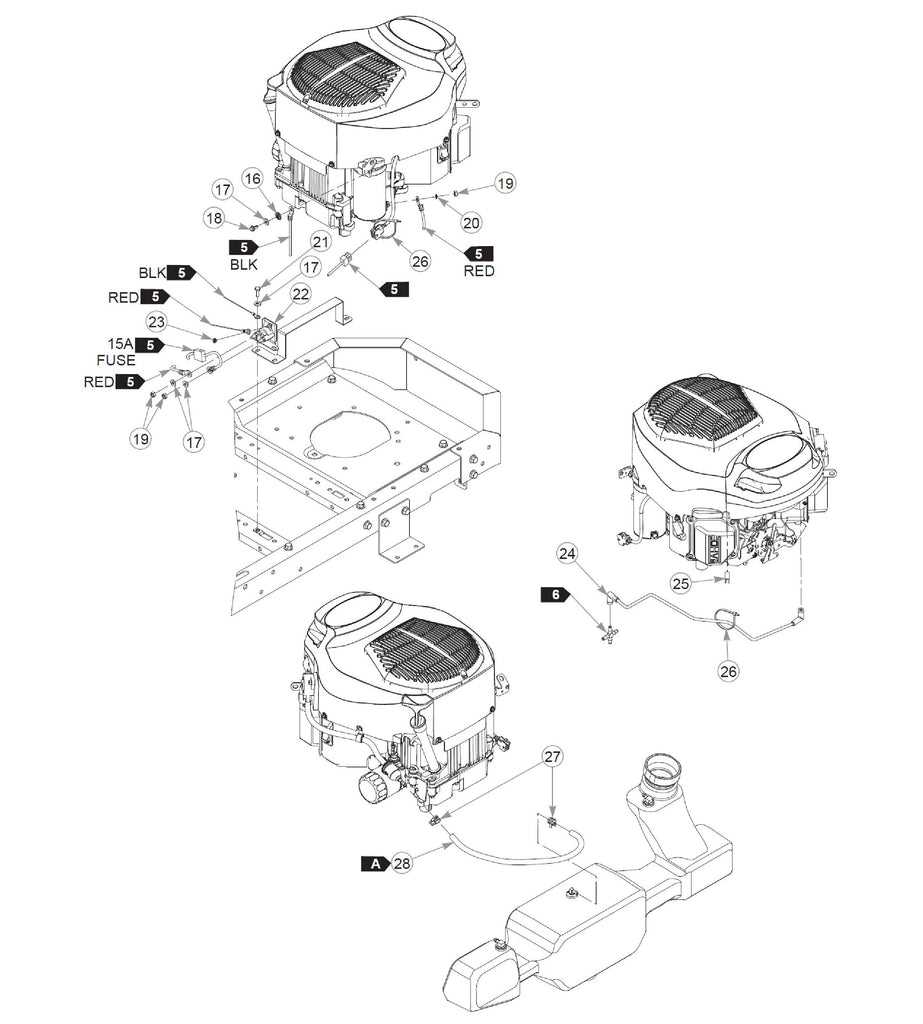

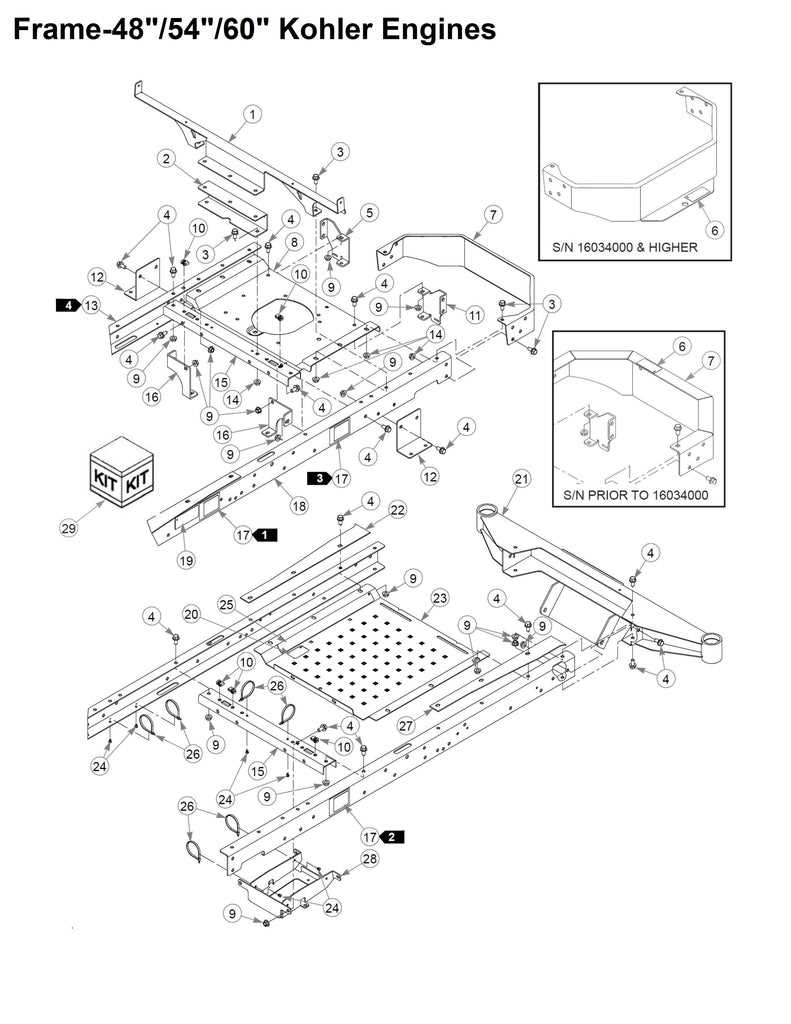

The intricate world of small engine mechanics is filled with a variety of elements that work in harmony to ensure optimal performance. Each component, from the most minor to the most crucial, plays a significant role in the overall functionality of the machine. This section aims to provide a comprehensive look at how these pieces interact and the importance of understanding their arrangement.

For anyone involved in maintenance or repair, familiarizing oneself with the configuration of these elements can lead to more efficient troubleshooting and repairs. Knowing where each part fits within the assembly allows for a clearer understanding of how the engine operates as a whole. This knowledge is invaluable for both seasoned technicians and DIY enthusiasts alike.

In this guide, we will explore the various components, highlighting their functions and interconnections. By visualizing the layout, readers can gain deeper insights into potential issues and the best practices for upkeep. Such familiarity not only enhances repair skills but also contributes to the longevity of the machinery.

