When it comes to maintaining outdoor machinery, a clear grasp of its internal structure is crucial. Each piece plays a vital role in ensuring optimal performance and longevity. Familiarity with these elements allows users to troubleshoot issues effectively and make informed decisions regarding repairs and replacements.

By examining a visual representation of these components, enthusiasts can easily identify the individual parts and their functions. This insight not only aids in routine maintenance but also enhances the overall efficiency of the equipment. Whether you are a novice or an experienced user, delving into the specifics can significantly enhance your understanding.

Ultimately, being well-acquainted with the configuration of your tools empowers you to tackle any challenges that may arise. A comprehensive view of the assembly ensures you are prepared for any task, allowing you to enjoy seamless operation in your outdoor activities.

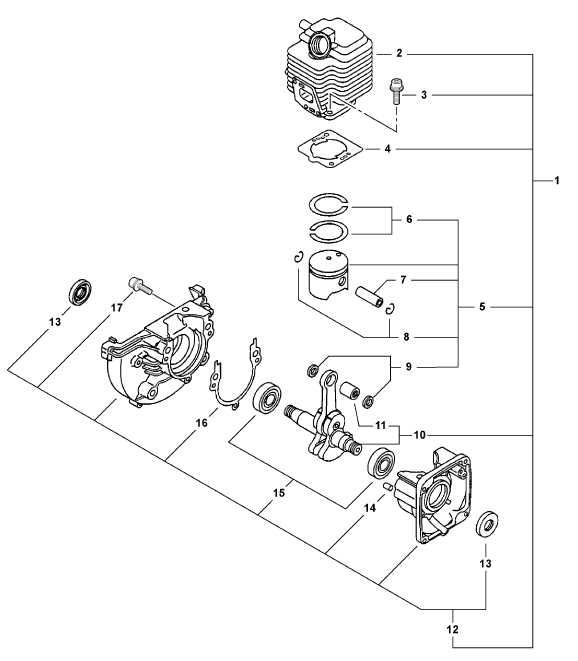

Understanding Echo GT-200R Components

Grasping the various elements that make up this gardening tool is essential for effective maintenance and optimal performance. Each component plays a crucial role in ensuring that the device operates smoothly, allowing users to achieve their desired results with minimal effort. By familiarizing oneself with these parts, one can enhance the longevity and functionality of the equipment.

Main Components

- Engine: The heart of the machine, responsible for powering the entire unit.

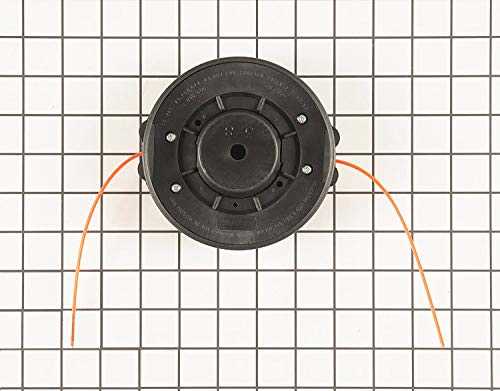

- Cutting Head: The part that performs the actual trimming, typically fitted with a specific type of blade or string.

- Fuel System: Includes the tank and lines, crucial for delivering the necessary fuel to the engine.

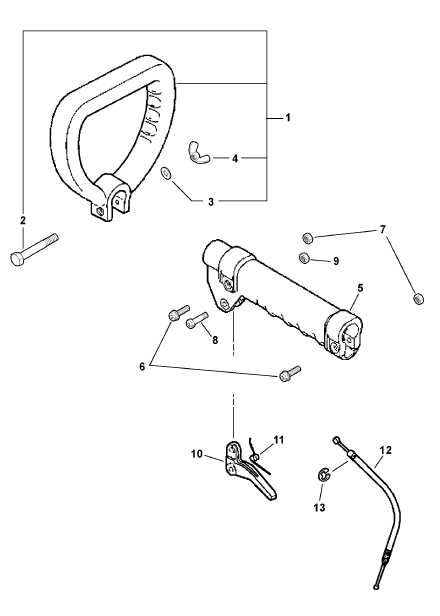

- Handle: Provides grip and control, essential for maneuvering the tool effectively.

- Starter Mechanism: Facilitates the ignition of the engine, ensuring reliable starting every time.

