The efficient operation of agricultural machinery relies heavily on a clear comprehension of its various components. Each element plays a crucial role in ensuring optimal performance, reducing downtime, and enhancing productivity on the field. By familiarizing oneself with the intricate arrangement and functions of these parts, operators can make informed decisions regarding maintenance and repairs.

Exploring the configuration of these essential tools not only aids in troubleshooting issues but also provides insight into the design and engineering that supports modern farming practices. Whether dealing with wear and tear or seeking upgrades, understanding the relationships between different components is vital for maximizing efficiency and ensuring longevity.

Moreover, having access to comprehensive visual representations can greatly assist users in identifying the right components needed for various tasks. This knowledge empowers operators to tackle challenges effectively, enhancing the overall functionality of their machinery and ensuring a successful harvest season.

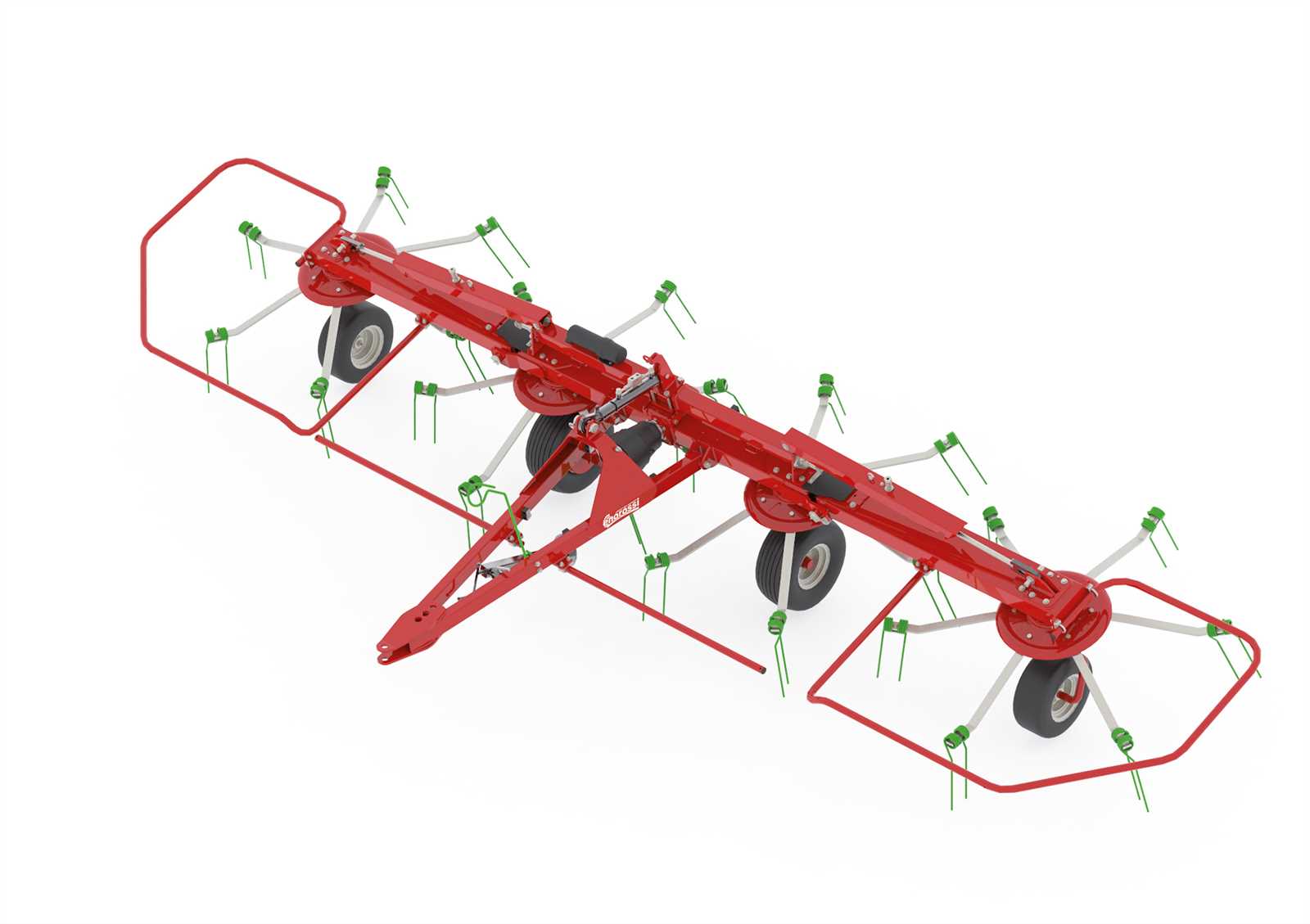

Understanding Enorossi Hay Tedder Parts Diagram

This section provides a comprehensive overview of the components involved in the operation of a specific agricultural implement. Gaining insight into these elements is crucial for effective maintenance and optimal functionality, allowing users to enhance their productivity and ensure the longevity of their machinery.

