Understanding the various elements of a specialized device can greatly enhance its maintenance and functionality. By familiarizing yourself with each component, users can ensure smooth operation and extend the lifespan of their equipment. This guide aims to offer insights into the intricate details of such mechanisms, providing valuable knowledge for enthusiasts and professionals alike.

Each piece serves a unique purpose, contributing to the overall performance and efficiency of the equipment. Recognizing how these elements interact with each other is crucial for troubleshooting and routine upkeep. With a clear understanding, the process of identifying potential issues becomes more intuitive, allowing for precise adjustments and repairs.

Whether you are looking to replace specific elements or simply wish to deepen your knowledge of the internal structure, this guide will be your companion. Explore how each part plays a role in the seamless operation of your device, making it easier to maintain optimal functionality over time.

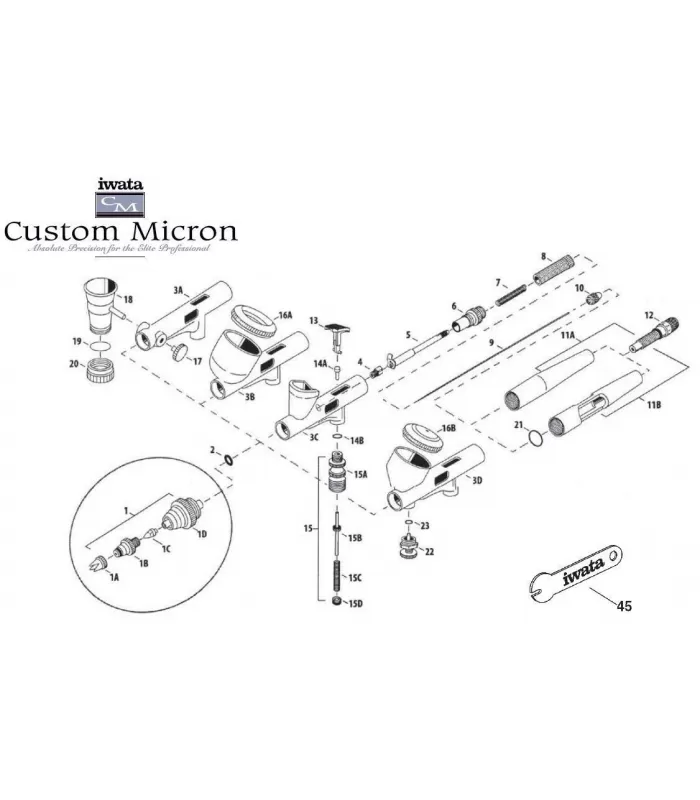

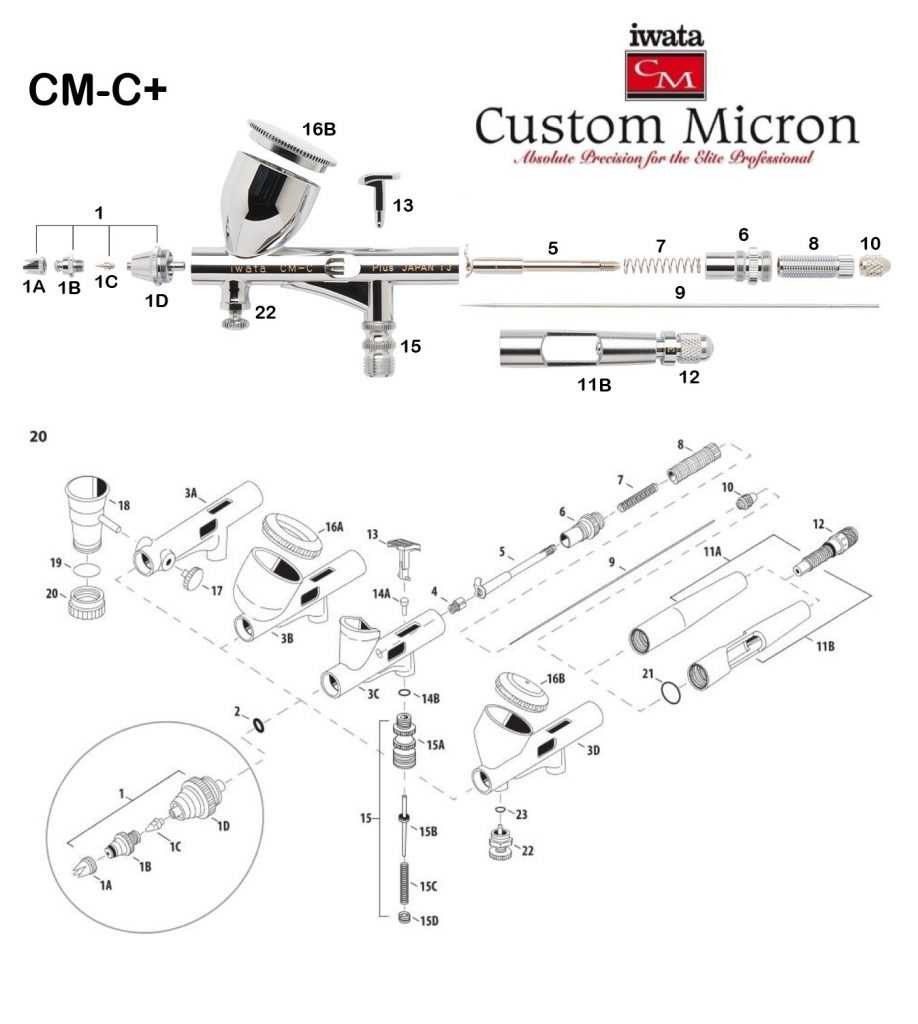

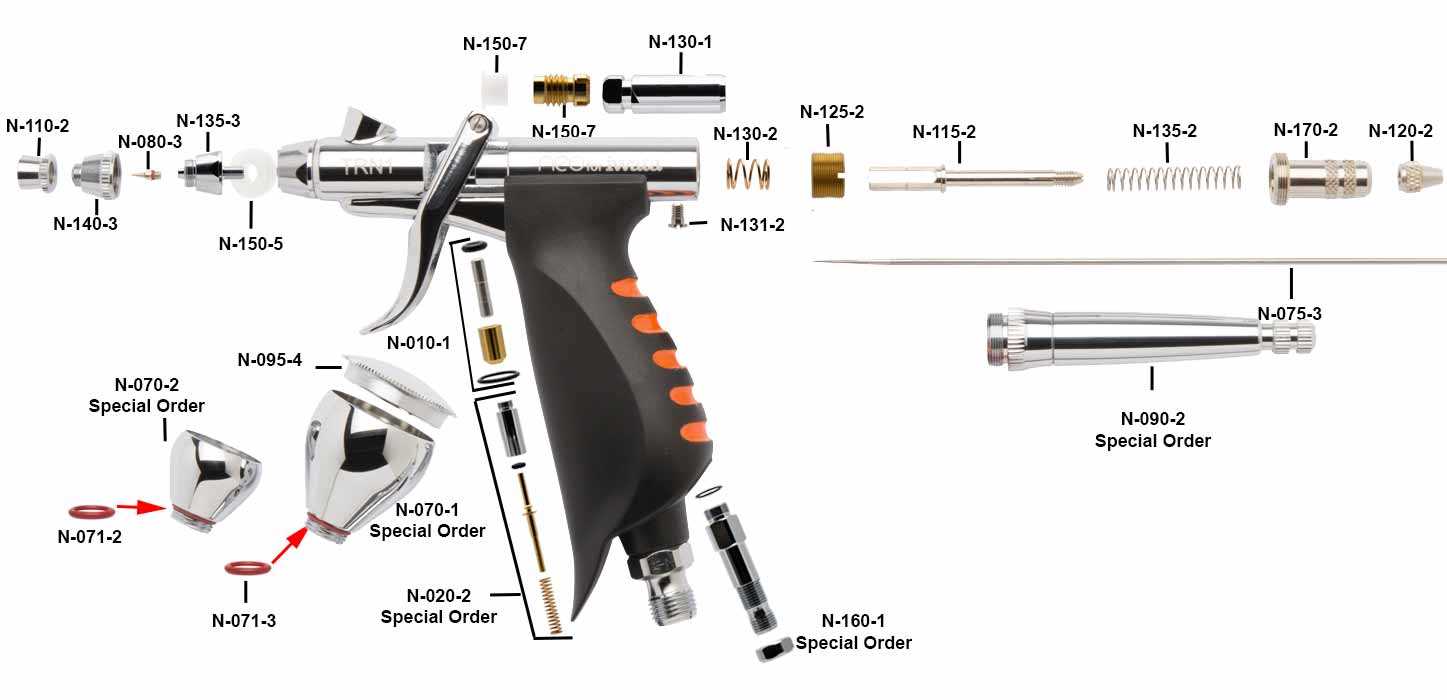

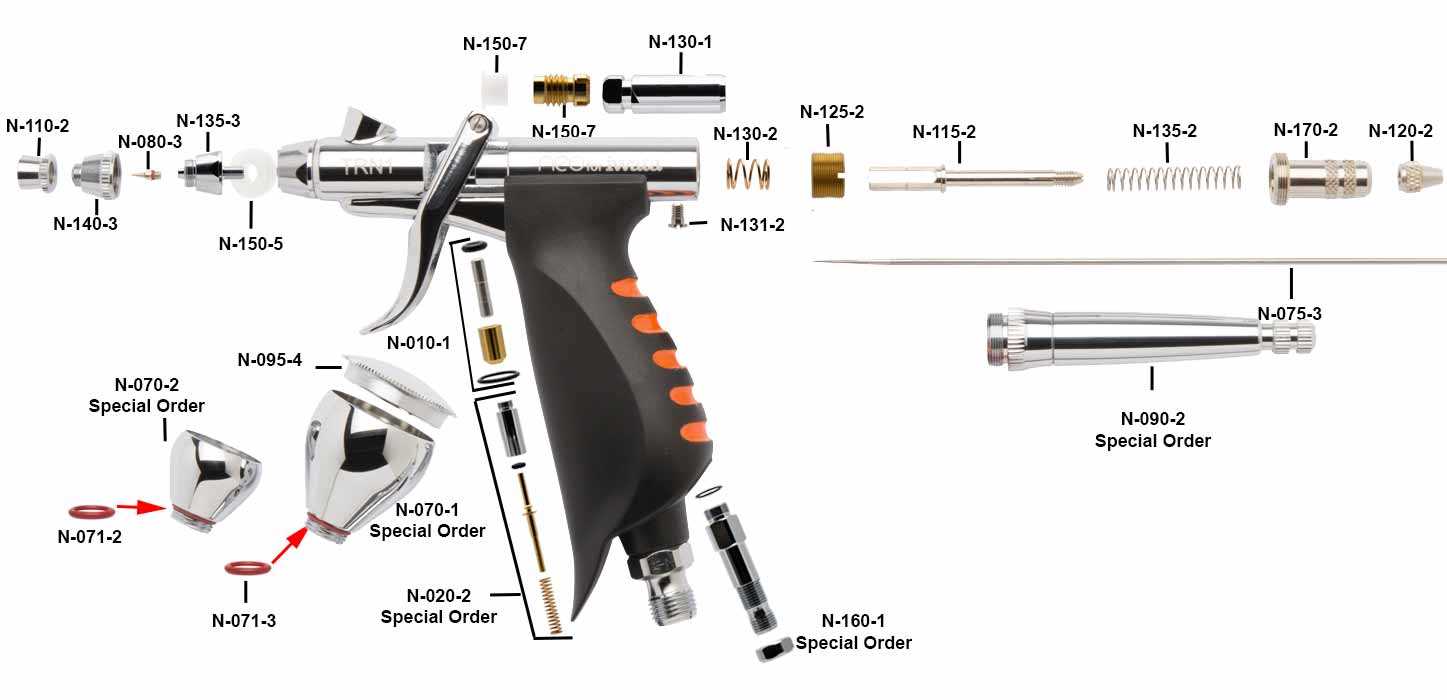

Iwata Neo Parts Diagram

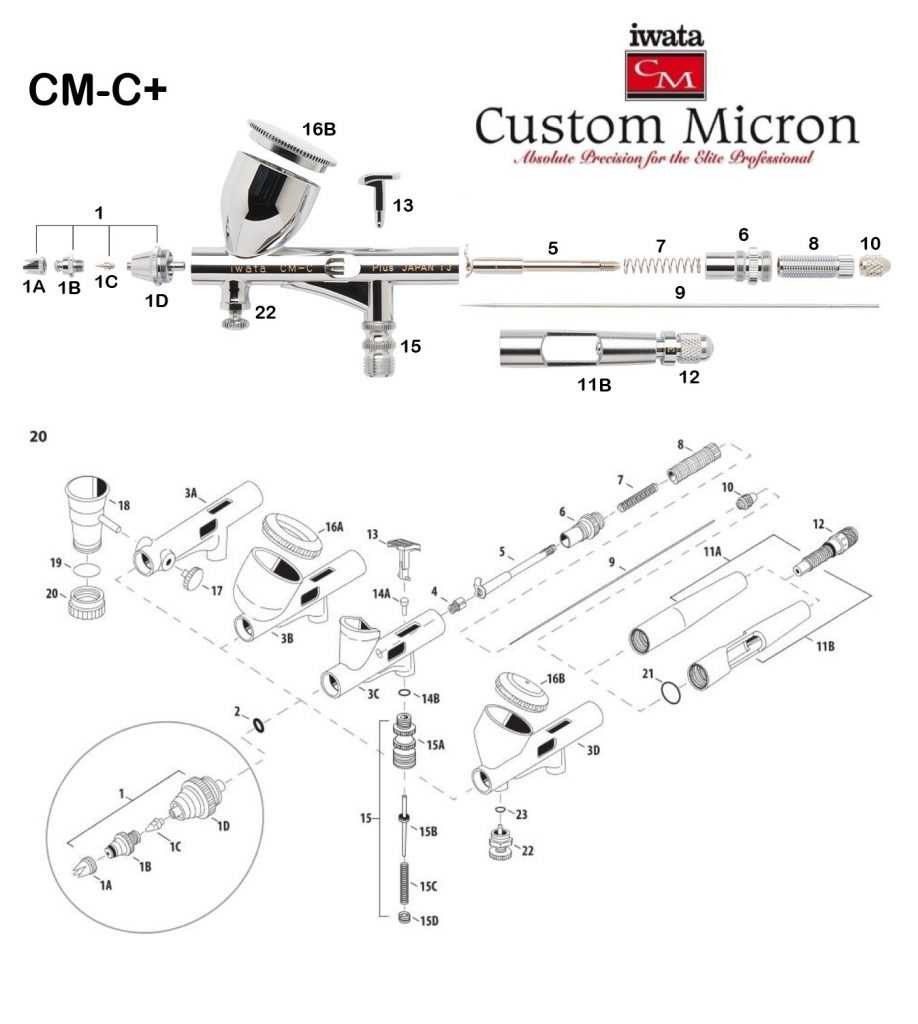

The breakdown of this airbrush system offers a clear view of its key components, making maintenance and understanding the structure easier. The illustration serves as a guide to identify different elements, ensuring smoother assembly and disassembly. Such clarity helps users maintain their equipment in optimal condition.

Key Components Overview

