Understanding the inner workings of soil cultivation machinery is crucial for maintaining its efficiency and performance. By examining the structural elements, users can gain insight into how different mechanisms contribute to smooth operation in the field. This knowledge allows for timely upkeep and ensures long-term durability.

Each piece of equipment, composed of various interconnected systems, relies on precise engineering. Familiarity with these systems helps operators identify potential issues early, ensuring smooth functionality even in demanding environments. A detailed exploration of these mechanisms can be invaluable for anyone involved in equipment management or repairs.

In this guide, we delve into the specifics of crucial mechanical assemblies and their respective roles. Knowing how these parts interact and perform under different conditions can lead to better maintenance practices, ultimately enhancing the equipment’s lifespan and productivity.

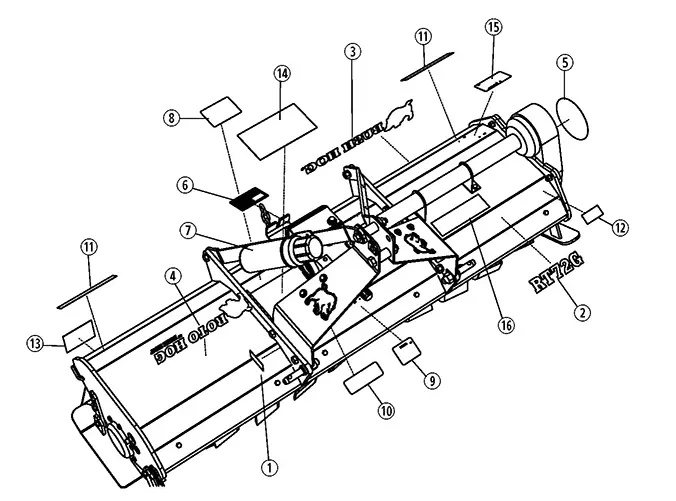

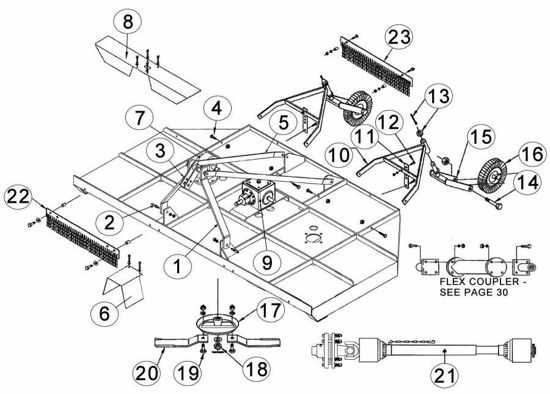

Essential Components of King Kutter Tillers

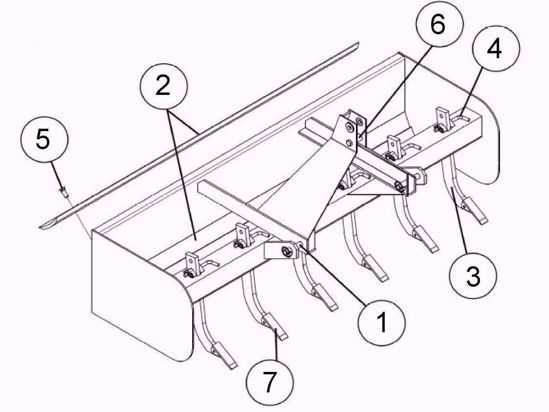

Understanding the main elements of soil preparation equipment is key to ensuring effective and smooth operation. Each part plays a crucial role in the overall performance, working together to achieve efficient ground processing. By familiarizing yourself with the essential components, you can maintain and optimize the functionality of your machine.

