When it comes to agricultural machinery, having a thorough understanding of the various elements involved is crucial for efficient operation and maintenance. Each component plays a vital role in ensuring the overall performance of the equipment, enhancing productivity and reliability.

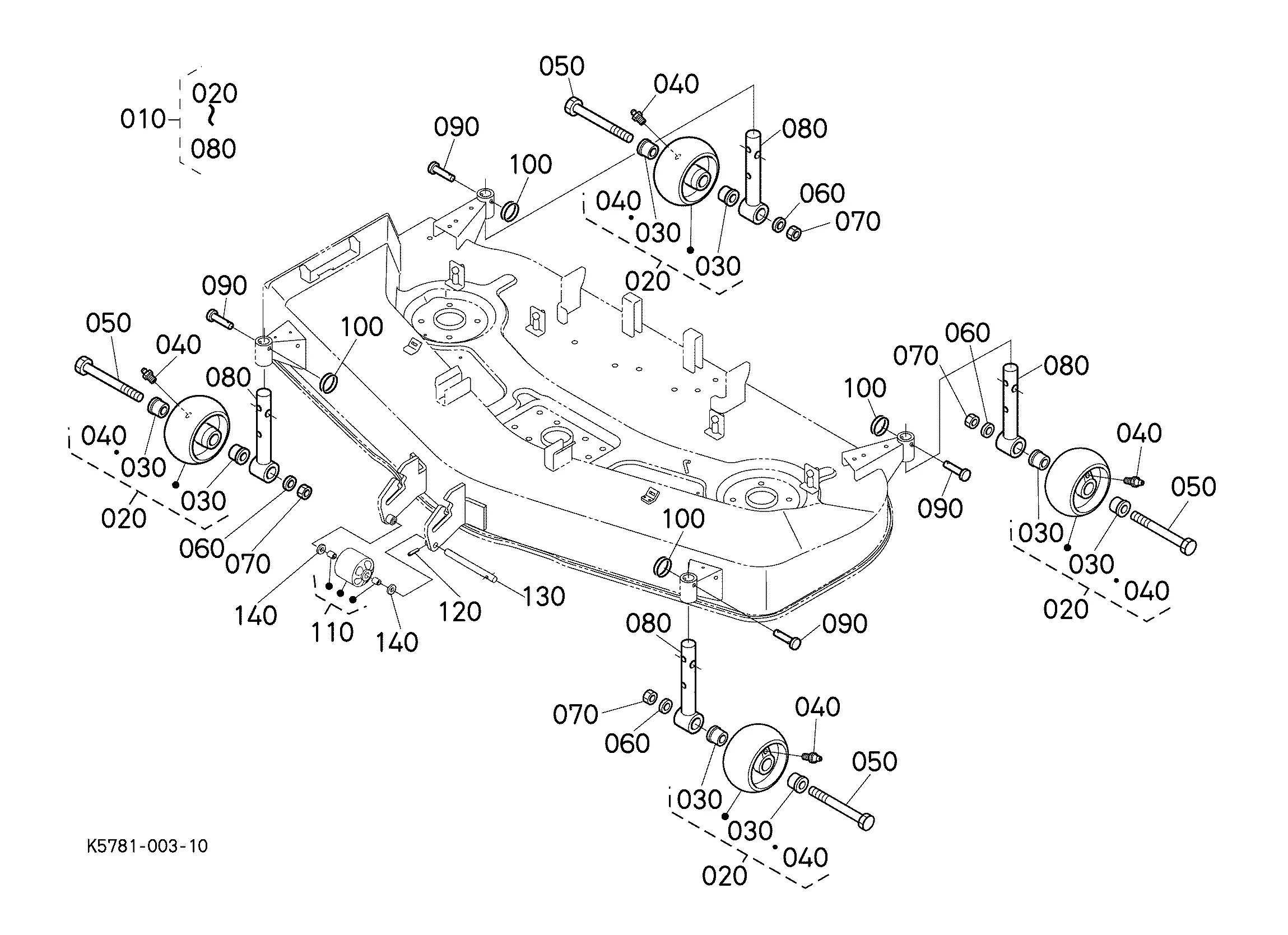

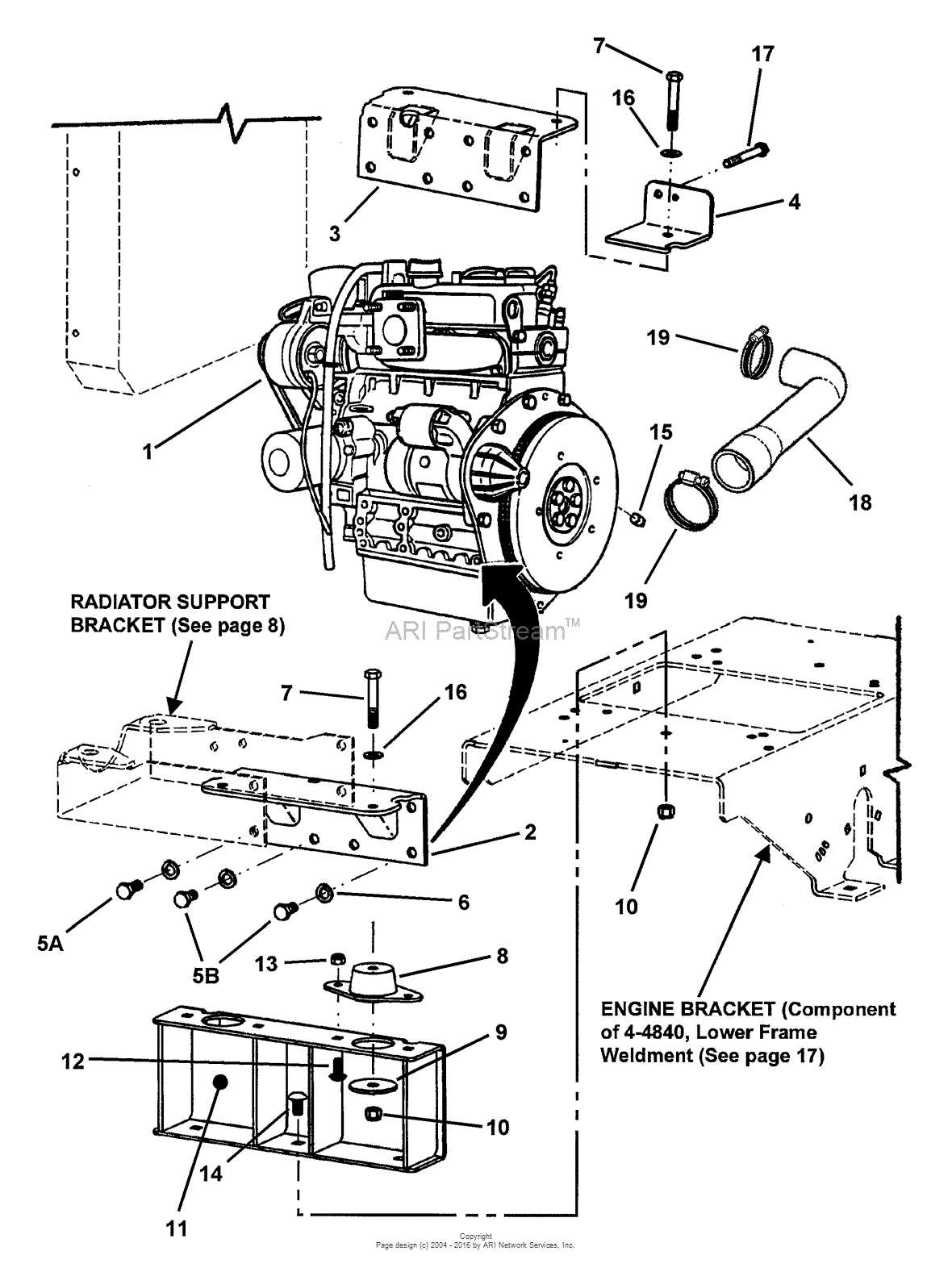