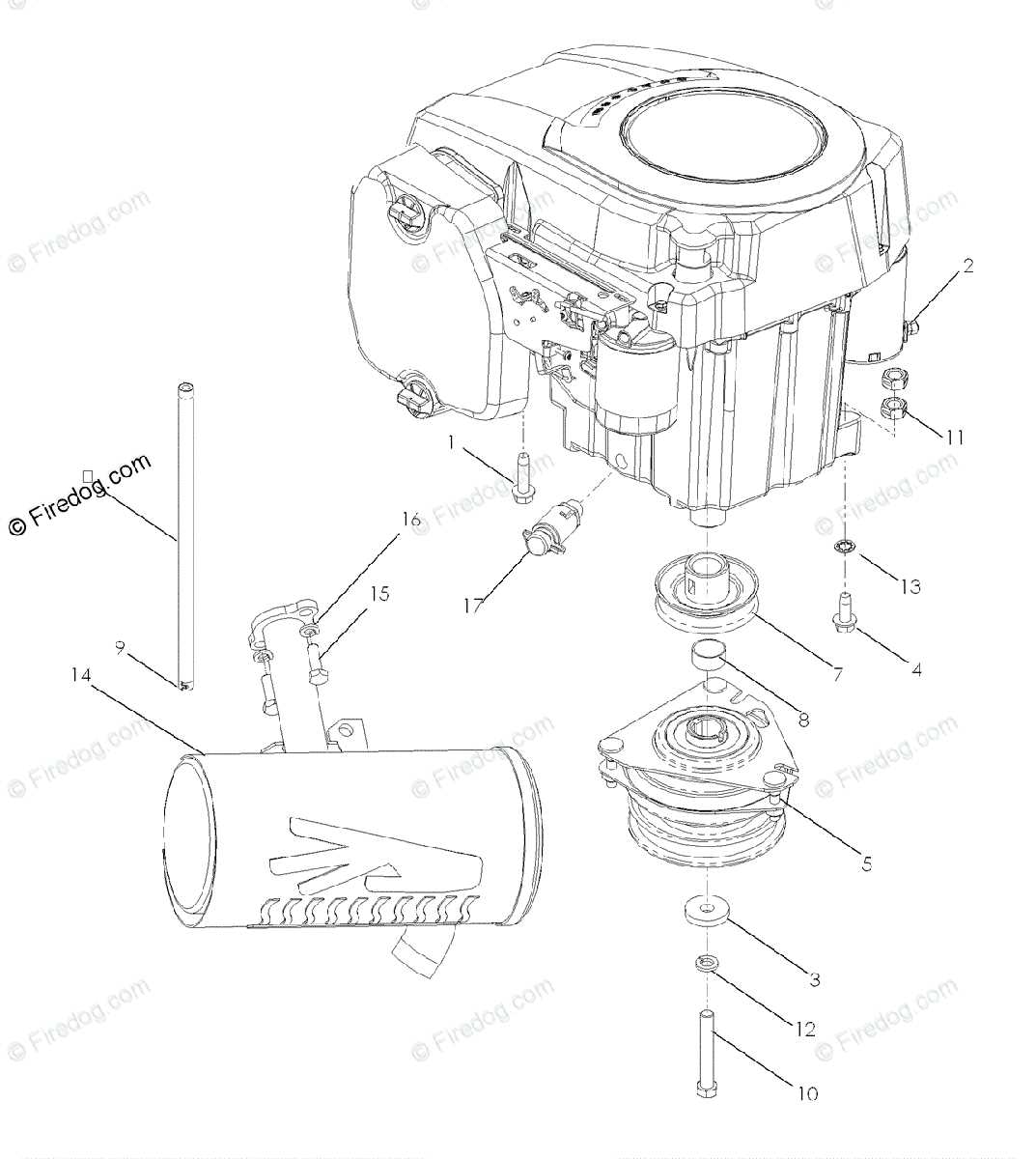

Kohler Courage 20 Overview

This section provides a comprehensive insight into a robust engine model designed for various outdoor applications. Its performance and reliability make it a popular choice among users seeking efficiency and durability in their equipment. Understanding the key features and functionality can enhance user experience and maintenance practices.

The engine is known for its powerful output, making it suitable for demanding tasks. Its engineering emphasizes simplicity and accessibility, allowing for straightforward servicing and upkeep. Whether utilized in lawn care or landscaping, this model delivers consistent results, proving to be an invaluable asset for both professionals and enthusiasts.