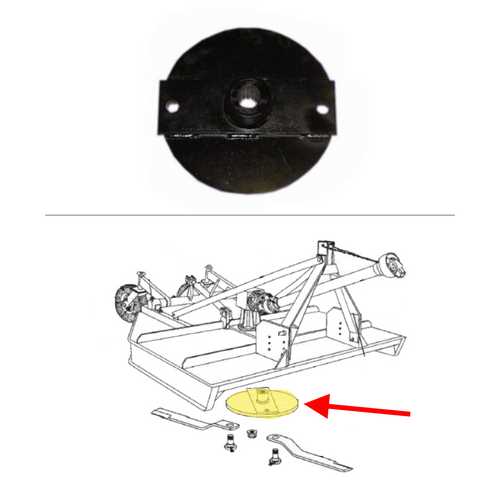

- Blades: These sharp cutting tools are responsible for breaking up and turning the soil, ensuring proper aeration and mixing.

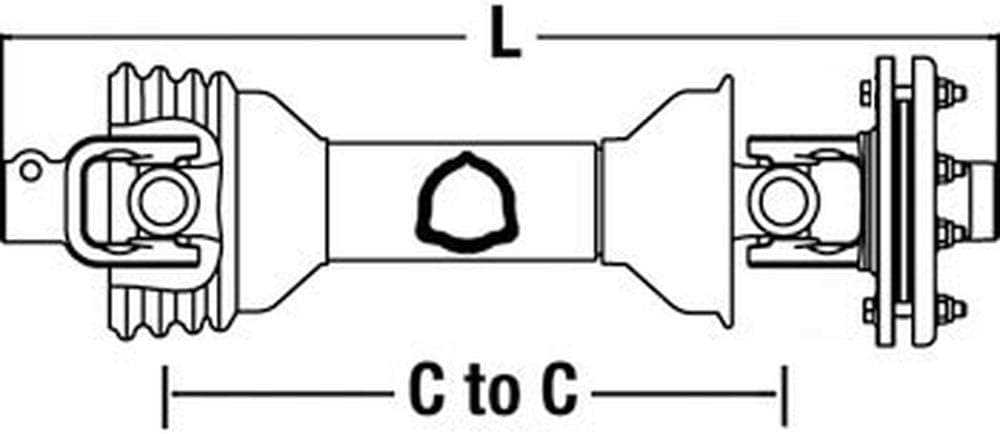

- Transmission: This mechanism transfers power from the engine to the blades, ensuring consistent and smooth operation during soil cultivation.

- Frame: The sturdy structure supports the entire equipment, providing stability and allowing for attachment to various vehicles.

- Adjustable Depth Control: This feature enables operators to modify the working depth, ensuring precise cultivation based on

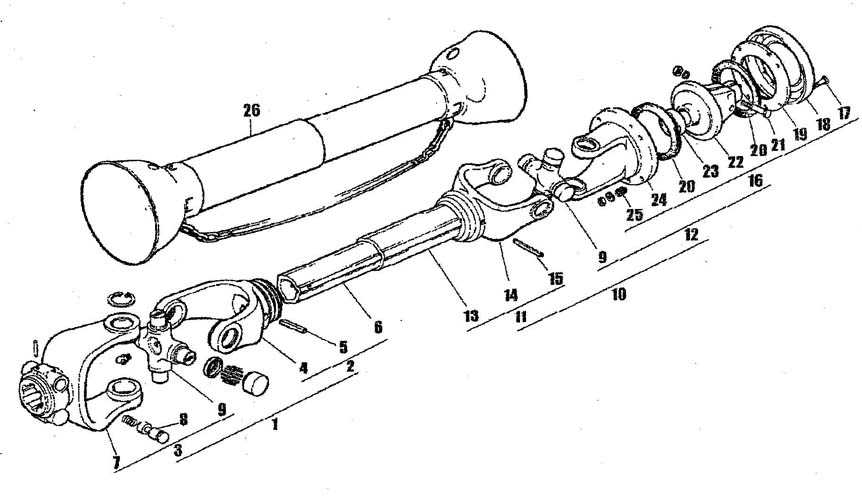

Understanding the Structure of Rotary Tillers

Rotary cultivators are essential tools in modern agriculture, designed to break up soil efficiently and prepare it for planting. Their mechanism consists of interconnected components that work together to achieve optimal soil preparation, making them invaluable for various types of terrain and crops.

Main Components Overview

The core mechanism of rotary cultivators revolves around several key parts that allow for the effective churning and loosening of the ground. Understanding these elements will help in maintaining and troubleshooting the equipment over time.