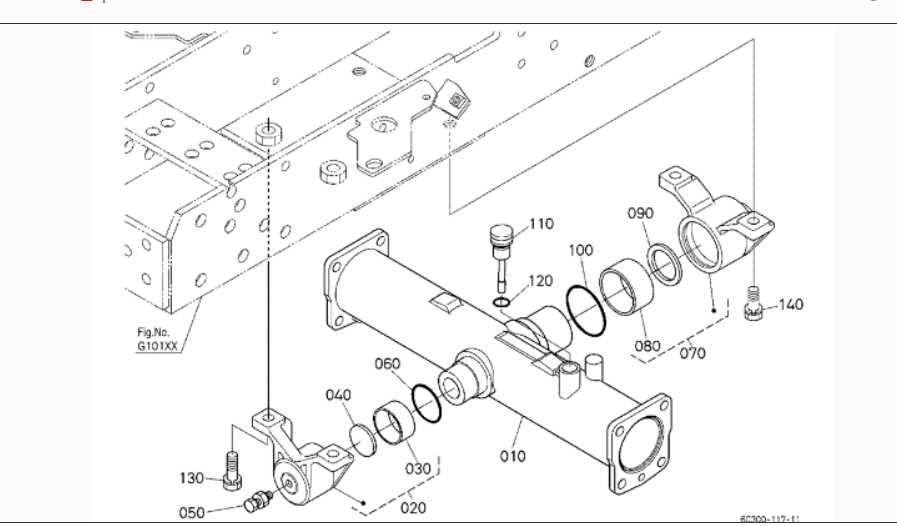

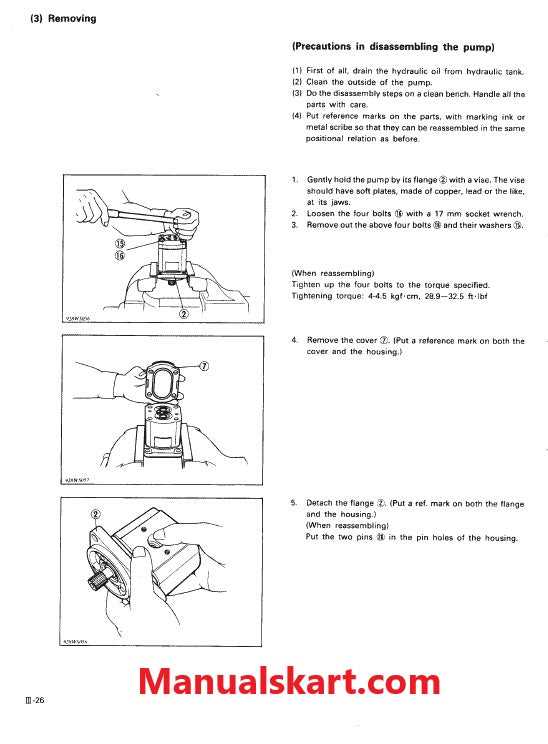

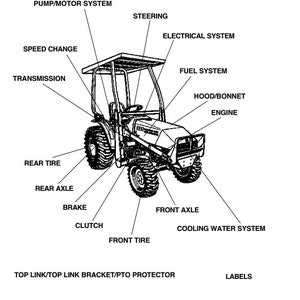

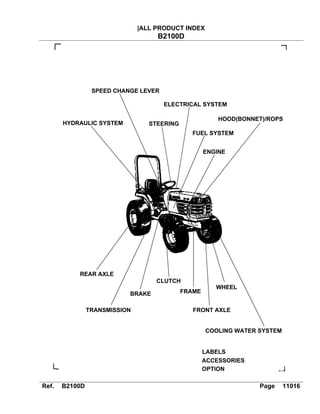

Visual aids can significantly assist in grasping the intricate details of these elements. By examining a detailed representation, operators can easily identify individual parts, their functions, and how they interact with one another. This understanding ultimately leads to better troubleshooting and repairs.

Whether you are a seasoned professional or a newcomer, delving into the specifics of machinery components empowers you to take control of your equipment’s upkeep. By familiarizing yourself with these elements, you can ensure longevity and peak performance.

