The intricacies of agricultural machinery often require a closer examination to ensure optimal functionality. A thorough understanding of the individual elements that contribute to these systems can significantly enhance performance and longevity. By exploring the structure and relationships between these essential components, users can achieve the ultimate efficiency in their operations.

In this section, we will delve into the various elements that make up the assembly of a typical spraying apparatus. From the mechanisms that facilitate fluid movement to the attachments that ensure precise application, each segment plays a crucial role in achieving desired results. Recognizing how these components interact can empower users to troubleshoot issues effectively and maintain their equipment in peak condition.

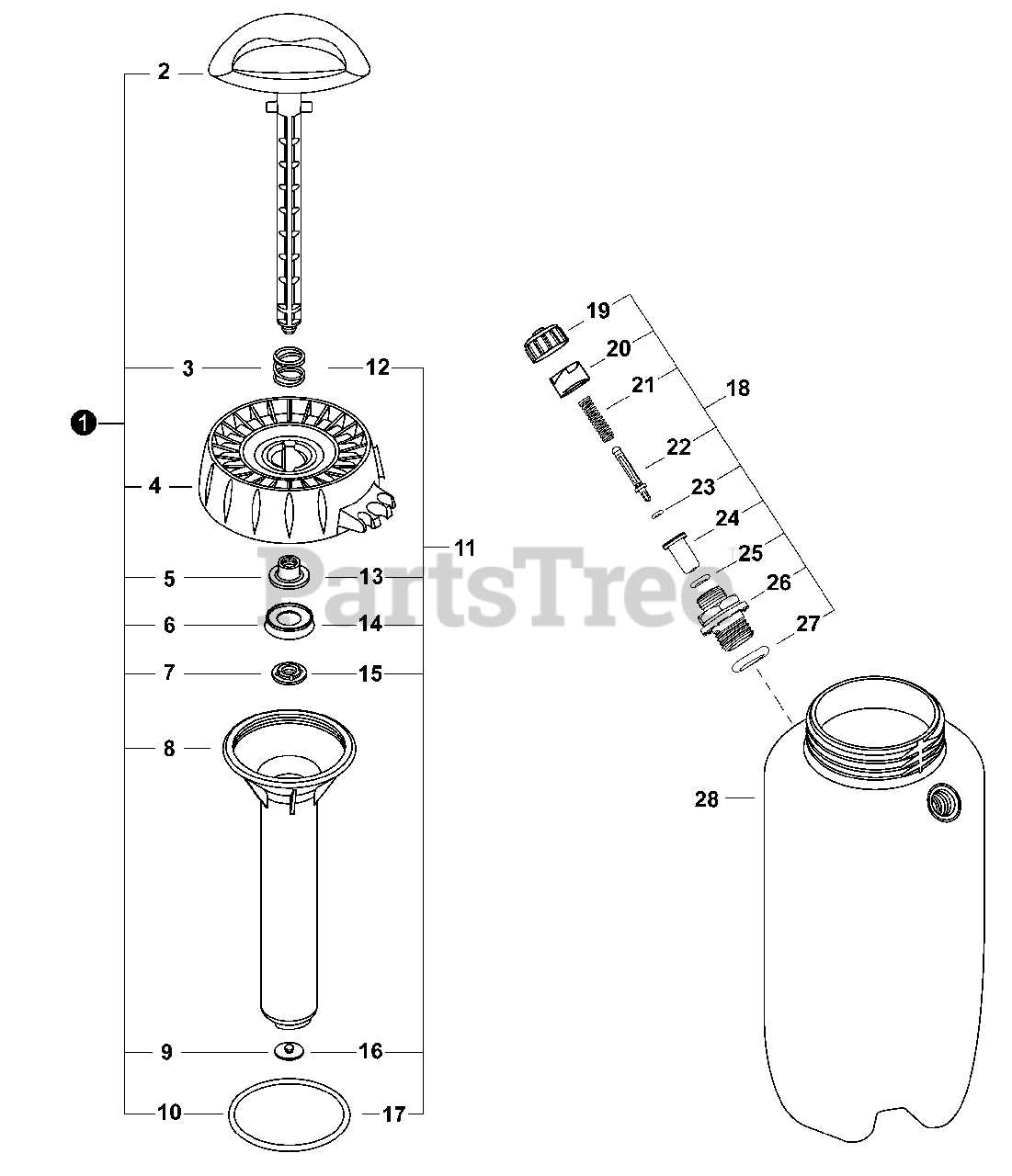

Moreover, visual representations can greatly aid in comprehending the layout and functionality of these systems. A well-organized schematic serves as a valuable tool for both novices and seasoned operators alike, providing clarity and fostering a deeper appreciation for the technology behind modern spraying solutions. By grasping these concepts, users can maximize their investment and enhance their productivity.

Understanding Fimco Sprayer Pumps

This section delves into the mechanics and functionality of essential equipment used for fluid distribution in agricultural and gardening applications. A thorough comprehension of these devices enhances efficiency and effectiveness in various tasks, ensuring optimal performance during use.

At the core of these systems is a mechanism designed to facilitate the movement of liquids, providing a consistent flow for various operations. Key components work in harmony to ensure reliability, durability, and ease of maintenance.

| Component | Description |

|---|---|

| Motor | Provides the necessary energy to operate the system. |

| Housing | Encases the internal components, protecting them from external elements. |

| Valves | Regulate the flow of liquid, ensuring accurate distribution. |

| Filters | Prevent contaminants from entering the system, maintaining performance. |

| Connectors | Facilitate attachment to hoses and other equipment. |

Understanding these elements not only aids in troubleshooting but also helps in making informed decisions regarding upgrades and replacements. Familiarity with the inner workings ensures users can maximize the utility of their equipment.

Key Components of Fimco Sprayers

Understanding the essential elements of these devices is crucial for effective operation and maintenance. Each component plays a significant role in ensuring optimal performance, enhancing efficiency, and extending the lifespan of the equipment.

Core Mechanisms