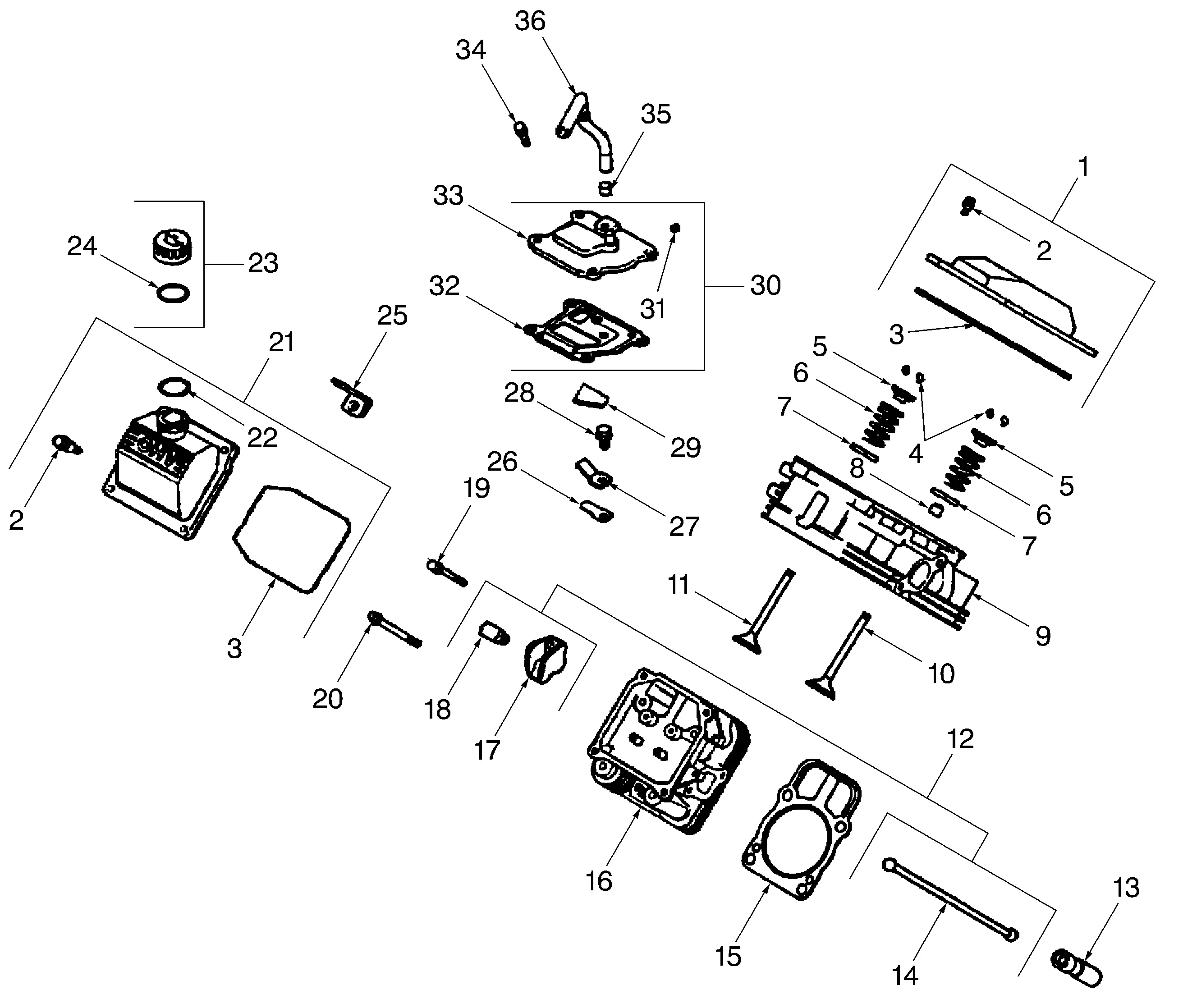

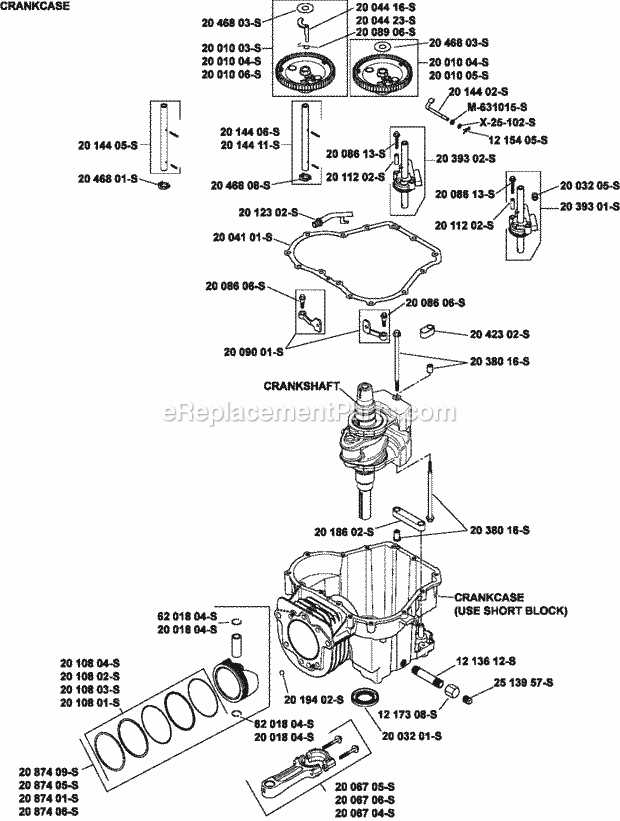

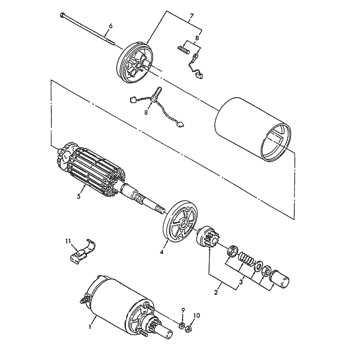

Understanding Engine Components

Engines are intricate systems that convert fuel into mechanical energy, driving various machines and vehicles. Each element plays a crucial role in ensuring optimal performance and efficiency. By exploring these components, one can appreciate the complexity and engineering that goes into modern propulsion systems.

Key Elements of an Engine

At the core of any engine are vital components such as the cylinder, piston, and crankshaft. These parts work together in a synchronized manner to facilitate the combustion process, enabling power generation. Understanding their functions can provide insights into how engines operate under different conditions.

The Role of Supporting Systems

In addition to the main parts, supporting systems like the fuel delivery and cooling mechanisms are essential for maintaining engine health. These systems ensure that fuel reaches the combustion chamber efficiently and that excessive heat is dissipated, preventing damage and enhancing longevity. A thorough comprehension of these systems contributes to more effective maintenance and troubleshooting.

