In the realm of construction and earth-moving activities, the functionality of complex machines relies on a well-orchestrated assembly of various elements. Each component plays a pivotal role in ensuring efficiency and precision, transforming raw power into reliable performance on the job site.

The intricate network of these mechanisms can seem daunting at first glance, yet a closer examination reveals a logical structure that underpins their operation. By exploring the relationships between these vital elements, one can ultimately gain insights into how they contribute to the machine’s overall effectiveness.

Familiarity with the individual features not only enhances operational understanding but also aids in maintenance and troubleshooting. As we delve deeper into this subject, we will uncover the unique characteristics and functions that define these essential machines in the construction industry.

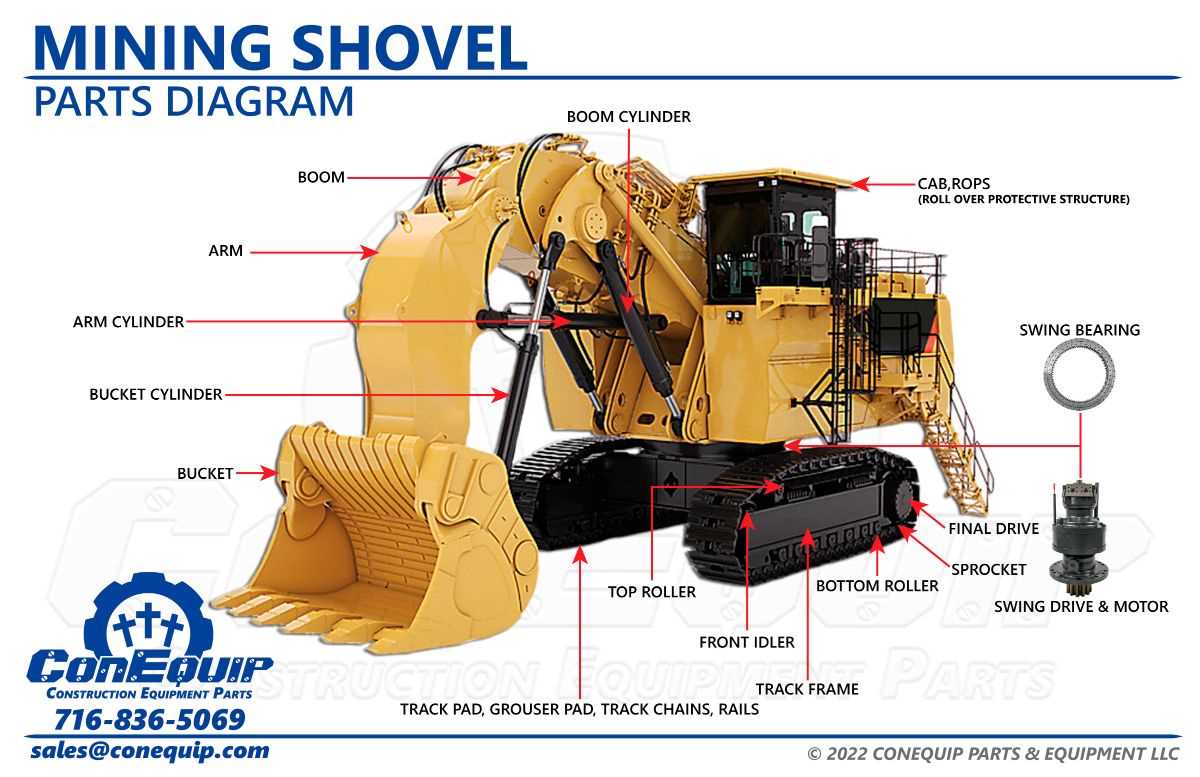

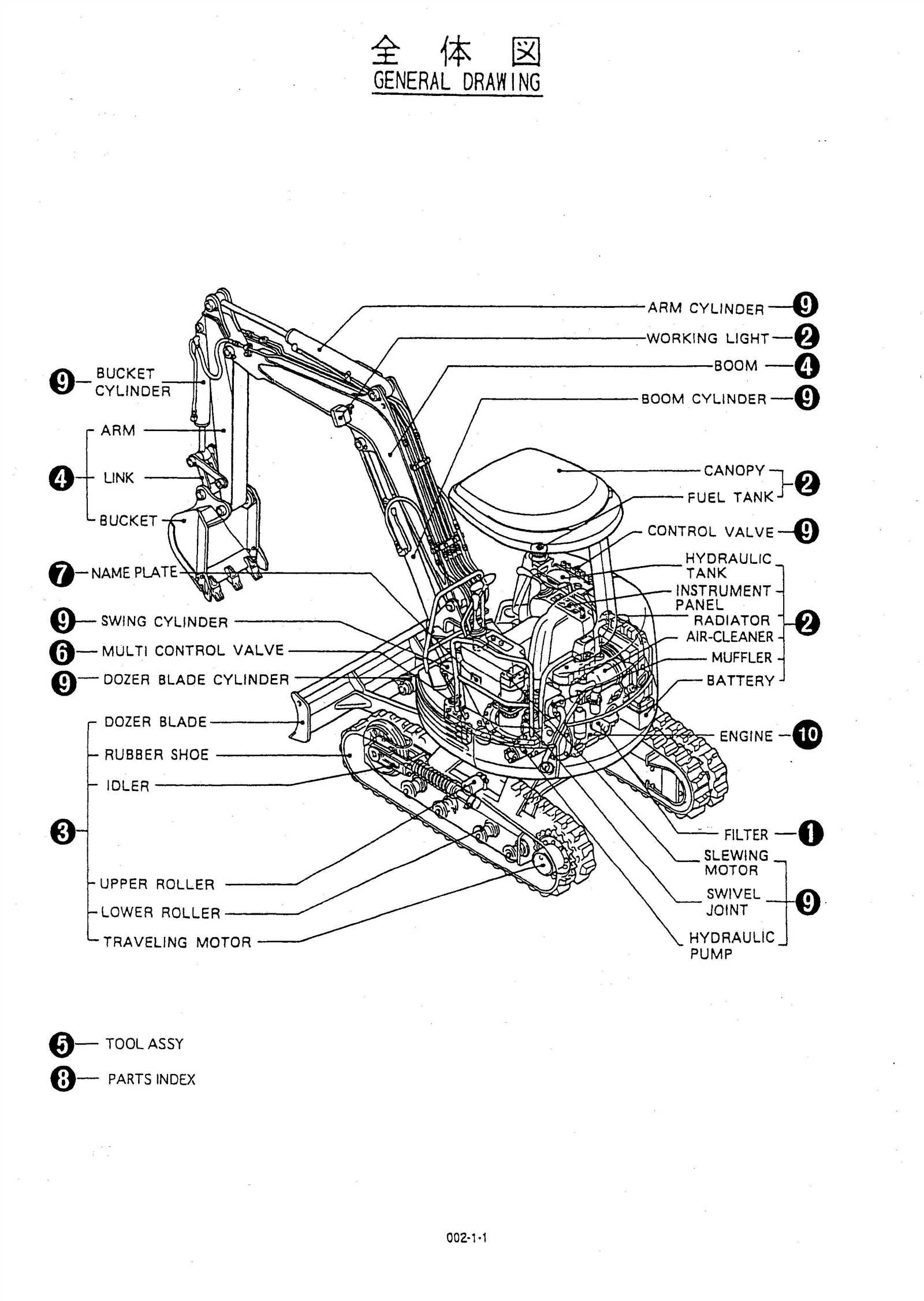

Understanding Excavator Components

Comprehending the individual elements of heavy machinery is essential for efficient operation and maintenance. Each component plays a crucial role in ensuring the overall functionality and performance of the equipment. By exploring these elements, operators can enhance their knowledge and optimize their work processes.

| Component | Description |

|---|---|

| Crawler | Provides mobility across various terrains. |

| Arm | Enables reaching and lifting materials. |

| Bucket | Used for digging and transporting soil or debris. |

| Cab | Houses the operator controls and provides visibility. |

| Hydraulic System | Facilitates movement and force through fluid power. |

Importance of Accurate Diagrams

Clear and precise representations are crucial in the machinery field. They serve as essential tools for understanding complex systems, ensuring proper assembly and maintenance, and enhancing communication among technicians and operators.

Benefits of Detailed Illustrations

- Facilitate efficient troubleshooting by providing clear guidance.

