In the realm of agricultural machinery, the effective attachment of implements is crucial for enhancing productivity and performance. This section delves into the intricate components involved in connecting various tools to tractors, providing insights into their functions and arrangements. Understanding these elements is essential for both maintenance and operational efficiency.

The seamless integration of equipment can significantly influence the effectiveness of farming tasks. Each component plays a pivotal role in ensuring stability, maneuverability, and ease of use. By familiarizing oneself with the configuration of these elements, operators can optimize their machinery’s capabilities and address any issues that may arise.

This exploration not only aids in comprehending the mechanics at play but also serves as a guide for anyone looking to enhance their agricultural experience. Equipped with this knowledge, users can make informed decisions regarding their equipment, ensuring a smooth and efficient workflow.

Kubota Hitch System Overview

This section provides an insight into the functionality and significance of the attachment mechanism commonly used in agricultural machinery. This system plays a crucial role in enhancing the versatility of tractors by allowing the connection of various implements, thereby optimizing their utility in different farming tasks.

Key Features

- Enables easy attachment and detachment of implements.

- Enhances stability and control during operation.

- Facilitates a wide range of tasks, from plowing to towing.

- Designed for durability to withstand harsh working conditions.

Common Implement Types

- Plows

- Tillers

- Seeders

- Spreaders

- Harvesters

Understanding the mechanics behind this attachment system is essential for any operator aiming to maximize efficiency and productivity in their agricultural endeavors.

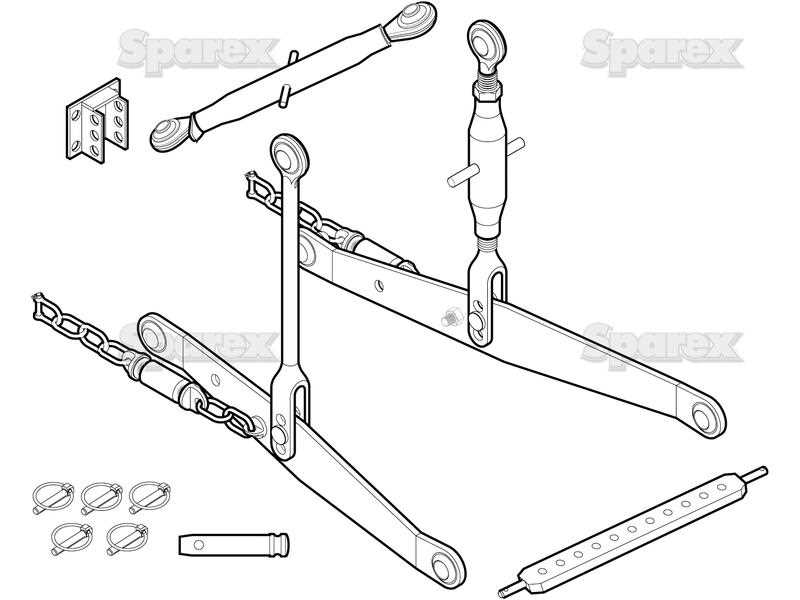

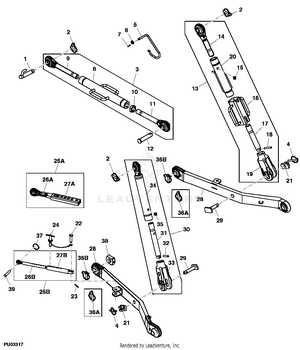

Key Components of the Hitch

The essential elements of a towing mechanism play a crucial role in enhancing the functionality and efficiency of agricultural machinery. Understanding these components allows users to appreciate how they work together to facilitate various tasks in the field.

