The intricate structure of a 22 horsepower unit reveals a multitude of essential elements that contribute to its efficient operation. Familiarizing oneself with these components can greatly enhance maintenance practices and troubleshooting efforts. Each element plays a pivotal role in ensuring optimal functionality and longevity.

In this section, we will delve into a detailed exploration of the various segments that make up this powerful system. By gaining insights into their arrangement and interrelationships, users can better appreciate how each part contributes to the overall performance. Knowledge of these elements is vital for anyone looking to optimize their machinery’s efficiency.

Whether you are a seasoned technician or a novice user, understanding the layout and functionality of the components will empower you to make informed decisions. Enhanced comprehension not only facilitates repairs but also aids in recognizing potential issues before they escalate. Embracing this knowledge is the first step towards ensuring the reliability and effectiveness of your equipment.

Key Components of the Engine

This section provides an overview of essential elements that contribute to the functionality and performance of a small power unit. Understanding these vital components is crucial for maintaining efficiency and ensuring longevity. Each part plays a specific role in the overall operation, making them indispensable in achieving optimal performance.

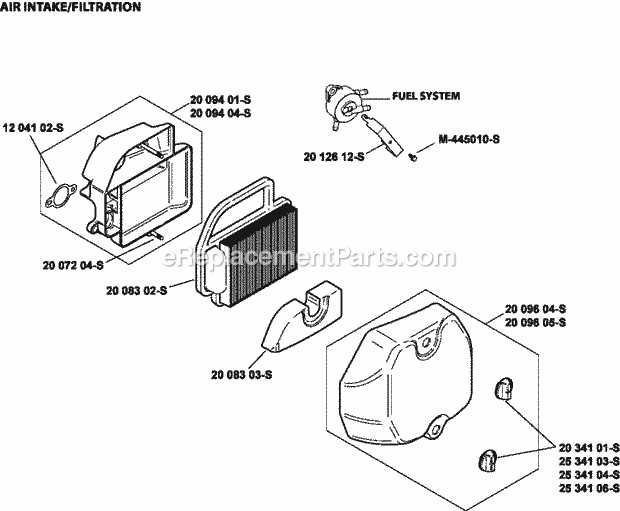

Fuel Delivery System

The fuel delivery system is responsible for transporting fuel from the tank to the combustion chamber. It typically consists of various elements, including the fuel pump, lines, and filters. Ensuring this system is clean and functioning properly is essential for preventing performance issues and maximizing power output.

Ignition Assembly

The ignition assembly initiates the combustion process, providing the necessary spark to ignite the fuel-air mixture. This system includes the spark plug, ignition coil, and wiring. A well-functioning ignition assembly is crucial for reliable starts and smooth operation.

