In the realm of heavy machinery, the ability to elevate and manipulate substantial loads relies on a complex assembly of components. Each element plays a critical role in ensuring safety, efficiency, and functionality. This intricate system is designed to perform a variety of tasks, making it essential for industries ranging from construction to shipping.

By exploring the various segments of these lifting apparatuses, one can gain insights into how they operate and interact. Each segment contributes to the ultimate goal of achieving precise control and stability, crucial for effective load handling. Understanding these functions allows for better maintenance and improved operational strategies.

Delving into the specifics reveals not only the engineering marvel behind these machines but also the innovation that drives their design. Each feature is meticulously crafted to enhance performance, making knowledge of their structure invaluable for professionals in the field.

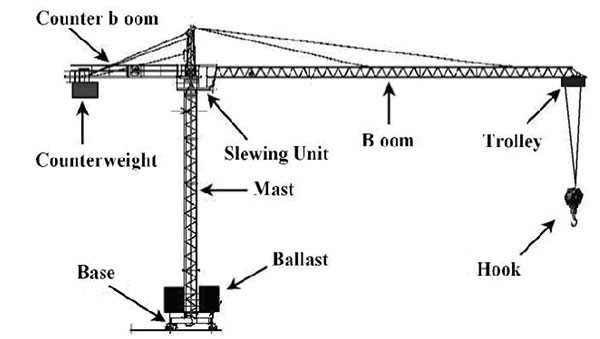

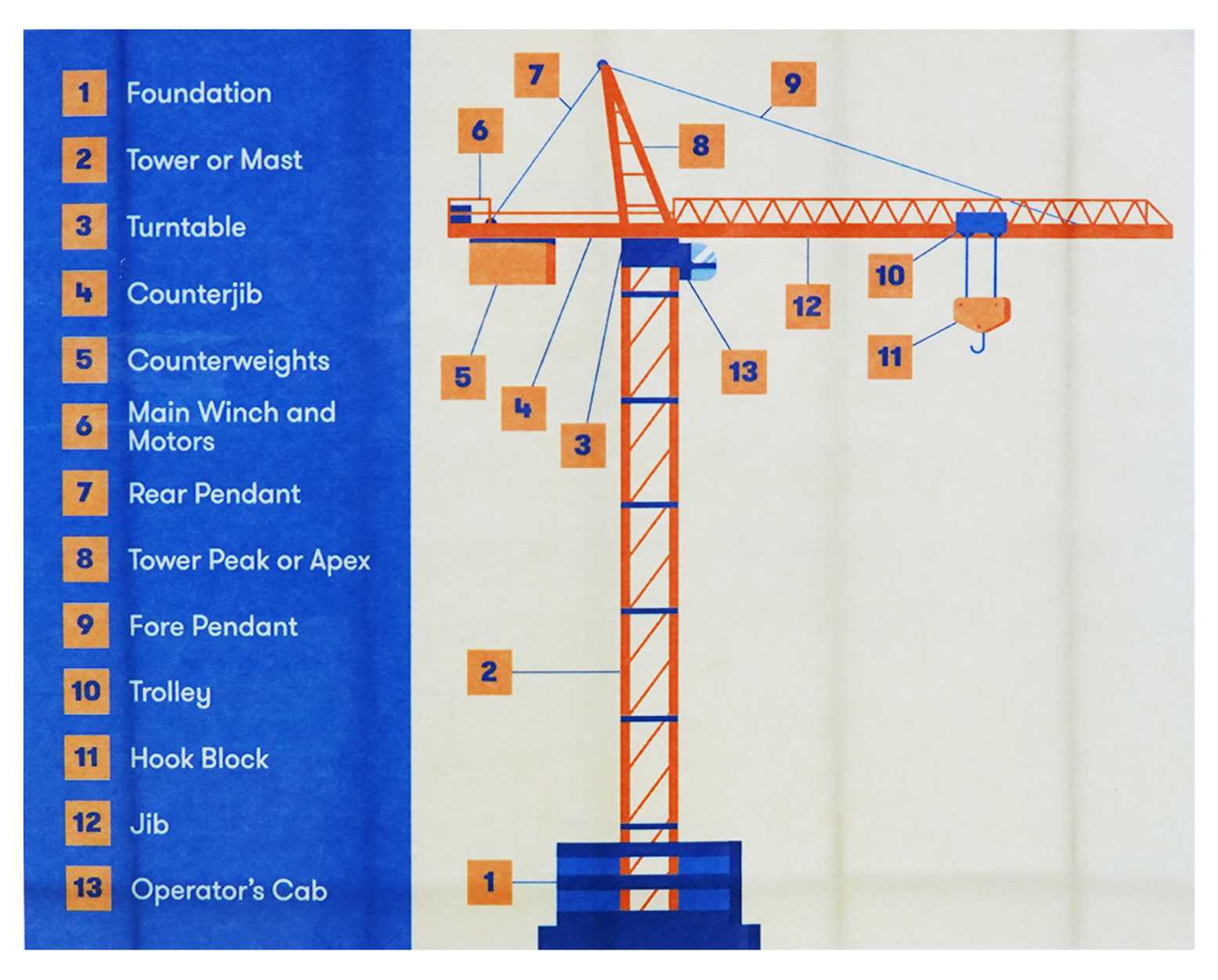

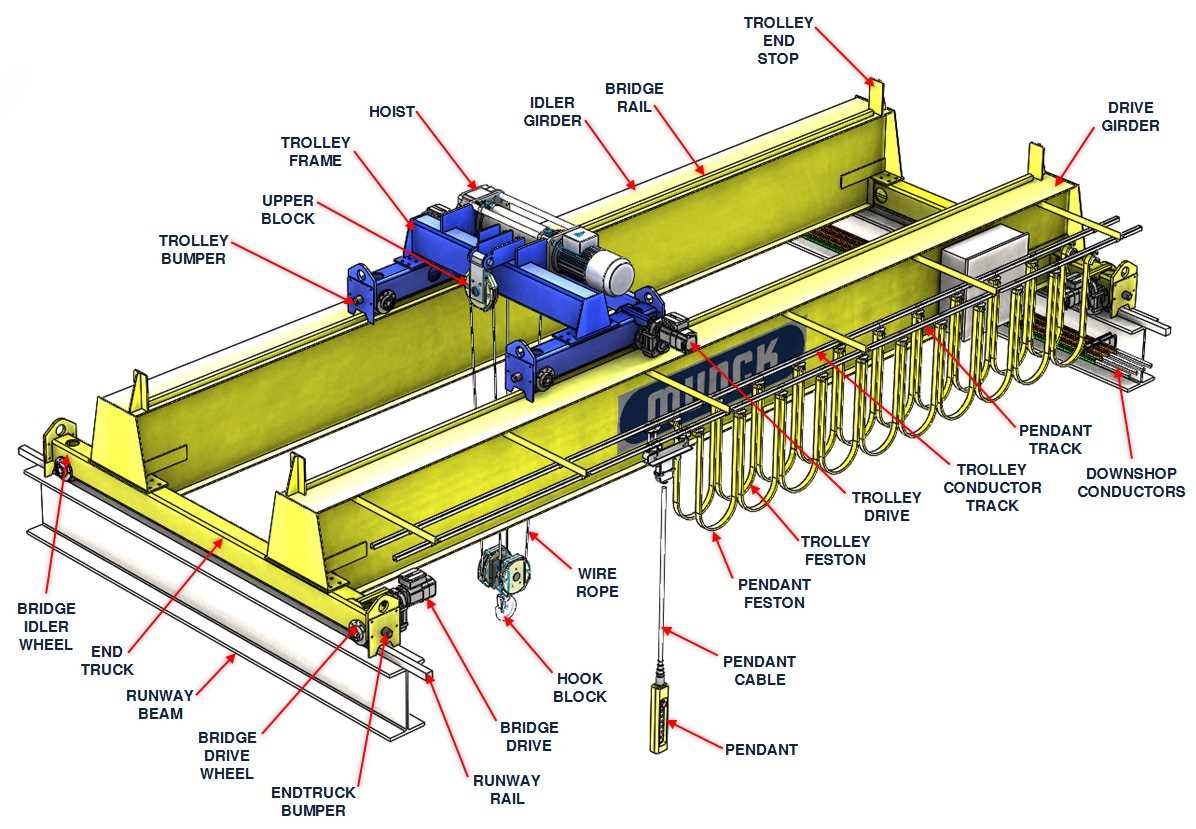

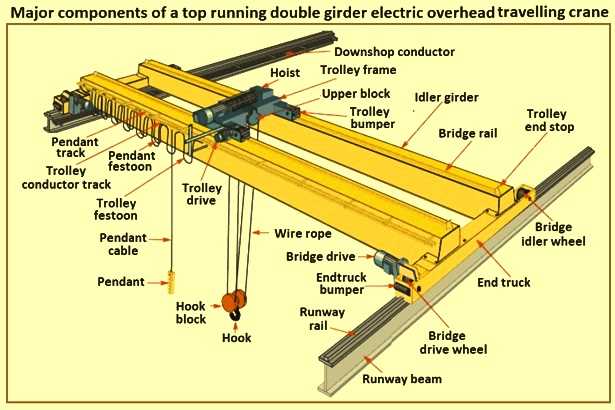

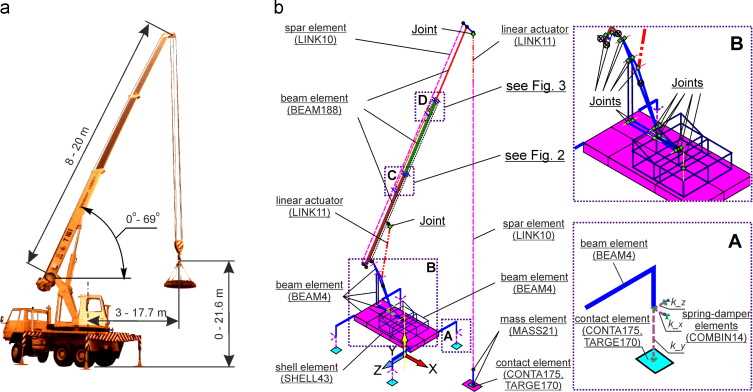

Understanding Crane Diagram Components

The intricate layout of lifting machinery is essential for effective operation and safety. Grasping the various elements involved is crucial for anyone engaged in handling or managing these structures. Each component plays a vital role in ensuring that loads are moved efficiently and securely.

Firstly, the framework acts as the backbone, providing stability and support. It is designed to withstand the stresses and strains encountered during lifting tasks. Secondly, the hoisting mechanism is responsible for raising and lowering objects, utilizing a combination of pulleys and cables to facilitate movement. This component must operate smoothly to prevent accidents and ensure precision.

Additionally, control systems are integral for maneuvering the equipment safely. Operators rely on these systems to execute commands accurately, maintaining a careful balance between speed and safety. Moreover, safety features such as brakes and limit switches are crucial for preventing mishaps during operation.

Understanding these components allows users to appreciate their interconnectivity and the importance of regular maintenance. Each element must function harmoniously to achieve optimal performance, making knowledge of these systems essential for effective management and operation.

Key Elements of Crane Mechanics

The intricate workings of lifting machinery rely on several fundamental components that ensure efficient operation and safety. Each element plays a crucial role in the overall functionality, enabling the movement and manipulation of heavy loads with precision. Understanding these essential features is vital for optimizing performance and preventing mechanical failures.

