The key to achieving a flawless finish lies in the precise interaction of various elements within a professional coating device. Each component plays a vital role in ensuring smooth application and consistent results. Understanding how these individual parts function together is essential for both maintenance and performance optimization.

Every tool is made up of interconnected parts that influence its overall efficiency. Recognizing the function of each segment can help users troubleshoot issues, ensure proper assembly, and maximize the tool’s lifespan. From the primary chamber to the nozzle, every detail contributes to the quality of work.

Mastering the anatomy of such a device offers advantages in both professional settings and DIY projects. By familiarizing yourself with the device’s internal structure, you can better control the flow, pressure, and application technique, all of which are crucial for achieving the desired finish.

Understanding HVLP Spray Gun Components

Efficient application tools consist of various crucial elements that work together to deliver precise finishes. These key components ensure that the material is applied evenly and accurately, offering control over the flow, pressure, and atomization process. Each element plays a vital role in the overall functionality, and understanding their interaction is essential for effective operation and maintenance.

The central feature of these devices is the mechanism that regulates the flow of fluid, allowing the user to adjust the consistency and coverage. This control is essential for achieving desired results, whether it’s a smooth coat or a textured finish. Additionally, air circulation plays a significant role in how the liquid is dispersed, and the nozzle or tip ensures that the material is evenly atomized, preventing clumps or uneven spraying.

Other vital elements include the body and trigger, which offer ergonomic control and responsiveness, and the internal channels that direct the air and fluid. Together, these parts contribute to the efficiency and longevity of the tool, allowing for precise, consistent application with minimal waste.

Key Parts of an HVLP Spray Gun

Understanding the essential components of a high-efficiency airbrush is crucial for achieving the desired precision and smooth application. These tools rely on a combination of intricate elements working in tandem to ensure optimal performance, whether it’s for painting, coating, or other similar tasks. Each element plays a distinct role, from controlling the airflow to managing the fluid dispersion, and mastering them can elevate the quality of the final result.

The Air Control Mechanism

The airflow control is fundamental in regulating the pressure and speed at which materials are applied. This component ensures that the right amount of air is directed through the nozzle, giving the operator flexibility in terms of the finish quality. Without precise control over the air, it would be challenging to achieve the fine details or consistent coverage required for many tasks.

Fluid Delivery System

The fluid delivery system manages the material feed, allowing for a steady and adjustable flow. This part is essential for ensuring that the right amount of material is dispensed at the correct pressure, influencing both the thickness and consistency of the application. Proper adjustment here is crucial for avoiding issues such as uneven layers or excessive splattering.

