In the realm of efficient coating and finishing, a thorough comprehension of the essential elements that make up an air application device is crucial. Each component plays a vital role in achieving a seamless and professional result. Knowing how these elements work together not only enhances performance but also extends the lifespan of the equipment.

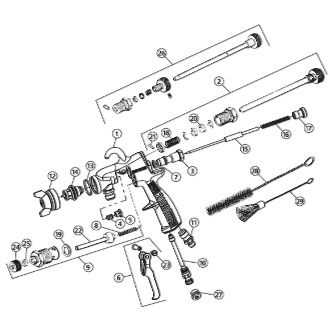

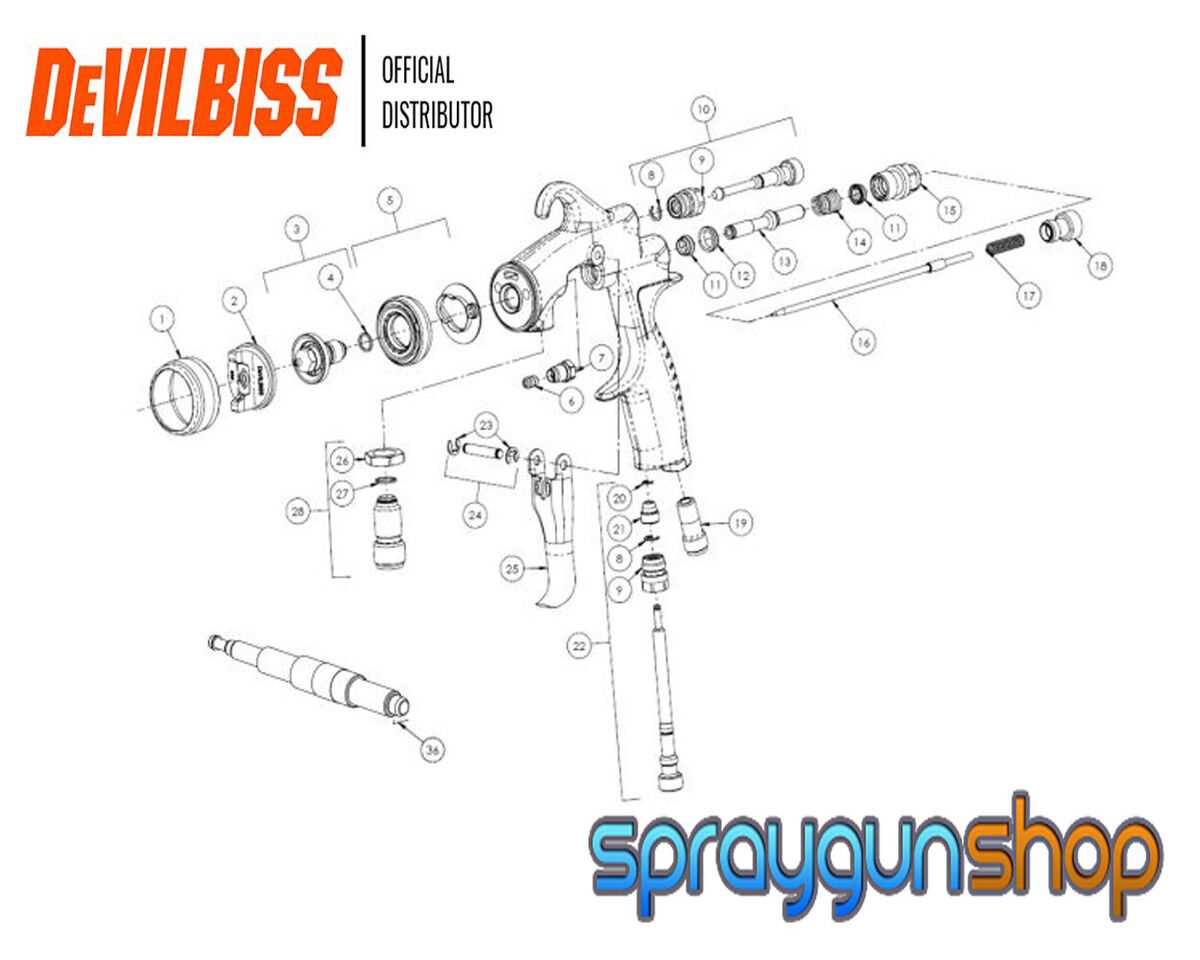

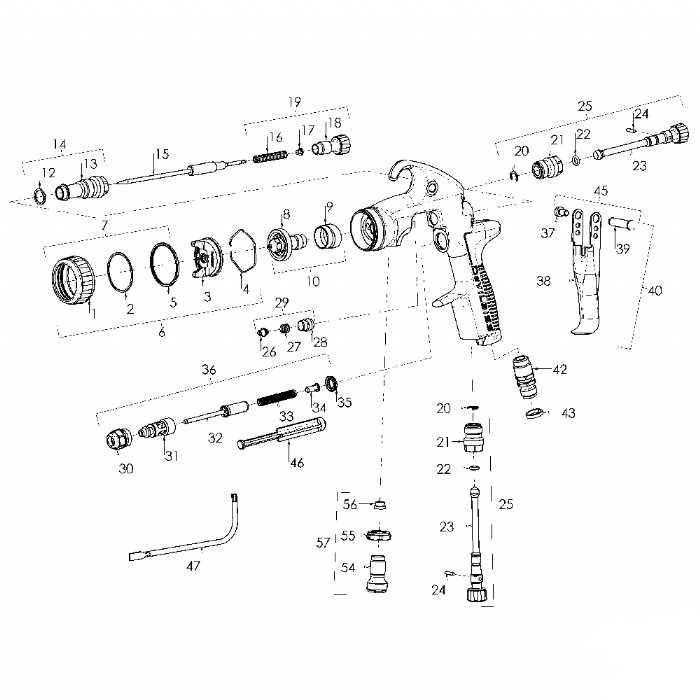

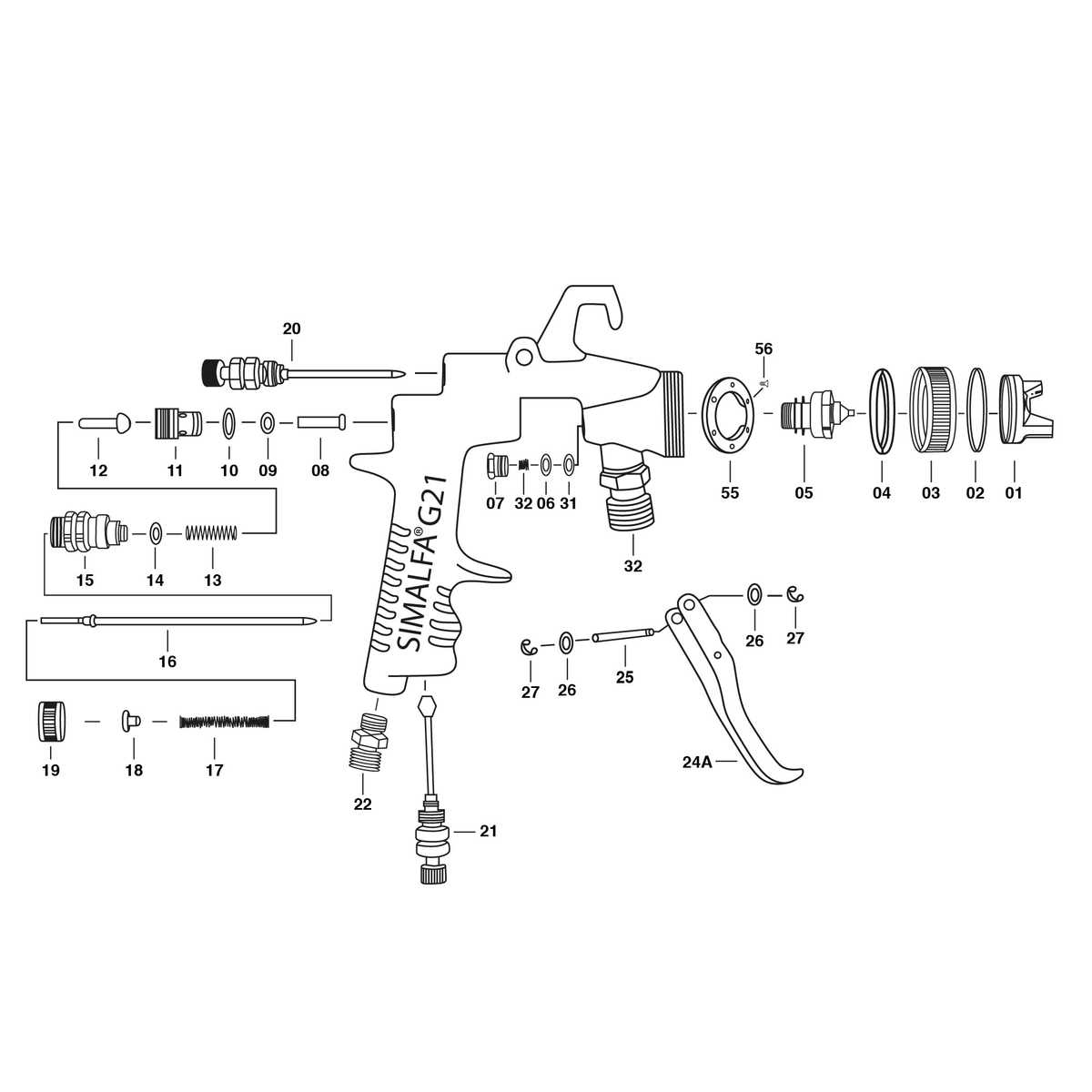