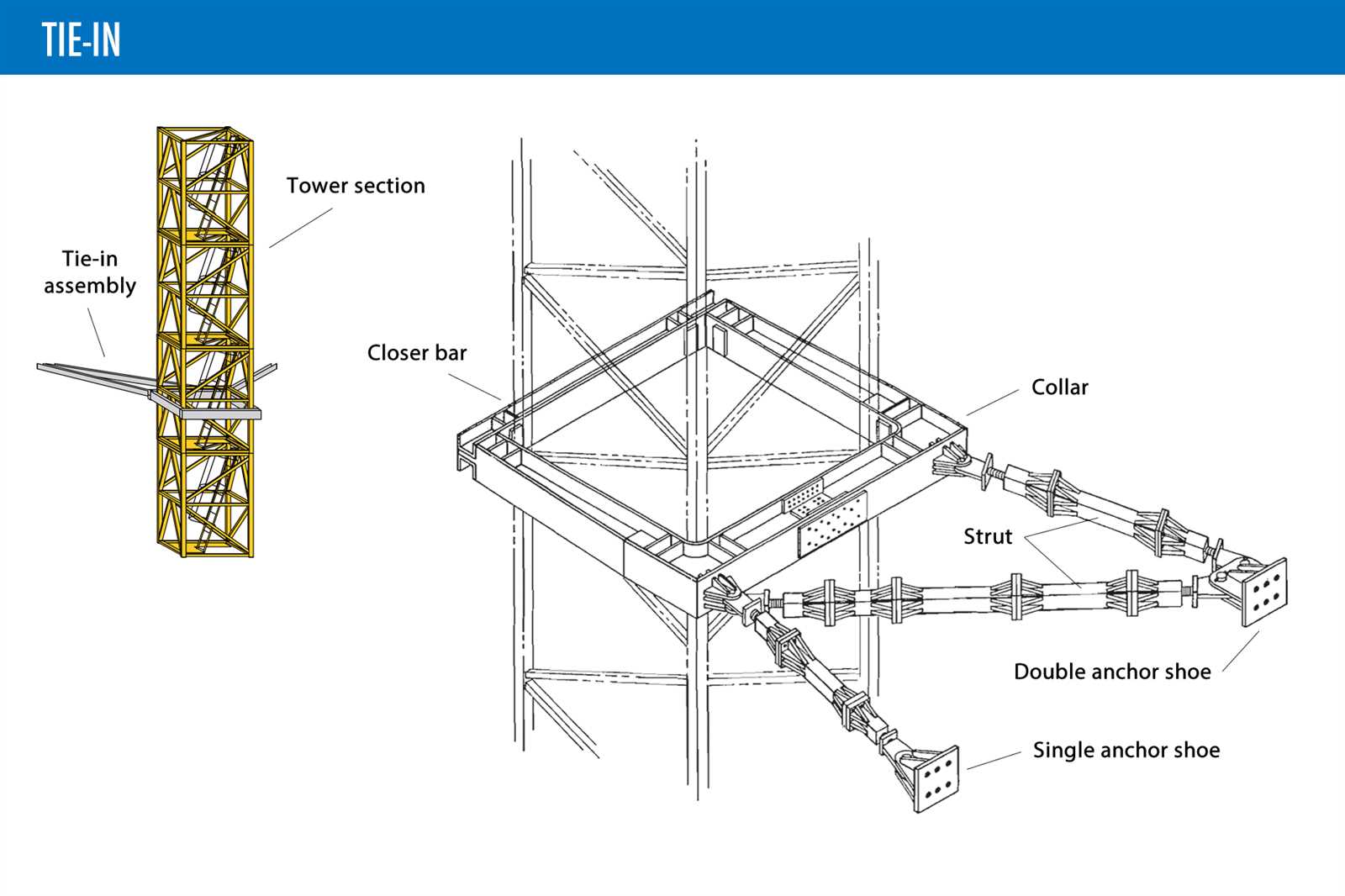

Structural Framework

The backbone of any lifting apparatus consists of a robust framework designed to withstand various forces. This structure supports the entire assembly, providing stability during operations. Its design is engineered to distribute weight evenly, allowing for safe handling of substantial loads while minimizing the risk of tipping or collapse.