Component Function Blades Sharp, rotating tools that cut into the soil and break it apart. Drive Shaft Connects to the power source and drives the rotation of the blades. Gearbox Key Replacement Parts for Optimal Performance

Ensuring the longevity and efficiency of your equipment requires periodic updates with essential components. Regular maintenance and timely replacement of critical elements help maintain smooth operation and prevent unexpected breakdowns. In this section, we will explore the key elements that contribute to optimal functionality and why it’s crucial to replace them as needed.

Blades and Cutting Mechanism

Over time, the cutting mechanism tends to wear out, especially when exposed to tough conditions. Replacing worn-out blades is essential for maintaining precision and ensuring the tool works at its best capacity. A sharp and durable cutting mechanism enhances efficiency and reduces strain on the machine.

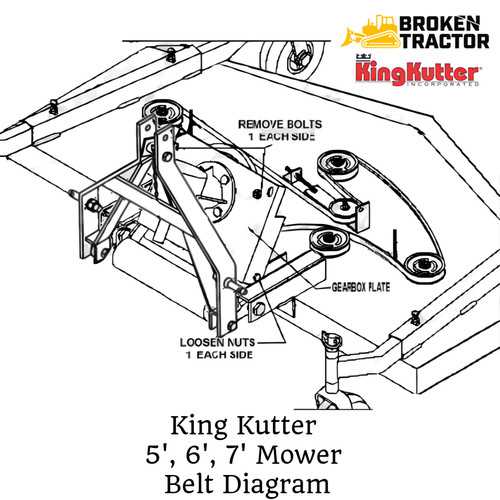

Drive Components

The drive system plays a pivotal role in powering the equipment. Regular inspection and replacement of gears, belts, and related components help in preventing slippage or power loss. A well-maintained drive mechanism ensures the tool operates smoothly, delivering the expected results even in demanding conditions.

Maintenance Tips for Prolonging Tiller Lifespan

To ensure the longevity of your equipment, regular upkeep is essential. Proper maintenance can prevent unnecessary wear and tear, keeping the machine in optimal working condition for years. Below are some essential tips to help maintain your device and extend its life.

- Check and change the oil regularly to ensure smooth operation of the engine and internal components.

- Inspect and clean air filters frequently to prevent dust and debris from clogging the system.

- Lubricate moving parts, such as gears and joints, to reduce friction and avoid premature damage.

- Tighten any loose bolts and fasteners to prevent parts from vibrating and causing mechanical issues.

- After each use, remove dirt and debris from the machine to prevent rust and corrosion.

By following these simple steps, you can maximize the efficiency of your equipment and reduce the risk of costly repairs down the

How to Identify Worn-Out Tiller Parts

Maintaining optimal performance requires regular checks to detect any signs of wear. Over time, different components can degrade, affecting the overall efficiency and leading to potential breakdowns if left unaddressed. Understanding the key indicators of deterioration helps ensure smooth operation and avoid costly repairs.

Unusual noises during operation often signal that something is not functioning as it should. Grinding, squeaking, or rattling may point to friction or loose elements.

Visual inspection can reveal cracks, bends, or corrosion that develop over time. Pay special attention to the mechanical edges and joints, as they are most exposed to stress.

If you notice a decline in performance, such as reduced efficiency or difficulty in achieving the same level of soil preparation, it’s a strong indication that certain parts are no longer in their optimal

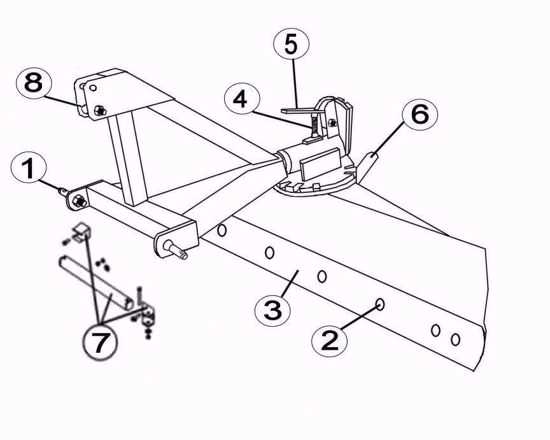

Assembly Guide for King Kutter Tillers

When it comes to constructing essential agricultural machinery, understanding the assembly process is crucial. This guide will provide detailed instructions to ensure that your equipment is assembled correctly, enhancing its performance and longevity.

