistent feeding. Proper maintenance of the drive system is critical. Regularly inspecting belts for tension and checking the alignment of pulleys can prevent breakdowns. Lubricating moving parts minimizes friction, extending the li Hydraulic System Layout and ElementsThe arrangement of the fluid-driven mechanisms is crucial for efficient operation. It involves various components working together to convert energy into mechanical motion, ensuring smooth and reliable functioning. Understanding the placement and interaction of these components can help in maintaining and troubleshooting the entire system. The primary elements of this setup include a power source, transmission components, and control units. Each part plays a specific role in regulating the flow and pressure of the fluid, allowing for precise movement and force application.

|