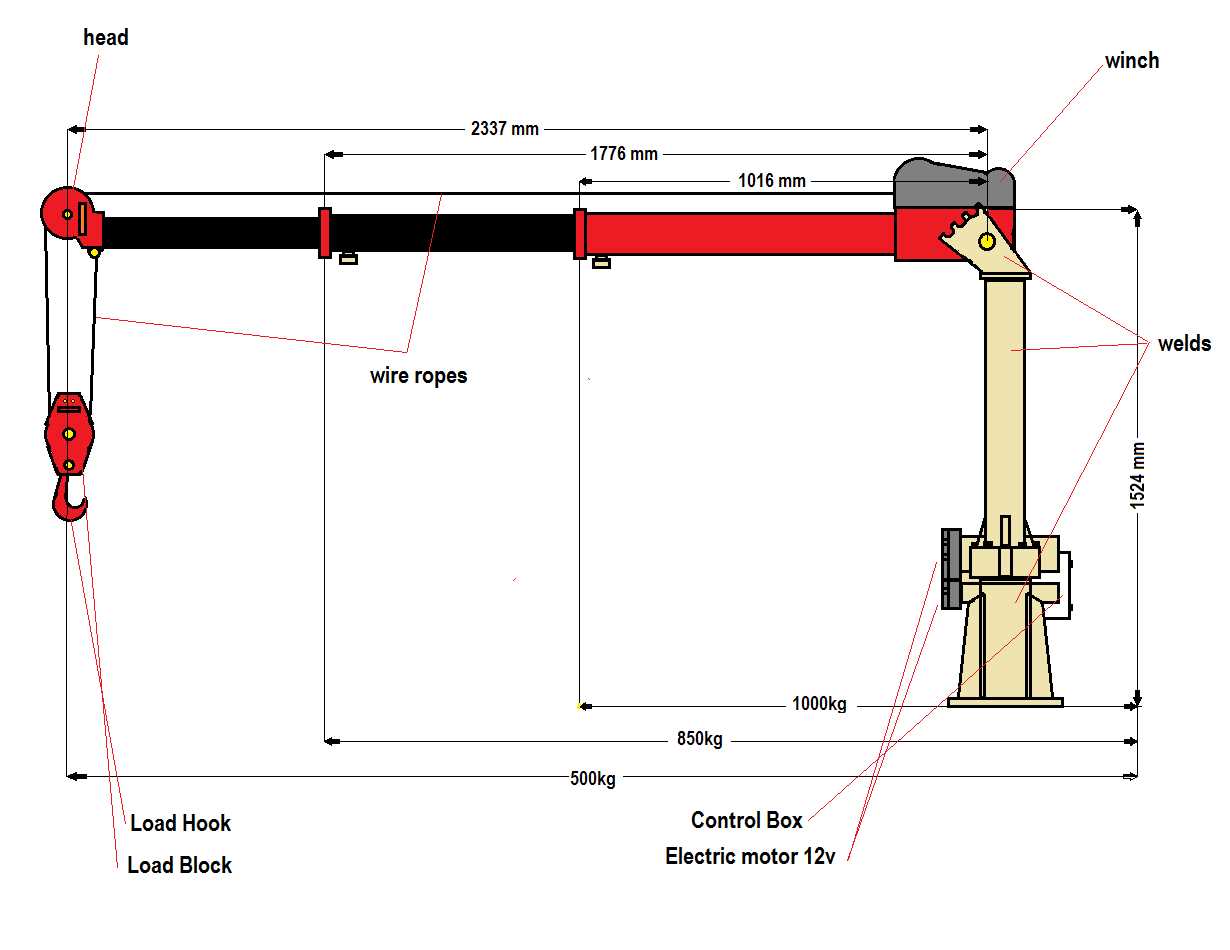

Lifting Mechanism

The mechanism responsible for elevating and lowering objects is a sophisticated assembly of gears, pulleys, and cables. This system converts rotational motion into vertical lift, enabling operators to move items efficiently. The choice of materials and engineering precision in this component directly impacts the reliability and effectiveness of the entire system.