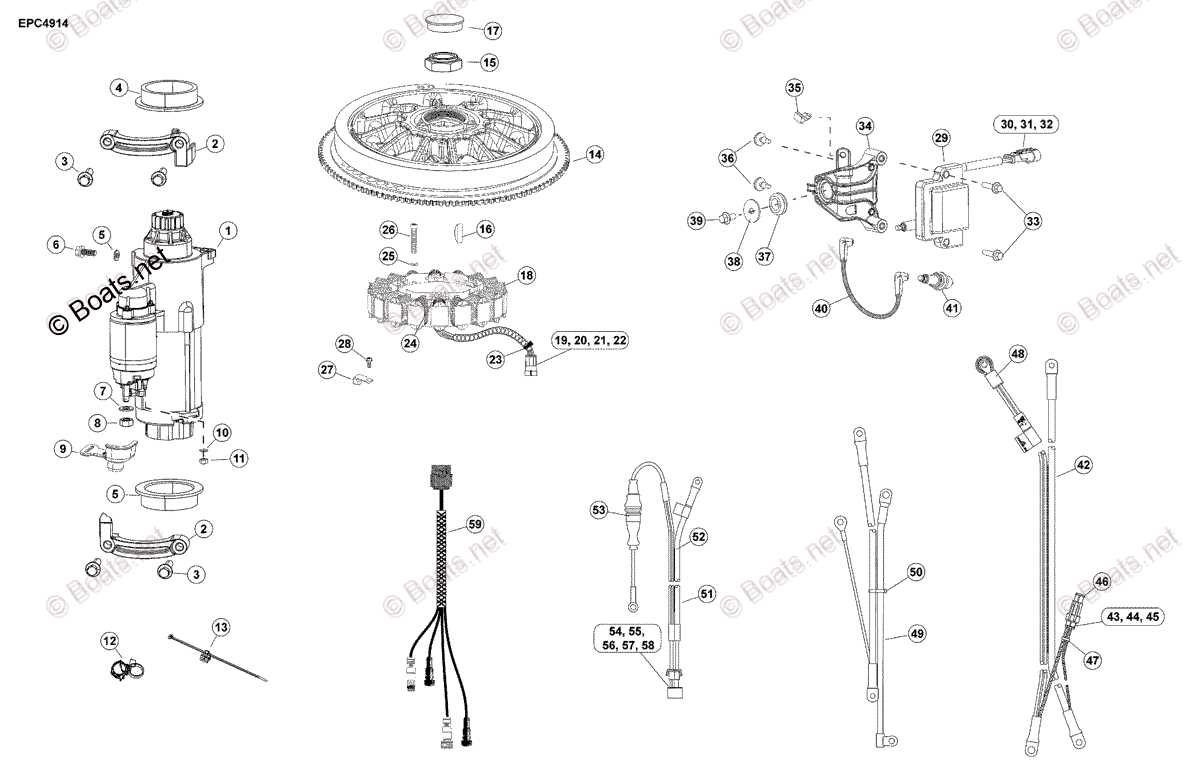

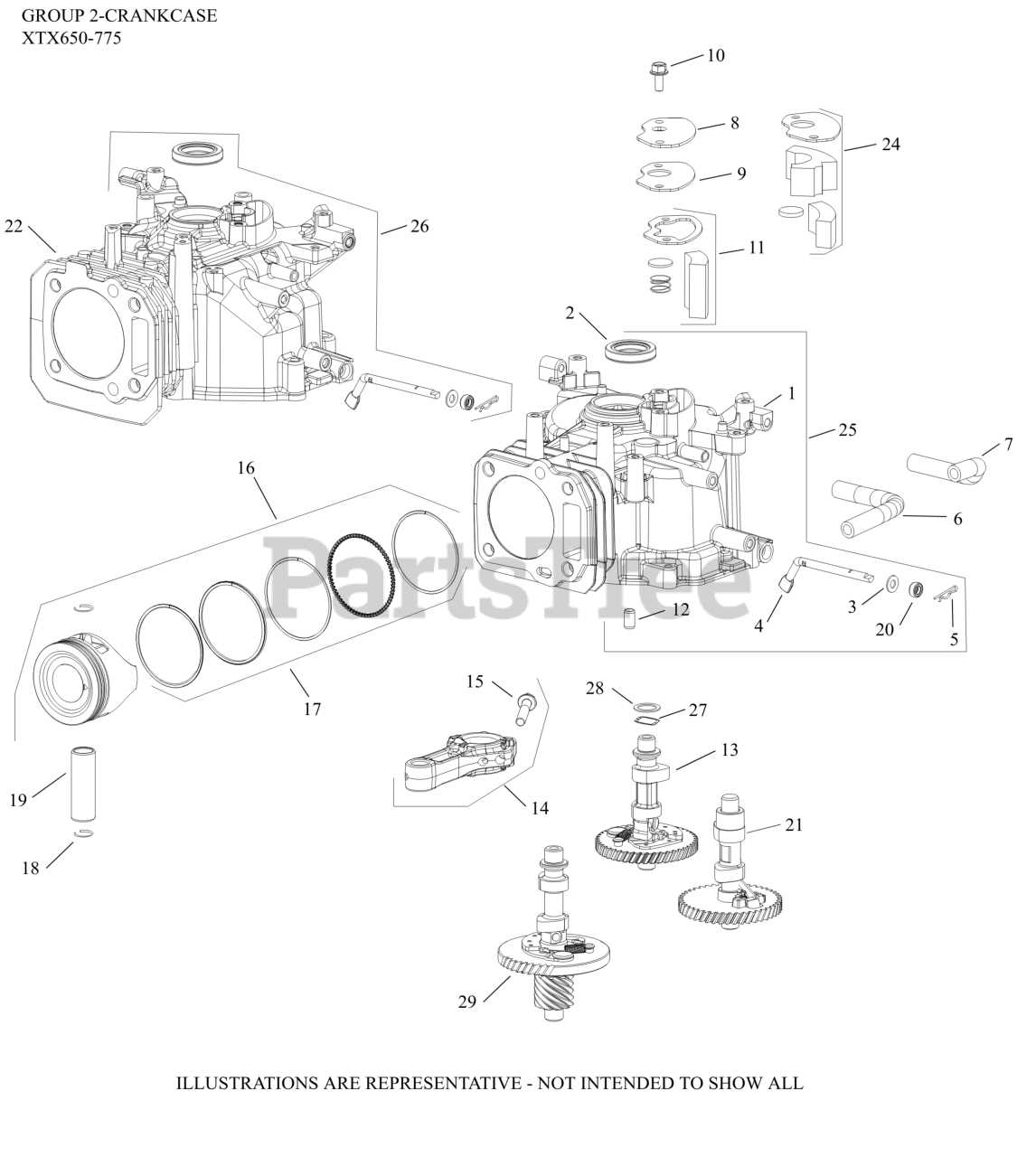

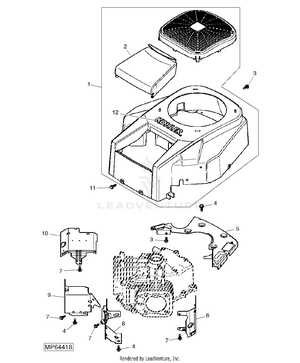

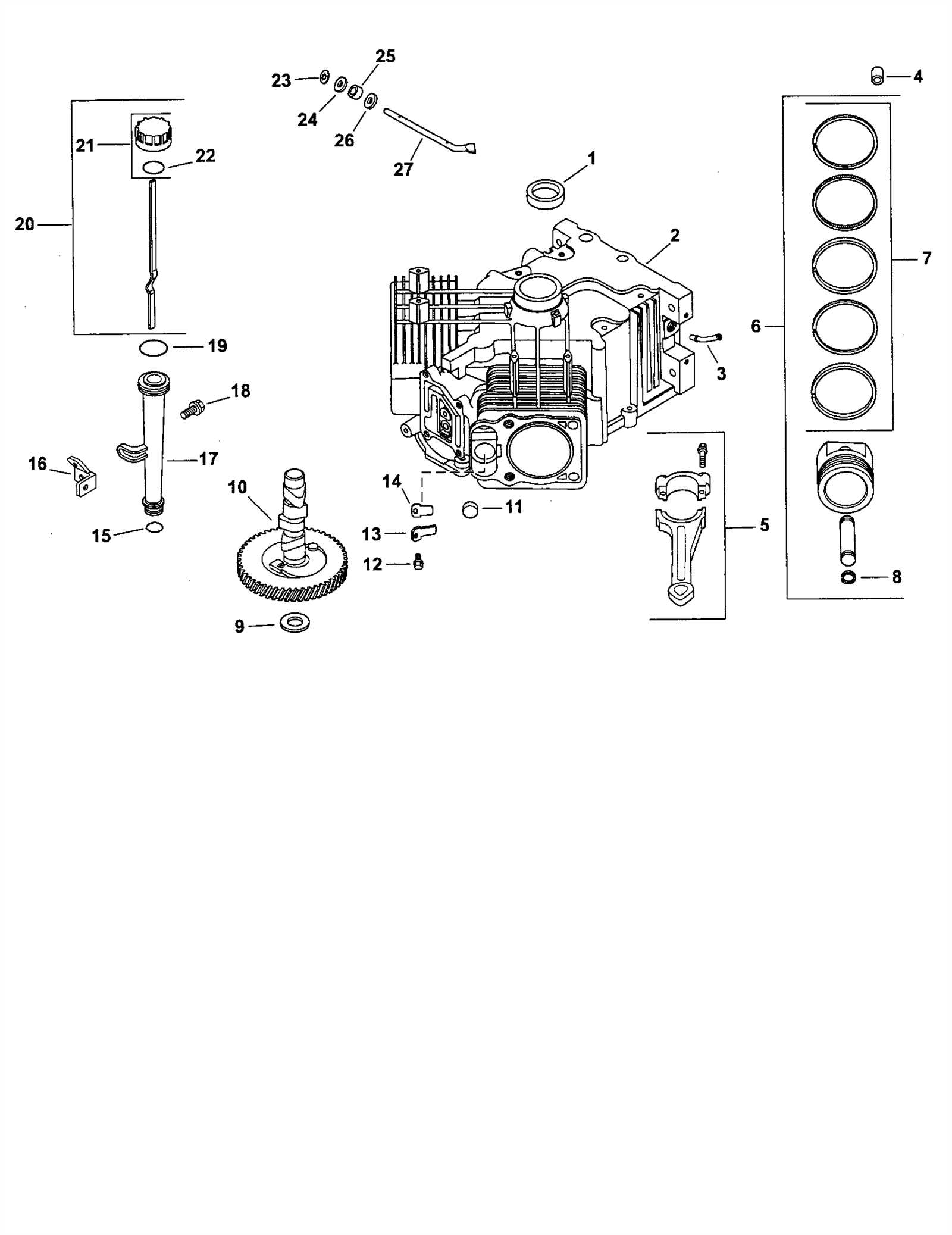

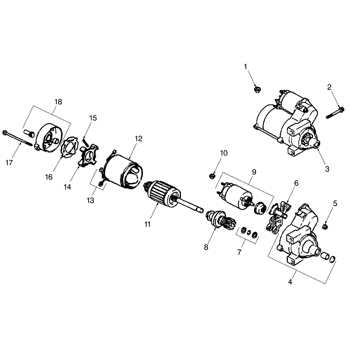

Understanding the Parts Diagram

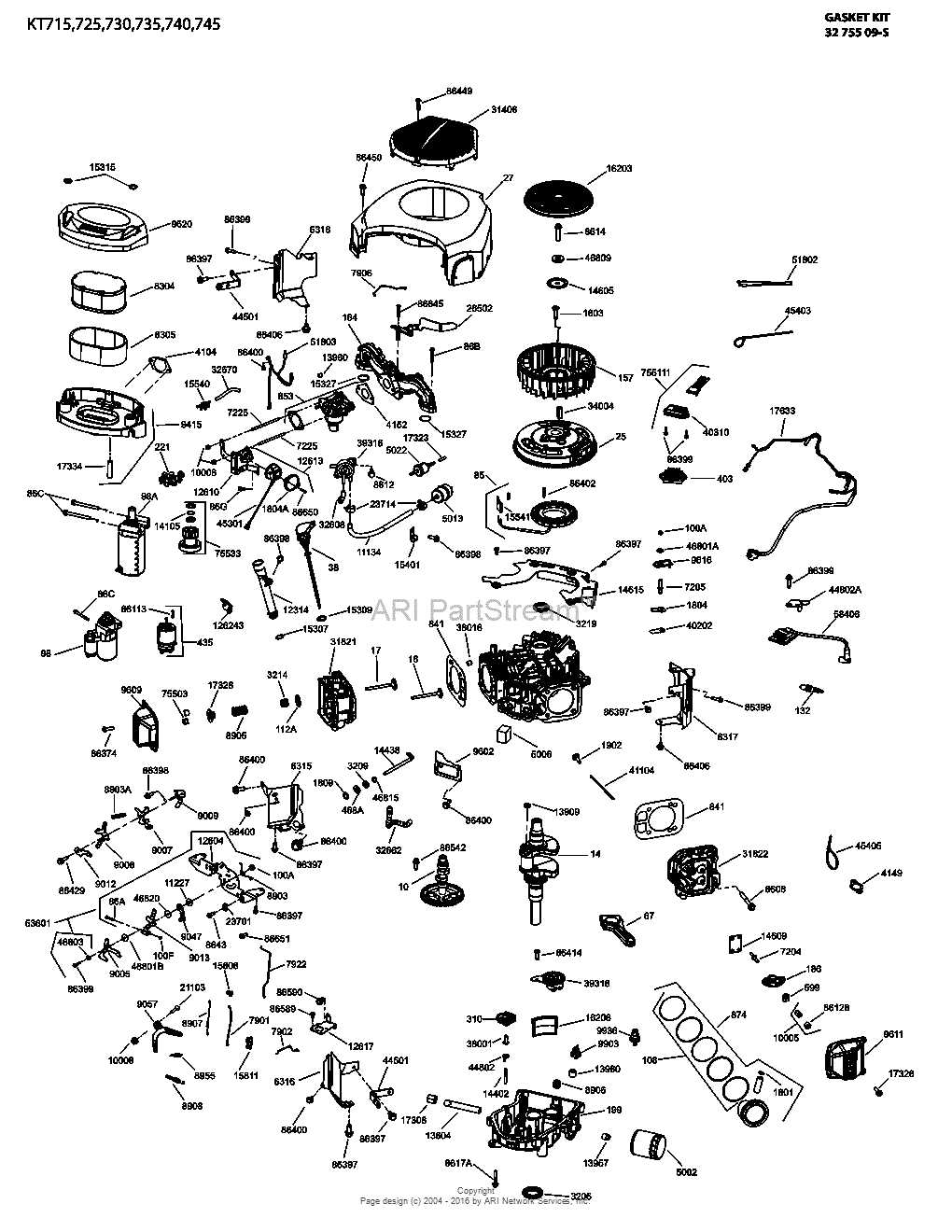

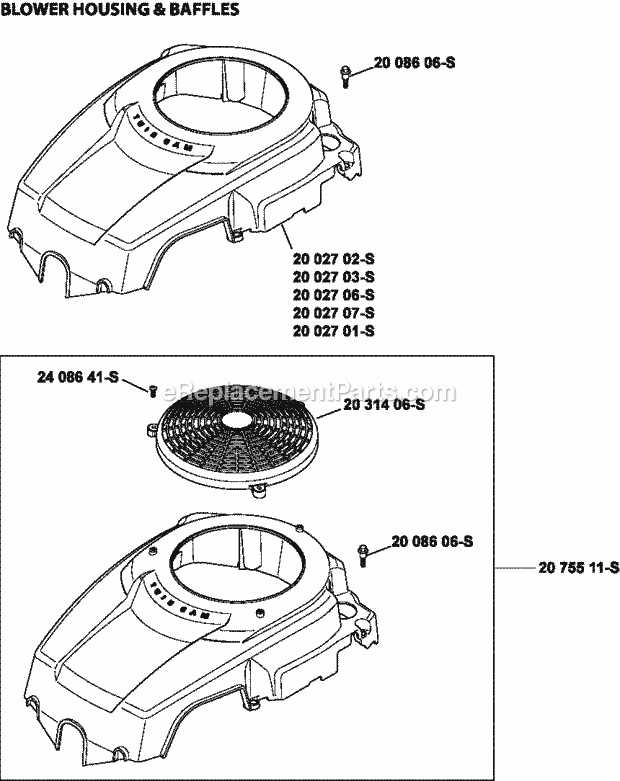

The visual representation of components is essential for comprehending the structure and functionality of mechanical systems. Such illustrations serve as valuable tools for identifying individual elements and their relationships within the overall assembly. By analyzing these visuals, users can gain insights into the operational mechanisms and maintenance requirements of the system.

Typically, these representations categorize various components, showcasing their placement and connections. Each section highlights specific items, often accompanied by labels or numbers, facilitating easy reference. This organization aids users in troubleshooting, repairs, and part replacements, ultimately ensuring efficient operation and longevity.

Furthermore, familiarity with the representation enhances one’s ability to communicate effectively about repairs and maintenance tasks. Knowing how to interpret the visual layout allows for clearer discussions with technicians and suppliers, leading to more informed decisions when sourcing replacements or performing adjustments. Understanding these representations not only simplifies the repair process but also promotes a deeper appreciation of the entire mechanical setup.

