In the world of construction and woodworking, the efficiency of any tool relies heavily on its internal mechanisms. A thorough comprehension of these components can significantly enhance the effectiveness and longevity of your equipment. Each element plays a critical role, contributing to the overall performance and reliability of the device.

By familiarizing yourself with the various segments and their functions, you can troubleshoot issues more effectively and ensure that your tool operates at peak performance. Understanding how each piece interacts with others not only aids in maintenance but also empowers users to maximize their productivity.

Whether you’re a seasoned professional or a DIY enthusiast, having a clear visual reference can demystify the intricacies of your tool. This knowledge fosters confidence, allowing you to tackle projects with assurance and precision, ultimately leading to superior results.

Bostitch Framing Nailer Overview

This section provides a comprehensive look at a powerful tool designed for construction tasks. It emphasizes functionality, efficiency, and ease of use, catering to both professionals and DIY enthusiasts.

Key Features

- Robust construction for durability

- Lightweight design for maneuverability

- Adjustable depth control for precision

- Fast loading mechanism for increased productivity

Common Applications

- Building frameworks for structures

- Installing decking and siding

- Assembling wooden furniture

- Performing renovations and repairs

Key Components of Framing Nailers

Understanding the essential elements of a fastening tool can greatly enhance its effectiveness and usability. Each component plays a vital role in ensuring precision and reliability during construction tasks. Familiarity with these parts can assist users in maintenance, troubleshooting, and optimizing performance.

Main Elements

The primary components of these tools work together to deliver accurate fastening. Each part contributes to the overall functionality, making it crucial to recognize their individual roles.

| Component | Description |

|---|---|

| Housing | The outer shell that protects internal mechanisms and provides stability. |

| Trigger Mechanism | Controls the activation of the device, allowing for single or continuous firing. |

| Piston | Drives the fastener into the material, powered by compressed air or gas. |

| Magazine | Holds the fasteners in place for quick and easy loading. |

| Depth Adjustment | Allows users to modify the depth of the fastener for various applications. |

Additional Features

Beyond the core elements, additional features enhance usability and safety. Understanding these can improve overall experience and performance.

| Feature | Benefit |

|---|---|

| Safety Lock | Prevents accidental firing, ensuring user safety. |

| Exhaust Port | Directs air away from the user, enhancing comfort during operation. |

| Grip Handle | Offers better control and reduces hand fatigue during extended use. |

Understanding Nailer Functionality

In the realm of construction and woodworking, the tool designed for driving fasteners plays a crucial role. Grasping the mechanics behind its operation enhances efficiency and accuracy in projects. This section explores the essential components and their interactions, shedding light on how this device performs its tasks seamlessly.

- Power Source: The energy that drives the mechanism can come from various sources, including pneumatic pressure, battery, or electricity.

- Actuation Mechanism: This determines how the tool engages the fastener, influencing the speed and force with which it is driven.

- Guide System: Proper alignment and guidance ensure that each fastener is placed precisely where needed, minimizing errors.

Understanding these elements not only aids in effective use but also in maintenance and troubleshooting. Regular inspection of the following components is vital:

- Seals and O-rings

- Trigger and safety mechanisms

- Drive blade and nose assembly

By familiarizing oneself with these critical aspects, users can achieve optimal performance and prolong the lifespan of their equipment.

Maintenance Tips for Longevity

Regular upkeep is essential to ensure the durability and efficiency of your tool. By adhering to a few simple practices, you can significantly extend its lifespan and maintain optimal performance. A well-maintained device not only enhances productivity but also reduces the likelihood of malfunctions and costly repairs.

Routine Cleaning

After each use, take a few moments to clean your equipment thoroughly. Remove dust, debris, and residue from the exterior and interior components. This will prevent build-up that can lead to wear and tear over time. Utilize a soft brush or compressed air to reach difficult areas, ensuring all parts are free from contaminants.

Regular Lubrication

Applying the appropriate lubricant to moving parts is crucial for smooth operation. Check the manufacturer’s recommendations for suitable products and intervals for application. Keeping components well-lubricated minimizes friction and reduces the risk of premature failure, allowing for seamless functionality throughout the tool’s life.