The system includes various essential parts that work together to deliver precision and control. Understanding the layout helps users replace elements when necessary and keep the equipment functioning correctly. Knowing how each element interacts can be crucial for consistent performance.

Detailed Structure and Functions

Each element within this setup has a specific role, contributing to the overall efficiency and effectiveness of the tool. The diagram aids in recognizing how the different elements fit together, providing a visual representation of their placement and purpose. This knowledge is especially useful for troubleshooting or upgrading individual elements.

Understanding the Iwata Neo Components

The core elements of this airbrush system consist of various pieces that work together to ensure smooth and efficient performance. Each element has a specific role, contributing to the precise control and effective spray patterns.

- Main Body: The foundation of the tool, where the internal mechanisms are housed. It provides a sturdy framework that supports all other elements.

- Nozzle System: This critical piece determines the flow and consistency of the spray. It is designed to handle different viscosity levels and enables adjustments for fine detail work.

- Trigger Mechanism: The control element that regulates airflow and paint release. Its responsiveness directly affects the user’s ability to manage the spray output.

- Paint Reservoir: Positioned at the top, this chamber holds the liquid medium. Its design allows for efficient feeding into the internal channels, ensuring a continuous flow.

- Air Valve: This component manages the air pressure entering the device, which is essential for maintaining steady and balanced output.