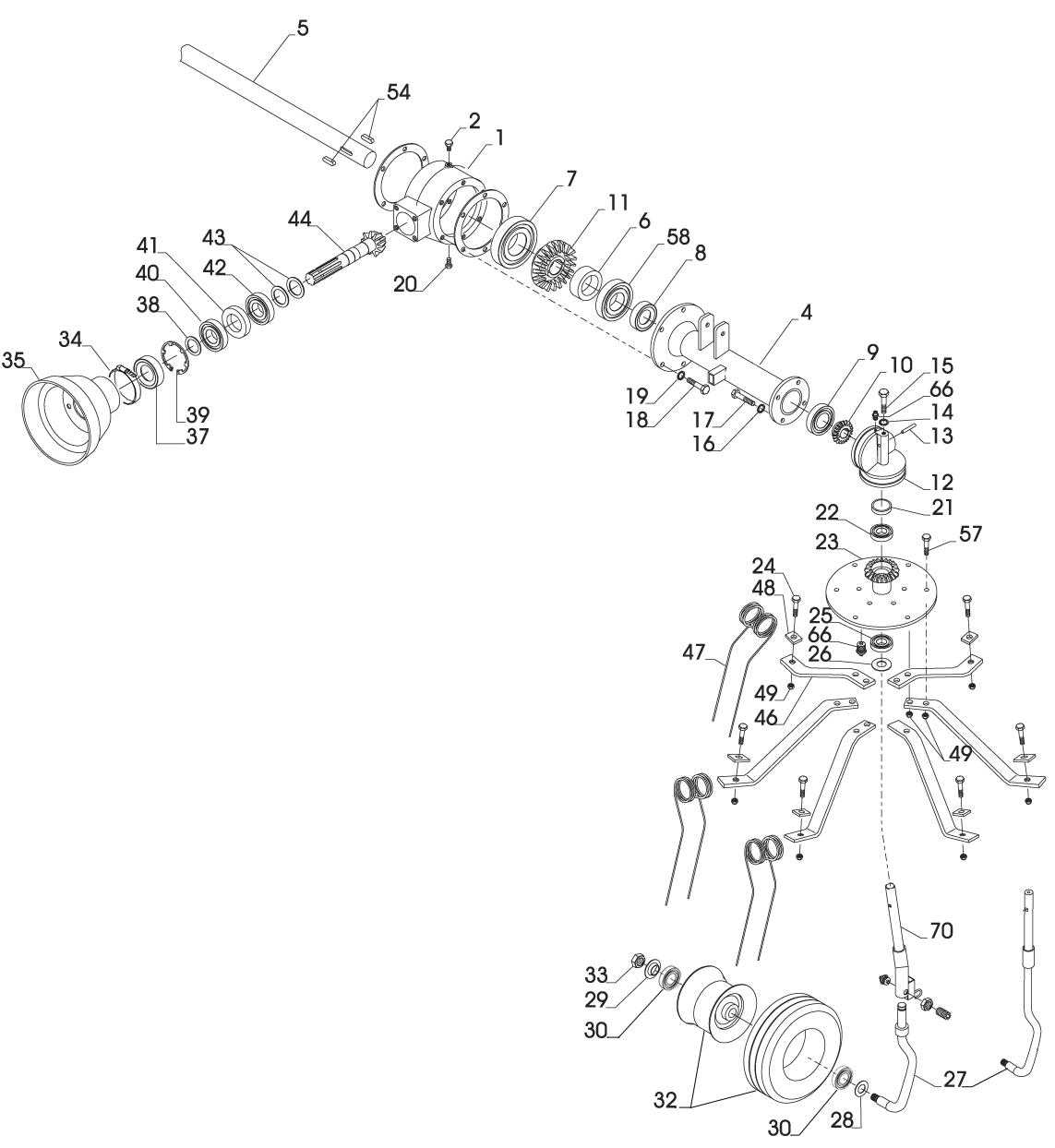

The intricate assembly consists of various segments, each serving a unique function in the overall operation. Key components include the rotating arms, which facilitate the distribution of the material, and the drive mechanism, responsible for powering these movements. Additionally, the framework provides structural integrity, supporting all other elements and ensuring stability during use.

Understanding the arrangement and role of these components enables operators to diagnose issues efficiently. For instance, recognizing wear on specific elements can lead to timely repairs, preventing larger problems and ensuring seamless operation. Moreover, familiarity with the configuration aids in optimizing adjustments to achieve the best results in different field conditions.

In conclusion, a thorough comprehension of the individual components and their interactions is essential for any operator seeking to maximize the effectiveness of their agricultural implement. By focusing on these aspects, users can enhance their approach to maintenance and operation, ultimately leading to greater efficiency and productivity in their farming practices.

Exploring the Anatomy of Enorossi Hay Tedder

The intricate design of agricultural machinery plays a vital role in enhancing efficiency during the harvesting process. Understanding the various components and their functions can significantly improve the overall operation and maintenance of this essential equipment. This section delves into the critical elements that constitute this particular implement, highlighting their significance and interrelationships.

Key Components and Their Functions

Each element within this agricultural tool serves a specific purpose that contributes to the overall effectiveness of the machinery. For instance, the rotating arms are crucial for the redistribution of crops, ensuring even drying and preventing clumping. Similarly, the gear system is fundamental for transmitting power efficiently, allowing for smooth operation and optimal performance.

