Maintaining outdoor equipment is essential for optimal performance and longevity. A clear understanding of the individual elements that make up these machines allows for efficient repairs and replacements. This section will explore the various components involved, focusing on their roles and interconnections within the overall system.

Each segment serves a specific function, contributing to the effective operation of the equipment. From the cutting assembly to the power system, recognizing how these components interact is crucial for troubleshooting issues and ensuring peak functionality. Familiarity with these components can lead to better maintenance practices and an extended lifespan for your equipment.

Whether you are a seasoned operator or new to lawn care, grasping the layout and purpose of each element is invaluable. This knowledge empowers you to make informed decisions when it comes to repairs, upgrades, or modifications. As you delve into this exploration of machine components, you will gain insights that enhance your understanding and confidence in handling your outdoor tools.

Modern cutting systems are designed with a range of innovative characteristics that enhance efficiency and performance. These components work together to ensure effective operation, providing users with a reliable tool for maintaining landscapes. Understanding the critical aspects of these systems can significantly improve their utilization and maintenance.

Key Components

- Power Source: Reliable engines are essential for delivering the necessary power to operate the cutting mechanisms efficiently.

- Cutting Mechanism: Different styles of blades and decks contribute to various cutting widths and grass handling capabilities.

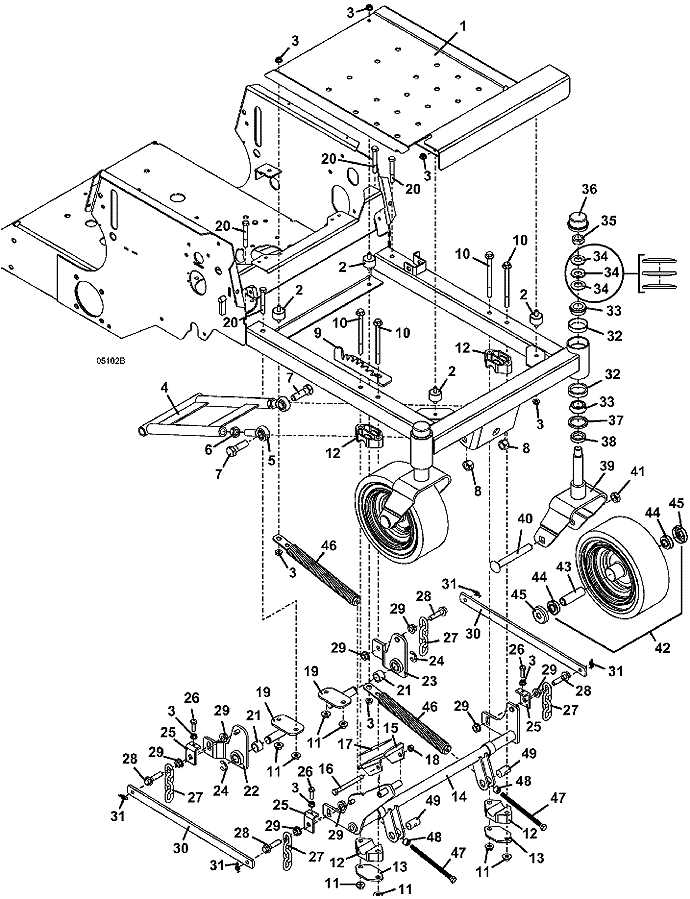

- Chassis Design: A well-engineered frame provides stability and maneuverability on different terrains.

Operational Features

- Height Adjustment: This feature allows users to modify the cutting height easily, accommodating various grass types and seasonal conditions.

- Transmission Options: Different drive systems, such as manual or automatic, offer flexibility and ease of use for operators.

- Ergonomic Controls: User-friendly controls ensure comfort and safety during operation, minimizing fatigue.