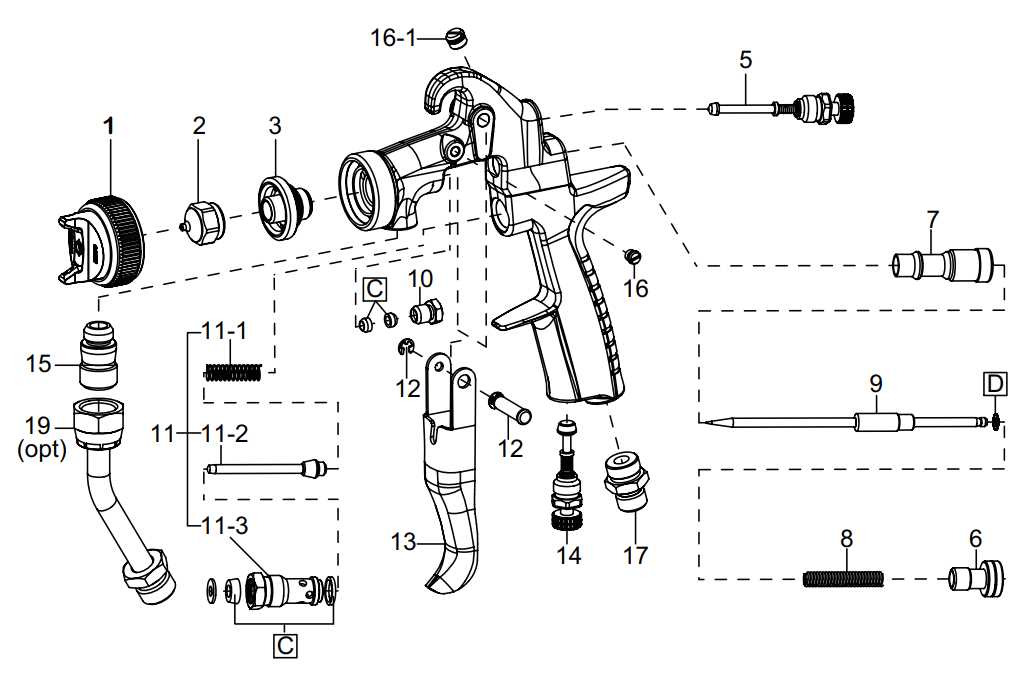

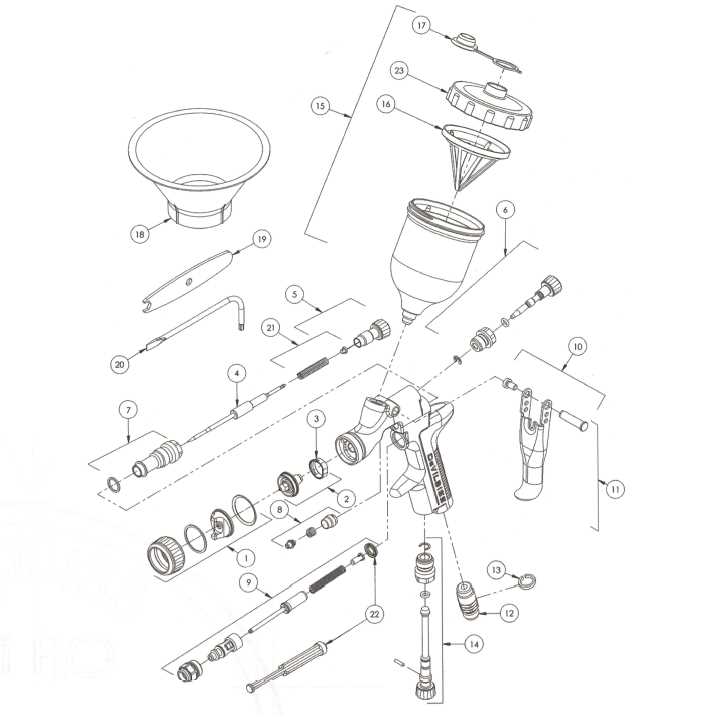

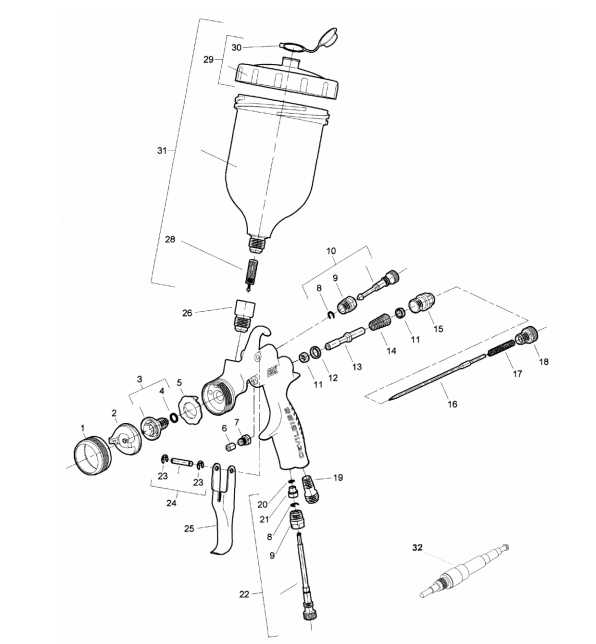

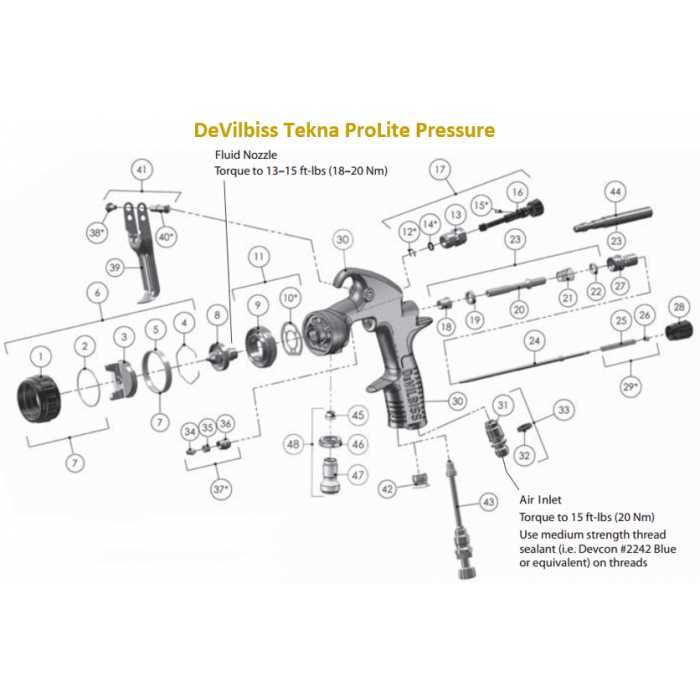

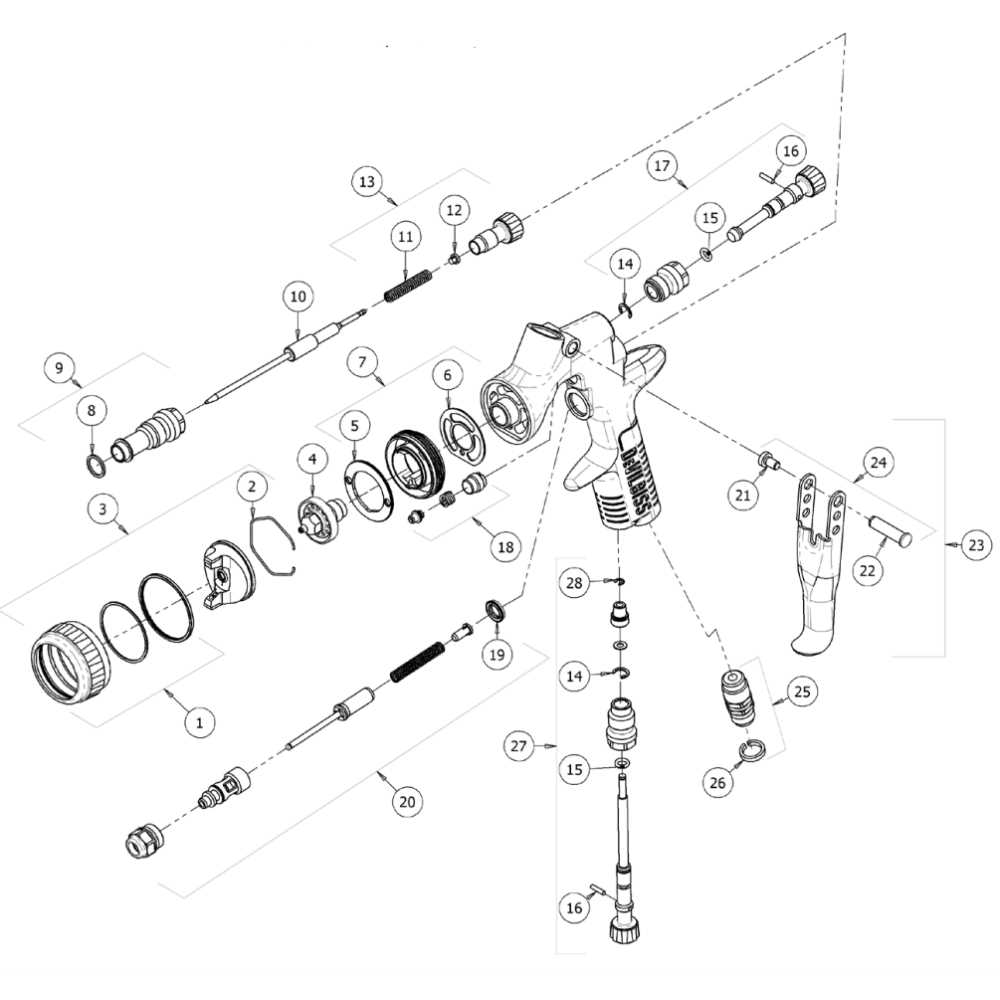

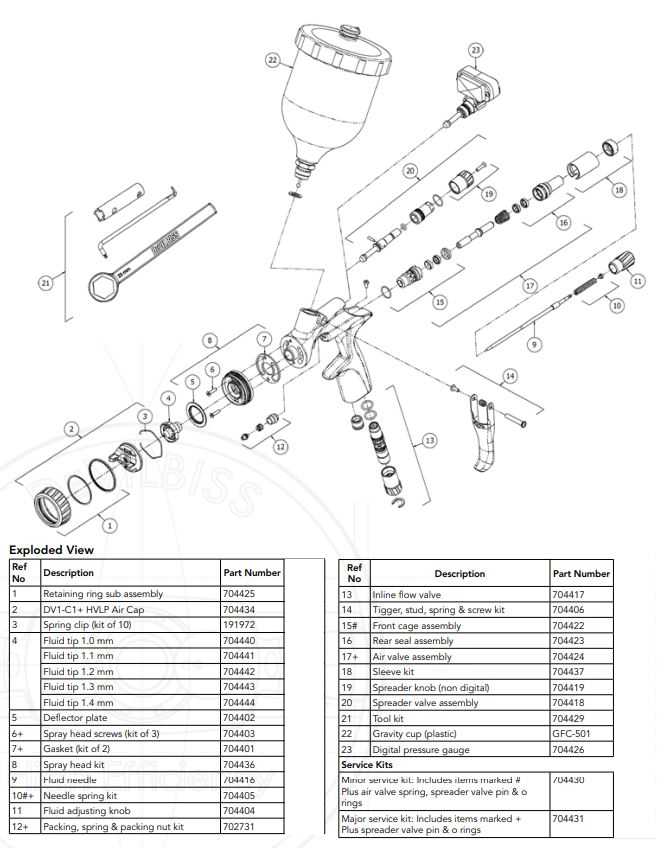

Visual representations can significantly aid in grasping the functionality of these instruments. By examining a detailed illustration, users can easily identify various sections and understand their specific purposes. This knowledge empowers operators