Maintenance and Care Tips

Proper upkeep is essential to prolong the lifespan of this machinery. Regular inspection of moving parts, such as bearings and chains, is vital to avoid unexpected breakdowns. Lubrication of the mechanical joints can help minimize friction, ensuring smoother operation. Moreover, staying attuned to any unusual noises can serve as an early warning for potential issues, allowing for timely intervention.

In summary, a thorough understanding of the various components and their roles is essential for maximizing efficiency and reliability. Investing time in maintenance practices will ultimately yield better performance and durability, benefiting users in the long run.

Key Components of Enorossi Hay Tedder

This section explores the essential elements that contribute to the effective functioning of a machine designed for the efficient management of forage. Understanding these crucial components can enhance operational performance and maintenance practices.

Crucial Mechanisms

The operation of the equipment relies on several critical mechanisms. These components work in unison to ensure smooth functioning, facilitating the timely processing of grass or other vegetation. Each mechanism plays a distinct role in optimizing the workflow and achieving the desired results.

| Component | Function |

|---|---|

| Rotating Arms | Responsible for lifting and distributing the material evenly. |

| Tines | Help in gathering and spreading the material across the ground. |

| Gearbox | Transfers power from the tractor to the rotating elements. |

| Chassis | Provides structural support and stability during operation. |

Maintenance Considerations

Regular inspection and upkeep of these vital components are essential for prolonging the lifespan of the machine and ensuring efficient performance. Attention to wear and tear can prevent potential breakdowns and costly repairs.