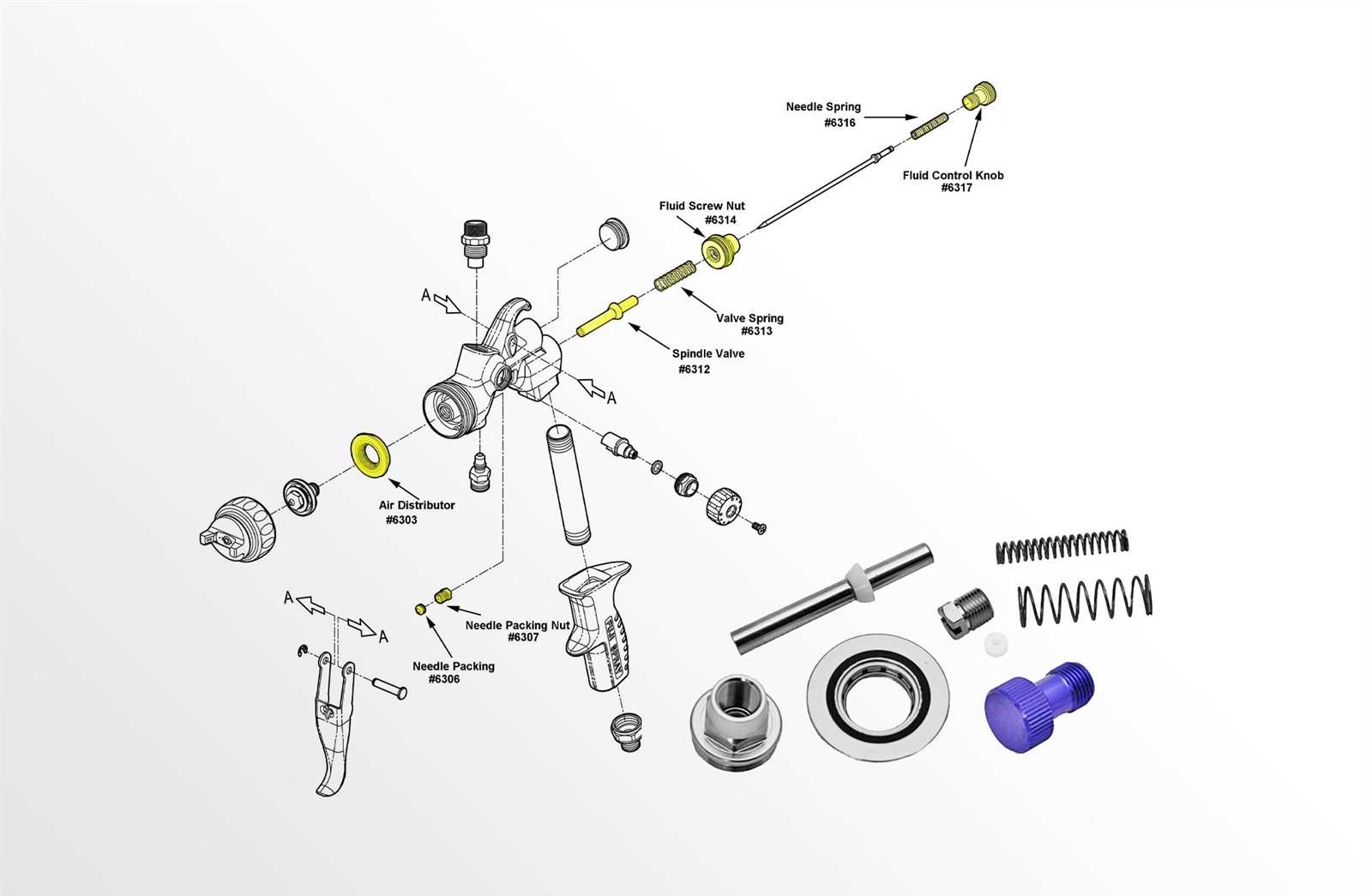

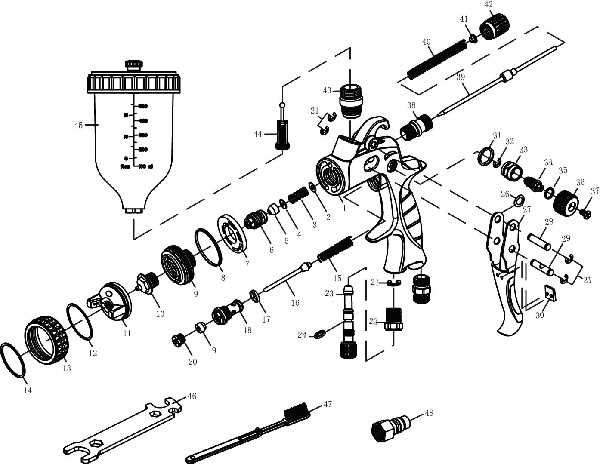

How to Read a Spray Gun Diagram

Understanding the structure of a coating tool is essential for its effective usage and maintenance. The technical drawings provide detailed insight into the internal mechanisms, making it easier to assemble, disassemble, and troubleshoot. By carefully analyzing the blueprint, you can identify each individual component and its function within the tool.

To interpret these illustrations correctly, follow these key steps:

- Identify Key Components: Focus on the main elements, such as the trigger, fluid nozzles, and air passages. These parts are crucial for the tool’s functionality.

- Understand the Flow: Diagrams usually indicate the flow of material and air, helping you understand how each part interacts during operation.

- Pay Attention to Symbols: Different symbols represent specific functions or assembly points. Familiarizing yourself with these symbols is important for proper comprehension.

- Check the Assembly Sequence: A good diagram will show how the parts fit together, often in a step-by-step process, ensuring proper reassembly and maintenance.

By following these guidelines, you can gain a clear understanding of how the device operates and maintain it with confidence.

Common Problems in HVLP Spray Guns

When working with painting tools designed for high-volume, low-pressure applications, several issues can arise that affect performance. These challenges may stem from various factors, including blockages, wear and tear, or improper adjustments. Recognizing and addressing these issues is crucial to ensuring consistent results and avoiding delays in the finishing process.

One frequent problem is inconsistent flow, which can lead to uneven coverage. This may be due to a clogged nozzle or improper air pressure settings. Another issue is paint spitting or dripping, often caused by air leaks or incorrect viscosity of the material. Additionally, the tool may exhibit a poor spray pattern, which can result from faulty components or improper maintenance.