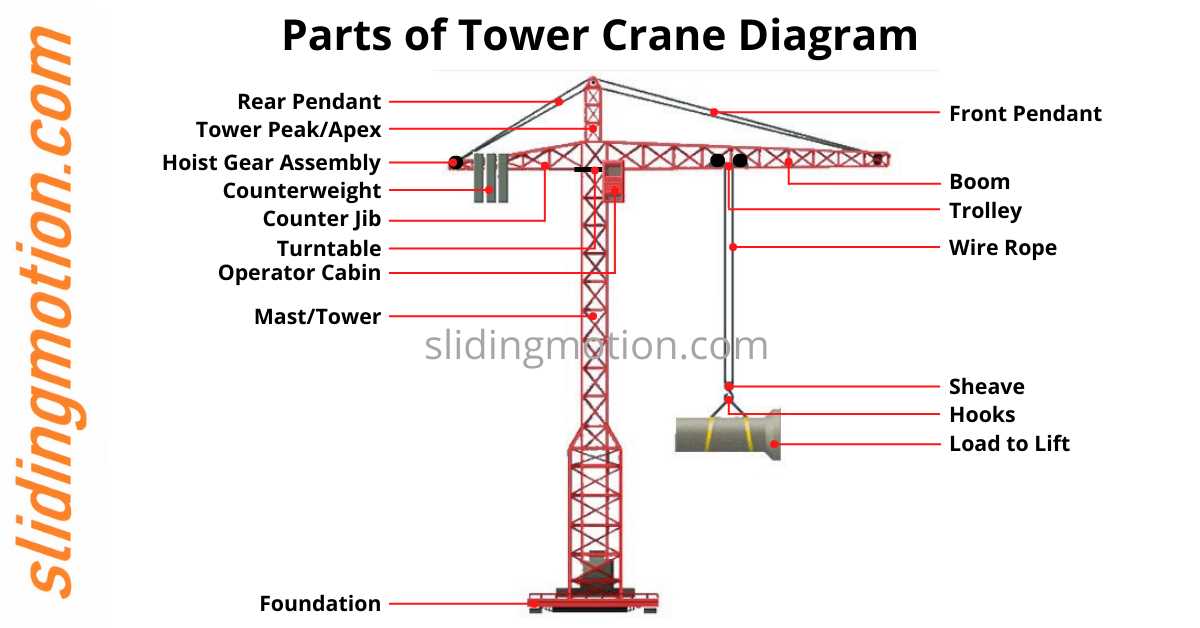

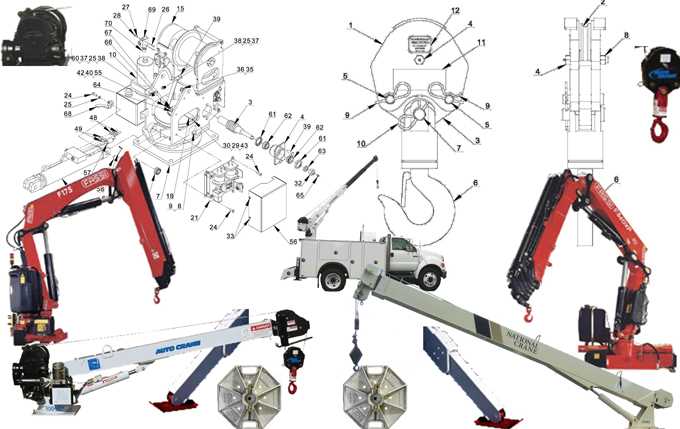

Function of the Boom in Cranes

The boom serves as a crucial element in the operation of lifting machinery, providing the necessary reach and support for various loads. Its design and function significantly impact the overall efficiency and effectiveness of lifting tasks.

- Extending Reach: The boom allows operators to access areas that are otherwise difficult to reach.

- Load Distribution: It helps distribute the weight of the load evenly, enhancing stability.

- Height Adjustment: The adjustable nature of the boom enables lifting at different heights, adapting to various job requirements.

- Versatility: It can be configured for different types of loads, making it suitable for multiple applications.

Ultimately, the boom’s role is integral to successful lifting operations, impacting safety and performance in diverse environments.