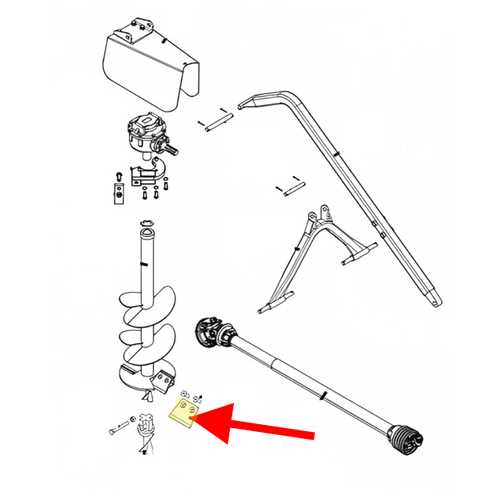

Upper Link: This component connects the implement to the tractor and helps in adjusting the angle and height for optimal performance.

Lower Links: These are pivotal for securing the implement to the machine, ensuring stability and control during operation.

Draft Link: This element aids in transferring the load from the implement to the tractor, crucial for maintaining balance and maneuverability.

Top Link Bracket: A vital connection point that supports the upper link, allowing for precise adjustments and enhancing overall functionality.

Quick Coupler: This feature enables swift attachment and detachment of implements, streamlining workflow and saving time in the field.

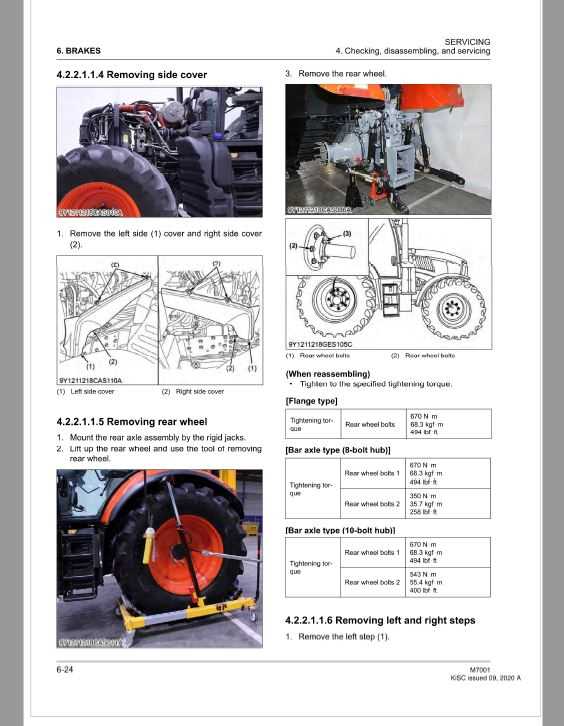

Understanding Hitch Diagrams

Comprehending the layout and components of attachment systems is crucial for efficient agricultural operations. A well-structured illustration provides insights into the arrangement and functionality of various elements, enabling operators to optimize their equipment’s performance.

Key Components

Each system comprises several integral parts that work together to ensure seamless connectivity and operation. Familiarity with these elements allows users to identify issues and make necessary adjustments, enhancing overall efficiency.

Reading the Illustration

Interpreting these visual representations can significantly improve your understanding of machinery operations. Recognizing symbols and connections helps in troubleshooting and maintaining equipment, leading to a more effective use of resources.

Common Issues with 3 Point Hitches

Understanding the frequent problems encountered with rear-mounted equipment can greatly enhance operational efficiency. Various complications can arise, affecting the overall functionality and performance of the attachments. Addressing these issues promptly ensures smooth operation and prolongs the life of the machinery.

Alignment Problems: Misalignment is a common concern that can lead to uneven wear and difficulty in attaching or detaching implements. Regular checks for proper positioning can help mitigate these issues.

Worn Components: Over time, certain elements can experience significant wear, resulting in diminished performance. Inspecting and replacing these worn parts as needed is crucial to maintain optimal operation.

Hydraulic Leaks: Hydraulic systems are prone to leaks, which can lead to loss of power and functionality. Regular maintenance and prompt repairs are essential to prevent more extensive damage.

Improper Adjustments: Incorrect settings can cause operational inefficiencies and lead to premature wear. Familiarity with the adjustment mechanisms and periodic reviews can help ensure correct configurations.

