In the realm of machinery and engineering, a thorough comprehension of the intricate elements that facilitate movement is essential. These devices operate by converting energy into mechanical force, enabling a wide range of applications from industrial machinery to everyday tools. Each component plays a crucial role in ensuring efficiency and reliability.

Delving into the architecture of these systems reveals a network of interconnected elements, each designed for specific functions. Understanding how these various components interact allows for better maintenance, troubleshooting, and innovation. Recognizing the significance of each element contributes to a deeper appreciation of the technology that drives many modern applications.

Exploring the specific roles and configurations of these essential components not only aids in operational efficiency but also enhances safety and performance. By analyzing the arrangements and functions, one can gain valuable insights into optimizing these systems for various industrial and practical uses.

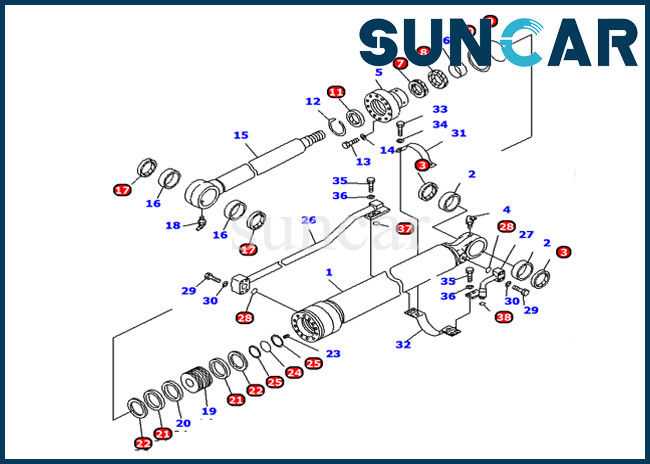

Key Components of Hydraulic Cylinders

Understanding the essential elements that enable a system to function efficiently is crucial for any mechanical operation. These components work in harmony to provide movement and force, making them indispensable in various applications.

Piston is the central element that transforms fluid pressure into linear motion. Its movement is what generates the necessary force to drive machinery.

Rod connects the piston to the external environment, allowing the motion produced within to be translated into practical work. Its durability is vital for sustaining operational effectiveness.

Chamber houses the fluid and piston, creating the necessary environment for pressure changes. The design and integrity of this component are essential for optimal performance.

Seals are critical for preventing leaks, maintaining pressure, and ensuring that the internal components operate smoothly. They must withstand various conditions while providing a reliable barrier.

End caps secure the assembly and support the connection to other parts of the system, ensuring stability and alignment during operation. Their robustness is key to the overall durability of the mechanism.

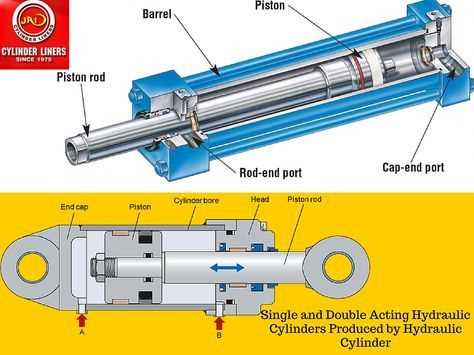

Understanding Hydraulic Cylinder Functionality

In the realm of machinery, the devices that convert fluid pressure into mechanical force play a crucial role in various applications. Their operation hinges on a carefully orchestrated interplay between different elements, each designed to perform a specific task. By examining how these systems work, one can appreciate their efficiency and versatility in numerous industries.

Components and Their Roles

At the core of this mechanism lies a chamber filled with fluid. As pressure is applied, it causes a movable element to shift, generating motion. This movement can be linear or rotational, depending on the configuration and intended use. Each component within the assembly contributes to the overall functionality, from seals that prevent leakage to connectors that facilitate integration with other systems.

Applications and Benefits

These devices find utility in a wide range of fields, including construction, manufacturing, and automotive sectors. Their ability to deliver substantial force while maintaining compact sizes makes them invaluable for tasks that require precision and reliability. Additionally, their operation can be easily controlled, allowing for smooth adjustments and enhanced productivity.