Each piece must function in harmony to achieve optimal results. Proper maintenance and understanding of these elements help ensure a longer lifespan

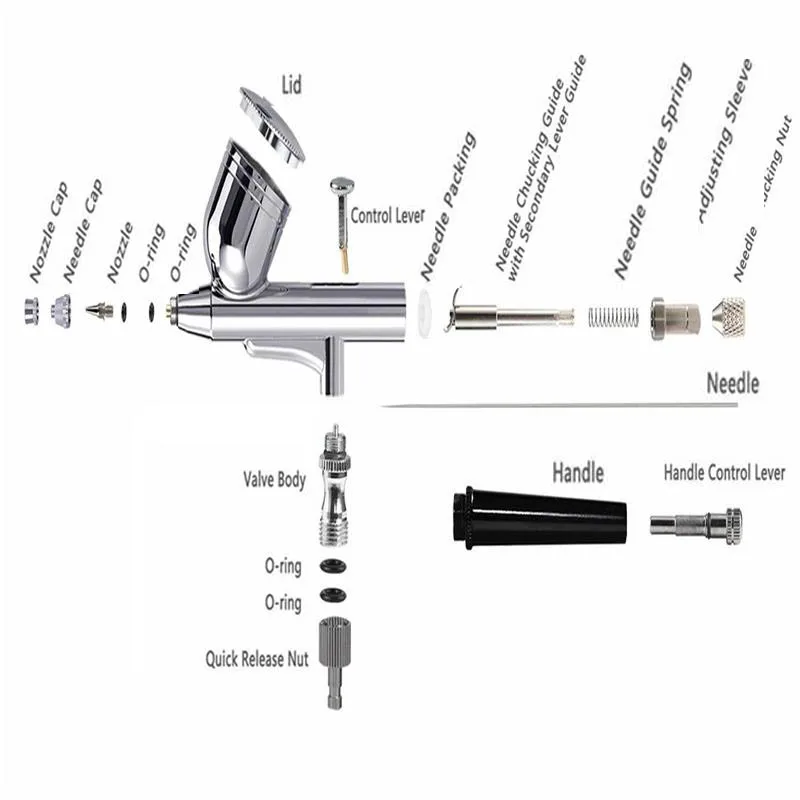

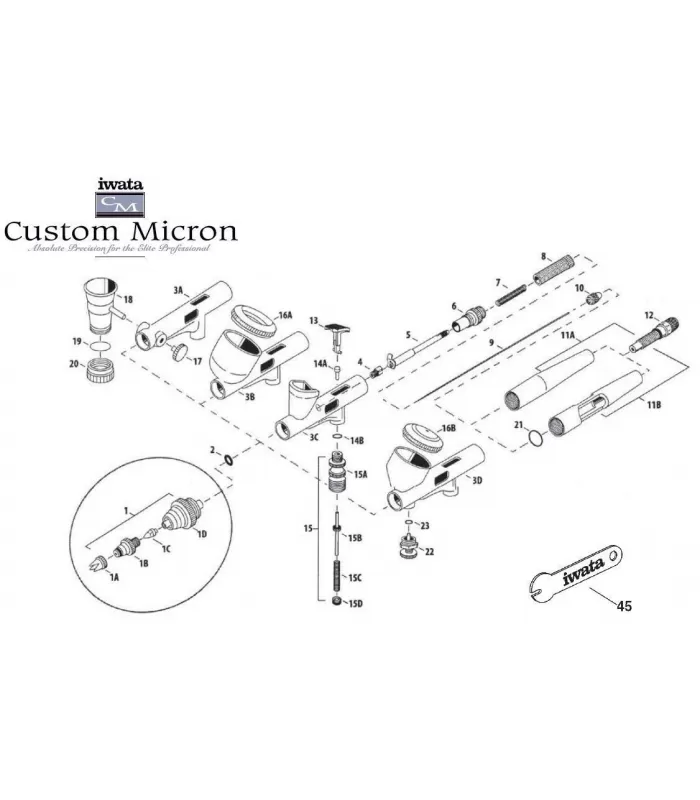

Detailed Breakdown of Airbrush Components

Understanding the different elements of an airbrush can significantly improve its use and maintenance. Each part plays a crucial role in ensuring a smooth flow and precise application. Knowing the function and structure of these elements allows for better upkeep and troubleshooting, ensuring optimal performance over time.

Main Body Structure

The primary section of the airbrush holds all critical elements together, providing stability and control. It houses the internal mechanisms that regulate airflow and paint mixing, creating a balanced output. This area often includes a trigger mechanism, allowing the user to adjust the flow of air and liquid with precision.