Functionality of Major Parts

The core components of any power-generating system play a crucial role in ensuring optimal performance and efficiency. Each unit is designed to perform specific functions that contribute to the overall operation. Understanding how these elements interact can provide valuable insights into their importance and maintenance needs.

Critical Components Overview

The combustion chamber serves as the heart of the system, where fuel mixes with air and ignites to produce power. This process relies on precise timing and efficient airflow to maximize energy output. Similarly, the cooling system prevents overheating, ensuring that the machinery operates within safe temperature limits, thus prolonging its lifespan.

Supporting Structures

Additionally, the lubrication system plays a vital role by reducing friction between moving elements, which minimizes wear and tear. Furthermore, the electrical components are essential for ignition and power distribution, enabling smooth operation. Each of these key units must function harmoniously to achieve reliable performance.

Maintenance Tips for Engine Parts

Proper upkeep of your machinery components is essential for ensuring longevity and optimal performance. Regular attention can prevent costly repairs and enhance efficiency, leading to a smoother operation.

Here are some essential practices to follow:

- Regular Inspection: Conduct frequent checks to identify any signs of wear or damage. Look for leaks, unusual noises, or vibrations.

- Cleaning: Keep all surfaces clean to prevent dirt and debris buildup. This includes wiping down surfaces and using compressed air to clear hard-to-reach areas.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and wear. Ensure that the lubricants used meet the required specifications.

- Filter Changes: Replace filters as recommended to ensure optimal function. Clogged filters can hinder performance and lead to overheating.

- Storage: When not in use, store your equipment in a dry, sheltered environment to protect it from the elements. Cover it to avoid dust accumulation.

By adhering to these guidelines, you can extend the life of your machinery and maintain its peak performance. Consistency in maintenance is key to avoiding unexpected failures and ensuring efficient operation.

Common Issues and Troubleshooting

Regular maintenance can often prevent the most frequent problems associated with power machinery. However, when complications do arise, identifying and addressing them promptly is crucial for optimal performance. This section outlines some prevalent challenges and provides guidance on effective solutions.

| Issue | Symptoms | Potential Solutions |

|---|---|---|

| Hard Starting | Difficulty in initiating operation, unusual noises | Check fuel supply, inspect the ignition system, and ensure proper battery voltage. |

| Overheating | Excessive heat, reduced efficiency | Inspect the cooling system for blockages, clean air filters, and verify proper oil levels. |

| Uneven Performance | Inconsistent power output, sputtering | Examine fuel quality, clean the carburetor, and adjust throttle settings. |

| Excessive Vibration | Unusual shaking during operation | Check for loose components, inspect the mounting hardware, and ensure proper alignment. |

| Fuel Leaks | Visible fuel around the unit, strong fuel odor | Inspect fuel lines for cracks, replace damaged seals, and tighten connections. |

Replacement Parts and Upgrades

Maintaining optimal performance in outdoor machinery often involves the need for components that can either replace worn-out elements or enhance existing functionality. Understanding which replacements and enhancements are available allows users to improve the efficiency and lifespan of their equipment significantly. This section outlines various options for substitution and enhancement that can be implemented to achieve peak operation.

Common Replacement Options

Identifying the right alternatives for your machinery is crucial for effective upkeep. Below is a summary of commonly used substitutes that can improve the performance of your equipment:

| Component | Description | Benefits |

|---|---|---|

| Fuel Filter | Ensures the fuel system remains clean and free of contaminants. | Enhances combustion efficiency and prolongs component life. |

| Air Filter | Prevents dirt and debris from entering the combustion chamber. | Improves air intake and boosts overall power output. |

| Spark Plug | Ignites the fuel-air mixture for combustion. | Ensures reliable starting and optimal performance. |

Upgrades for Enhanced Performance

In addition to replacing worn components, considering upgrades can lead to substantial improvements in capability and efficiency. Here are some popular upgrade options:

| Upgrade | Description | Advantages |

|---|---|---|

| High-Performance Carburetor | Increases fuel and air flow for better combustion. | Boosts horsepower and torque. |

| Performance Muffler | Reduces exhaust restrictions and improves sound. | Enhances power and provides a sportier sound. |

| Heavy-Duty Oil Filter | Offers superior filtration compared to standard options. | Extends engine life and reduces maintenance frequency. |

Resources for Kohler Engine Owners

For individuals maintaining their small power units, having access to a variety of resources can significantly enhance the experience of ownership. Whether you are seeking information for troubleshooting, maintenance, or upgrades, several platforms offer valuable insights and tools tailored to your needs.