Commonly Used Replacement Parts

In the realm of outdoor equipment maintenance, understanding frequently required components is essential for ensuring longevity and optimal performance. Recognizing which elements are most often replaced can aid in timely repairs and efficient upkeep, minimizing downtime and enhancing reliability.

| Component Name | Description | Purpose |

|---|---|---|

| Blade | A sharp, rotating implement that cuts grass and vegetation. | Essential for achieving a clean and even cut. |

| Fuel Filter | A filter that removes impurities from the fuel supply. | Ensures clean fuel reaches the engine, promoting efficiency. |

| Belt | A flexible loop that transmits power from the engine to various components. | Facilitates movement and operation of the cutting system. |

| Battery | A rechargeable power source that provides electricity. | Enables the starting of the engine and powers electrical systems. |

| Air Filter | A component that cleans incoming air before it enters the engine. | Prevents dust and debris from causing engine damage. |

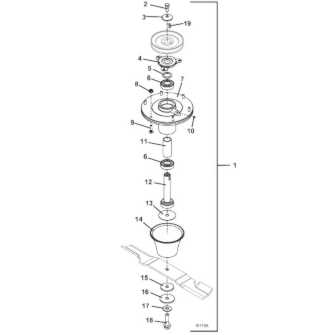

Identifying Key Mower Mechanisms

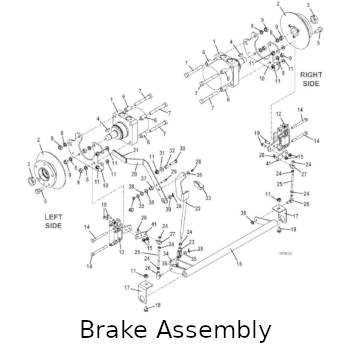

Understanding the essential components of a cutting machine is crucial for effective maintenance and operation. Each element plays a significant role in the overall functionality, ensuring optimal performance and durability. Recognizing these critical mechanisms can aid in troubleshooting and enhance the longevity of the equipment.

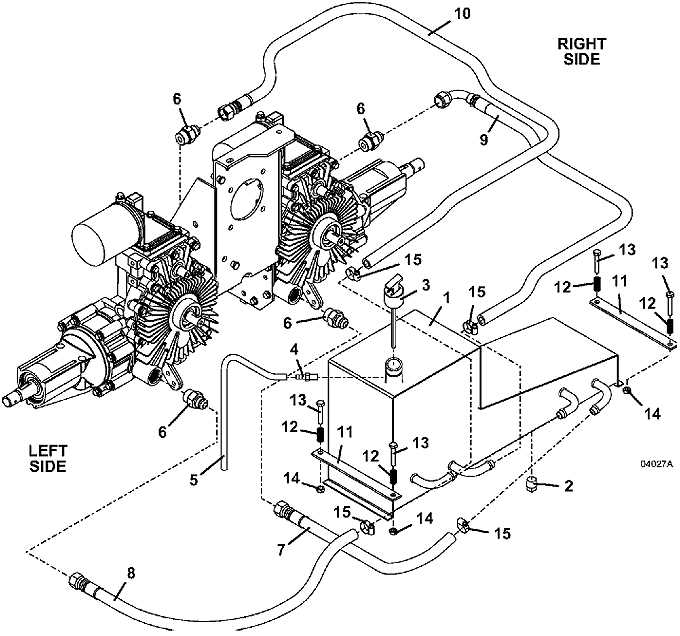

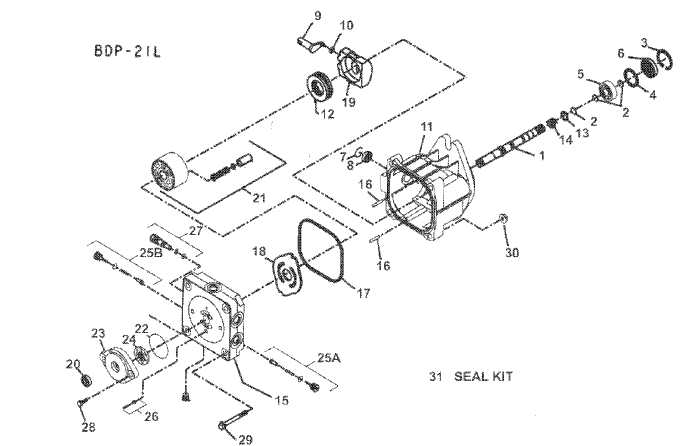

- Drive System: This mechanism transfers power from the engine to the cutting blades, enabling efficient movement.

- Cutting Assembly: Comprising the blades and housing, this part is responsible for achieving a precise cut and maintaining the desired height.

- Deck Structure: The frame that houses the cutting assembly, providing stability and support during operation.