Common Issues and Solutions

When working with powerful tools designed for driving fasteners, users may encounter a variety of challenges that can hinder performance. Understanding these common issues and their solutions can enhance efficiency and prolong the lifespan of the equipment.

-

Jamming:

This is one of the most frequent problems. Fasteners may become stuck in the feeding mechanism, preventing proper operation.

- Check for debris or bent components causing obstruction.

- Ensure the fasteners used are compatible with the tool.

- Regularly clean the feeding system to avoid buildup.

-

Inconsistent Driving:

When fasteners do not drive consistently, it can affect the quality of the work.

- Inspect air pressure levels; insufficient pressure can lead to weak drives.

- Verify that the tool is adequately lubricated to ensure smooth operation.

- Examine the depth adjustment settings; improper settings can lead to uneven driving.

-

Leakage:

Air leaks can significantly reduce the tool’s efficiency and power.

- Check all connections for tightness and secure fittings.

- Inspect hoses for cracks or damage that could lead to leaks.

- Replace any worn seals or gaskets to maintain airtight integrity.

-

Misfires:

Unexpected misfires can be both frustrating and dangerous.

- Ensure the safety mechanism is functioning correctly.

- Use the appropriate fasteners to prevent misalignment.

- Keep the tool clean and well-maintained to avoid operational failures.

By addressing these common issues proactively, users can ensure optimal functionality and enhance the overall performance of their tools.

Choosing the Right Nailer Parts

Selecting the appropriate components for your tool is essential for achieving optimal performance and longevity. The right elements not only enhance functionality but also ensure safety during operation. Understanding the various options available can significantly impact your projects.

When considering your choices, it’s crucial to evaluate the compatibility of each element with your specific device. Factors such as size, material quality, and design play a pivotal role in determining how effectively your equipment will operate. Investing in high-quality elements can lead to improved efficiency and reduced maintenance needs over time.

Additionally, it’s important to consult reliable resources and seek advice from experienced users. They can provide valuable insights into which components are best suited for your needs. Always prioritize manufacturers that are known for their reliability and innovation, as this can influence your overall experience and satisfaction.

Finally, keep in mind that regular maintenance and timely replacement of worn-out components are essential for maintaining peak performance. A well-maintained tool not only performs better but also lasts longer, saving you time and money in the long run.