Maintaining Your HVLP Spray Gun

Regular upkeep is essential for the longevity and optimal performance of your painting equipment. Proper maintenance ensures smooth operation, precise coating, and extends the lifespan of the device. Focusing on cleaning, lubrication, and inspection helps avoid costly repairs and ensures consistently high-quality results.

Cleaning your equipment after each use is critical. Residual material left behind can clog the system, causing uneven application and damage over time. Make sure to thoroughly rinse all internal components and remove any debris or dried particles. Use appropriate cleaning agents to prevent corrosion or wear.

Lubrication should be performed periodically to ensure moving parts operate smoothly. This reduces friction, preventing unnecessary wear and tear. Be cautious to use the right type of lubricant that won’t negatively affect your equipment’s materials or performance.

Inspection of all components is essential to spot potential issues early. Regularly check for signs of wear, cracks, or leaks. Keeping an eye on these small details can help you identify problems before they become more serious and costly.

Differences Between HVLP and Conventional Guns

The main distinction between modern low-pressure systems and traditional high-pressure models lies in the way they handle airflow and material transfer. These systems serve similar purposes, but their efficiency and technique differ significantly, affecting the final results and the overall performance.

Airflow and Transfer Efficiency

In terms of airflow, low-pressure systems use a more controlled and steady approach, which helps reduce waste and allows for a finer finish. In contrast, older high-pressure models are known for faster material application but tend to result in more overspray and less precise coating.

Application Techniques and Usability

Low-pressure technology offers improved control over the amount of material applied, making it easier for users to achieve a smooth finish with fewer errors. On the other hand, conventional high-pressure tools require more skill and experience to handle due to the faster material release, which can lead to uneven layers if not managed properly.

Choosing the Right Nozzle for Your Gun

Selecting the correct nozzle is essential for achieving smooth and even coating. The size and shape of the nozzle play a crucial role in how the material is distributed, ensuring optimal coverage and minimizing overspray. The right choice will depend on the material you are using and the type of surface you’re working on.

Understanding Nozzle Sizes

Nozzles come in various sizes, each designed to handle different types of materials. Thicker materials like latex or heavy paints require larger nozzles, while smaller nozzles are ideal for finer finishes and thinner substances.

- Large nozzles: Best for high-viscosity materials, ensuring smooth application without clogging.

- Medium nozzles: Suitable for versatile use, balancing between heavy and light materials.

- Small nozzles: Perfect for detailed work, providing precision and control with thinner coatings.

Matching the Nozzle to the Material

Each material behaves differently when applied

Spray Gun Parts and Their Functions

Understanding the various components of a modern coating device is crucial for efficient and precise painting. Each element plays a unique role in ensuring smooth and even distribution of the liquid medium. Mastering these components allows for better control and performance, whether you’re tackling large surfaces or intricate details.

Air Cap: The air cap directs airflow around the material, shaping the pattern and helping regulate the atomization process. A well-maintained air cap ensures consistency in the application.

Fluid Nozzle: This element controls the flow of the material. The size of the nozzle affects the thickness of the application, allowing users to adjust based on the task’s specific needs.

Needle Valve: This valve works in conjunction with the fluid nozzle to control the release of material. It helps prevent dripping and ensures a clean start and stop during application.

Trigger: The trigger activates the flow of both air and material, providing the user

Upgrading and Customizing Your Spray Gun

Enhancing the performance of your painting tool allows for better precision and adaptability to various tasks. By making thoughtful adjustments and additions, you can significantly improve the overall efficiency and quality of your work. Customizing these tools to fit your specific needs opens up possibilities for professional results.

Adjustable Nozzles for Precision

One of the simplest ways to improve your painting device is by selecting adjustable nozzles. These allow for better control of paint flow, ensuring even application on surfaces. Nozzles can vary in size and pattern, giving you the freedom to fine-tune your approach based on the project’s requirements.

- Choose between different nozzle sizes for varied textures.

- Opt for interchangeable heads for more versatility.

- Consider high-quality materials for durability.

Fine-Tuning Airflow and Pressure

Controlling the airflow and pressure of your device is essential for smooth application. Many tools come with adjustable controls, but upgrading them with more advanced regulators can offer better precision. This allows for consistency across different materials and surfaces.

- Install a pressure gauge for accurate monitoring.

- Add an airflow regulator for consistent performance.

- Fine-tune settings to match your material type.