Maintenance Tips

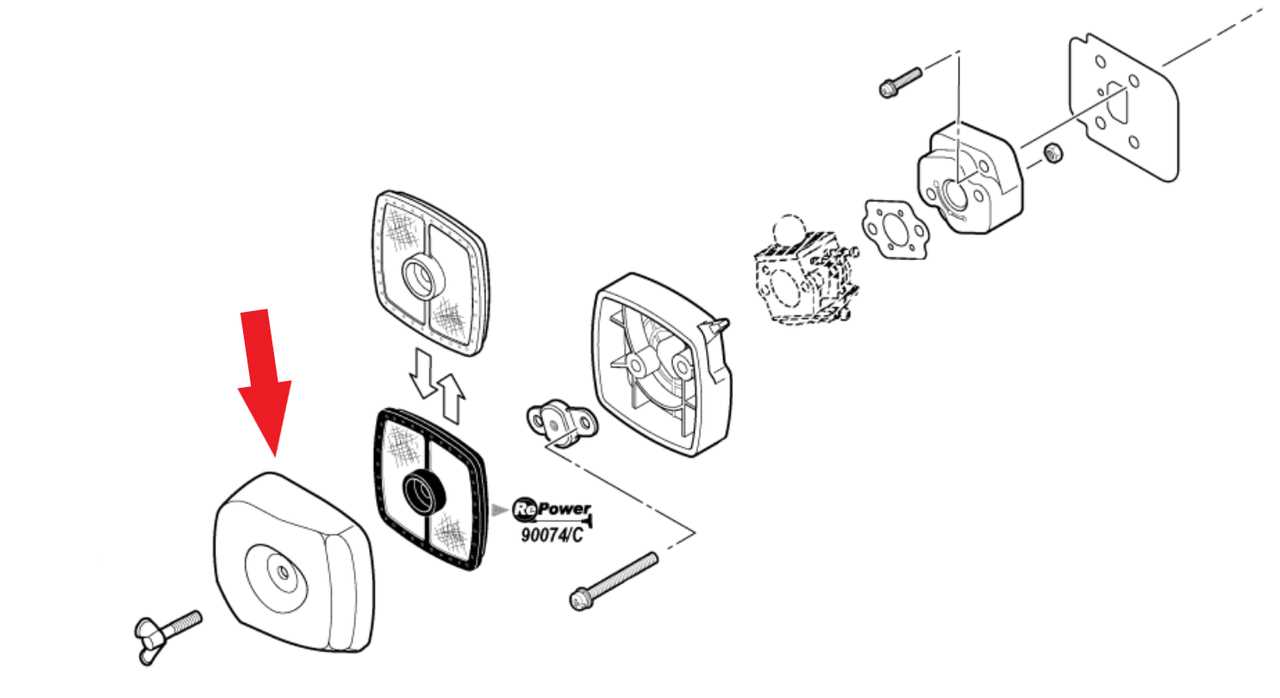

- Regularly check and clean the air filter to ensure proper airflow.

- Inspect the cutting head for wear and replace the string or blade as needed.

- Monitor fuel levels and ensure the fuel system is free of leaks.

- Keep the handle and grip clean for better control during use.

- Consult the manual for specific maintenance schedules and procedures.

Parts Diagram Overview

This section provides a comprehensive examination of the components essential for optimal performance of a particular model. Understanding the arrangement and function of these elements is crucial for effective maintenance and repair.

Understanding Component Layout

The arrangement of the various elements can significantly impact the overall functionality. By exploring how these parts interact, users can gain insights into troubleshooting and enhancing efficiency.

Importance of Familiarization

Familiarity with each component not only aids in identifying issues but also empowers users to perform necessary adjustments confidently. Recognizing the roles of individual elements enhances the ultimate understanding of the entire system.

Importance of Maintenance Parts

Regular upkeep of equipment is crucial for ensuring optimal performance and longevity. The components that facilitate this maintenance play a significant role in preserving functionality and efficiency. By replacing worn or damaged elements, users can avoid unexpected breakdowns and costly repairs, ultimately enhancing the reliability of their machinery.

Proper care through the timely replacement of essential components not only helps in maintaining the equipment’s performance but also contributes to safety. Malfunctioning machinery can pose serious risks, and having quality replacement items on hand reduces the likelihood of accidents. Additionally, proactive maintenance can lead to improved fuel efficiency and lower operational costs.

Investing in high-quality replacement elements ensures that equipment operates as intended, maximizing productivity. This approach fosters a better understanding of the machinery, allowing operators to identify potential issues early. Consequently, a well-maintained system can provide superior results, ensuring that users get the most out of their investment over time.

Identifying Key Components

Understanding the essential elements of any machinery is crucial for effective maintenance and repair. Each component plays a specific role, contributing to the overall functionality and performance of the device. By familiarizing oneself with these parts, users can troubleshoot issues more efficiently and ensure longevity in operation.

| Component Name | Function |

|---|---|

| Fuel Tank | Holds the fuel necessary for operation. |

| Air Filter | Prevents debris from entering the engine, ensuring clean airflow. |

| Ignition System | Ignites the fuel-air mixture, enabling the engine to start. |

| Starter Mechanism | Initiates the engine’s operation. |

| Exhaust System | Channels harmful gases away from the engine and operator. |

Common Issues with Echo GT-200R

Maintaining a garden tool can sometimes lead to unexpected challenges. Users often encounter a range of problems that can affect performance and reliability. Understanding these common issues can help in troubleshooting and ensuring optimal functionality.