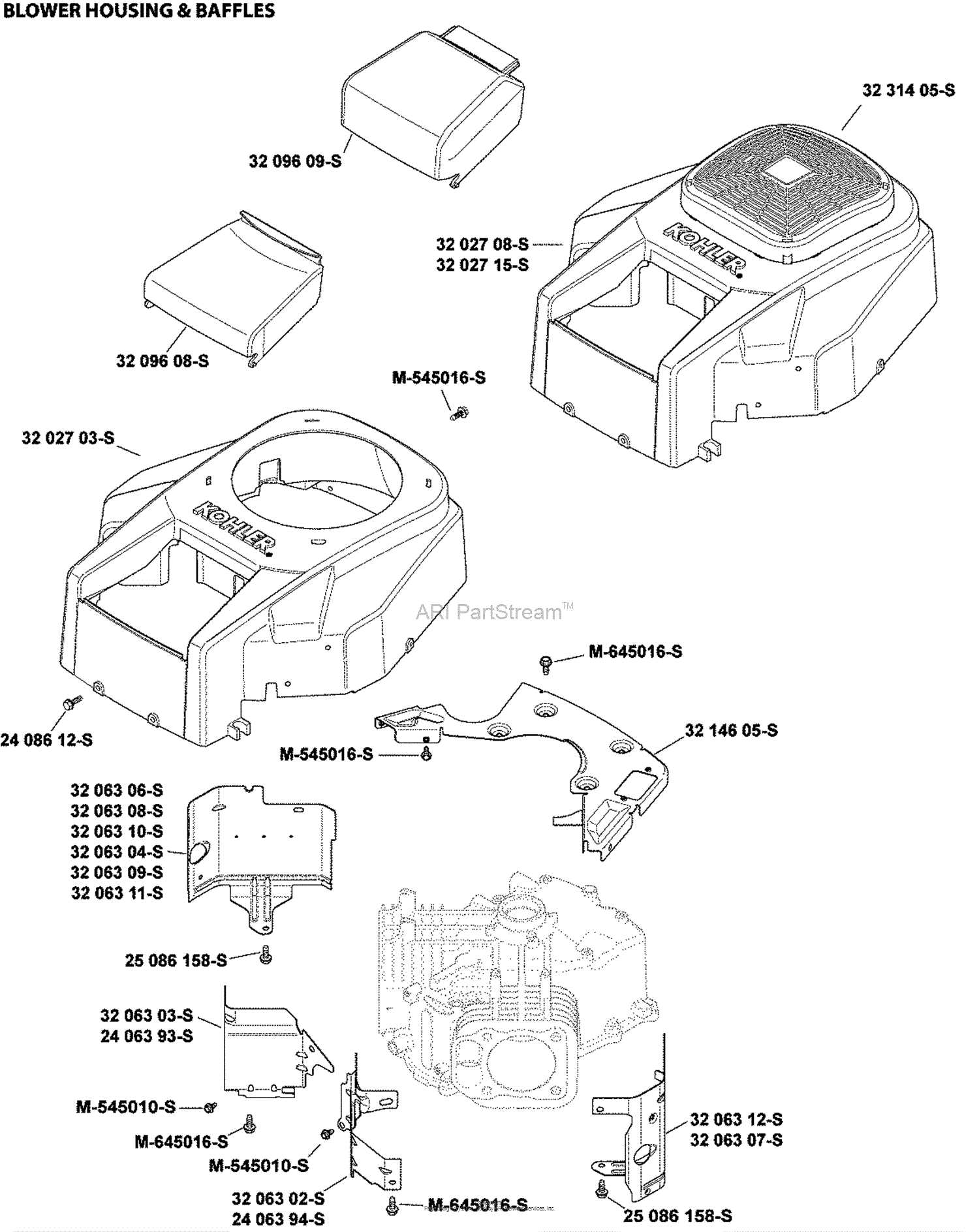

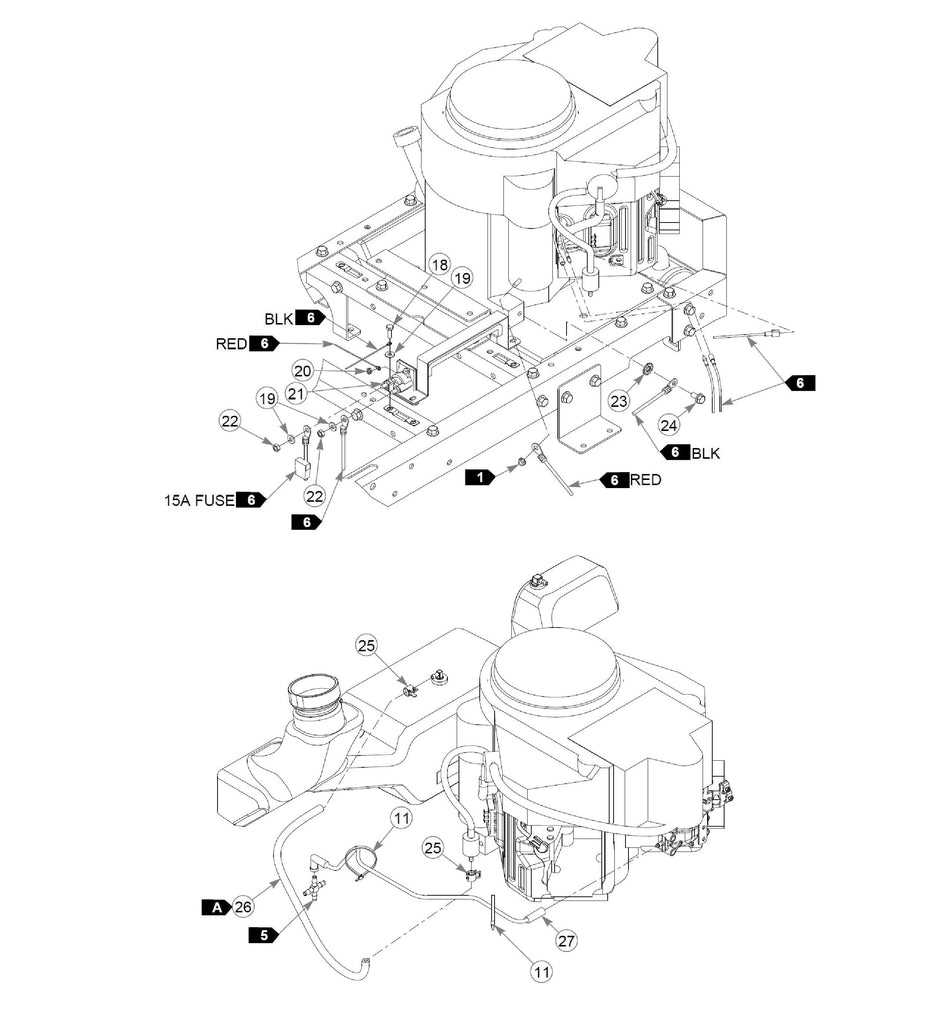

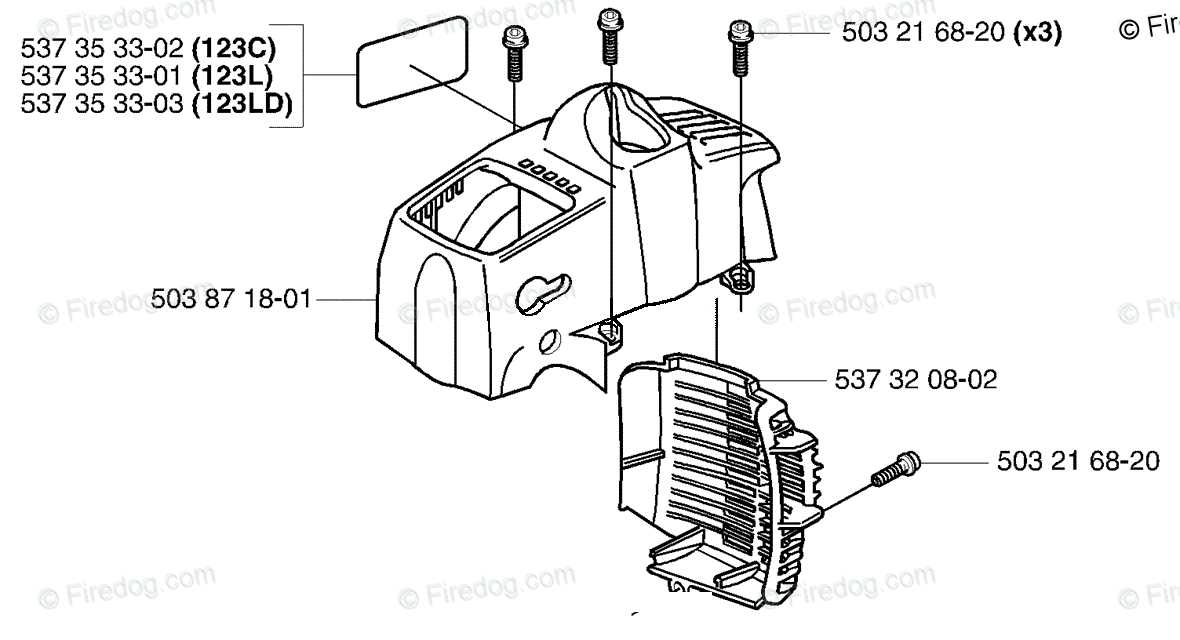

Importance of Parts Diagram

Understanding the layout of components within a machine is crucial for effective maintenance and repair. Visual representations serve as essential guides, helping technicians and enthusiasts navigate complex systems with ease.

Benefits of Visual Guides

- Enhances clarity in identifying components.

- Streamlines troubleshooting processes.

- Facilitates communication among team members.

Application in Maintenance

- Improves accuracy in reassembly.

- Reduces the likelihood of errors.

- Supports efficient inventory management of replacement items.

Common Issues with Kohler Courage 20

Engines of this type often encounter a range of challenges that can affect their performance and reliability. Understanding these common problems is essential for effective maintenance and troubleshooting, ensuring that the engine operates smoothly and efficiently over time.

Frequent Problems

Users may face various difficulties, including starting issues, power loss, and overheating. Identifying these symptoms early can prevent more serious complications and costly repairs.

Preventative Measures

Regular maintenance and attention to detail can mitigate many of these challenges. Ensuring proper fuel quality, regular oil changes, and checking for debris in the air filter can significantly enhance engine performance.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Starting Difficulties | Weak battery, faulty ignition system | Check battery charge, inspect ignition components |

| Power Loss | Clogged fuel filter, air intake blockage | Replace fuel filter, clean air intake |

| Overheating | Low coolant levels, blocked cooling fins | Top up coolant, clean cooling fins |

How to Read the Diagram

Understanding a schematic representation can greatly enhance your ability to maintain and troubleshoot equipment. This guide will help you navigate the essential components and their relationships.