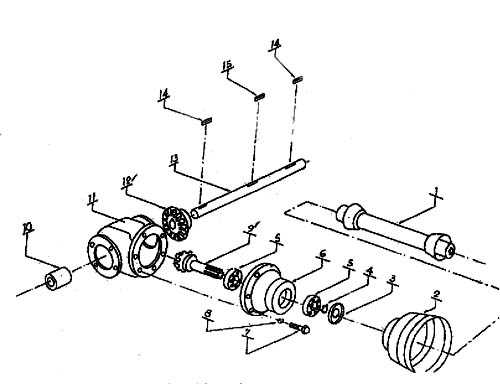

Importance of Familiarizing with Parts Diagrams

Understanding the intricacies of machinery is crucial for efficient operation and maintenance. A visual representation of components serves as an invaluable tool for users, providing insight into the arrangement and functionality of each element. This knowledge enhances one’s ability to troubleshoot issues, perform repairs, and conduct regular maintenance, ultimately leading to improved performance and longevity of the equipment.

Moreover, becoming acquainted with these visual guides facilitates quicker identification of required components during service. When users are familiar with the layout and specific roles of various elements, they can expedite repairs, reducing downtime significantly. This efficiency is particularly vital in agricultural settings, where time directly correlates with productivity and profitability.

Additionally, having a clear understanding of each component’s role encourages better decision-making when it comes to upgrades or replacements. Users can assess the compatibility of new parts and make informed choices that optimize their machinery’s performance. In summary, familiarization with visual representations of machinery is essential for anyone looking to enhance their operational efficiency and maintain the reliability of their equipment.

How to Interpret Enorossi Hay Tedder Parts Diagram

Understanding the layout and components of agricultural machinery is essential for effective maintenance and operation. The visual representation of machinery components serves as a crucial guide, aiding users in identifying and comprehending the various elements involved in the equipment’s functionality. Familiarity with these illustrations can significantly enhance one’s ability to troubleshoot issues and perform necessary repairs.

Recognizing Symbols and Labels

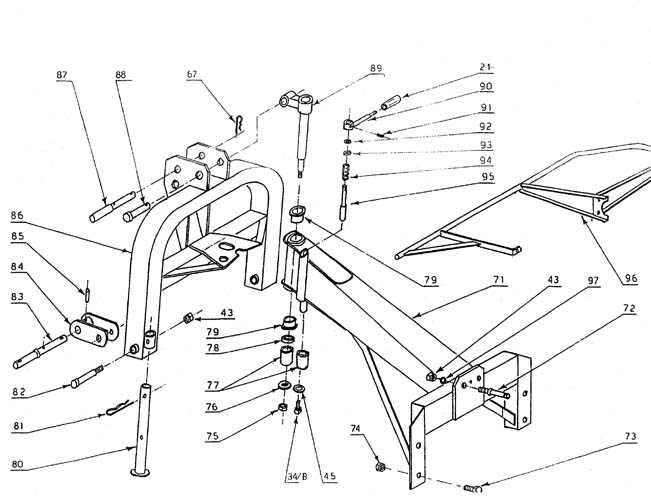

Each component in the illustration is accompanied by specific symbols and labels that denote its function and connection to other elements. Pay attention to these indicators, as they provide vital information about the arrangement and relationship of the machinery parts. Common symbols may include arrows indicating direction, numbers for sequence identification, and letters for component classification. A thorough understanding of these markings facilitates quicker and more accurate repairs.

Understanding Component Relationships

It’s important to analyze how each element interacts with others within the machinery. Identify groups of components that work in tandem, as this knowledge allows for a better grasp of the overall system’s operation. For example, recognizing the linkage between drive mechanisms and other parts can clarify how power is transmitted throughout the machine. By comprehending these connections, operators can more effectively address any issues that may arise.