Nozzle and Needle Mechanics

The nozzle and needle work in harmony to control the release of the medium. The needle adjusts the opening of the nozzle, impacting the amount of material released during operation. Proper alignment of these elements is key to achieving a fine spray pattern and smooth transitions.

| Component |

Description |

Purpose |

| Trigger |

A lever that controls airflow and material release. |

Adjusts spray intensity and flow rate. |

Key Elements of the Iwata Neo

The device is designed with precision and efficiency, providing users with an intuitive and smooth experience. Its components work in harmony to ensure reliable operation, allowing for detailed and accurate performance. This section highlights the essential aspects that contribute to its functionality, offering a closer look at the structure and design.

Main Functional Components

- Nozzle System: The small, precision-crafted nozzle ensures a fine and consistent flow, making it suitable for detailed tasks.

- Fluid Cup: The top-mounted reservoir is easy to access and clean, enabling a seamless transition between different tasks.

- Trigger Mechanism: The responsive trigger allows for precise control over the flow, offering users an enhanced level of accuracy during use.

Supportive Structural Features

- Ergonomic Handle: A comfortable grip ensures prolonged use without fatigue, designed to fit naturally in the user’s hand.

- Adjustable Settings: The customizable settings allow users to fine-tune the flow an

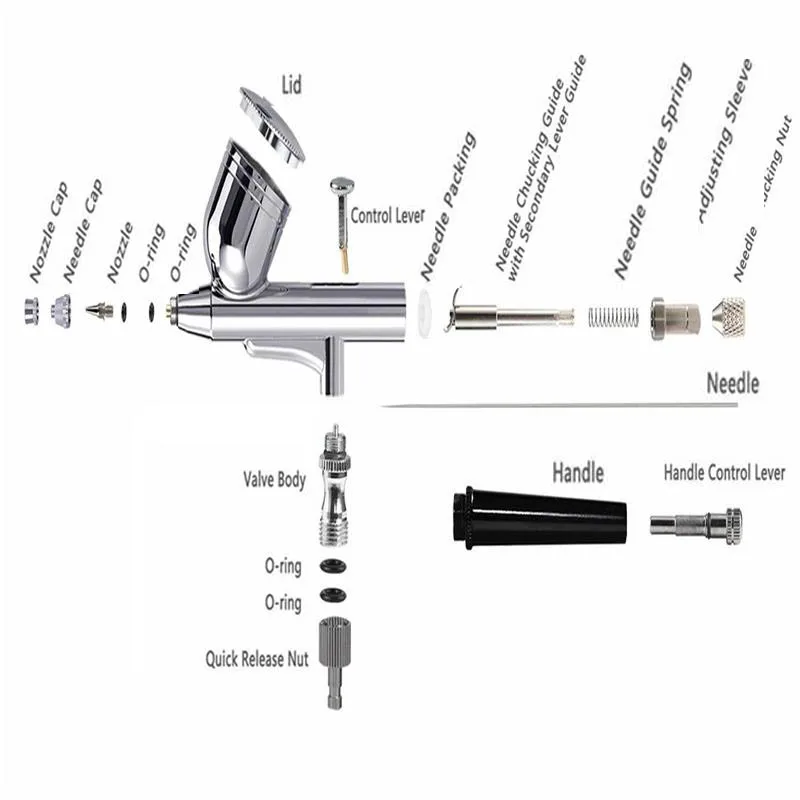

How to Identify Airbrush Components

Recognizing the different elements of an airbrush is essential for proper use and maintenance. Each piece plays a specific role, ensuring smooth performance and precise results. Understanding these components helps in troubleshooting and maintaining the device.

- Nozzle: This small element controls the flow and atomization of the paint, ensuring a fine and even spray pattern.

- Needle: Positioned inside the body, this part moves back and forth, regulating the flow of paint as the trigger is pressed.

- Trigger: A vital control mechanism that allows you to manage the air and paint mixture, adjusting the output with varying pressure.

- Air Cap: Surrounds the nozzle and directs airflow, aiding in the atomization process for smooth application.

- Fluid Cup: A container that holds the paint or medium, allowing easy refills during use.

- Body: The central part where all other elements are assembled, providing stability and housing internal mechanisms.