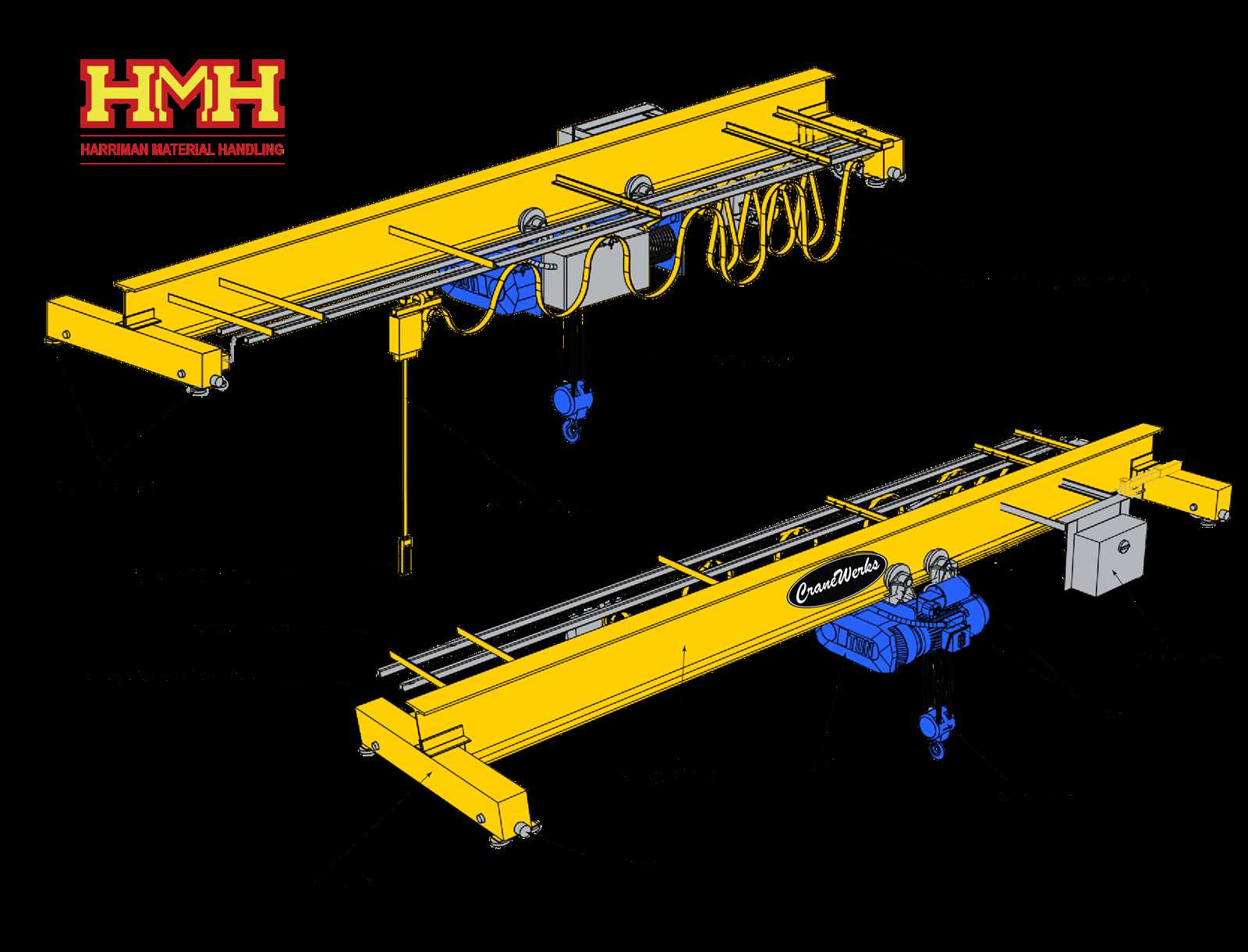

Importance of the Hoist System

The hoist system plays a crucial role in the efficiency and safety of lifting operations. It serves as the primary mechanism for elevating and lowering loads, making it essential for various applications in construction and industrial environments. Understanding its significance helps in optimizing performance and ensuring operational safety.

Key Functions

This mechanism provides several vital functions that enhance overall functionality. It not only facilitates the movement of heavy objects but also ensures precise control during lifting tasks. The reliability of this system directly impacts productivity and safety standards.

Safety Considerations

Implementing a robust hoist system is fundamental for minimizing risks associated with lifting operations. Regular maintenance and adherence to safety protocols can prevent accidents and ensure the longevity of the equipment. Proper training for operators further contributes to a secure working environment.

| Function | Description |

|---|---|

| Load Handling | Facilitates the lifting and lowering of heavy materials. |

| Precision Control | Allows for careful maneuvering of loads in confined spaces. |

| Safety Mechanisms | Includes features to prevent overload and ensure secure lifting. |

| Efficiency Boost | Enhances productivity by streamlining lifting processes. |

Role of the Counterweight in Stability

The counterweight plays a crucial function in ensuring balance and support for lifting mechanisms. Its strategic placement helps counteract the forces exerted during operation, contributing significantly to overall safety and efficiency.

