In the realm of construction and landscaping, the efficiency of compact machinery is paramount. These agile machines are designed to navigate tight spaces while delivering impressive power and versatility. A comprehensive knowledge of their internal mechanisms is essential for optimal operation and maintenance.

To truly grasp the functionality of these machines, one must explore the intricate layout of their components. Each element plays a crucial role, contributing to the overall performance and reliability of the equipment. By delving into the specifics of these vital structures, operators can ensure longevity and efficiency in their daily tasks.

Ultimately, understanding how each section interacts not only enhances operational skills but also aids in troubleshooting and repairs. This insight allows users to maximize productivity and minimize downtime, solidifying their success in various projects.

Understanding Mini Excavator Components

When operating heavy machinery, recognizing the essential elements is crucial for optimal functionality. Each section plays a vital role in ensuring efficiency and effectiveness during various tasks. By familiarizing oneself with these fundamental components, operators can enhance their performance and maintenance practices.

Powertrain systems serve as the heart, providing the necessary force to execute movements. Hydraulic mechanisms facilitate the dynamic operations, enabling precise control and versatility. Structural frameworks, often made from robust materials, ensure stability and support during rigorous activities.

Furthermore, attachments contribute to the adaptability of the machine, allowing it to tackle a range of jobs. Understanding the interplay between these elements not only aids in troubleshooting but also maximizes the lifespan of the equipment.

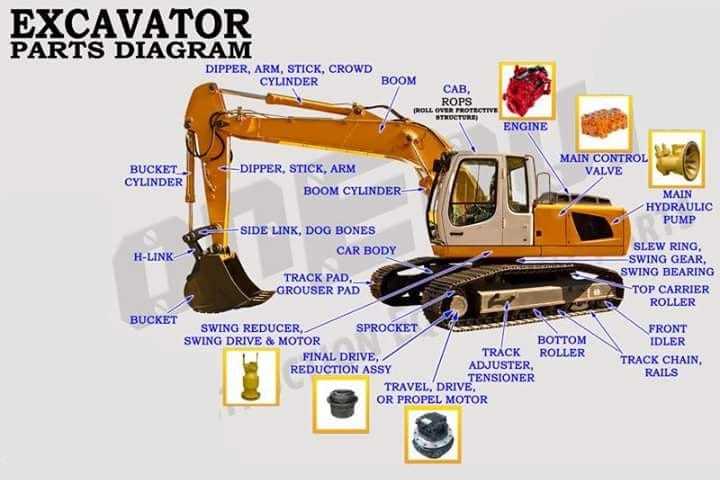

Key Parts of Mini Excavators Explained

This section delves into the essential components that contribute to the functionality and efficiency of compact earth-moving machines. Understanding these elements can enhance the user’s ability to operate and maintain the machinery effectively.

Core Components

- Boom: The long arm that extends outward, providing reach and leverage for digging tasks.

- Bucket: A scoop-like attachment used for digging, lifting, and moving materials.

- Stick: Connects the boom to the bucket, allowing for precise control during operation.

- Tracks: The undercarriage that provides stability and mobility on various terrains.

- Cab: The operator’s enclosure, designed for comfort and visibility.

Supporting Systems

- Hydraulic System: Powers the movement of the boom, stick, and bucket, enabling efficient operation.

- Engine: The power source that drives the entire machine.

- Control System: Includes levers and pedals for maneuvering the equipment with precision.

- Counterweight: A mass positioned at the rear to balance the machine during operation.

