| Suspension System |

Essential Components of the Off-Road Vehicle

The core elements of this all-terrain machine play a crucial role in ensuring reliable and smooth performance across varied landscapes. Each part has been thoughtfully designed to withstand tough conditions and deliver a balanced, dependable experience for the rider. Understanding these elements is key to maintaining peak functionality and extending the lifespan of the vehicle.

Engine and Transmission System

The heart of this rugged vehicle is its robust power source, which provides the necessary force for challenging terrains. Coupled with a seamless transmission, it allows for efficient power delivery, ensuring the rider can navigate through different environments with ease. Regular care and tuning of these components are vital for optimal operation.

Suspension and Braking Mechanisms

A well-designed suspension system is integral for absorbing shocks, making rides comfortable even on uneven surfaces. Alongside this, reliable braking mechanisms offer the essential stopping power, adding

Engine Structure and Key Elements

The internal composition of the power unit plays a crucial role in its overall functionality, impacting efficiency and durability. Understanding the core components within the system helps in maintaining and optimizing performance over time. Each element, whether small or large, contributes to the smooth operation of the entire mechanism.

Core Mechanical Components

The engine relies on a variety of mechanical components that work together to convert energy into motion. These include pistons, which compress and ignite fuel, as well as the crankshaft, which transforms linear movements into rotational force. Additionally, valves regulate airflow, ensuring a balanced mixture of air and fuel.

Supporting Systems for Efficiency

Several auxiliary systems are designed to enhance the engine’s overall performance. The cooling system prevents overheating, while the lubrication system minimizes

Transmission and Drivetrain Details

The transmission and drivetrain play a crucial role in ensuring smooth power transfer from the engine to the wheels, allowing for efficient and reliable movement across various terrains. Understanding the components and their functions is essential for maintaining optimal performance.

| Component |

Description |

| Transmission Gears |

These gears adjust the power ratio, helping to control speed and torque for different driving conditions. |

| Drive Shaft |

This component transmits rotational power from the gearbox to the rear axle, ensuring a stable connection. |