By providing a counterbalance, it mitigates the risk of tipping and enhances the performance of lifting tasks. This balance is essential for handling heavy loads while maintaining control.

| Function | Importance |

|---|---|

| Counterbalance Forces | Prevents tipping over |

| Load Distribution | Ensures even weight distribution |

| Operational Safety | Reduces accidents and injuries |

| Efficiency Improvement | Enhances lifting capabilities |

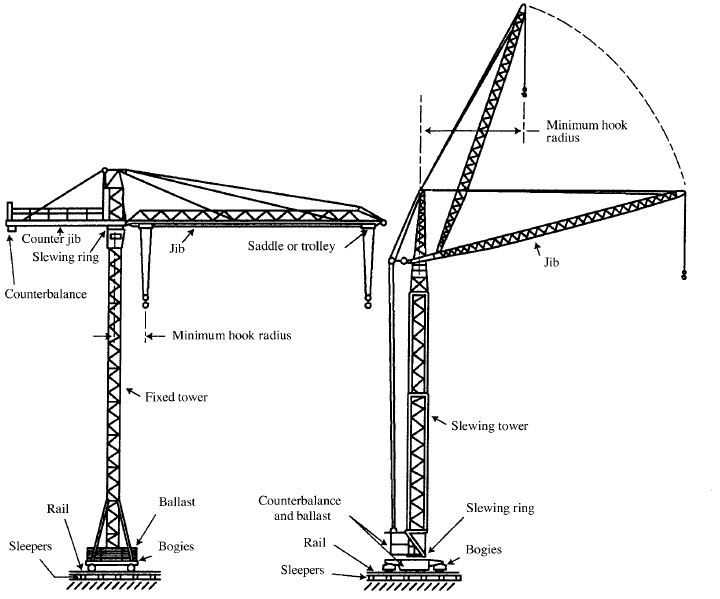

Insights into the Swing Mechanism

The swing mechanism plays a crucial role in the overall functionality of lifting machinery, allowing for dynamic movement and precise positioning. This component enables operators to manipulate the angle of the load, enhancing both efficiency and safety during operations.

Understanding the intricacies of this mechanism involves several key aspects:

- Articulation: The mechanism typically incorporates a rotating assembly that permits lateral movement, enabling the load to pivot around a central point.

- Control Systems: Advanced controls, often integrated with sensors, allow for smooth operation and adjustments, ensuring that the load can be positioned accurately.

- Hydraulic Integration: Many systems utilize hydraulic power to facilitate the swinging action, providing the necessary force for heavy lifting.

Moreover, regular maintenance of this mechanism is essential to prevent wear and ensure optimal performance. Key maintenance practices include:

- Routine inspections of the hydraulic fluid and hoses for leaks.

- Lubrication of moving parts to minimize friction.

- Calibration of control systems to maintain accuracy in operation.

In summary, a comprehensive understanding of the swinging mechanism and its operational components significantly enhances the effectiveness and safety of lifting tasks.

