In the realm of agricultural machinery, comprehending the layout of individual components is essential for efficient maintenance and repair. This section aims to provide a comprehensive overview of how various elements within a specific machine interact with one another. By grasping the arrangement and function of these components, operators can enhance their understanding and performance of the equipment.

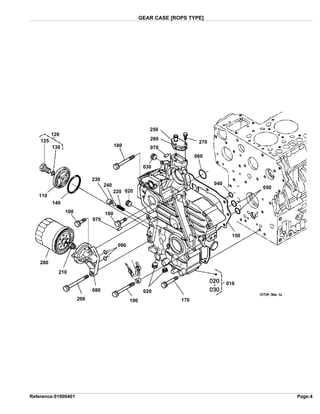

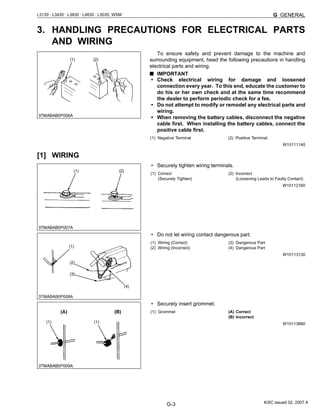

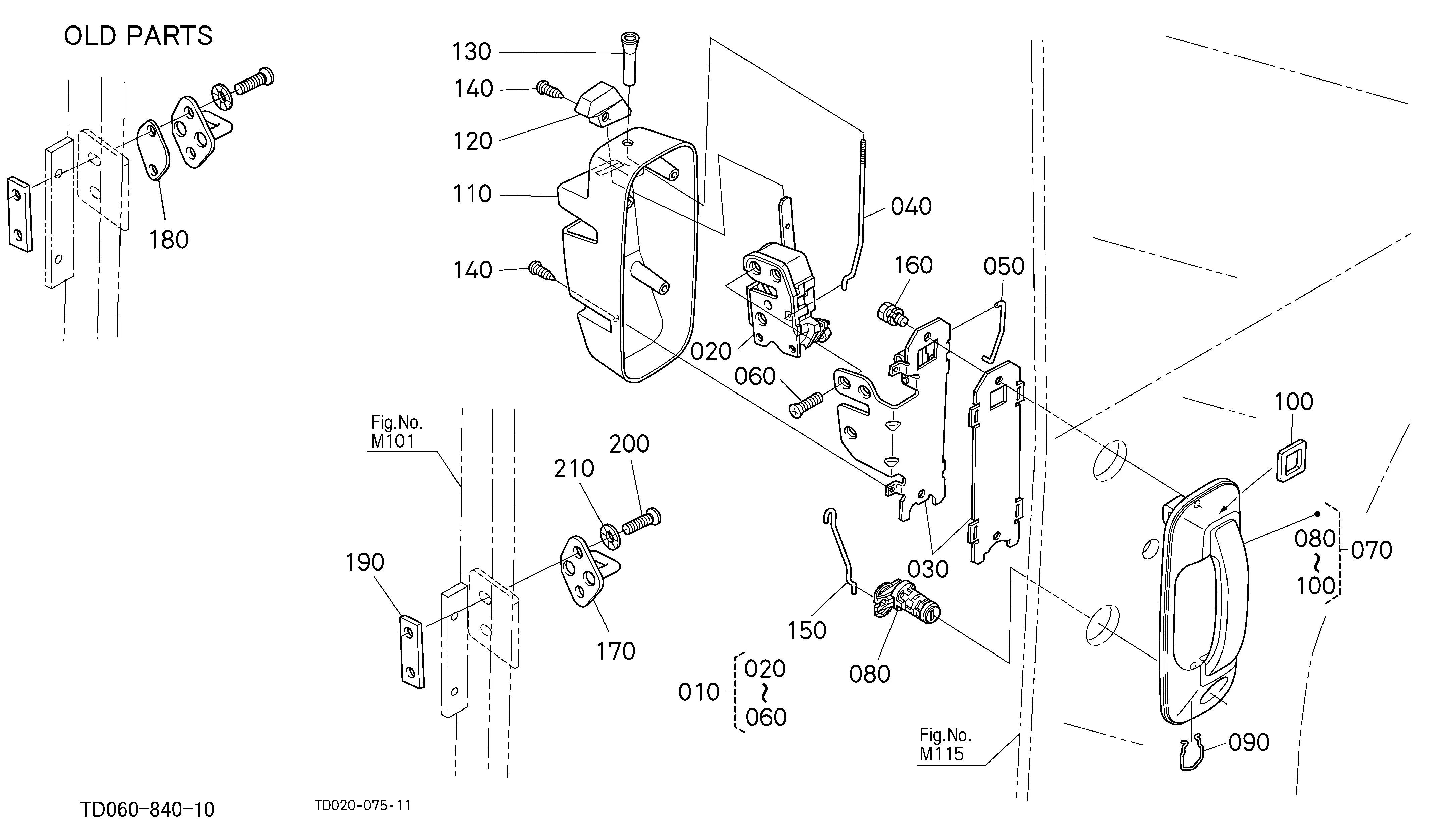

Detailed illustrations serve as valuable resources for identifying parts and their respective roles in the overall functionality of the machinery. Such visual representations not only simplify the process of locating specific elements but also facilitate effective troubleshooting. Whether for routine maintenance or addressing more complex issues, having access to well-organized visuals can significantly improve the efficiency of repair efforts.