- Reduce the risk of errors during repairs and installations.

- Enhance safety measures by clarifying operational components.

Impact on Training and Development

- Streamline the learning process for new operators.

- Support continuous professional development with updated information.

- Foster a deeper understanding of machinery functionality.

Common Excavator Part Types

This section explores various components essential for the efficient operation of heavy machinery used in construction and earth-moving tasks. Understanding these elements can enhance maintenance and functionality.

- Bucket: Used for digging and transporting materials.

- Arm: Connects the bucket to the main structure, allowing movement.

- Boom: The long arm that extends from the chassis, providing reach.

- Cab: The operator’s compartment, designed for comfort and visibility.

- Tracks: Enable mobility across various terrains.

- Hydraulic System: Powers the machine’s movements through fluid dynamics.

Each of these components plays a crucial role in enhancing the ultimate efficiency and performance of heavy machinery.

Maintenance Tips for Excavator Parts

Proper upkeep of heavy machinery components is essential for ensuring longevity and optimal performance. Regular attention can prevent costly repairs and enhance efficiency. Here are some crucial maintenance suggestions to consider.

| Tip | Description |

|---|---|

| Regular Inspections | Conduct routine checks to identify wear and tear before they escalate into significant issues. |

| Lubrication | Ensure all moving elements are adequately lubricated to reduce friction and wear. |

| Cleanliness | Keep components free of dirt and debris to maintain efficiency and prevent damage. |

| Fluid Levels | Regularly monitor and replenish hydraulic and coolant fluids to ensure proper functioning. |

| Follow Manufacturer Guidelines | Adhere to the manufacturer’s recommendations for maintenance schedules and procedures. |