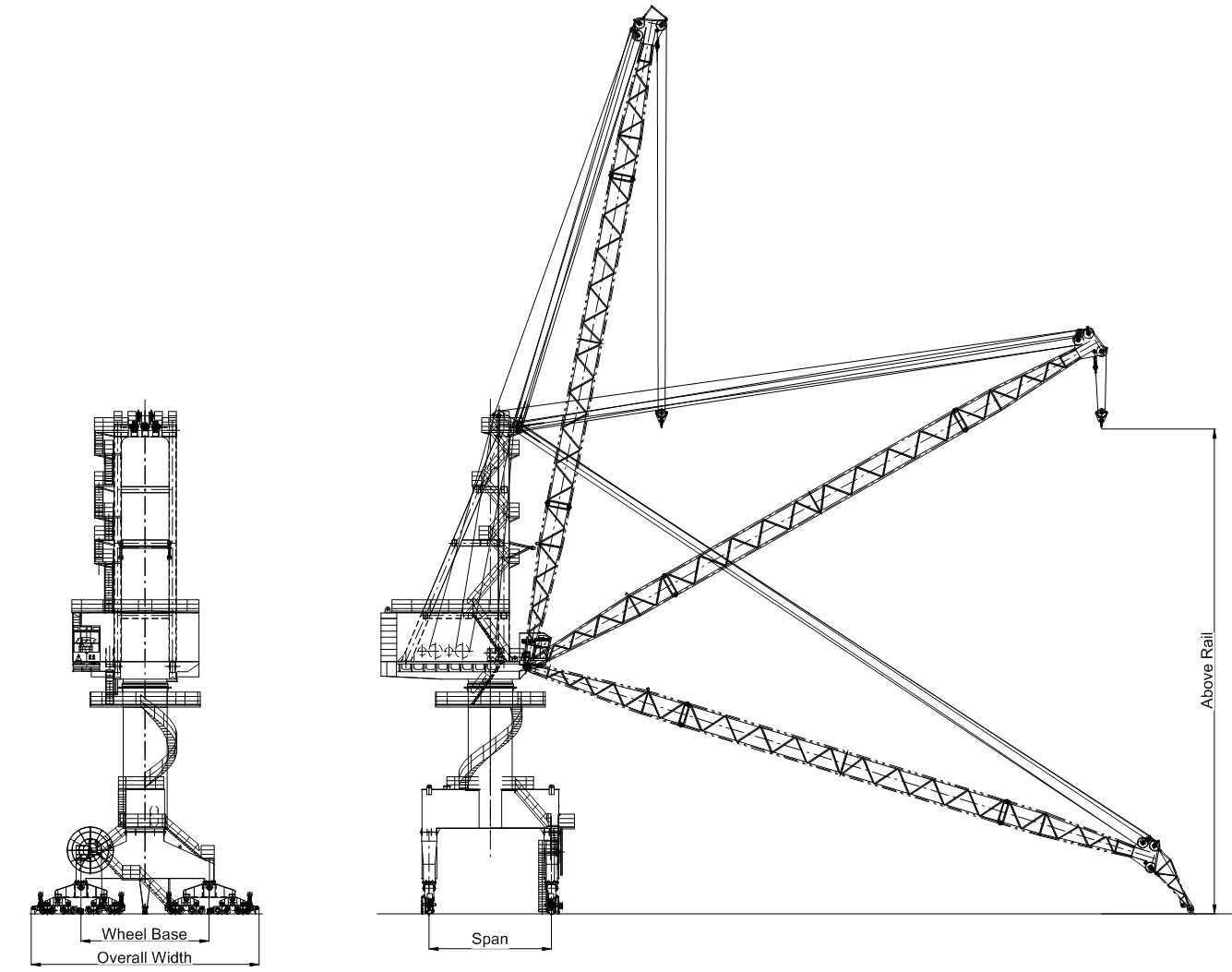

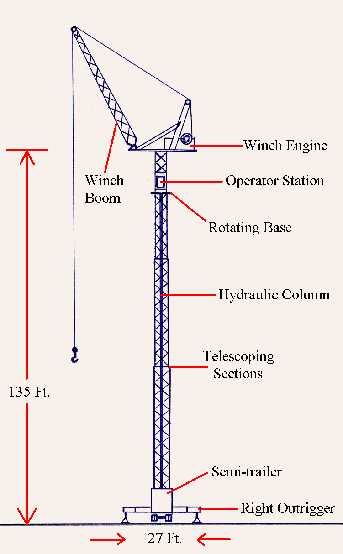

Significance of the Base and Outriggers

The stability and functionality of heavy-lifting equipment are heavily influenced by the foundational elements that support it. These structures play a crucial role in distributing weight and ensuring balance during operation, which is essential for safe and efficient lifting processes.

Foundation Stability

The base serves as the primary point of contact with the ground, anchoring the entire system. Its design must account for various environmental factors, including soil composition and surface conditions. A well-constructed base not only supports the load but also minimizes the risk of tipping or shifting, particularly when handling heavy materials.

Role of Outriggers

Outriggers extend the footprint of the equipment, providing additional stability and support. By distributing weight over a larger area, they help prevent excessive strain on any single point. These extensions are vital when working on uneven terrain or in confined spaces, as they enhance overall safety and operational efficiency. Proper deployment of outriggers is critical to maintaining equilibrium and achieving optimal performance.

Overview of Load Lines and Rigging

Understanding the intricacies of load lines and rigging is essential for ensuring safe and efficient operations in lifting scenarios. These elements are critical in determining how weight is managed and distributed during the lifting process, contributing to the overall stability and safety of the operation.

Load lines are vital components that play a significant role in handling heavy materials. Their function includes:

- Facilitating the movement of loads with precision.

- Ensuring that forces are evenly distributed to prevent failure.

- Providing clear indicators of capacity and limitations.

Rigging encompasses the techniques and tools used to attach loads to lifting equipment. Effective rigging is key to maximizing safety and performance. Important aspects include:

- Choosing the right type of slings based on the load shape and weight.

- Employing appropriate hardware such as hooks, shackles, and connectors.

- Understanding the principles of balance and center of gravity to enhance stability.

By mastering these concepts, operators can significantly improve the efficiency and safety of lifting operations, ultimately leading to better outcomes in various industries.

Visualizing Crane Diagrams Effectively

Effective representation of lifting machinery structures is crucial for clear communication and understanding. By employing various techniques, one can enhance clarity and engagement in presentations and educational materials.

- Utilize color coding to differentiate elements.

- Incorporate labels that provide immediate context.

- Use layers to show complex relationships between components.

- Implement 3D modeling for a more immersive experience.

These strategies can help audiences grasp intricate concepts and facilitate deeper discussions. Engaging visual aids not only enhance learning but also support efficient decision-making processes.