Common Maintenance Tips Derived from Diagram Insights

Effective upkeep of agricultural equipment relies heavily on understanding its components and how they interact. Analyzing the structure and organization of these implements can reveal crucial insights into their maintenance needs, ensuring optimal performance and longevity. Here are some practical tips based on common observations from component layouts.

Regular Inspection and Cleaning

Frequent checks for wear and tear can prevent significant issues. Ensure that all components are free from debris and residue, which can hinder functionality. Regularly clean the machinery to avoid buildup that could lead to malfunctions.

Lubrication of Moving Parts

Applying appropriate lubricants to joints and moving parts is essential for reducing friction and preventing premature wear. Pay attention to the manufacturer’s recommendations regarding lubrication frequency and types of products to use, as this can significantly enhance operational efficiency.

Troubleshooting Using Parts Diagrams

Effective problem-solving in machinery often relies on visual aids that outline the components and their functions. These illustrations serve as a valuable resource for identifying issues and facilitating repairs. By understanding the configuration of various elements, users can quickly locate potential trouble spots and devise appropriate solutions.

Identifying Common Issues

When facing malfunctions, the first step is to consult the visual representation of the equipment. Such aids provide a clear overview of the assembly, making it easier to pinpoint common problems. For instance, if a specific feature is not functioning correctly, users can reference the schematic to check for wear or misalignment in related components. This approach minimizes guesswork and allows for a more systematic investigation.

Streamlining the Repair Process

Once an issue is identified, the next phase involves determining the necessary steps for resolution. Visual guides can greatly enhance this process by offering insight into disassembly and reassembly. Understanding the sequence of operations not only aids in efficient repairs but also reduces the risk of damaging parts during the procedure. Moreover, having a clear reference enables users to ensure that all components are correctly positioned, promoting optimal performance.

Upgrading and Customizing Based on Diagram Details

Enhancing equipment functionality and performance often involves a thorough examination of its schematic representation. This allows users to identify components that can be improved or tailored to better suit specific needs. By understanding the layout and interconnections, one can make informed decisions on modifications that not only optimize efficiency but also extend the lifespan of the machinery.

Identifying Key Components for Improvement

Once the schematic representation is analyzed, it becomes easier to pinpoint critical elements that may benefit from enhancement. Common areas to focus on include:

| Component Type | Potential Upgrades | Benefits |

|---|---|---|

| Bearings | High-performance options | Increased durability and reduced friction |

| Drive belts | Reinforced materials | Improved resistance to wear and tear |

| Control systems | Modern electronic controls | Enhanced precision and automation capabilities |

Customization Options for Specific Needs

Customization allows users to tailor their machinery to specific tasks. By integrating unique attachments or modifying existing features, operators can achieve desired results more effectively. Exploring various configurations can lead to improved output and greater satisfaction in usage.

Resources for Obtaining and Using Parts Diagrams Efficiently

Accessing and utilizing visual references for components is essential for effective maintenance and repair processes. Understanding where to find reliable sources can greatly enhance productivity and ensure that equipment operates smoothly. The following insights aim to guide users in efficiently obtaining and leveraging these visual aids.

Online Resources and Databases

The internet serves as a vast repository for component visuals. Official manufacturer websites often provide downloadable resources that include detailed illustrations and comprehensive information. Additionally, third-party platforms and agricultural machinery forums can be valuable for locating community-shared references, enhancing the diversity of available information. Utilizing search engines with specific queries can yield results tailored to individual needs, promoting efficiency in the search process.

Utilizing Printed Manuals and Catalogs

Physical manuals and catalogs are indispensable for users who prefer tangible resources. These documents typically offer structured layouts, making it easier to locate specific sections. They often contain not only visual representations but also descriptive text that aids in understanding functionality and compatibility. Keeping these resources organized can facilitate quicker access during repairs or maintenance tasks, thereby optimizing workflow.