1. Gather Required Components: Before starting, make sure you have all necessary components and tools at hand. This includes various frames, blades, and hardware. A thorough inventory will help avoid interruptions during assembly.

2. Step-by-Step Assembly: Begin by laying out the main frame on a flat surface. Attach the side panels securely, ensuring they align properly. Next, install the cutting elements, taking care to follow the manufacturer’s specifications for positioning and tightness. It is important to maintain balance and stability for optimal functionality.

3. Final Adjustments: Once all pieces are connected, perform a thorough inspection. Check for any loose fittings and adjust as necessary. Make sure that all moving parts operate smoothly. Lubricate as required to ensure seamless operation.

Following these steps will not only help in effective assembly but will also contribute to the overall efficiency of your machinery in the long run.

Troubleshooting Common Issues with Tillers

Operating ground cultivation equipment can present various challenges that may hinder performance and efficiency. Understanding common problems and their potential solutions is essential for maintaining optimal functionality. By addressing these issues promptly, users can ensure their equipment operates smoothly and effectively.

Difficulty Starting: If the machine struggles to start, it could be due to a lack of fuel, a dead battery, or issues with the ignition system. Ensure that there is adequate fuel and that the battery is charged. Checking the spark plug for wear or damage may also help identify the problem.

Poor Tilling Performance: When the equipment fails to break up the soil effectively, the blades might be dull or damaged. Inspect the tines for any signs of wear and replace them if necessary. Additionally, adjusting the depth setting may improve performance in challenging soil conditions.

Vibration and Noise: Excessive vibrations or unusual noises can indicate loose components or misalignment. Regularly check all bolts and fasteners to ensure they are tightened properly. Also, inspect the gearbox and other moving parts for signs of wear or damage that could contribute to this issue.

Overheating: If the equipment becomes excessively hot during operation, it may be due to a clogged air filter or low oil levels. Regular maintenance, including cleaning or replacing the air filter and checking oil levels, can prevent overheating and prolong the lifespan of the machine.

By recognizing and addressing these common challenges, operators can enhance the efficiency and longevity of their cultivation tools, ensuring they remain effective for various gardening and agricultural tasks.

Upgrading Tiller Blades for Better Efficiency

Enhancing the performance of soil preparation tools can significantly improve agricultural productivity. One of the most impactful upgrades involves the cutting components, which directly influence the efficiency of soil cultivation. By selecting the right enhancements, users can achieve optimal results while minimizing effort and energy consumption.

Benefits of Improved Cutting Components

- Increased Soil Penetration: Advanced designs allow for deeper and more effective soil disruption.

- Reduced Fuel Consumption: Optimized blades can lower the energy needed for operation, leading to cost savings.

- Enhanced Durability: Higher-quality materials extend the lifespan of cutting elements, reducing replacement frequency.

Choosing the Right Upgrades

- Material Selection: Consider options like hardened steel or carbide for better longevity and performance.

- Blade Shape: Choose designs that promote efficient soil movement and reduce drag.

- Size Compatibility: Ensure upgrades are suitable for the specific model to maintain optimal functionality.