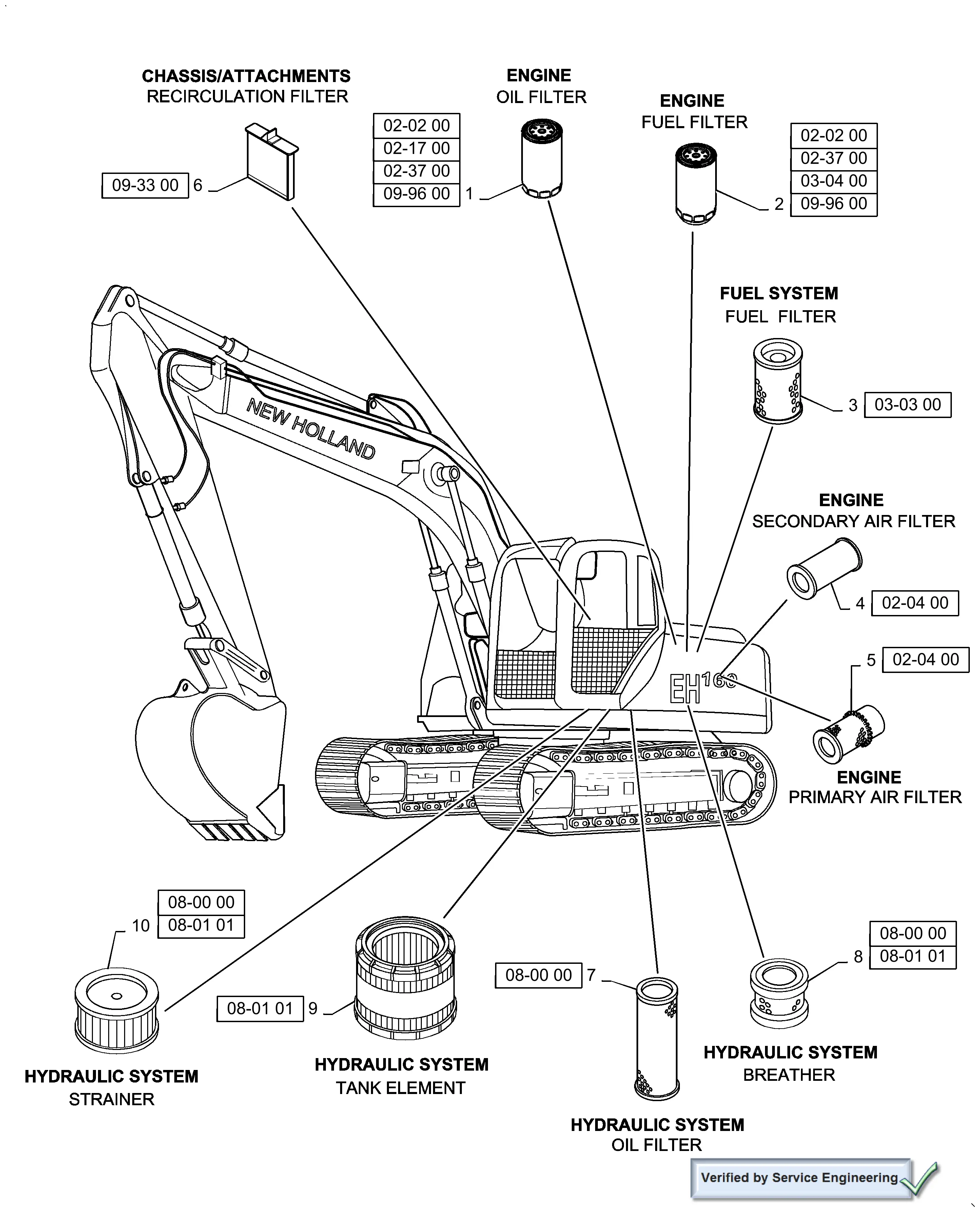

Importance of Diagrams in Maintenance

Visual representations play a crucial role in the upkeep and repair of machinery. They provide a clear overview of components and their interconnections, making it easier for technicians to understand complex systems. These illustrations enhance efficiency and accuracy, significantly reducing the risk of errors during maintenance tasks.

Benefits of Utilizing Visual Guides

- Enhanced Clarity: Visual aids simplify intricate details, allowing for a quicker grasp of how different elements function together.

- Improved Troubleshooting: Technicians can identify issues faster by referencing visual layouts, streamlining the diagnostic process.

- Time Efficiency: With a clear guide, maintenance tasks can be completed more rapidly, minimizing downtime.

- Training Resource: New personnel can learn from these illustrations, aiding in their understanding of machinery operation.

Conclusion

Incorporating visual representations into maintenance protocols not only enhances operational efficiency but also fosters a safer work environment. By leveraging these tools, technicians can perform their duties with greater precision and confidence.

How to Read a Parts Diagram

Understanding the layout of components is essential for efficient maintenance and repair. This knowledge enables operators and technicians to quickly identify specific elements and their functions within the machinery. Grasping the structure of these visual representations simplifies troubleshooting and ordering the right components.