Moreover, familiarizing oneself with the layout of components can aid in better decision-making during operations. Understanding how each part contributes to the machine’s performance allows users to optimize usage and ensure longevity. In essence, a clear depiction of the machine’s structure is crucial for anyone involved in the care and operation of agricultural equipment.

This section will provide a comprehensive overview of a specific agricultural machinery model, focusing on its essential components and their functionalities. Understanding the structure and functionality of various elements will aid in the maintenance and efficient operation of the equipment.

Key Features of the Machine

The discussed machinery is known for its versatility and robust performance. Key features include:

- High power output suitable for various tasks.

- Durable construction for longevity and reliability.

- Ergonomic design for operator comfort and ease of use.

Importance of Understanding Components

Recognizing the various components is crucial for effective maintenance. Here are some reasons why:

- Identifying parts helps in troubleshooting issues promptly.

- Understanding assembly allows for better repairs and replacements.

- Knowledge of specifications aids in proper operation and efficiency.

Key Features of the Kubota L3430

This compact tractor is designed to deliver exceptional performance and versatility, making it suitable for various agricultural and landscaping tasks. With a robust engine and advanced transmission system, it ensures efficient power delivery and smooth operation across different terrains.

One of its standout characteristics is the remarkable maneuverability, allowing operators to navigate tight spaces with ease. The ergonomically designed controls enhance user comfort and accessibility, ensuring that even prolonged use remains efficient and strain-free.

Additionally, the hydraulic system plays a vital role in enhancing functionality, enabling the attachment of various implements that significantly increase productivity. The well-balanced structure contributes to stability during operation, making it a reliable choice for both professional and personal use.

Overall, this machine embodies durability and efficiency, making it an invaluable asset for anyone in need of a reliable workhorse.

Importance of Parts Diagrams

The visual representation of components is crucial for understanding the assembly and functioning of machinery. These illustrations serve as essential tools for both maintenance and repair, enabling users to identify each element’s location and function within a complex system.

Firstly, such illustrations facilitate efficient troubleshooting by allowing technicians to quickly pinpoint issues. When a specific component malfunctions, having a clear visual guide helps in assessing the problem without unnecessary disassembly.

Moreover, these representations play a vital role in the ordering process of replacements. With a comprehensive view of the entire system, users can accurately determine the needed elements, minimizing errors and ensuring that the right parts are acquired for optimal performance.

Additionally, they enhance the learning experience for new users and technicians. Understanding the layout and relationship between components fosters a deeper comprehension of how systems operate, ultimately contributing to improved skills and knowledge in machinery handling.

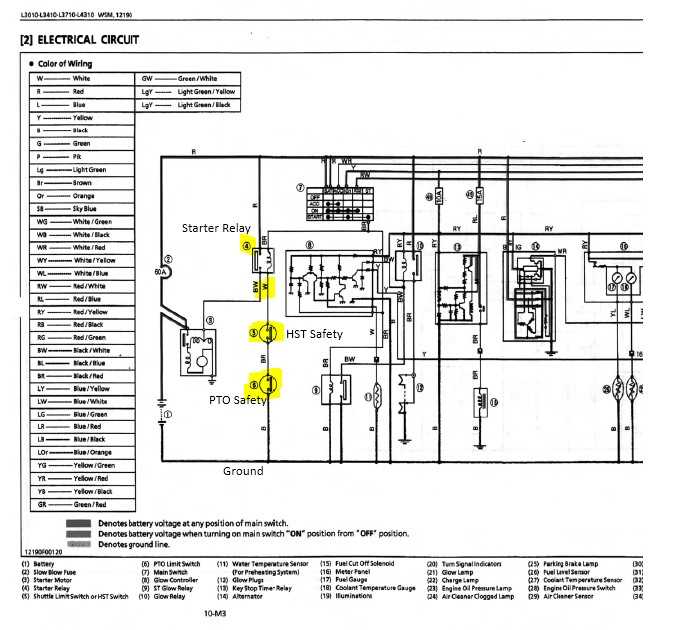

Understanding the L3430 Components

The intricate assembly of machinery encompasses a variety of essential elements that contribute to its overall functionality. Each component plays a vital role, working in harmony to ensure optimal performance. Recognizing the significance of these parts is crucial for effective maintenance and troubleshooting.

Among the primary segments are the engine, transmission, and hydraulic systems, each designed to fulfill specific tasks. The engine serves as the powerhouse, converting fuel into mechanical energy. The transmission facilitates the transfer of power, allowing for smooth movement and control. Meanwhile, the hydraulic system enhances lifting capabilities and operational efficiency.