Common Materials Used in Cylinder Construction

When designing and manufacturing systems that rely on fluid pressure to perform mechanical tasks, the choice of materials is crucial for ensuring longevity, reliability, and efficiency. Various components involved in these mechanisms must withstand high pressure, wear, and corrosion while maintaining structural integrity under challenging operating conditions. The selection of the right materials ensures optimal performance and durability over time.

Steel is one of the most commonly used materials for constructing the main housing and moving components. Its excellent strength and durability allow it to withstand high stress and pressure without significant deformation. Additionally, steel can be alloyed with other elements to improve specific properties like corrosion resistance or fatigue strength.

Aluminum is another popular choice, particularly for systems that require lighter weight. It provides a good balance of strength and weight reduction while still maintaining resistance to corrosion. Aluminum is often used in applications where reduced mass is a priority, without compromising on mechanical performance.

For sealing components, such as rings and gaskets, elastomers like nitrile, neoprene, or polyurethane are frequently used. These materials offer exceptional resistance to wear, pressure, and chemical degradation, ensuring a secure seal and minimizing leakage in the system.

Bronze and brass are also utilized for their excellent corrosion resistance, especially in components exposed to moisture and chemicals. These materials are particularly useful in components that require good machinability along with resistance to wear and oxidation.

Finally, stainless steel is often selected for components that will be exposed to harsh environments or extreme temperatures. Its inherent resistance to rust and corrosion makes it ideal for applications where long-term reliability is essential, especially in offshore or marine settings.

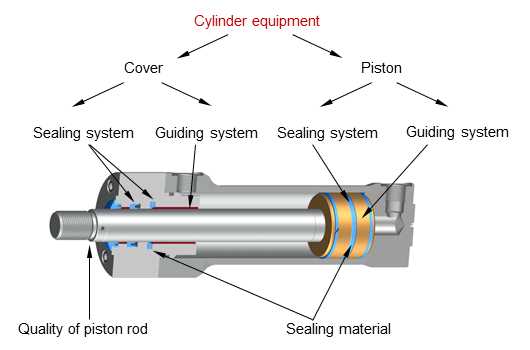

Seals and Their Importance in Performance

Seals play a critical role in ensuring the efficiency and reliability of mechanical systems that involve pressurized fluid movements. These components are designed to prevent leakage, protect against contaminants, and maintain internal pressure. Their function is essential in preventing damage to internal elements while ensuring smooth and uninterrupted operation.

Without proper sealing, the entire system can suffer from reduced performance, increased wear, and even catastrophic failure. The right material, design, and installation of seals can significantly enhance the durability and longevity of the equipment. Effective seals contribute to energy efficiency by minimizing energy loss through leaks and maintaining optimal fluid levels within the system.

Additionally, seals protect other critical elements from exposure to harmful particles and debris that could lead to abrasive wear. By minimizing these risks, seals help in maintaining a consistent performance level and reducing maintenance costs. In summary, seals are integral to ensuring the system operates at peak efficiency and remains reliable over time.

How the Piston Works in a Hydraulic System

The functioning of a key component in pressurized fluid systems is essential for converting energy into mechanical movement. This element plays a pivotal role in creating force and motion through the controlled flow of liquid. Understanding its operation reveals the intricacies of these systems and their applications in various industries.

At its core, the mechanism involves several critical processes:

- Pressure Application: The process begins when pressurized fluid enters the chamber, exerting force on the surface of the component.

- Movement Generation: As the fluid pressure increases, the component moves linearly, transforming fluid energy into mechanical energy.

- Force Transmission: This linear movement is harnessed to perform work, such as lifting heavy objects or pushing components in machinery.

- Return Cycle: Once the pressure is released, the component returns to its original position, often aided by springs or gravity, preparing for the next cycle.

Key factors influencing the operation include:

- Fluid Characteristics: The type and viscosity of the fluid can significantly impact efficiency and responsiveness.