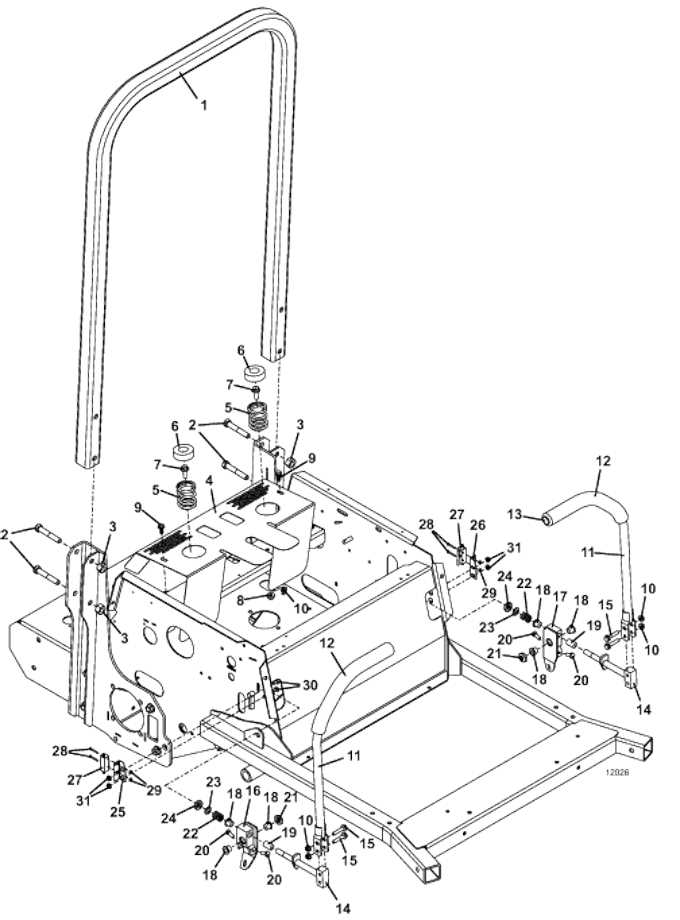

- Control Panel: The interface through which the operator manages speed, direction, and other settings for optimal use.

- Fuel System: Essential for powering the engine, this mechanism includes the tank, filter, and lines that deliver fuel efficiently.

By familiarizing oneself with these key components, operators can ensure better care, identify issues promptly, and enhance the overall user experience.