Additionally, various attachments and accessories enhance versatility, enabling the machine to tackle a broader range of tasks. Understanding these components not only aids in repairs but also maximizes the machine’s potential in diverse applications. Familiarity with the intricacies of the assembly ensures that operators can effectively leverage its capabilities for improved productivity.

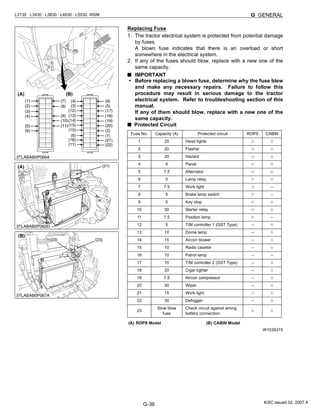

Common Replacement Parts

In the realm of machinery maintenance, understanding frequently needed components is essential for optimal performance and longevity. Whether for routine upkeep or unexpected repairs, certain elements are often required to ensure smooth operation and reliability.

Among the most sought-after items are filters, which play a crucial role in maintaining clean fluids and preventing contaminants from causing damage. Belts are another vital aspect, providing necessary motion transfer between various mechanical parts. Additionally, seals and gaskets are important for preventing leaks and ensuring a tight fit in connections.

Furthermore, attention to fluid levels is critical, with oils and coolants needing to be checked and replaced regularly to prevent overheating and wear. Understanding these commonly replaced components can help in planning maintenance schedules and ensuring equipment runs efficiently.

Maintenance Tips for Longevity

Ensuring the long-term functionality of machinery involves a series of diligent practices. Regular upkeep not only enhances performance but also extends the lifespan of equipment. By following systematic maintenance procedures, users can prevent premature wear and avoid costly repairs.

Routine Inspections

Frequent checks are essential to identify potential issues before they escalate. Inspecting various components helps maintain optimal performance. Focus on the following aspects during inspections:

| Component | Inspection Frequency | Action Required |

|---|---|---|

| Oil Level | Every 50 hours | Change if low |

| Filters | Every 100 hours | Replace if clogged |

| Belt Tension | Every 25 hours | Adjust if loose |

Proper Storage Practices

Storing equipment in a controlled environment prevents damage from weather elements. Ensure that machinery is clean and dry before storage. Additionally, consider using protective covers to shield from dust and debris, enhancing overall maintenance.

Where to Find Genuine Parts

Locating authentic components for machinery is essential for maintaining optimal performance and longevity. Utilizing reliable sources ensures that the equipment runs smoothly and efficiently, minimizing the risk of breakdowns.

Here are several options to consider when searching for original replacements:

- Authorized Dealers: Visiting certified distributors is one of the most dependable methods. They offer a wide range of genuine items and can provide expert advice.

- Online Marketplaces: Numerous e-commerce platforms specialize in machinery supplies. Always verify the seller’s reputation and look for customer reviews.

- Manufacturer Websites: Many companies maintain an online presence where customers can directly order original components. This option often guarantees authenticity.

- Local Repair Shops: Some workshops focus on specific brands and can supply authentic components or assist in sourcing them.

By exploring these avenues, individuals can ensure they acquire high-quality replacements that meet the necessary standards for their equipment.

Visual Guide to Assembly

This section provides a comprehensive overview of the assembly process for agricultural machinery, aimed at enhancing user understanding and operational efficiency. By following visual aids, users can gain insights into the various components and their interactions within the system.

To effectively assemble the equipment, it is essential to recognize the key elements involved:

- Identifying essential components

- Understanding the correct order of assembly

- Utilizing appropriate tools for each task

Here are some recommended steps to ensure a smooth assembly process:

- Preparation: Gather all necessary components and tools in a clean, organized workspace.

- Component Identification: Refer to the visual guides to identify each piece and its designated location.

- Step-by-Step Assembly: Follow the outlined sequence, ensuring each component is securely fastened before proceeding to the next.

- Final Inspection: Once assembly is complete, perform a thorough inspection to verify that everything is correctly installed and functional.

By adhering to these guidelines, users can effectively navigate the assembly of their machinery, ensuring optimal performance and longevity.

FAQs About the Kubota L3430

This section addresses common inquiries related to a popular model known for its reliability and performance. Users often seek clarification on various aspects, including functionality, maintenance, and compatibility with attachments.

- What is the engine capacity of this model?

The engine capacity is designed to provide optimal performance, ensuring efficient operation under various conditions.

- How often should maintenance be performed?

Regular maintenance is crucial. It is recommended to follow a schedule that includes checks for oil levels, filter replacements, and general inspections.

- Are there any specific attachments compatible with this model?

Yes, there are numerous attachments available that enhance functionality, including loaders and mowers. Ensure compatibility with the specific model specifications.

- Where can I find replacement components?

Replacement components can be sourced from authorized dealers or online retailers specializing in agricultural machinery.

- What is the fuel efficiency of this unit?

The fuel efficiency varies based on usage, but it generally offers a competitive rate compared to similar models in its class.