At the heart of the system are the mechanisms that facilitate the distribution of liquids. These components are designed to create pressure and ensure an even flow, which is vital for achieving consistent coverage. Proper functioning of these mechanisms directly impacts the overall effectiveness of application tasks.

Control Elements

Control elements allow users to manage the output and adjust settings according to specific requirements. Features such as pressure regulators and valves are integral in customizing the operation, ensuring that the application is tailored to the type of task at hand, whether it be fertilization or pest control.

How to Identify Pump Parts

Understanding the components of a liquid transfer mechanism is essential for effective maintenance and repair. Recognizing each element’s function helps ensure optimal performance and longevity. This guide will aid in identifying various elements that make up these systems.

Key Components to Recognize

- Housing: The outer shell that encases all internal elements, providing protection and structural integrity.

- Impeller: A rotating part that enhances fluid movement, creating pressure differences to facilitate flow.

- Seal: A crucial element that prevents leaks, maintaining efficiency and safety during operation.

- Motor: The power source that drives the mechanism, often electric or gasoline-operated.

- Inlet and Outlet Fittings: Points where the fluid enters and exits the system, vital for proper flow direction.

Steps for Identification

- Examine the outer shell for any labels or markings indicating the model or specifications.

- Check the internal components by removing the housing, taking care to document their arrangement.

- Identify the rotation mechanism and ensure it’s connected to the power source.

- Look for any signs of wear or damage on seals and fittings to determine necessary replacements.

- Consult user manuals or online resources for diagrams that may provide additional clarity.

Maintenance Tips for Sprayer Pumps

Regular upkeep is essential for ensuring the longevity and efficiency of your spraying equipment. By following a few straightforward practices, you can enhance performance and minimize the risk of malfunctions. This guide outlines key strategies to maintain your system in optimal condition.

Routine Inspections

Perform periodic checks to identify wear and tear or potential issues. Look for leaks, corrosion, or damaged components that may hinder functionality. Addressing these concerns promptly can prevent more significant problems in the future.

Proper Cleaning

After each use, thoroughly clean the equipment to remove residues that could cause blockages or degradation. Use appropriate cleaning solutions and follow manufacturer recommendations to ensure effective maintenance without damaging any components.

