The functionality of agricultural machinery relies heavily on its various components working in harmony. A thorough grasp of each element enhances maintenance and repair, ensuring optimal performance in the field. This knowledge empowers users to address issues effectively and prolong the lifespan of their equipment.

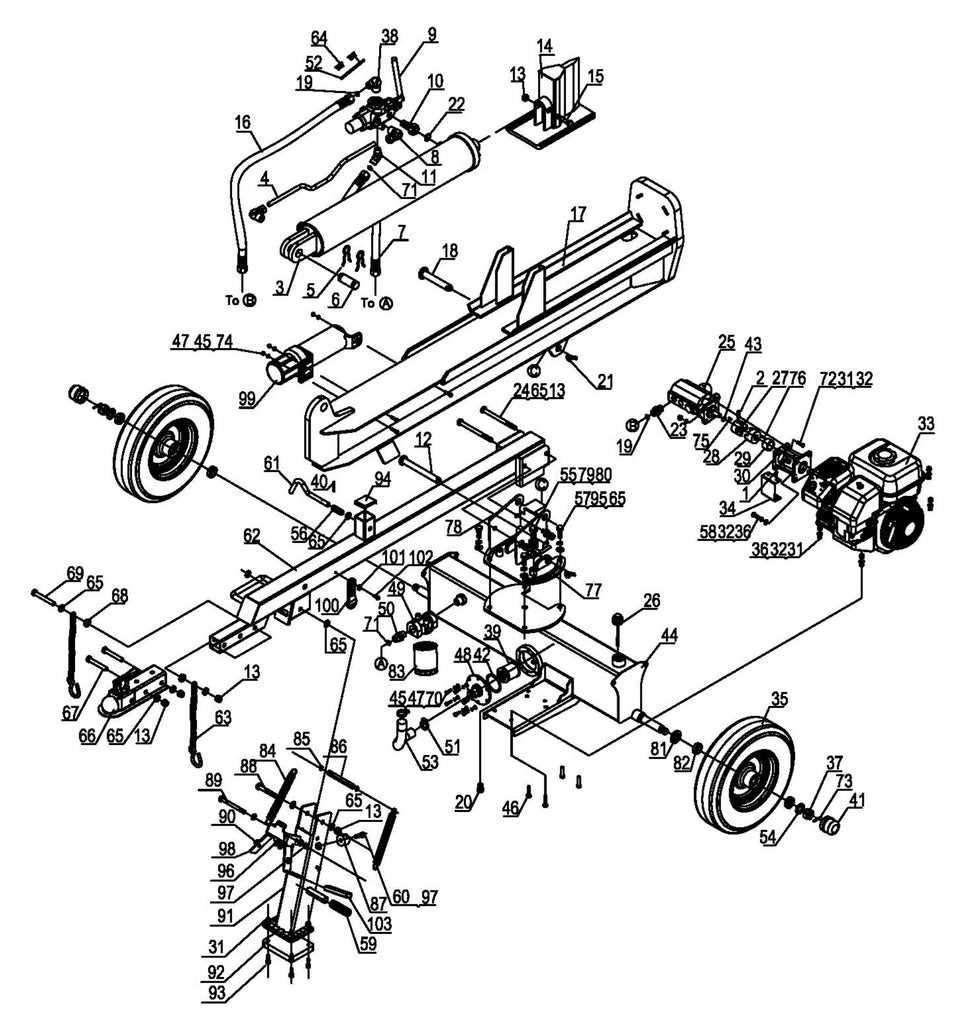

Visual representations of these components can significantly aid in identifying parts and understanding their roles. By exploring detailed layouts, operators can swiftly pinpoint areas needing attention, making the upkeep process more efficient. This guide aims to elucidate the essential components of your machinery, providing insights into their specific functions.

Equipping oneself with this knowledge is the ultimate step towards mastery over one’s equipment. As you delve into the intricacies of the machinery’s framework, you’ll discover how each part contributes to overall efficiency, paving the way for enhanced productivity in agricultural endeavors.

Understanding County Line Tiller Components

Gaining insight into the various elements of agricultural equipment is crucial for efficient operation and maintenance. Each component plays a vital role in the overall functionality, ensuring that tasks are executed smoothly and effectively. Familiarity with these elements not only enhances performance but also aids in troubleshooting and repairs.

Main Elements of the Equipment

- Frame: The sturdy structure that supports all other components and provides stability during operation.

- Blades: Essential for breaking up soil and preparing it for planting, these sharp implements are key to effective cultivation.

- Gearbox: Responsible for transferring power from the engine to the working components, ensuring optimal performance.

- Tines: Designed to dig and aerate the soil, they come in various shapes and sizes to suit different tasks.

- Hitch: Connects the equipment to a tractor, allowing for easy maneuverability and transport.

Importance of Understanding Components

Knowing the role of each element is beneficial for various reasons:

- Enhances efficiency in operation by allowing for better handling of the machinery.

- Facilitates timely maintenance, which can prevent costly repairs and downtime.

- Improves safety by ensuring all components are functioning correctly and securely attached.

Overall, a solid understanding of these key elements empowers operators to maximize the potential of their agricultural equipment, leading to successful farming outcomes.

Importance of Tiller Parts Diagrams

Understanding the intricacies of machinery is essential for effective maintenance and repair. Visual representations of components serve as invaluable tools for both novice and experienced users, enabling them to identify and troubleshoot issues with precision.

Enhanced Troubleshooting

Clear visuals allow for quick identification of malfunctions, streamlining the repair process. When users can see how each element interacts, they can delve deeper into problem-solving, ultimately leading to faster resolutions.

Effective Maintenance Planning

Using graphical guides fosters better organization and understanding of maintenance schedules. By knowing which parts require regular attention, operators can ensure optimal performance and longevity of their equipment.