Understanding the Kubota B2320 Parts Diagram

Having a clear view of the component layout and system structure is essential when working with any machinery. This detailed map offers a comprehensive look into the internal and external elements of a compact tractor, helping users identify individual parts and their functions. Such diagrams play a vital role for maintenance, repairs, and replacement tasks, ensuring that the right components are addressed effectively and accurately.

Component Identification

Each element of the machine is carefully illustrated, allowing you to recognize various components such as the engine, transmission, and hydraulic system. Whether you are performing routine maintenance or troubleshooting issues, being able to quickly identify specific parts can save valuable time and reduce the risk of errors during repairs.

Assembly and Functionality

Understanding how all these elements interact within the machine is just as crucial. The map not only highlights individual pieces but also shows how they fit together and contribute to the overall functionality of the equipment. This ensures that operators can make informed decisions when addressing performance concerns or upgrading specific systems.

Key Components of the Kubota B2320 Tractor

This section explores the essential elements that contribute to the functionality and efficiency of this agricultural machine. Each part plays a critical role in ensuring optimal performance, from power generation to operational controls.

Engine and Transmission

The heart of any tractor lies in its engine, which provides the necessary power to perform various tasks. Coupled with a reliable transmission system, it ensures smooth operation and control across different terrains, enhancing productivity.

Hydraulic System

A robust hydraulic system is vital for executing various implements and attachments. It enables the operator to perform tasks like lifting, digging, and grading with precision, ultimately improving the overall efficiency of the equipment.

How to Read Kubota B2320 Diagrams

Understanding technical illustrations is essential for effective maintenance and repair of machinery. These visual guides provide crucial information about the components and their relationships, enabling users to identify parts and understand their functions. Familiarity with symbols and conventions used in these illustrations enhances the ability to troubleshoot and perform repairs efficiently.

Begin by familiarizing yourself with the legend, which explains the symbols used throughout the illustration. This will help you decipher the meanings of various icons and lines that represent different elements of the machine. Pay attention to color codes as well, as they often indicate specific categories of components, such as hydraulic or electrical systems.

Next, break down the illustration into sections. Focus on one area at a time, tracing connections between parts to understand how they interact. This methodical approach allows for a clearer comprehension of the overall structure and function, making it easier to identify issues or determine the necessary replacement parts.

Lastly, cross-reference the illustration with the manufacturer’s manual for detailed specifications and assembly instructions. This additional resource will deepen your understanding and ensure accurate repairs. By mastering the interpretation of these visual aids, you will ultimately enhance your capability to maintain and optimize your machinery’s performance.

Common Issues and Parts Replacement

Understanding the typical challenges that may arise with machinery is essential for effective maintenance. Regular inspections and timely replacements can significantly extend the lifespan of the equipment. This section outlines frequent problems and the components that often require attention.

Frequent Problems

- Engine performance issues

- Hydraulic system leaks

- Electrical failures

- Transmission difficulties

- Excessive noise or vibrations

Component Replacement Suggestions

- Monitor and replace filters regularly to ensure optimal engine function.

- Inspect hydraulic hoses for signs of wear and replace them if leaks are detected.

- Check battery connections and replace the battery if it shows signs of failure.

- Maintain proper fluid levels in the transmission and replace fluids as needed.

- Lubricate moving parts to minimize noise and reduce wear.

By addressing these common issues proactively and replacing worn components, operators can maintain efficiency and prevent more significant problems down the line.

Locating Genuine Kubota B2320 Parts

When maintaining your compact utility vehicle, it’s crucial to find reliable components that ensure optimal performance and longevity. Using authentic elements designed specifically for your machine will help avoid compatibility issues and potential damage. Whether you’re looking for filters, belts, or other essential components, sourcing genuine replacements guarantees that your equipment remains in top condition, ensuring efficiency and safety during operation.

Where to Find Authentic Components

Finding the right sources for authentic elements can be straightforward if you know where to look. Authorized dealerships and official online retailers are often the most trustworthy places to search. These suppliers typically offer original components that are specifically designed to fit and function within your equipment. Avoid third-party sellers unless they are well-known and have a proven track record of providing high-quality products.