- Sealing Mechanisms: Proper seals are crucial to prevent leaks and ensure optimal performance.

- Chamber Design: The shape and size of the chamber determine the force generated and the speed of movement.

In summary, the functionality of this component is central to the effective operation of pressurized systems, allowing for controlled and efficient mechanical movements in a variety of applications.

The Role of Rods in Cylinder Efficiency

In any system where force transmission and motion are essential, the role of the connecting elements is critical to maintaining smooth operation and optimal performance. One such element, the rod, plays a pivotal role in transferring power between moving components, ensuring that energy is effectively utilized. Its design, material quality, and precise fit can have a significant impact on the overall efficiency of the mechanism.

The rod’s primary function is to convert pressure energy into mechanical motion, which directly influences how smoothly and reliably the system performs. A well-designed rod contributes to minimizing friction and wear, which can lead to longer operational life and reduced maintenance costs. On the other hand, a poorly designed or worn rod can increase resistance, cause misalignment, and decrease the overall productivity of the equipment.

Durability and strength are key factors in ensuring that the rod performs efficiently under high pressure and stress conditions. Materials like hardened steel are often used to enhance these properties, allowing the system to operate at higher capacities without compromising reliability. Furthermore, precise manufacturing and correct installation of the rod help to reduce the risk of internal leaks and energy loss.

In summary, the role of the rod is indispensable for ensuring smooth power transmission and maximizing the efficiency of the entire system. Proper attention to its design, material, and maintenance can prevent costly downtime and ensure that operations run at their full potential.

Essential Safety Features in Cylinder Design

When it comes to the design of these mechanisms, ensuring user safety is paramount. Effective safety features play a crucial role in minimizing risks associated with pressure and movement. Engineers must consider various elements that contribute to the overall security and reliability of the system.

Pressure Relief Systems

Pressure relief systems are vital for preventing dangerous over-pressurization. These mechanisms allow excess fluid to escape, maintaining safe operating levels and protecting against potential failures. Implementing these systems is essential for the longevity and dependability of the equipment.

Durable Materials

Utilizing durable materials ensures that the structure can withstand harsh conditions and prolonged use. High-quality materials reduce the likelihood of wear and tear, ultimately enhancing safety. Choosing the right composition is crucial for achieving optimal performance and reliability.

Assembly Techniques for Optimal Cylinder Performance

Achieving peak performance in any mechanical system relies heavily on meticulous assembly techniques. Proper integration of components ensures efficiency, longevity, and reliability. Understanding the nuances of each stage in the assembly process can significantly enhance operational capabilities and reduce the likelihood of failure.

Key Considerations During Assembly

When assembling components, several factors play a critical role. Precision in alignment, appropriate torque specifications, and the use of suitable materials contribute to the overall effectiveness of the mechanism. Each step must be executed with care to maintain the integrity of the assembly.

Recommended Techniques

| Technique | Description |

|---|---|

| Cleanliness | Ensuring all components are free of contaminants before assembly helps prevent operational issues. |

| Torque Management | Applying the correct torque to fasteners prevents damage and ensures secure connections. |

| Alignment Verification | Checking alignment during assembly avoids misfits and enhances functionality. |

| Material Selection | Choosing compatible materials for different components increases durability and performance. |

By adhering to these assembly techniques, operators can significantly improve the functionality and lifespan of the system, ultimately leading to greater satisfaction and reliability in operation.

Maintenance Tips for Long-lasting Hydraulics

Ensuring the durability and efficiency of fluid-powered systems is crucial for optimal performance. Regular care not only extends the lifespan of components but also enhances overall functionality. Implementing simple maintenance routines can prevent costly repairs and downtime.

Regular Inspection

Conduct frequent checks on seals, connections, and fluid levels. Look for leaks or wear that could indicate underlying issues. Addressing these problems early can save time and resources.

Fluid Quality

Utilize high-quality fluids and maintain proper filtration. Contaminants can lead to severe damage over time. Regularly replacing the fluid based on manufacturer recommendations will help maintain system integrity.