How to Identify Tiller Parts

Understanding the various components of your gardening equipment is crucial for effective maintenance and troubleshooting. Each element plays a significant role in the overall functionality, and recognizing them can enhance your experience and efficiency. Whether you’re replacing a worn piece or simply wanting to familiarize yourself with your machine, knowing the names and purposes of each section is essential.

Common Components

Typically, machines feature a set of recognizable sections, such as the motor, blades, and frame. The motor is the powerhouse, driving the entire mechanism, while the blades are responsible for breaking up soil. The frame provides stability and supports all other elements, ensuring they work harmoniously together. Familiarizing yourself with these basic components will help you diagnose issues more easily.

Finding Reference Materials

To aid in identification, reference manuals and online resources can be invaluable. These documents often include labeled illustrations, making it easier to pinpoint specific sections and understand their functions. Additionally, joining online forums or local gardening groups can provide insights from experienced users, allowing you to learn from their expertise and share knowledge.

Common Issues with Tiller Components

Maintenance of agricultural machinery often reveals a range of challenges that can impede their effectiveness. Understanding the frequent problems associated with these implements can enhance their longevity and performance. Addressing these issues promptly is crucial for optimal operation.

Wear and Tear: Over time, various components may experience significant degradation due to constant use. This can lead to reduced efficiency and potential breakdowns. Regular inspections are vital to identify and replace worn-out parts before they cause further damage.

Clogging: Soil and debris can accumulate within the machinery, obstructing movement and function. Ensuring that the implement is cleared of any obstructions is essential for maintaining performance and preventing overheating.

Misalignment: Components may become misaligned due to heavy usage or impacts with hard surfaces. This can lead to uneven operation, affecting the overall effectiveness of the tool. Routine checks can help ensure everything is correctly positioned.

Corrosion: Exposure to moisture and chemicals can result in rust and deterioration of metal parts. Applying protective coatings and storing equipment in a dry environment can mitigate this issue significantly.

Hydraulic Problems: If the implement uses hydraulic systems, leaks or pressure drops can cause serious functionality issues. Regular maintenance of hydraulic fluid levels and seals is essential to prevent malfunctions.

By being aware of these common challenges, operators can take proactive measures to ensure their equipment remains in peak condition, thereby enhancing productivity and reducing downtime.

Maintenance Tips for County Line Tillers

Proper upkeep of your gardening equipment is essential for ensuring its longevity and optimal performance. Regular maintenance not only enhances efficiency but also prevents costly repairs down the line. By adhering to a structured maintenance routine, you can keep your machinery in excellent working condition and ready for any task.

Routine Inspection

Conducting frequent checks of your equipment is crucial. Examine the blades for wear and tear, ensuring they are sharp and free from damage. Look for loose bolts and screws, as these can lead to significant issues during operation. Regularly inspect belts and cables for fraying or cracking, replacing them as necessary to avoid breakdowns.

Cleaning and Lubrication

After each use, clean the machinery thoroughly to remove dirt and debris. This prevents rust and corrosion, which can shorten the lifespan of various components. Additionally, ensure that moving parts are properly lubricated to reduce friction and enhance performance. Use manufacturer-recommended lubricants for the best results, and follow the guidelines for application intervals.

Where to Find Replacement Parts

When the time comes to replace worn components of your agricultural equipment, knowing where to source quality replacements is essential. The right suppliers can ensure you maintain efficiency and longevity in your machinery, helping you avoid unnecessary downtime.

Authorized Dealers

One of the most reliable sources for replacements is through authorized dealers. These establishments often provide:

- Genuine products that meet manufacturer specifications

- Expert advice on compatibility and installation

- Warranty options for peace of mind

Online Retailers

The internet offers a vast marketplace for finding what you need. Key benefits of shopping online include:

- Convenience of browsing from home

- Access to customer reviews for informed decisions

- Potential for competitive pricing and discounts

Always ensure to verify the credibility of the online store before making a purchase to avoid counterfeit items.

Assembly Instructions for Tiller Parts

This section provides a clear guide to help you successfully assemble the various components of your gardening equipment. Proper assembly is crucial for optimal performance and longevity of the machine, ensuring that each piece fits correctly and functions as intended.

Required Tools

- Wrench set

- Screwdriver

- Pliers

- Lubricant

- Safety gloves

Step-by-Step Assembly Process

- Start by laying out all components in an organized manner, checking against the provided list to ensure everything is present.

- Begin with the main frame; attach the wheels securely using the appropriate bolts.

- Connect the engine section, ensuring that all cables and hoses are properly aligned.

- Install the operational controls, verifying that each lever and switch is functional.

- Finally, check all connections and tighten any loose bolts to prevent future issues.

By following these guidelines, you can ensure that your equipment is assembled correctly, allowing for efficient and effective use in your gardening tasks.

Upgrades and Modifications for Performance

Enhancing the efficiency and functionality of agricultural equipment can significantly impact productivity. By implementing various enhancements, users can achieve greater output and improved handling during operations.

Engine Modifications: Upgrading the engine can provide increased horsepower and torque, allowing for more robust performance. Consider investing in high-performance air filters and exhaust systems to maximize airflow and efficiency.

Attachment Enhancements: Incorporating specialized attachments can improve versatility. Options such as advanced cutting implements or reinforced frames can enhance durability and adaptability to different soil conditions.

Transmission Upgrades: Modifying the transmission system can lead to smoother operation and better control. Upgraded gear ratios can optimize speed and power delivery, resulting in a more efficient workflow.

Maintenance Practices: Regularly scheduled maintenance is crucial for sustaining performance. Keeping components clean and well-lubricated ensures longevity and minimizes the risk of breakdowns.