to make informed decisions regarding maintenance and troubleshooting, ensuring optimal operation.

Furthermore, familiarity with the configuration of these tools fosters confidence in their usage. Whether for industrial applications or home projects, recognizing the interconnectivity of each piece enhances both efficiency and precision. Emphasizing the significance of these components will lead to more effective and satisfying outcomes in any coating endeavor.

Understanding Devilbiss Spray Gun Mechanics

Mastering the intricacies of spray application tools is essential for achieving optimal results in various projects. This section delves into the fundamental components and their functions, offering insights into how each element contributes to the overall performance.

- Nozzle: This crucial component controls the flow and dispersion of the material, influencing the finish and coverage.

- Air Cap: It regulates the airflow and pressure, ensuring a fine mist or a heavy coat, depending on the desired outcome.

- Fluid Tip: The size of the fluid tip affects the viscosity of the material that can be used, impacting application speed and finish quality.

Understanding these components allows users to select the appropriate configurations for different materials and techniques.

- Identify the material type and viscosity.

- Select the correct nozzle and fluid tip size.

- Adjust the air cap for optimal spray pattern.

By mastering these mechanics, users can enhance their skills and achieve professional-quality finishes in their work.

Key Components of Spray Guns

Understanding the essential elements of a painting tool is crucial for achieving optimal results in various applications. Each component plays a vital role in the overall functionality and efficiency of the equipment, ensuring a smooth and even application of the material.

1. Fluid Nozzle: This part is responsible for controlling the flow and pattern of the liquid. Its size and shape significantly impact the dispersion and coverage of the coating.