Common Issues with Fimco Pumps

Understanding the frequent challenges encountered with these devices can enhance their longevity and efficiency. Users often face a range of issues that can hinder performance, leading to dissatisfaction and potential downtime. Identifying these common problems is essential for effective troubleshooting and maintenance.

1. Insufficient Pressure

A common concern is inadequate pressure during operation. This issue can stem from various sources:

- Clogs in the delivery system

- Worn or damaged seals

- Incorrect settings on the control unit

Regular inspections and cleaning can help mitigate these problems.

2. Leaks

Leaks can significantly affect functionality and can be caused by:

- Loose connections or fittings

- Degraded hoses or tubing

- Cracked or damaged components

Identifying and addressing leaks promptly is crucial to maintaining optimal operation.

Replacement Parts for Fimco Equipment

Maintaining the functionality of your equipment is crucial for optimal performance. Finding the right components is essential to ensure that all mechanisms operate smoothly and efficiently. Whether you are looking to enhance durability or replace worn-out elements, understanding the various options available can help in making informed decisions.

Common Components

Several key elements are commonly needed to restore functionality. Seals, hoses, and filters are often the first items to require attention, as they are subject to wear and tear over time. Choosing high-quality alternatives can significantly extend the lifespan of your machinery.

Where to Find Quality Replacements

Reputable suppliers offer a wide selection of compatible components. Online retailers and local distributors often have extensive catalogs that cater to various models. It’s advisable to consult product manuals or seek expert advice to ensure compatibility and achieve the best performance.

Diagram Overview for Efficient Repairs

A clear illustration is essential for understanding the components and their functions within any machinery. By analyzing a well-structured visual representation, users can identify issues quickly and locate the necessary elements for maintenance. This not only streamlines the repair process but also enhances overall efficiency.

Understanding the arrangement and connections between various elements is crucial for troubleshooting. A detailed chart can guide users through each section, enabling them to pinpoint specific problems and determine the correct steps for resolution. This systematic approach minimizes downtime and ensures that equipment operates at optimal performance.

In addition to facilitating repairs, a comprehensive visual guide serves as a valuable reference for routine maintenance. Regular checks and timely interventions can prevent larger issues from developing. By familiarizing oneself with the layout and function of each component, users can maintain their machinery effectively, ensuring longevity and reliability.

Upgrading Your Sprayer System

Enhancing your application system can significantly improve efficiency and performance. By integrating advanced components, you can achieve better coverage, increased durability, and optimal functionality. This investment not only streamlines your operations but also ensures that you are utilizing the latest technology available.

Consider upgrading to higher-capacity mechanisms that can handle larger volumes while maintaining precision. Improved nozzles can provide better spray patterns, allowing for more uniform distribution of liquids. Additionally, modernized controllers offer greater versatility, enabling you to adjust settings according to specific needs.

Implementing durable materials in your system can extend its lifespan and reduce maintenance costs. Evaluate the compatibility of new elements with your existing framework to ensure seamless integration. Regularly updating components not only enhances performance but also keeps your system aligned with industry standards.

Finally, don’t overlook the importance of user feedback. Engaging with operators can provide valuable insights into areas for improvement and innovation. A collaborative approach can lead to a more effective and responsive setup, ultimately maximizing your productivity.

Resources for Fimco Users

This section provides valuable information and tools for individuals utilizing the equipment in question. Whether you are seeking maintenance advice, troubleshooting tips, or general support, these resources will help ensure optimal performance and longevity of your machinery.

Online Communities

Joining forums and social media groups dedicated to this equipment can be highly beneficial. Engaging with fellow users allows you to share experiences, ask questions, and discover new techniques for effective operation. Many community members provide insights based on their personal experiences, which can enhance your understanding and skills.

Technical Manuals and Guides

Access to comprehensive manuals and instructional materials is essential for anyone looking to deepen their knowledge. These documents often include detailed procedures for assembly, maintenance, and troubleshooting. Downloading or accessing these guides online can empower you to handle common issues and perform regular upkeep with confidence.

Utilizing these resources effectively will greatly enhance your experience and expertise with your equipment.