- Air Valve: Regulates the flow of air into the tool, crucial for achieving the

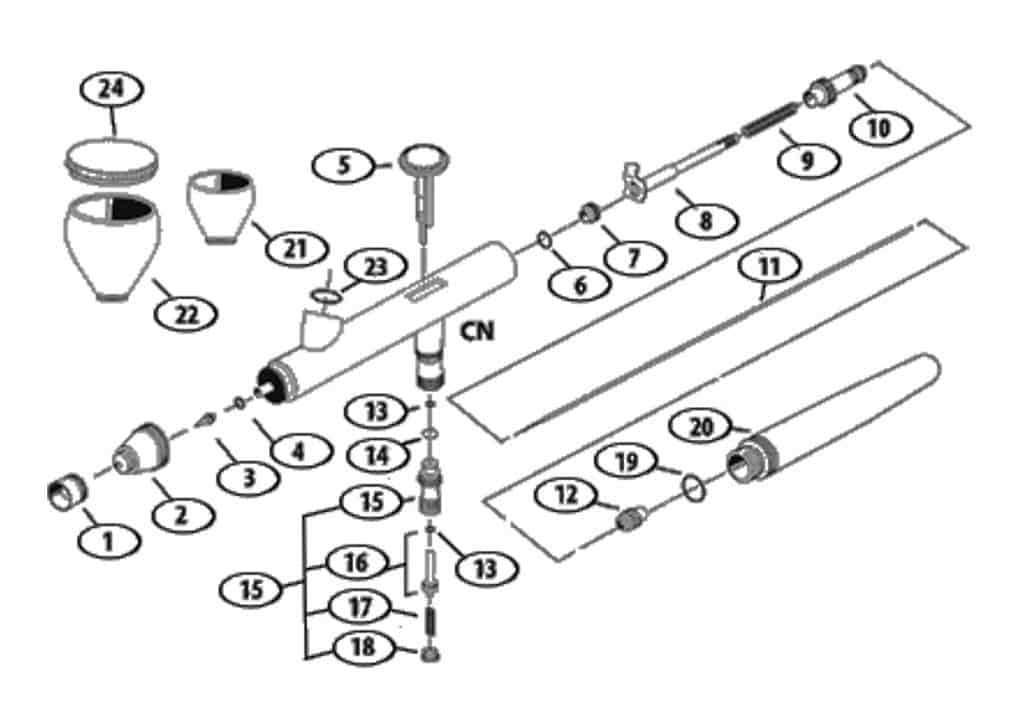

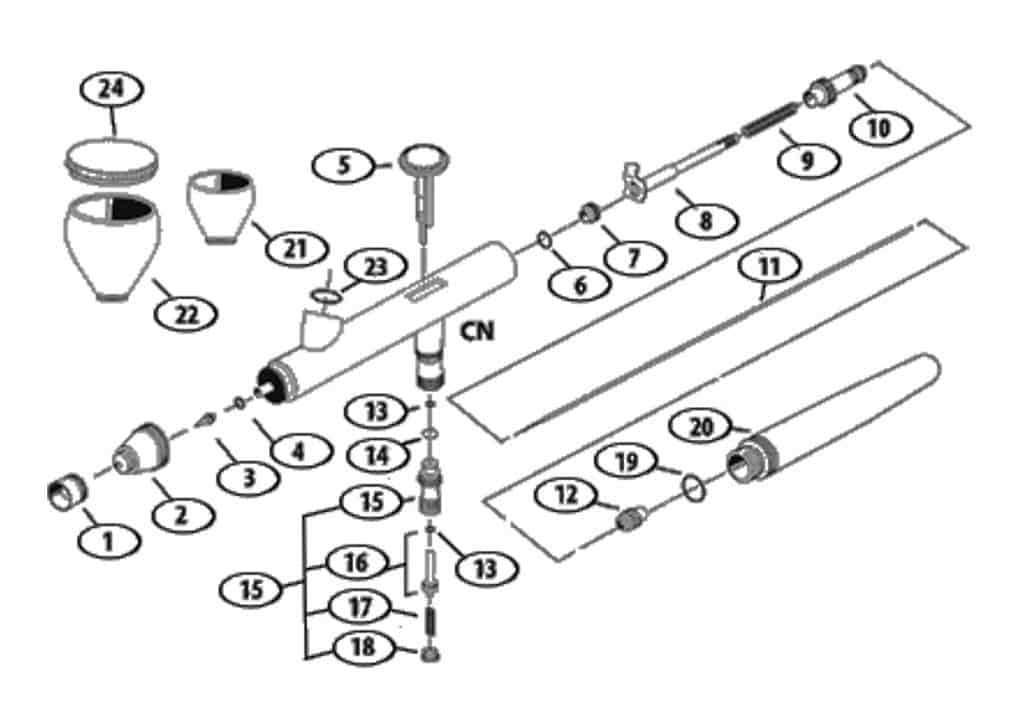

Exploring Internal Mechanisms of Iwata Neo

The intricate workings of this device reveal a carefully designed system that ensures optimal functionality. By examining its structure, one can appreciate how each component contributes to the overall performance, offering smooth operation and precise results. This understanding is crucial for those looking to maintain and optimize the device’s capabilities over time.

Key Functional Elements

The internal system includes various interconnected elements that control airflow, pressure, and fluid delivery. Each part is designed to seamlessly integrate with others, ensuring consistent and efficient performance. The design prioritizes durability, allowing for reliable use in diverse settings.

Maintaining Internal Efficiency

Proper maintenance of these mechanisms is essential for preserving their functionality. Regular checks and cleaning help prevent blockages and ensure smooth flow throughout the system. Understanding these components and their roles can aid users in keeping their device in peak condition for longer periods.

Common Parts in Airbrush Assembly

The components of an airbrush are designed to work together seamlessly, ensuring smooth and precise paint flow. Understanding these elements is crucial for maintaining the device’s performance and ensuring consistent results during use. Each piece plays a role in controlling airflow and paint release, contributing to the overall functionality of the airbrush.

Main Elements of the Airflow System

The air system includes components that regulate and direct air through the airbrush. This system often consists of mechanisms like adjustable valves, which allow for fine-tuning of airflow, and connectors that ensure a secure attachment to the compressor. These elements ensure that air pressure is consistently maintained for optimal spraying performance.

Key Components for Paint Flow

Managing the flow of paint requires precision, which is made possible by specific parts. This includes the nozzle, a crucial element that shapes the paint stream, and the needle, which adjusts the paint volume. These parts work together to ensure that the paint is delivered evenly, allowing for detailed work and smooth finishes. Regular care of these elements helps maintain accuracy and performance over time.