- Familiarize Yourself with Symbols: Each icon represents a specific part or function. Knowing these is crucial for accurate interpretation.

- Follow the Flow: Diagrams typically illustrate the sequence of operations. Trace the lines to see how energy or information moves.

- Check the Key: A legend often accompanies the illustration, providing definitions for various symbols and notations.

- Group Components: Parts are often clustered by function. Identifying these groups can simplify understanding their roles.

By applying these strategies, you will ultimately gain confidence in deciphering complex schematics, allowing for effective repairs and maintenance.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your engine requires a consistent maintenance routine. By following key practices, you can significantly extend the life of your machinery and enhance its efficiency.

Regular Inspections: Periodically check for wear and tear, including belts, filters, and connections. Addressing minor issues promptly can prevent major failures.

Oil Changes: Frequent oil changes are essential for keeping the internal components lubricated. Use high-quality lubricants suitable for your engine type.

Clean Air Filters: Keeping air filters clean promotes better airflow and improves combustion efficiency. Replace them according to the manufacturer’s recommendations.

Fuel Quality: Always use fresh, high-quality fuel to avoid engine performance issues. Contaminated fuel can lead to significant damage over time.

Storage Practices: If the engine is not in use, store it in a dry, sheltered location. Proper storage prevents rust and other environmental damage.

By implementing these strategies, you can ensure that your equipment remains reliable and functional for years to come.

Where to Find Replacement Parts

Locating suitable components for machinery can be a daunting task. However, understanding where to seek these items can simplify the process significantly. A variety of sources are available, each offering different advantages, whether you’re looking for new, refurbished, or aftermarket options.

Authorized Dealers

One of the most reliable sources for securing genuine components is through authorized dealers. These outlets often provide a comprehensive selection, ensuring compatibility with your equipment. Additionally, they typically offer expert advice and support, which can be invaluable for maintenance and repairs.

Online Marketplaces

The internet has transformed the way individuals source machinery components. Numerous online platforms cater to various needs, providing extensive catalogs and competitive pricing. Customer reviews and ratings can guide your selection, making it easier to choose a trustworthy seller. Always verify the return policy and warranty options when purchasing online to safeguard your investment.

Comparing with Other Engine Models

When evaluating different power units, it’s essential to consider their unique features, performance metrics, and maintenance requirements. Each engine type brings its own strengths and weaknesses, influencing decisions for various applications. Understanding these distinctions can help users select the most suitable option for their specific needs.

Performance and Efficiency

Many power units vary significantly in terms of output and fuel efficiency. Some models excel in delivering higher horsepower, making them ideal for heavy-duty tasks, while others prioritize fuel economy, catering to users focused on cost-effective operations. Torque characteristics also play a crucial role, particularly for tasks that demand consistent power delivery.

Durability and Maintenance

Durability is another key factor when comparing different engines. Some designs are built with high-quality materials that withstand wear and tear over time, reducing the frequency of repairs. Additionally, maintenance routines differ among models, with some requiring more frequent servicing than others. Understanding these requirements can guide users in choosing an engine that aligns with their long-term operational plans.

Expert Insights and Recommendations

Understanding the intricacies of small engine maintenance is crucial for ensuring optimal performance and longevity. Expert opinions highlight the importance of familiarizing oneself with the components involved, as this knowledge empowers users to address potential issues proactively. Consistent care and attention to detail can prevent minor problems from escalating into major repairs.

Regular Maintenance Tips

Scheduled inspections are vital. Check fuel systems, air filters, and spark plugs regularly to maintain peak functionality. Cleaning and replacing these components as needed can significantly enhance efficiency and reduce wear.

Choosing Quality Components

When it comes to replacements, investing in high-quality parts is essential. Superior materials not only improve performance but also ensure compatibility and durability, ultimately contributing to a more reliable operation.