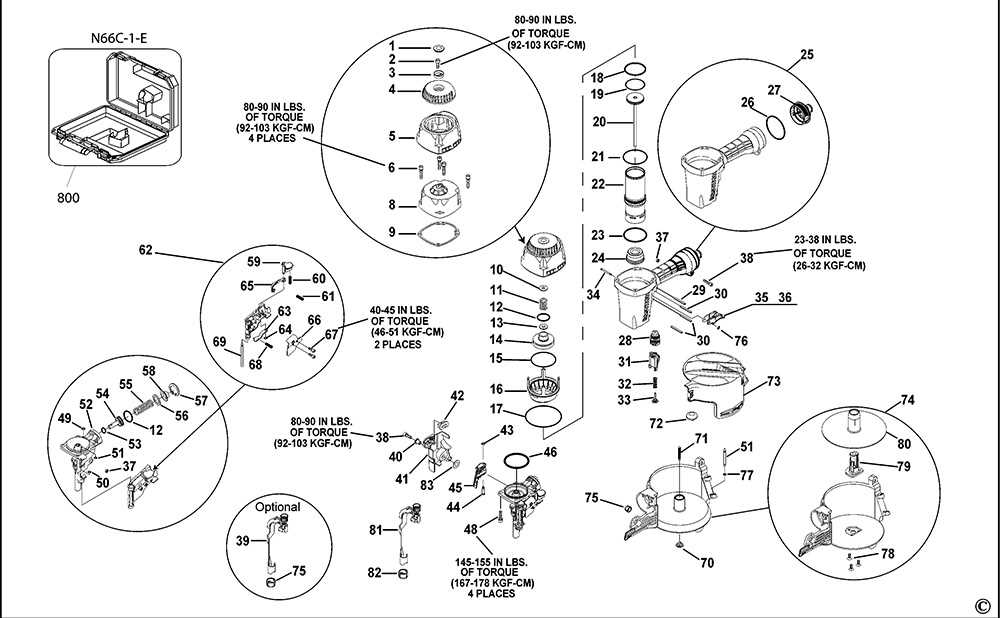

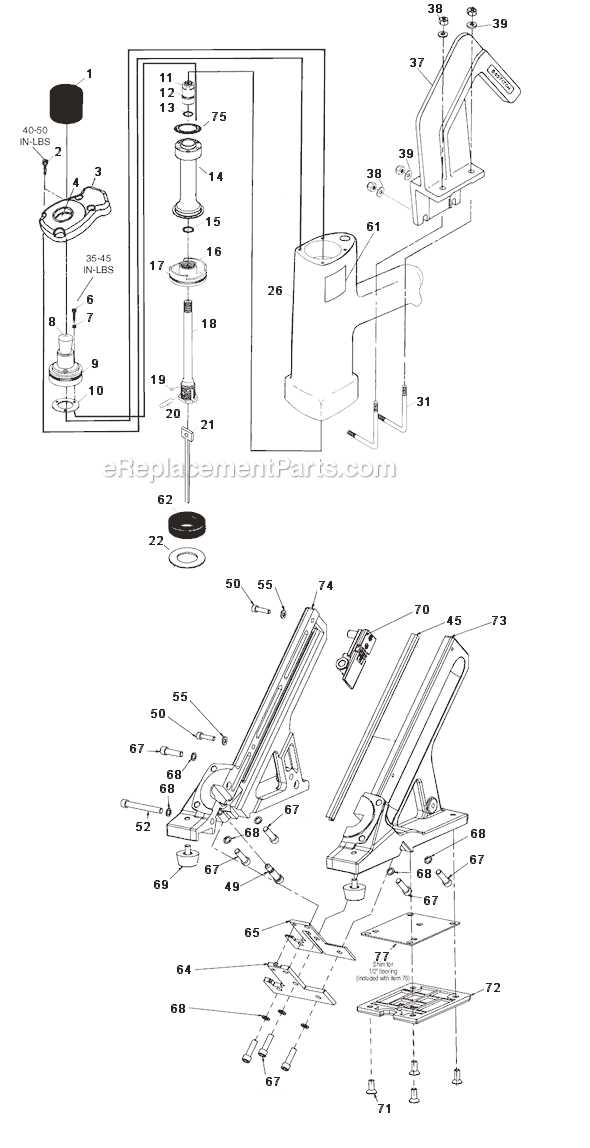

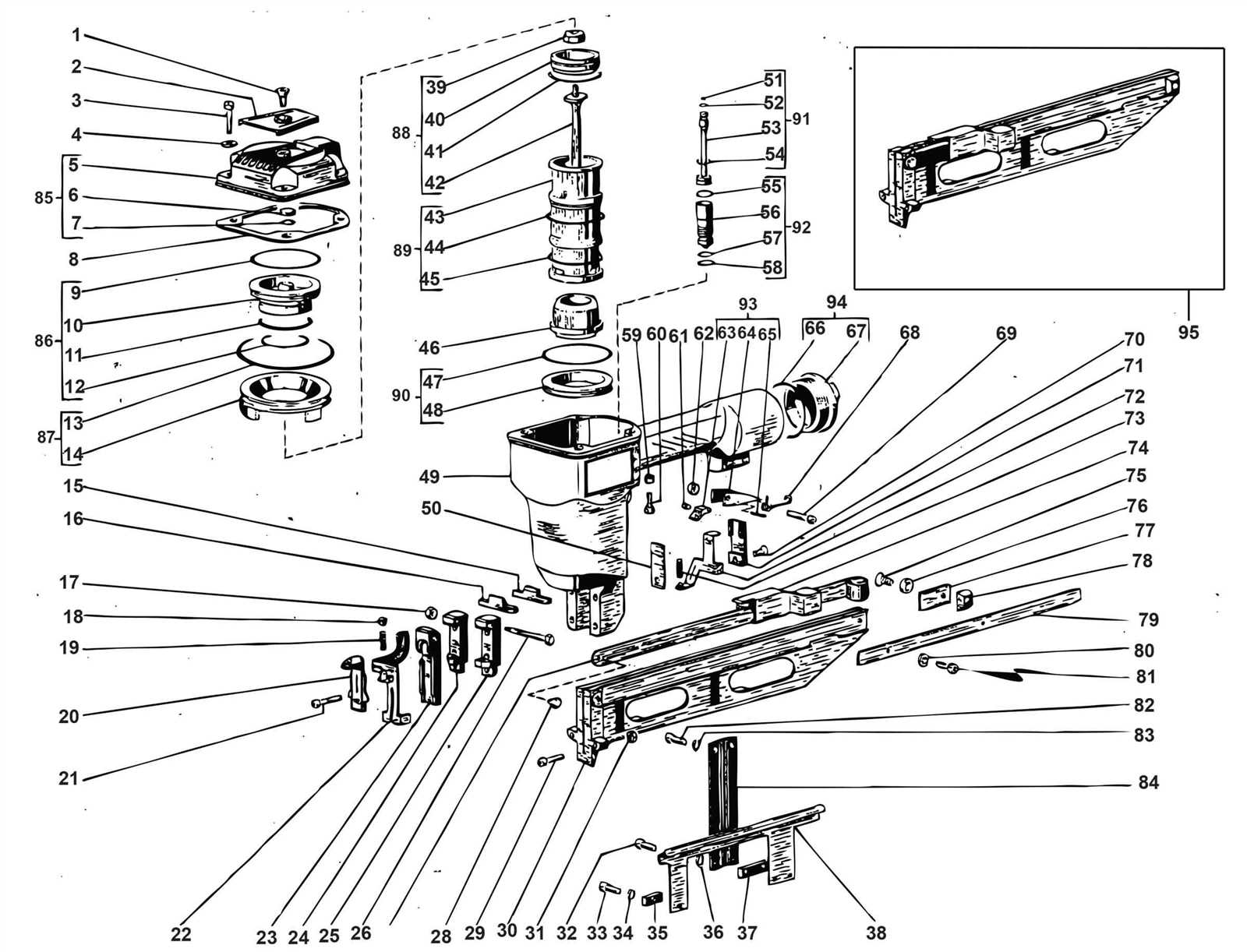

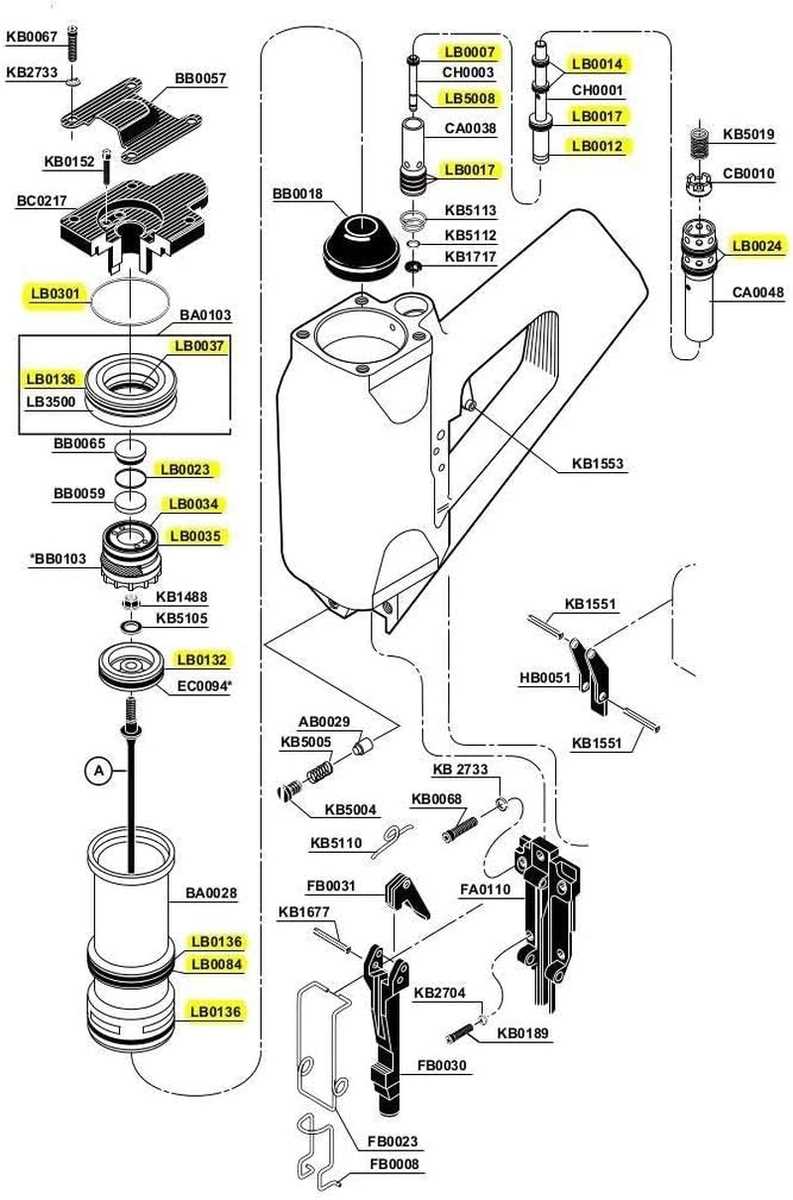

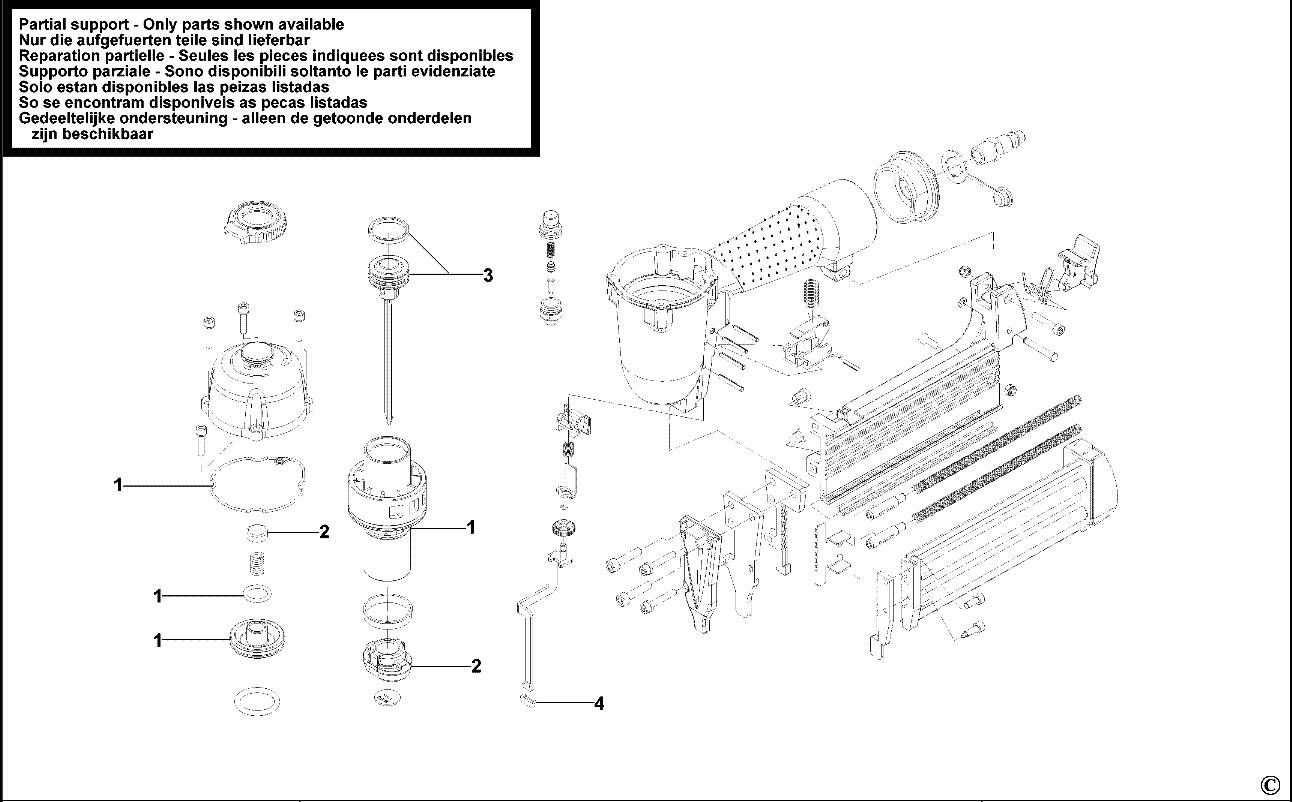

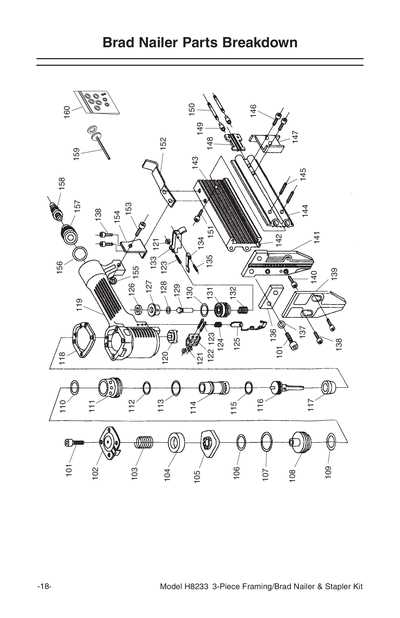

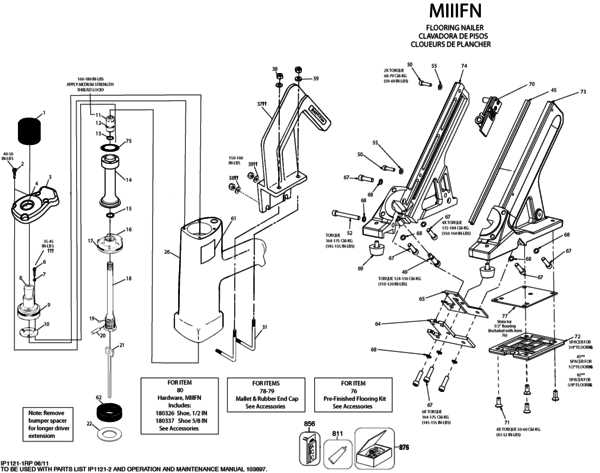

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair of tools. These illustrations serve as a roadmap, guiding users through the various elements that make up a mechanical device. Familiarizing oneself with these visuals can significantly enhance one’s ability to troubleshoot and replace specific items.

1. Identify the Key Components: Start by locating the main sections of the illustration. Most visuals will categorize