Online Communities and Forums

Participating in online forums dedicated to small machinery enthusiasts can be a great way to gain knowledge and share experiences. These communities often provide practical advice, troubleshooting tips, and recommendations for reliable suppliers. Engaging with fellow users fosters a sense of camaraderie and can lead to discovering solutions to common issues.

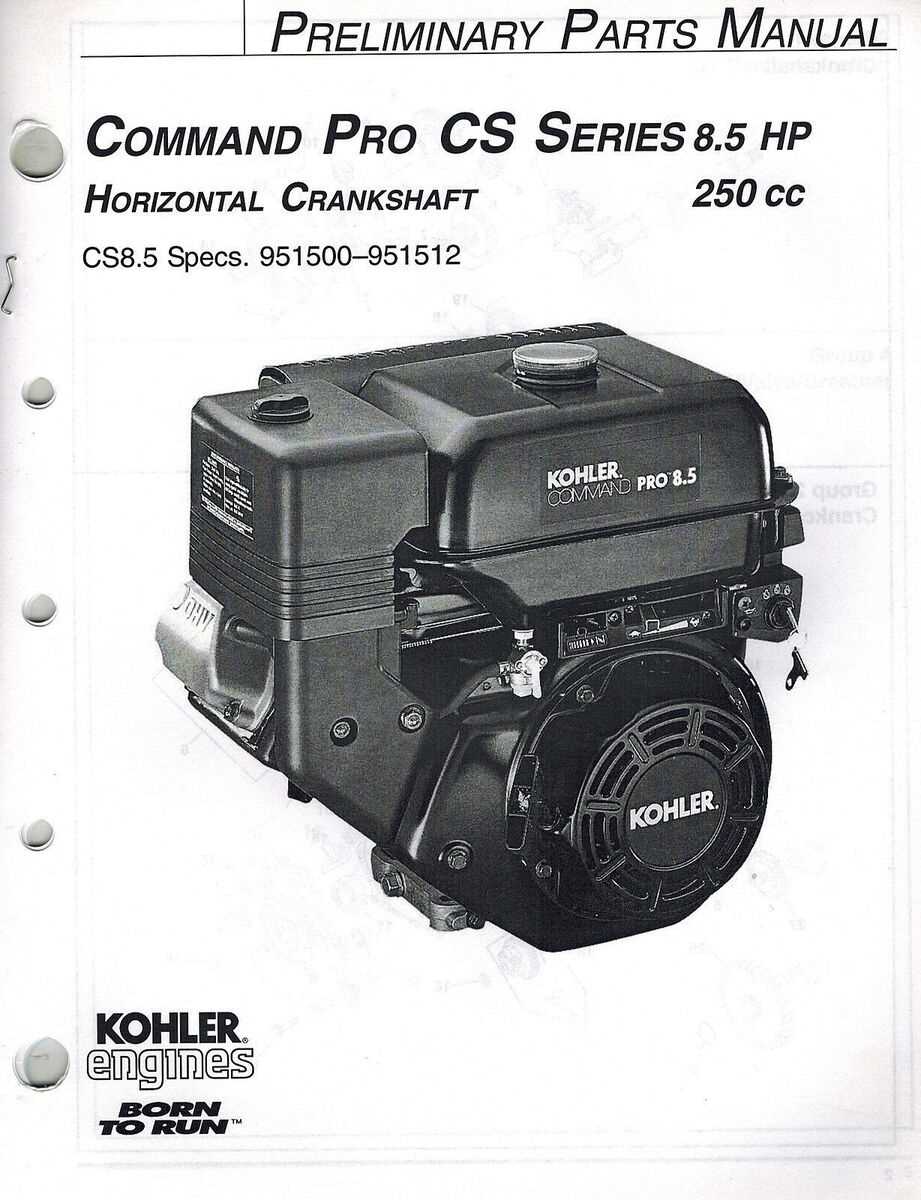

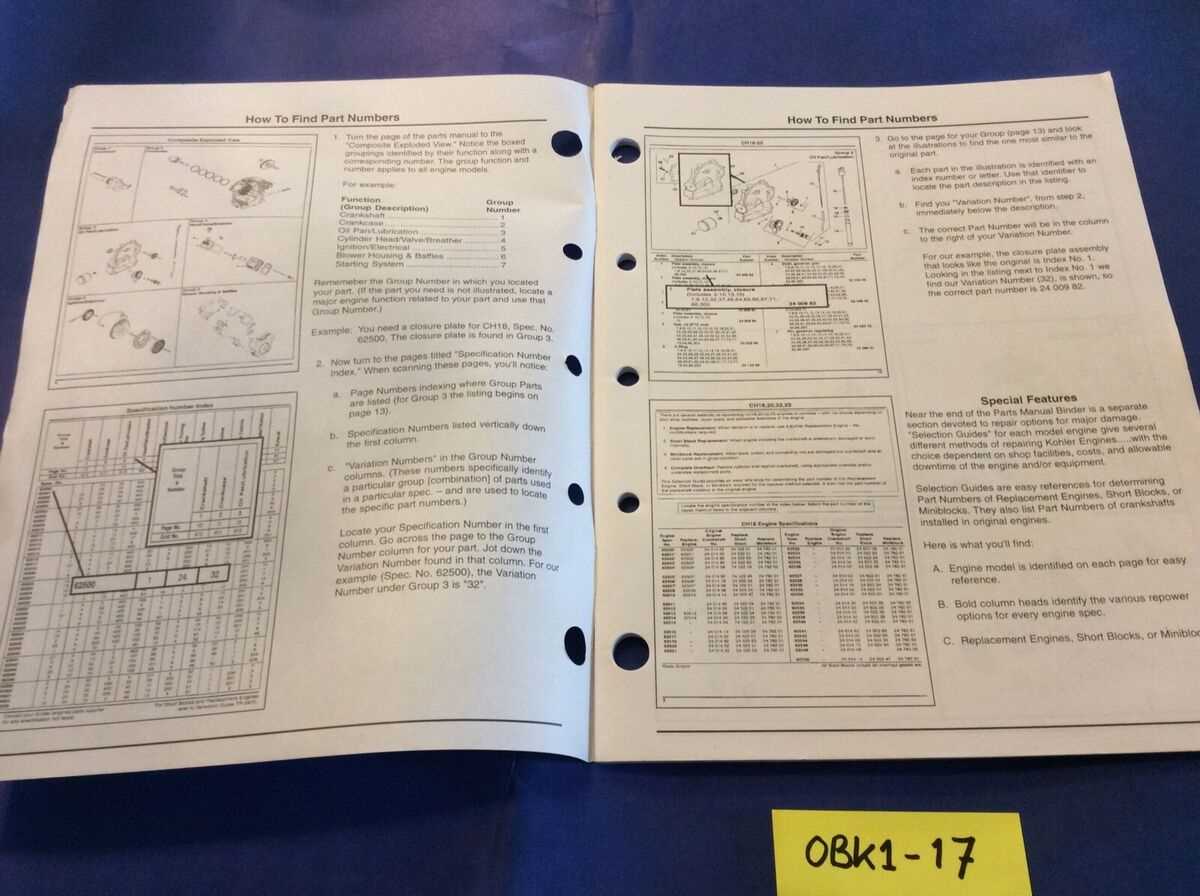

Official Manuals and Documentation

Consulting official manuals and documentation is essential for understanding the specifications and operational guidelines of your machinery. These resources typically contain detailed information about maintenance schedules, safety protocols, and component identification, ensuring you have all the necessary details for effective upkeep. Additionally, many manufacturers offer downloadable PDFs on their websites, making access to this information convenient.