Important Considerations When Searching

When searching for elements, it’s important to verify the compatibility of each piece with your model. Double-checking part numbers and consulting the manufacturer’s resources can prevent the purchase of incorrect or substandard items. Many suppliers offer online catalogs or customer service to help you find exactly what you need.

| Component | Recommended Source | Part Number Verification |

|---|---|---|

| Air Filter | Authorized Dealership | Check model-specific codes |

| Oil Filter | Official Online Retailer | Cross-reference with the manual |

| Belts | Trusted Local Supplier | Verify using equipment’s manual |

Maintenance Tips Using the Parts Diagram

Proper upkeep of your machinery is essential for ensuring its longevity and efficiency. Utilizing a visual representation of components can greatly aid in identifying specific elements that require attention. This approach not only streamlines maintenance tasks but also enhances your understanding of the overall system.

Start by familiarizing yourself with the layout of the components. This knowledge will help you locate parts quickly and determine which areas may need lubrication, replacement, or adjustment. Regular inspections based on this visualization can prevent minor issues from escalating into significant problems.

Additionally, when planning maintenance, refer to the illustrated guide to ensure you have the right tools and replacement elements on hand. This preparation minimizes downtime and allows for a more efficient workflow. Always document any changes or replacements made during servicing to keep a comprehensive maintenance history.

Finally, consult the visual resource whenever troubleshooting is necessary. Understanding the relationships between various parts can facilitate quicker diagnosis and resolution of issues, ultimately enhancing the performance and reliability of your equipment.

Troubleshooting with the Kubota B2320 Diagram

Effective problem-solving relies on a comprehensive visual representation of machinery components. Understanding the layout and connections can significantly enhance the troubleshooting process, allowing for quicker identification of issues.

Here are some common challenges and how to address them:

- Engine Won’t Start:

- Check the battery connections.

- Inspect the fuel supply.

- Examine the ignition system.

- Hydraulic Issues:

- Look for leaks in the hoses.

- Assess fluid levels.

- Evaluate the pump functionality.

- Overheating:

- Inspect the coolant levels.

- Examine the radiator for blockages.

- Ensure the fan is operating properly.

Utilizing a clear schematic can help pinpoint these problems efficiently, leading to the ultimate resolution and maintenance of the equipment.

How to Access Detailed Kubota B2320 Schematics

Understanding the intricacies of machinery often requires a closer look at their layouts and configurations. Accessing comprehensive schematics can greatly assist in maintenance and troubleshooting tasks. Here’s how you can effectively locate these invaluable resources.

Online Resources

- Visit official manufacturer websites for downloadable resources.

- Utilize online forums where enthusiasts and experts share documents.

- Explore parts retailers that often provide schematics as part of their service.

Physical Manuals

- Check if a physical manual was included with your equipment purchase.

- Look for manuals at local dealers or distributors specializing in heavy machinery.

- Consider purchasing a service manual that provides detailed layouts and instructions.

Benefits of Using a Parts Diagram for Repairs

Having a clear visual representation of machine components can significantly enhance the repair and maintenance process. It allows individuals to easily identify and understand the interconnections between different elements, ensuring efficient and accurate fixes. This approach minimizes the risk of errors and streamlines the workflow, which can save both time and money during repairs.

- Increased Accuracy: A well-structured visual reference helps prevent misidentification of parts, ensuring that each element is addressed properly during disassembly and reassembly.

- Improved Efficiency: With clear guidance, tasks can be performed faster, as there’s less need to stop and figure out which component fits where.

- Reduced Risk of Damage: By following a systematic view of how components are put together, users can avoid damaging sensitive or easily broken elements during the repair process.

- Cost Savings: Accurate identification of faulty parts and efficient repairs reduce the need for unnecessary replacements and can help extend the lifespan of the equipment.

- Better Planning: A visual guide provides a clear overview of all necessary components, aiding in proper preparation and preventing missing parts from delaying the repair.

In conclusion, utilizing a visual guide for maintenance offers clear advantages, from improving precision to reducing downtime and costs. It ensures a smoother process and contributes to the long-term reliability of equipment.