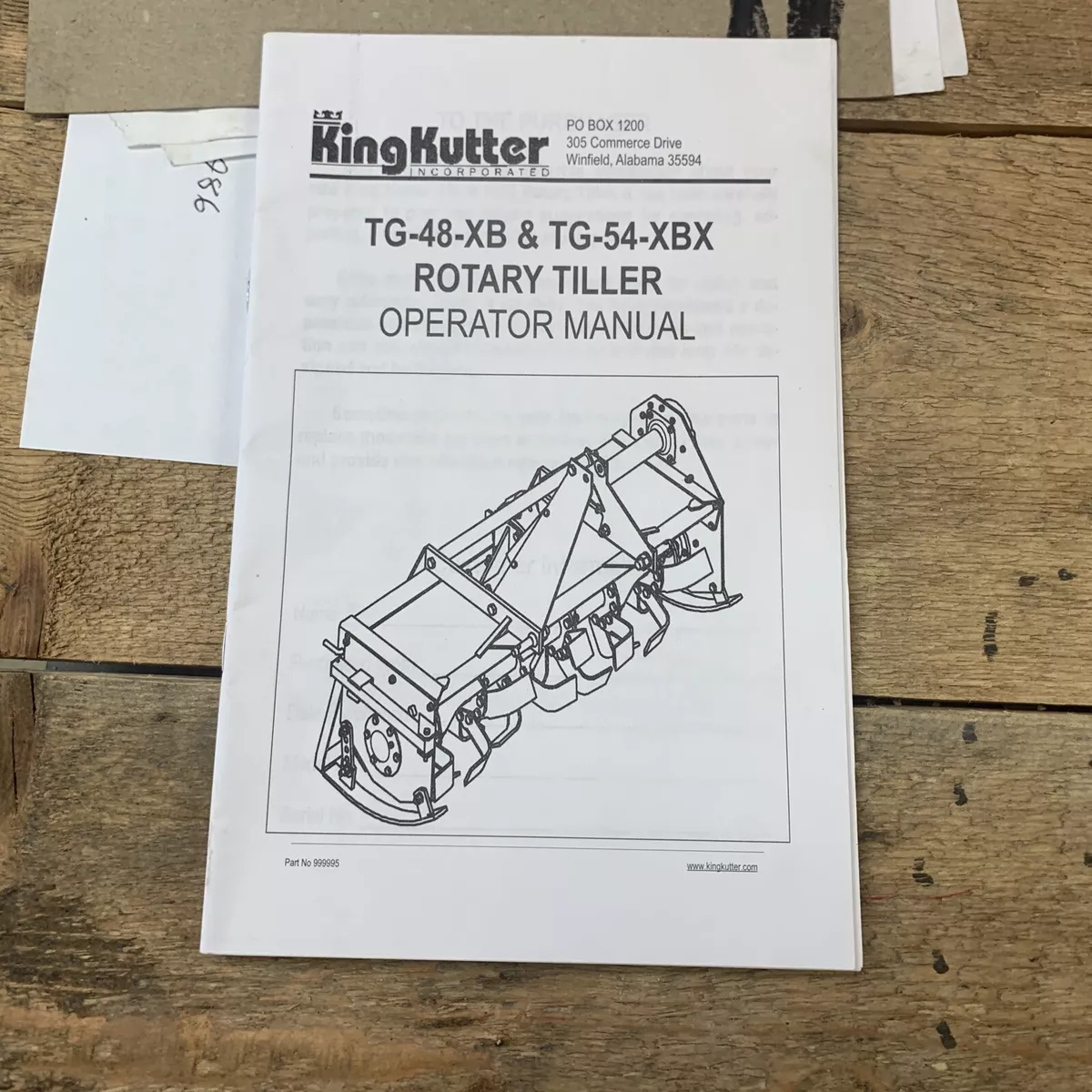

Where to Find Genuine Tiller Parts

Locating authentic components for your gardening equipment is essential for ensuring optimal performance and longevity. Reliable sources offer a variety of high-quality items, catering to various models and specifications.

Authorized Dealers: One of the best places to start is by visiting certified dealers who specialize in your specific brand. These retailers often stock genuine replacements, ensuring compatibility and reliability.

Manufacturer’s Website: Checking the official website of the equipment manufacturer can provide access to an extensive range of original items. This option often includes detailed product information and specifications.

Online Marketplaces: Reputable online platforms can be excellent resources for finding quality replacements. Look for sellers with positive reviews and ratings to ensure a satisfactory purchase experience.

Local Repair Shops: Nearby repair shops may also carry authentic items or can assist in ordering them. Consulting with professionals can provide insights into which components are best suited for your needs.

By exploring these avenues, you can secure the necessary components to maintain and enhance the functionality of your gardening tools.