parts into groups, making it easier to comprehend how different elements interact. Focus on understanding the function of each group.

2. Familiarize Yourself with Labels: Each component will typically be accompanied by a label or number. Take the time to correlate these identifiers with a list or legend, as this will provide clarity on the function and specifications of each part.

3. Understand the Flow: Pay attention to how parts are arranged within the illustration. This can indicate the assembly order or the sequence of operation. Recognizing the flow will help in reassembly after any disassembly tasks.

4. Note Common Symbols: Many diagrams use standardized symbols to represent various features. Familiarizing yourself with these symbols will allow for quicker interpretation of the visual, saving time during maintenance activities.

5. Use a Reference Guide: If available, consult a reference manual or online resource that explains the components in more detail. This can provide valuable insights and additional context that may not be immediately apparent from the illustration alone.

Upgrading Your Nailer Effectively

Enhancing the functionality of your tool can significantly improve your workflow and efficiency. This guide outlines key strategies to modernize your equipment, ensuring it meets your evolving needs.

Assessing Your Current Tool

Before making any upgrades, it’s crucial to evaluate the current condition and performance of your device. Consider the following:

- Check for wear and tear on components.

- Identify any limitations in power or speed.

- Review the types of fasteners you typically use.

Identifying Upgrades

Once you’ve assessed your tool, you can focus on specific enhancements. Here are some options to consider:

- New Features: Look for attachments or kits that add new capabilities, such as adjustable depth settings.

- Improved Components: Upgrade internal mechanisms for better reliability and performance.

- Ergonomic Design: Consider grips or handles that reduce fatigue during extended use.

By carefully selecting upgrades, you can ensure your tool remains effective and reliable for your projects.