- Starting Difficulties: One of the most frequent complaints is trouble starting the engine. This may be due to fuel issues, a clogged air filter, or spark plug problems.

- Power Loss: Users may notice a significant drop in power while operating the equipment. This can stem from a dirty carburetor or exhaust blockage.

- Excessive Vibration: If the tool shakes excessively during use, it might indicate that the cutting head is unbalanced or that the engine mount is damaged.

- Fuel Leaks: Leaking fuel can pose safety risks and affect performance. Check for damaged fuel lines or loose connections.

- Overheating: If the engine runs too hot, it may lead to permanent damage. Insufficient cooling, blocked vents, or low oil levels are common culprits.

Addressing these issues promptly can prolong the life of your gardening tool and enhance its efficiency. Regular maintenance and checks can help prevent many of these problems from occurring.

Where to Find Replacement Parts

Locating suitable components for your equipment can be essential for maintaining its performance and longevity. Whether you need a new handle, a filter, or a specific mechanism, there are several reliable sources to consider. Understanding where to search can save you time and ensure you obtain quality replacements.

Online retailers often provide a vast selection of components, making it easy to compare options and prices. Websites specializing in outdoor power tools typically have extensive catalogs. Manufacturer websites may also offer direct purchasing options, ensuring you receive genuine products tailored to your model.

Local hardware stores and specialized dealers can be valuable resources. These establishments often stock essential items or can order specific parts for you. Engaging with knowledgeable staff may also lead to helpful recommendations and advice.

Online marketplaces and forums dedicated to enthusiasts of similar equipment can be excellent places to find second-hand components. Members often sell or trade items, which can be a cost-effective solution. Additionally, these communities can provide insights and tips on identifying compatible components.

Ultimately, exploring various avenues for sourcing replacements will enhance your chances of finding the right items efficiently, ensuring your equipment remains in optimal condition.

Tips for Proper Assembly

Ensuring a smooth and effective assembly process is crucial for optimal performance and longevity of your equipment. Here are some key considerations to keep in mind during the assembly phase.

- Read the Instructions: Always start by thoroughly reviewing the provided instructions. Familiarizing yourself with each step can prevent mistakes.

- Organize Your Workspace: Keep your workspace tidy and organized. Having all necessary components and tools at hand will streamline the assembly process.

- Check for Compatibility: Before beginning, ensure that all parts are compatible and free from damage. This can save time and frustration later.

- Follow a Logical Sequence: Assemble components in a logical order, following the instructions closely to avoid confusion.

- Use the Right Tools: Utilize appropriate tools for each step to avoid damaging any parts during the assembly.

By following these tips, you can enhance the efficiency of the assembly process, ensuring that your equipment operates smoothly and effectively.

Comparing Parts with Other Models

This section explores the similarities and differences in components among various machines in the same category. Understanding these distinctions can aid in selecting the right equipment or finding compatible elements for repair and maintenance.

When evaluating machinery, consider the following aspects:

- Compatibility: Examine how components from different models interact and fit together.

- Durability: Assess the materials used in different designs and their longevity under similar conditions.

- Performance: Compare how variations in design impact efficiency and effectiveness.

Additionally, certain models may offer enhanced features or technology that could be beneficial:

- Enhanced ergonomics for user comfort.

- Advanced technology for better performance.

- Customizable options for specific tasks.

By delving into these comparisons, users can make informed decisions tailored to their needs and preferences.

Benefits of Using Genuine Parts

Opting for authentic components in maintenance and repair ensures reliability and longevity. These original items are specifically designed to fit and function seamlessly with your equipment, enhancing performance and reducing the risk of failure. By choosing genuine replacements, users can enjoy peace of mind knowing that their tools will operate at optimal levels.

Quality Assurance

One of the main advantages of using original components is the assurance of quality. These items undergo rigorous testing and adhere to strict manufacturing standards. This means they are built to withstand the demands of regular use, ensuring that your equipment remains operational for a longer period.

Enhanced Performance

Genuine components not only fit perfectly but also work harmoniously with the entire system. This integration leads to improved efficiency and effectiveness, maximizing productivity. In contrast, non-authentic replacements may lead to subpar performance or even damage to the equipment.

| Advantages | Details |

|---|---|

| Reliability | Designed for specific models, reducing compatibility issues. |

| Durability | Manufactured to high standards, ensuring a longer lifespan. |

| Performance | Optimized for maximum efficiency and effectiveness. |

| Support | Backed by warranties and manufacturer support services. |