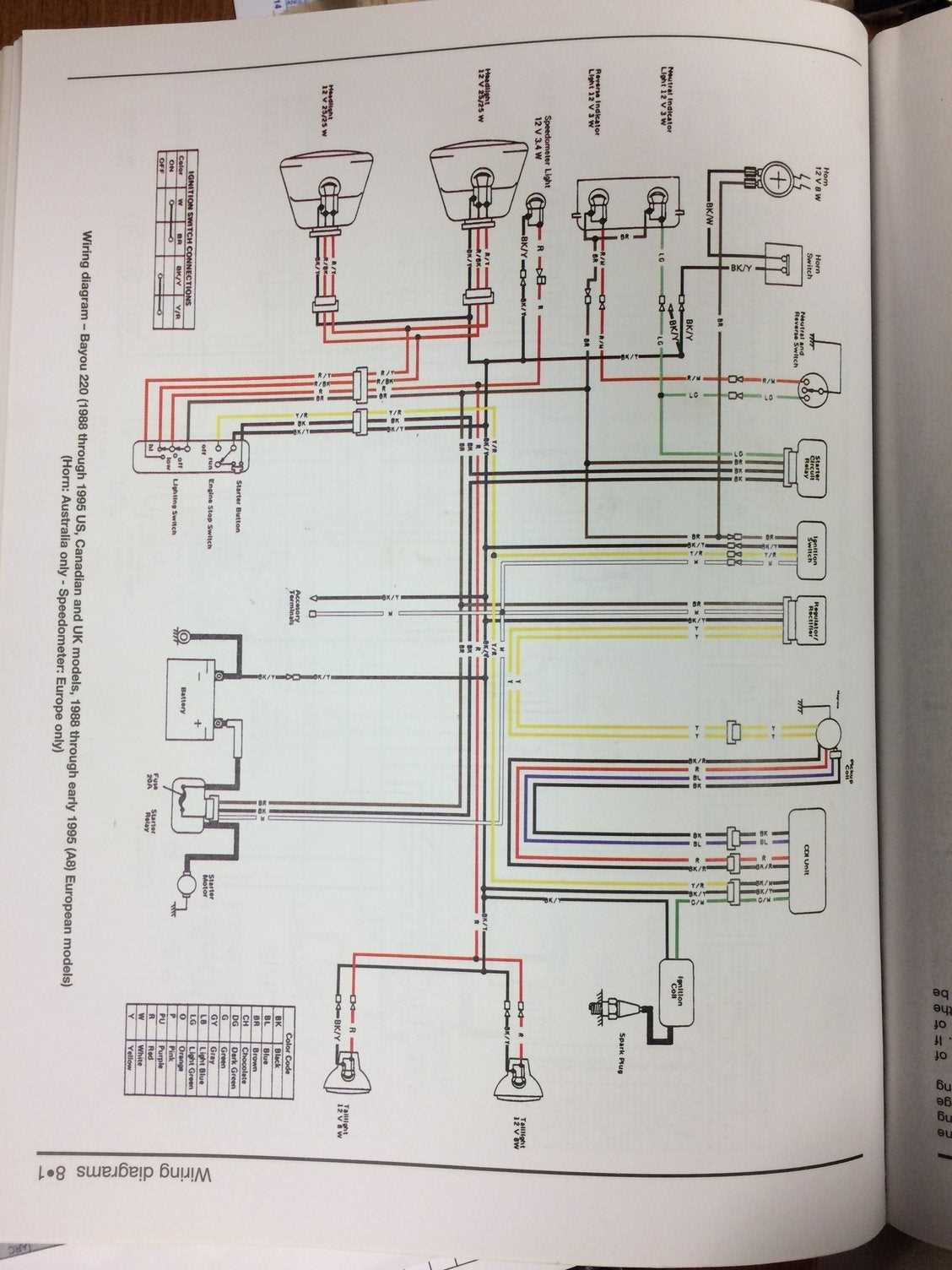

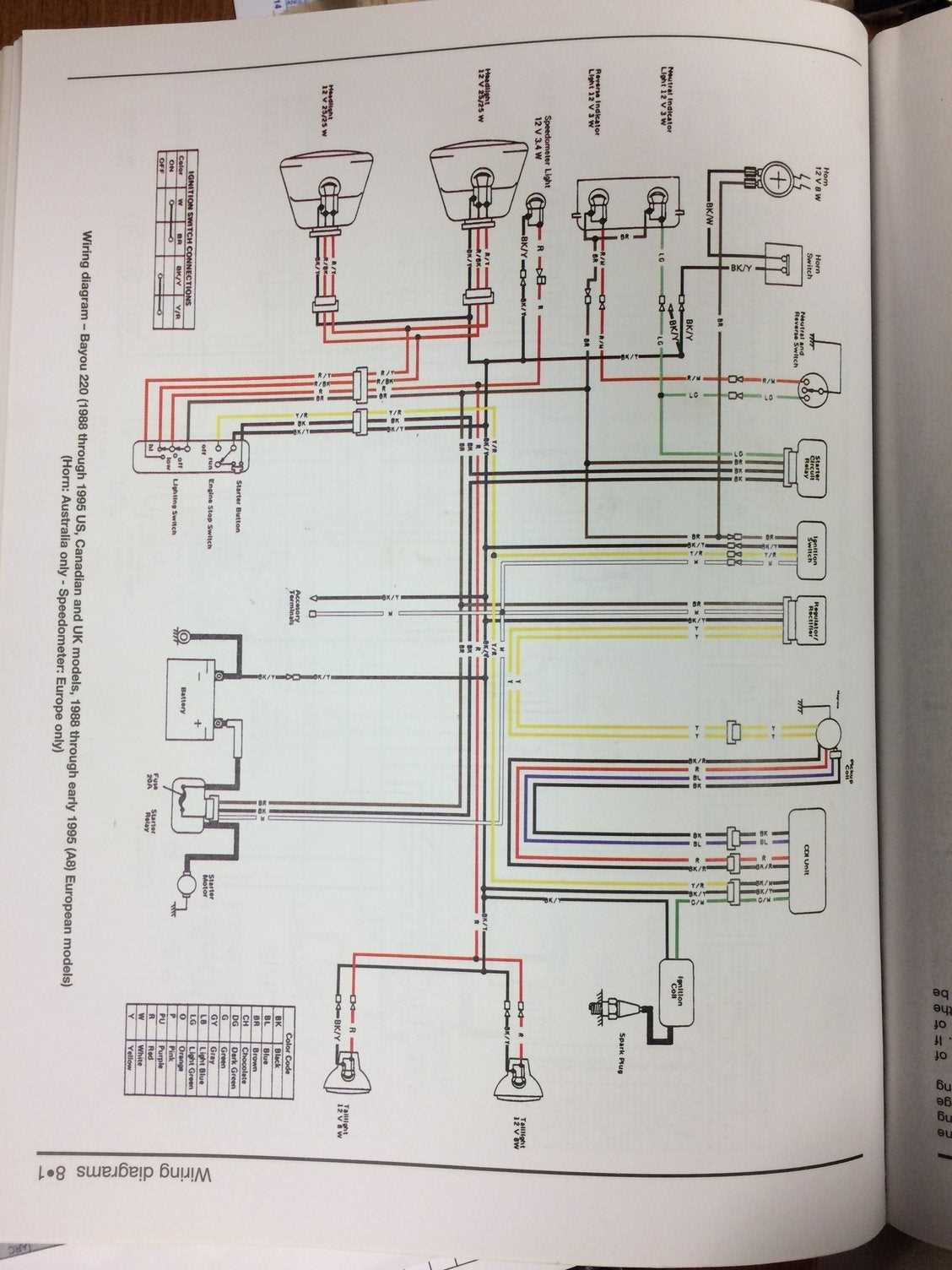

Understanding the Electrical System Layout

The electrical setup of a utility vehicle is crucial for its overall functionality, ensuring that various components operate in harmony. By familiarizing yourself with the key connections, you can gain a better grasp of how power flows throughout the entire system, from ignition to lighting. This knowledge helps in maintaining smooth operation and addressing any issues that may arise.

Key Components and Their Roles

In a typical setup, the battery serves as the primary power source, distributing energy to other elements such as the starter, lights, and controls. A voltage regulator ensures that the power output remains stable, preventing potential damage to the wiring or other sensitive parts. Meanwhile, the ignition coil plays a critical role in generating the spark needed for

Brake Assembly and Maintenance Tips

The proper functioning of a braking system is crucial for safety and performance. This section outlines essential aspects of assembling the brake components and offers valuable maintenance suggestions to ensure longevity and efficiency.

Brake Component Assembly

When putting together the braking mechanism, attention to detail is vital. Follow these guidelines for effective assembly:

- Ensure all parts are clean and free from debris.

- Verify that the brake pads are correctly aligned with the rotors.

- Apply appropriate lubrication to moving components to minimize friction.

- Secure all fasteners to the recommended torque specifications.

Maintenance Recommendations

Regular maintenance enhances performance and extends the life of the braking system. Consider the following practices:

- Inspect the brake pads regularly for wear and replace them as needed.

- Check the brake fluid level and top it off if necessary.

- Monitor for any unusual noises during operation, which may indicate issues.

- Clean the braking surfaces periodically to ensure optimal contact.

Suspension and Steering System Guide

The suspension and steering system plays a crucial role in ensuring a smooth and stable ride. This section delves into the essential components and functionalities that contribute to the overall performance of the vehicle, enhancing both handling and comfort.

Key Components

Understanding the primary elements of the suspension and steering system is vital for effective maintenance and repair. Here are the main components:

- Shock Absorbers: These components help to dampen the impact from road irregularities, providing stability and comfort.

- Springs: Springs support the vehicle’s weight and allow for movement, contributing to the ride quality.