Corrosion and Rust: Exposure to elements can lead to corrosion, compromising the integrity of the equipment. Regular cleaning and protective coatings can prevent rust from becoming a significant issue.

By being aware of these common challenges, operators can take proactive measures to maintain their equipment, ensuring reliability and performance in the field.

Parts Identification and Function

Understanding the components and their roles is crucial for maintaining and operating the equipment efficiently. Each element is designed with a specific purpose to ensure smooth operation and adaptability. This section will provide a detailed breakdown of various elements, focusing on their roles and how they contribute to the overall system’s functionality.

Key Components Overview

The mechanism includes several key elements, each interacting with the others to deliver optimal performance. From connecting points to adjustable segments, every part plays a vital role in stability and precision. Identifying these elements helps to ensure proper setup and maintenance for prolonged use.

Functional Breakdown

Each component has a distinct function, which contributes to the effectiveness of the entire assembly. Some elements allow for secure attachments, while others provide flexibility and control over the system. Below is a table highlighting the primary components and their respective roles:

| Component | Function |

|---|---|

| Linkage Arm | Provides support and ensures balanced movement during operation. |

Maintenance Tips for LongevityProper care and routine maintenance are crucial for ensuring the extended lifespan and optimal performance of your agricultural equipment. Regular attention to key components not only prevents wear but also minimizes downtime and repair costs. By following a few straightforward guidelines, you can keep your machine running smoothly for years to come. Start by checking the lubrication system regularly. Ensure that moving parts are adequately greased to reduce friction and avoid premature damage. Inspect the mechanical connections and tighten any loose bolts or fasteners to prevent wear and tear caused by vibrations. Additionally, always clean the equipment after each use to remove dirt, debris, and moisture, which can contribute to rust and corrosion. Periodic inspections of key components, such as the lifting mechanisms and structural supports, are also essential. Look for signs of stress or fatigue and replace worn-out parts promptly to maintain functionality. Lastly, store the equipment in a dry and secure location to protect it from the elements and prolong its service life. Upgrading Your Kubota EquipmentEnhancing your agricultural machinery can significantly improve performance and efficiency. By making thoughtful upgrades, you can optimize the capabilities of your equipment, ensuring that it meets your evolving needs. Whether it’s for increased lifting capacity, better maneuverability, or extended durability, upgrading specific components is a great way to get the most out of your machine. Customization options are vast, and selecting the right accessories can help tailor your machinery to suit particular tasks. For instance, adding improved connectors or attachments can boost versatility, making it easier to handle various tools. Consider upgrading the framework to enhance the load-bearing abilities and extend the machine’s lifespan. Proper installation is crucial to ensure safety and functionality. When installing new components, make sure to follow all recommended guidelines and check compatibility with your current system. Regular maintenance and timely upgrades are key to preventing wear and tear, ensuring your equipment continues to perform at its best for years. Where to Buy Replacement PartsWhen it’s time to replace a malfunctioning component, finding the right supplier is key to keeping your equipment in optimal condition. Whether you’re looking for individual elements or complete assemblies, there are several reliable sources that offer high-quality replacements for machinery repairs. Choosing the right retailer or distributor can make all the difference in ensuring durability and compatibility with your existing setup. Authorized DealersOne of the most dependable sources for new components is through authorized dealers. These vendors typically offer genuine items specifically designed for your equipment model. The benefit of purchasing through these authorized outlets is the assurance of product quality, as well as customer support and warranty services. You can often find both online and physical stores that specialize in these types of replacements.

Online MarketplacesFor those looking for a wider variety or potentially lower prices, online marketplaces provide an excellent alternative. Websites like Amazon, eBay, or other specialized online shops allow you to compare different products and sellers. Just be sure to check the seller’s reputation and read reviews to ensure you’re getting a quality item.

Always prioritize quality and compatibility, as these factors directly influence the performance and longevity of your equipment. |