Identifying Key Elements

Start by familiarizing yourself with the main sections illustrated in the representation. Each segment typically corresponds to a specific area of the machine. Look for labels or numbers that correlate with a list of components. This will help you connect visual information with textual descriptions, making it easier to pinpoint the exact items you need.

Understanding Relationships

Pay attention to how various elements interact with one another. Arrows or lines may indicate connections or pathways, showing how parts are assembled or function together. Recognizing these relationships is crucial for proper installation and repair, ensuring that each component works harmoniously within the system.

By taking the time to study and understand these visual guides, you enhance your ability to maintain the equipment effectively.

Common Issues with Excavator Parts

Understanding the frequent challenges associated with heavy machinery components is crucial for effective maintenance and operation. Various elements can experience wear and tear, leading to reduced performance and efficiency. Identifying these issues early can save time and costs in the long run.

Hydraulic System Failures

The hydraulic system is vital for the functionality of the equipment. Common problems include leaks and pressure loss, which can significantly affect the power and responsiveness of the machine. Regular inspections and timely repairs are essential to prevent these complications from escalating.

Track and Undercarriage Wear

Another prevalent concern involves the tracks and undercarriage. These components are subjected to immense stress and can suffer from damage such as cracking, stretching, or uneven wear. Proper alignment and maintenance routines can help extend the lifespan of these parts and ensure optimal performance.

Upgrading Mini Excavator Components

Enhancing machinery performance often requires a thoughtful evaluation of its components. By replacing outdated elements with modern alternatives, operators can significantly boost efficiency and functionality. This section explores various upgrades that can lead to better productivity and reduced operational costs.

| Component | Upgrade Options | Benefits |

|---|---|---|

| Engine | High-efficiency models | Improved fuel economy and power output |

| Hydraulic System | Advanced pumps and hoses | Faster cycle times and enhanced lifting capability |

| Cab | Ergonomic controls and technology | Increased operator comfort and precision |

| Track System | Rubber or steel tracks | Better traction and stability on various terrains |

Safety Features in Excavator Design

When operating heavy machinery, ensuring the well-being of both the operator and surrounding personnel is paramount. Advanced engineering incorporates various safety measures that significantly enhance operational security, mitigate risks, and promote a safer work environment.

Key safety features include:

- Operator Protection: Enclosed cabs with reinforced structures shield the operator from external hazards and flying debris.

- Visibility Enhancements: Large windows and strategically placed mirrors provide better sightlines, reducing blind spots and improving situational awareness.

- Stability Mechanisms: Integrated systems monitor weight distribution and terrain conditions to prevent tipping during operation.

- Emergency Shutdown: Quick-access emergency stop buttons allow for immediate cessation of operations in critical situations.

- Safety Alarms: Audible and visual alerts notify the operator of potential hazards, including proximity to obstacles and overload conditions.

Moreover, regular maintenance and adherence to operational guidelines are essential for ensuring these features function effectively. Continuous training for operators further enhances safety, fostering a culture of vigilance and responsibility on-site.

Tips for Effective Parts Replacement

Replacing components in heavy machinery can be a daunting task, but with the right approach, it can be streamlined and efficient. Understanding the process is crucial for ensuring that the machine operates at peak performance. Here are some strategies to enhance your replacement efforts.

1. Identify the Right Components: Always verify the specifications of the component you need to replace. Consult the manufacturer’s manual or trusted sources to ensure compatibility and quality.

2. Gather Necessary Tools: Having the appropriate tools on hand can significantly reduce the time spent on replacements. Make sure to have all required equipment readily available before starting the task.

3. Maintain a Clean Workspace: A tidy area can prevent accidental damage and make the replacement process smoother. Remove any debris or unnecessary items that could obstruct your work.

4. Follow a Systematic Approach: Take a step-by-step approach to disassembly and reassembly. Document each stage with notes or photos to ensure you can easily return components to their correct positions.

5. Test Thoroughly: After replacement, conduct a comprehensive test of the machinery to ensure that everything is functioning correctly. Look out for any unusual noises or performance issues that could indicate further adjustments are needed.

By implementing these strategies, you can enhance the efficiency and effectiveness of your component replacement tasks, leading to improved performance and longevity of your machinery.