2. Air Cap: The air cap regulates the air pressure and helps to atomize the liquid into a fine mist. The design of the air cap influences the finish quality and the spray pattern.

3. Trigger: The trigger allows the user to control the release of the liquid. Its design is critical for comfort and precision during operation.

4. Cup: The container holds the material to be applied. Its capacity and design affect how often the user needs to refill and can influence the tool’s balance.

5. Body: The main structure houses all components and affects the tool’s durability and ease of handling. A well-designed body enhances user experience and control.

6. Air Hose: This conduit delivers compressed air to the tool. The diameter and length can impact airflow and, consequently, the performance of the application.

Each of these elements contributes to the effectiveness of the device, making it essential for users to be familiar with their functions and interrelations to achieve the best outcomes in their projects.

Benefits of Using Devilbiss Models

Opting for high-quality equipment can significantly enhance your projects, ensuring efficiency and precision. These devices are known for their reliability and performance, making them a favorite among professionals and hobbyists alike.

Enhanced Efficiency

Models from this renowned brand are designed to deliver consistent results, reducing the time spent on each task. Their advanced technology allows for a smoother application process, minimizing the need for rework.

Durability and Longevity

Built with premium materials, these tools are engineered to withstand heavy use. Their robust construction ensures that users can rely on them for years, providing excellent value for investment.

| Feature | Benefit |

|---|---|

| Precision Engineering | Improved accuracy and finish |

| Ergonomic Design | Enhanced comfort during extended use |

| Easy Maintenance | Lower upkeep costs and hassle-free care |

Common Issues with Spray Gun Parts

Understanding the frequent challenges associated with application equipment is essential for maintaining optimal performance. Many users encounter specific problems that can affect the quality of their work, leading to inefficiencies and potential rework. Recognizing these issues early can save time and resources.

| Issue | Description | Solution |

|---|---|---|

| Clogging | Obstructions in the nozzle can prevent fluid from flowing smoothly. | Regularly clean the nozzle and ensure the material is filtered. |

| Uneven Spray Pattern | Inconsistent application can lead to uneven coverage. | Check for wear on the nozzle and adjust the pressure settings. |

| Leaking | Fluid may escape from connections or seals, causing waste. | Inspect and replace worn seals or tighten connections. |

| Inconsistent Pressure | Fluctuations in pressure can impact the flow rate. | Ensure the compressor is functioning properly and check hoses for damage. |

| Paint Texture Issues | Surface finish may be affected by the viscosity of the material. | Adjust the thinning of the material according to specifications. |

Maintenance Tips for Longevity

Regular upkeep is essential for extending the lifespan of your equipment and ensuring optimal performance. By following a systematic maintenance routine, you can prevent issues before they arise and enhance the efficiency of your tools. This section outlines key strategies to keep your apparatus in top condition.

Firstly, always clean your equipment thoroughly after each use. Residue buildup can lead to clogs and impair functionality. Use appropriate solvents and brushes to reach all nooks and crannies, ensuring no remnants remain.

Secondly, inspect components regularly for signs of wear and tear. Replace any damaged or worn parts promptly to avoid further complications. Keeping a close eye on the condition of seals, nozzles, and hoses can save you time and money in the long run.

Additionally, lubricate moving parts as needed. Proper lubrication reduces friction and minimizes wear, contributing to smoother operation. Use recommended lubricants that are compatible with your specific apparatus.

Lastly, store your equipment in a dry, clean environment when not in use. Protecting it from dust and moisture will help maintain its integrity and performance. Consider using protective cases or covers for added security.

How to Identify Parts Quickly

Recognizing components efficiently is essential for maintenance and repair tasks. Understanding the structure and functionality of each element allows for swift identification and resolution of issues. Familiarity with the layout can significantly enhance workflow, reducing downtime and improving overall performance.

Tips for Quick Recognition

To streamline the identification process, consider the following strategies:

- Familiarize yourself with the general layout and typical features of each element.