Maintenance Tips for Airbrush Components

Regular upkeep of your airbrush equipment is essential for maintaining optimal performance and ensuring longevity. With the right techniques and a few simple steps, you can keep the components working smoothly and efficiently. This guide provides key recommendations for keeping your device in top condition.

Regular Cleaning Routine

Consistent cleaning is crucial to prevent buildup and maintain smooth operation. It helps in removing residual materials that can affect the performance. To make the process effective, follow these steps:

- Rinse the equipment with appropriate solutions after each use.

- Disassemble the parts carefully for a thorough clean.

- Use soft brushes to remove any stubborn particles.

Lubrication and Inspection

Proper lubrication minimizes friction between moving elements, enhancing the lifespan of the airbrush. Inspect all connections to ensure that they are tightly secured and undamaged. Pay attention to these points during your maintenance routine:

- Apply a few drops of lubricant on the moving joints.

- Check for any signs of wear or damage and replace worn-out pieces.

- Ensure all seals are intact to avoid air leaks.

By following

Replacing and Upgrading Airbrush Components

Maintaining optimal performance in your airbrush involves periodically replacing and enhancing various elements. These upgrades can significantly improve functionality and extend the tool’s lifespan, ensuring a seamless application of materials. Understanding which components to modify and how to execute these changes is crucial for achieving the desired results in your projects.

Common parts that often require attention include the nozzle, needle, and trigger mechanism. Each of these components plays a vital role in the overall operation of the airbrush. Below is a table outlining typical upgrades and their benefits:

| Component |

Upgrade Option |

Benefits |

| Nozzle |

Replace with a finer or wider option |

Enhances precision and control over paint flow |

| Needle |

Upgrade to a more durable material |

Increases longevity and reduces wear |

| Trigger |

Install an ergonomic trigger |

Improves comfort and reduces fatigue during use |

By carefully selecting which elements to replace and upgrade, users can enhance the performance of their airbrush, resulting in more efficient and satisfying artistic endeavors.