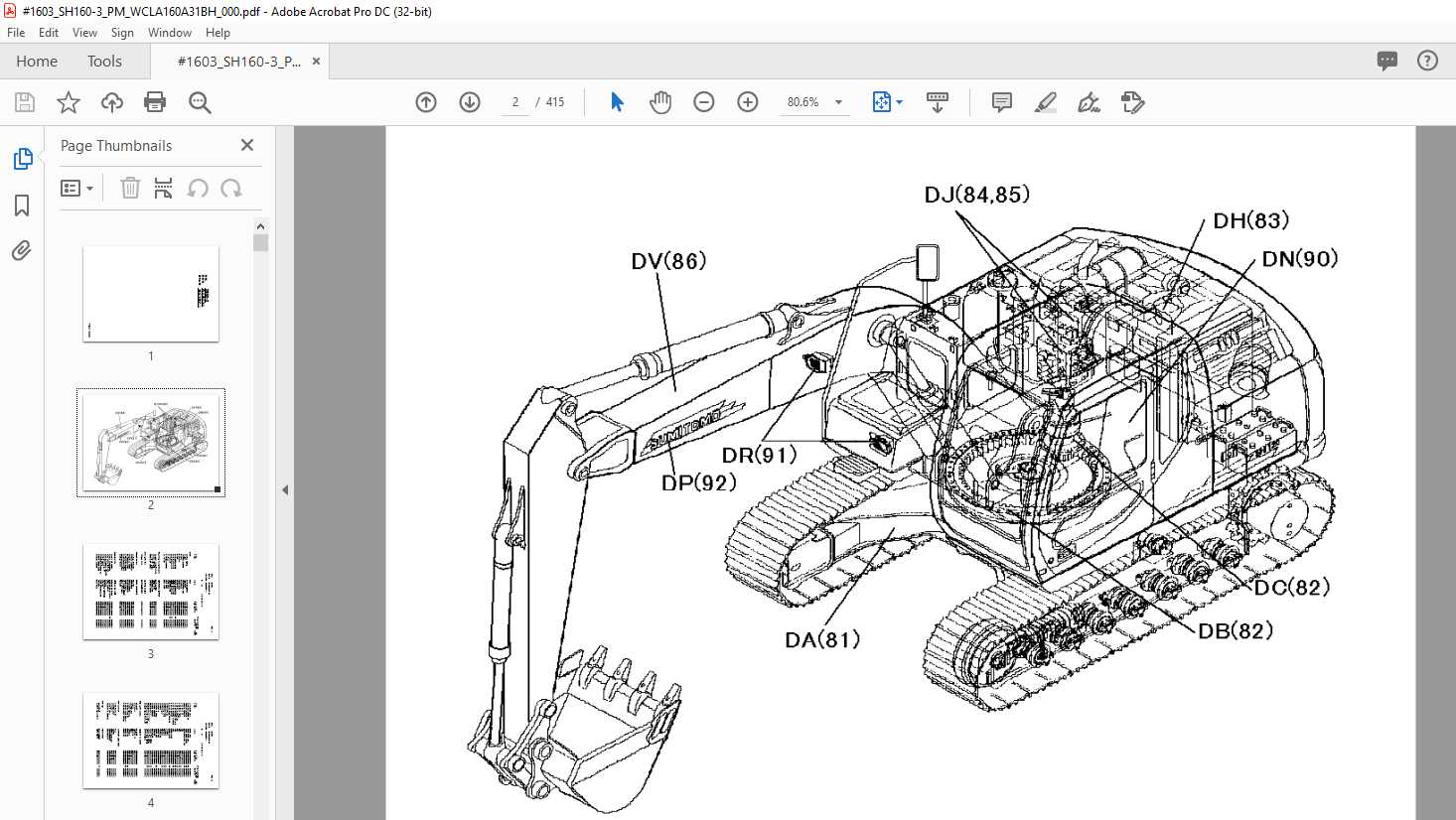

How to Read a Parts Diagram

Understanding a schematic representation of machinery components is crucial for effective maintenance and repairs. This visual guide helps identify each element and its relationship within the system, enabling efficient troubleshooting and assembly.

Identify Key Elements

Start by recognizing the symbols and labels used. Familiarize yourself with the legend, which explains the meaning of various icons. Each section typically denotes a specific function or group of components, making it easier to pinpoint issues.

Follow the Flow

Observe the connections between different elements. Tracking the flow of movement or fluid can reveal how each piece interacts with others. This understanding allows for a deeper insight into the overall operation, ensuring you can address problems effectively.

Identifying Wear and Tear Issues

Recognizing deterioration in machinery is crucial for maintaining optimal performance and preventing costly breakdowns. By closely monitoring specific components, operators can ensure longevity and efficiency, ultimately enhancing productivity.

Common Signs of Deterioration

Several indicators suggest that certain elements may be experiencing wear. Look for unusual noises, vibrations, or changes in operational efficiency, which often signal underlying problems.

Inspection Checklist

| Component | Signs of Wear | Recommended Action |

|---|---|---|

| Hydraulic System | Leaks, reduced pressure | Inspect hoses and seals; replace as needed |

| Tracks | Uneven wear, cracking | Realign or replace tracks |

| Bucket | Deformation, excessive wear | Repair or replace bucket |

Upgrading Excavator Parts for Efficiency

Enhancing machinery components is essential for boosting performance and ensuring longevity. By implementing advanced technologies and high-quality materials, operators can significantly increase productivity and reduce operational costs. This section explores key strategies for optimizing equipment functionality.

Benefits of Modernization

Modernizing machinery can lead to improved reliability, lower fuel consumption, and reduced maintenance needs. Upgraded components often feature better durability and efficiency, which translates to higher output and decreased downtime.

Key Upgrades to Consider

| Upgrade Type | Description | Benefits |

|---|---|---|

| Hydraulic Systems | Incorporating advanced hydraulic technology. | Improved lifting capacity and speed. |

| Tracks and Undercarriage | Upgrading to high-durability materials. | Enhanced stability and traction. |

| Engines | Installing fuel-efficient engines. | Lower emissions and operational costs. |

Resources for Parts Replacement Guides

When it comes to maintaining heavy machinery, having access to reliable resources for component replacement is crucial. These guides not only help ensure proper functioning but also enhance the longevity of the equipment. Here are some valuable sources to consider for effective replacements.

Online Platforms

- Manufacturer Websites: Direct access to official manuals and specifications.

- Industry Forums: Community-driven discussions and advice on common issues.

- YouTube Tutorials: Visual demonstrations for various maintenance tasks.

Printed Resources

- Service Manuals: Comprehensive guides detailing repair processes.

- Trade Magazines: Articles featuring best practices and new technologies.

- Technical Books: In-depth information on machinery operation and upkeep.