- Utilize labels and color coding to easily differentiate components.

- Keep a reference guide handy for detailed descriptions and functions.

Common Component Features

| Component | Description | Function |

|---|---|---|

| Body | Main structure housing the mechanism | Supports and contains all other elements |

| Nozzle | Opening for material to exit | Controls the flow and pattern of application |

| Trigger | Control lever for operation | Activates the release of material |

| Air Cap | Part that disperses the material | Creates the atomization effect |

Exploring Different Spray Patterns

Understanding the various application techniques is essential for achieving optimal results in painting and coating tasks. Each technique produces distinct finishes, allowing for greater flexibility in how materials are applied. By exploring these different methods, users can select the one that best meets their project requirements.

Types of Application Techniques

There are several common application techniques, each offering unique characteristics. The fan pattern provides a wide coverage area, making it ideal for large surfaces. In contrast, a spot pattern allows for precision application, which is particularly useful for detailed work or touch-ups. Selecting the appropriate technique can greatly influence both efficiency and finish quality.

Factors Influencing Choice

When deciding on an application technique, consider factors such as the type of material, the desired finish, and the specific requirements of the project. For example, thicker materials might require a different approach compared to thinner ones. Additionally, environmental conditions, such as humidity and temperature, can affect how the chosen technique performs, making it crucial to adapt accordingly.

Ultimately, mastering various application techniques enhances versatility and ensures superior outcomes in any painting or coating endeavor.

Upgrading Your Spray Gun Setup

Enhancing your painting equipment can significantly impact your workflow and the quality of your projects. By investing in improved components and accessories, you can achieve finer results, greater efficiency, and an overall more enjoyable experience. Whether you are a professional or a hobbyist, upgrading your setup can open up new possibilities and elevate your craftsmanship.

Consider the nozzle size: One of the first upgrades to contemplate is the nozzle size. Different projects require different spray patterns and material types, so having a range of nozzle sizes allows for versatility. A smaller nozzle is ideal for detailed work, while a larger one is better for covering larger areas quickly.

Evaluate your air supply: The quality and capacity of your air supply play a crucial role in performance. Upgrading your compressor can lead to more consistent pressure and improved atomization, resulting in a smoother finish. Additionally, incorporating a high-quality air filter can help prevent contaminants from affecting your results.

Upgrade the trigger mechanism: A responsive and ergonomic trigger can make a significant difference in comfort and control. Look for options that offer adjustable sensitivity, allowing for more precise application with less fatigue during long sessions.

Explore advanced technology: Consider incorporating new technology such as pressure regulation systems or automated features. These innovations can help optimize material usage and reduce waste, leading to cost savings and a more environmentally friendly approach.

By thoughtfully upgrading your equipment, you can enhance your capabilities and enjoy the art of painting even more. Investing in the right enhancements not only improves your results but also enriches your overall experience.

Where to Find Replacement Parts

Finding components for your equipment can often be a challenging task. However, with the right resources, you can easily locate the necessary items to ensure optimal performance. This section highlights effective strategies for sourcing the required elements, so you can keep your tools running smoothly.

Online Retailers

The internet offers a vast selection of suppliers specializing in various types of machinery and accessories. Websites dedicated to equipment can provide you with a comprehensive range of options. Be sure to check user reviews and ratings to find reputable vendors. Additionally, many online marketplaces offer competitive prices and fast shipping, making them an excellent choice for quick replacements.

Local Suppliers

Visiting local hardware or specialty stores can also yield positive results. These shops often carry a variety of essential components and may even offer expert advice. Establishing a relationship with a local supplier can lead to better recommendations and support for your specific needs.

Networking with Professionals in your field can lead to valuable insights and potential sources for hard-to-find items. Online forums and social media groups dedicated to enthusiasts or professionals often share information about reliable suppliers and new product releases.

By utilizing these resources, you can ensure that you find the necessary components to maintain and enhance your equipment’s functionality.