- Steering Linkage: This system connects the steering wheel to the wheels, translating driver input into movement.

- Ball Joints: These flexible connectors allow for movement in multiple directions, ensuring smooth steering and suspension action.

Maintenance Tips

Regular upkeep of the suspension and steering system is essential for safety and performance. Consider the following maintenance practices:

- Inspect shock absorbers for signs of leakage and wear.

- Check springs for any signs of corrosion or damage.

- Ensure the steering linkage is free from play and adequately lubricated.

- Monitor tire alignment and adjust as necessary to prevent uneven wear.

Fuel System and Carburetor Breakdown

This section delves into the intricacies of the fuel delivery mechanism and the associated components that play a crucial role in the performance of the engine. Understanding these elements is vital for effective maintenance and troubleshooting, ensuring optimal functionality and efficiency.

Components of the Fuel Delivery System

The fuel delivery system encompasses various parts that work synergistically to supply the engine with the necessary fuel mixture. Key elements include the fuel tank, fuel lines, and the pump, which collectively ensure a steady flow of fuel. Regular inspection and cleaning of these components are essential for preventing blockages and maintaining performance.

Carburetor Functionality

The carburetor is a pivotal element that mixes air and fuel in the correct proportions before it enters the combustion chamber. Proper adjustment of the carburetor settings can significantly influence engine performance and responsiveness. Regular maintenance, including cleaning and inspection of the jets and floats, is recommended to avoid performance issues.

Frame and Body Part Specifications

This section delves into the essential characteristics of the structural components and exterior sections of the vehicle, emphasizing their role in providing stability, support, and overall functionality. Understanding these specifications is vital for ensuring optimal performance and maintenance.

Key Dimensions

Accurate measurements are crucial for proper fitting and compatibility. Below are the fundamental dimensions that define the framework and outer structure:

| Component |

Measurement |

Material |

| Frame Length |

± 90 inches |

Steel |

| Frame Width |

± 42 inches |

Steel |

| Body Height |

± 48 inches |

Plastic/Metal |

Construction Details

The assembly of the chassis and outer panels is designed for durability and resilience. Common features include reinforced junctions and weather-resistant coatings, which enhance longevity and protect against environmental factors.