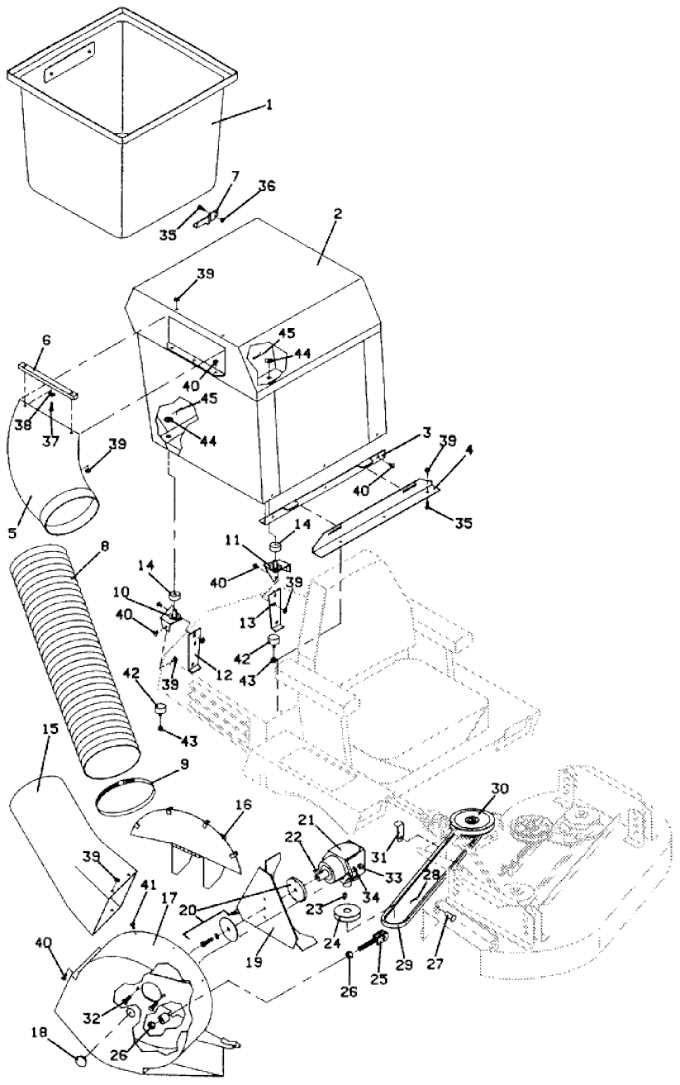

Assembly Overview for Maintenance

This section provides a comprehensive guide for assembling essential components for effective upkeep. Understanding the structure and arrangement of these elements is crucial for ensuring optimal performance and longevity of the equipment. Proper assembly techniques contribute to smoother operation and facilitate easier repairs when necessary.

Essential Components and Their Functions

Familiarity with the various elements involved in the assembly process enhances the overall maintenance experience. Each component plays a specific role, contributing to the efficiency and reliability of the machinery. Knowing how these parts interact allows for more informed decision-making during upkeep.

Assembly Techniques and Best Practices

Adopting best practices during assembly is vital for achieving the desired functionality. Utilizing the correct tools and methods can prevent common issues, ensuring that the setup is both secure and efficient. Regular inspection and adjustment of these connections also play a significant role in maintaining the system’s integrity.

Tools Needed for Parts Replacement

When it comes to maintaining equipment effectively, having the right tools is essential. The correct instruments not only simplify the process but also ensure safety and precision during the replacement of components. Knowing which tools to gather beforehand can save time and enhance efficiency.

First and foremost, a good set of wrenches is crucial. These tools allow for the tightening and loosening of nuts and bolts, ensuring that every connection is secure. Additionally, screwdrivers in various sizes will help tackle different screws encountered during the process.

Furthermore, having a reliable socket set is beneficial for reaching tight spots that standard wrenches might not fit. A pry bar can also assist in separating stubborn parts that may be stuck together. Lastly, don’t forget about safety gear such as gloves and goggles, which are essential for protecting yourself while working.

Interpreting Mower Wiring Schematics

Understanding electrical schematics is essential for effective troubleshooting and maintenance. These visual representations offer a clear view of how components are interconnected, allowing for a systematic approach to diagnosing issues. Mastering the interpretation of these diagrams can significantly enhance one’s ability to perform repairs and modifications.

Key Elements of Wiring Diagrams

Wiring illustrations typically consist of symbols and lines that denote various components and their connections. Each symbol represents a specific element, such as switches, motors, or sensors, while the lines illustrate the electrical pathways between them. Familiarity with these symbols is crucial for correctly interpreting the schematic.

Common Troubleshooting Techniques

When examining an electrical schematic, it is important to follow a logical troubleshooting process. Start by identifying the problem area based on symptoms. Next, trace the circuit using the diagram to locate potential faults, such as broken connections or damaged components. This methodical approach can save time and ensure accurate repairs.

Safety Precautions During Repairs

Ensuring safety while conducting maintenance is essential to prevent accidents and injuries. Adopting proper measures can create a secure working environment and protect both the individual and the equipment being serviced.

- Personal Protective Equipment (PPE): Always wear appropriate gear, including gloves, safety goggles, and sturdy footwear, to minimize the risk of injury.

- Secure the Workspace: Keep the area free of clutter and ensure adequate lighting to enhance visibility during repairs.

- Disconnect Power Sources: Always unplug or disconnect the equipment from its power source before starting any maintenance work to prevent accidental activation.

- Use the Right Tools: Utilize tools that are specifically designed for the task to ensure efficiency and reduce the chance of malfunction.

- Read the Manual: Familiarize yourself with the manufacturer’s instructions and guidelines to understand proper handling and repair procedures.

- Stay Alert: Concentrate on the task at hand and avoid distractions to maintain focus and prevent mishaps.

By following these safety guidelines, individuals can work more effectively and reduce the likelihood of accidents during maintenance tasks.

Where to Find Genuine Components

When it comes to maintaining your equipment, sourcing authentic elements is crucial for ensuring optimal performance and longevity. Quality components not only enhance efficiency but also guarantee safety during operation. Below are several reliable avenues to consider for obtaining genuine items.

Authorized Dealers

One of the most dependable methods for acquiring authentic components is through authorized distributors. These retailers often provide:

- Direct access to manufacturer-certified elements

- Expert advice on compatibility and installation

- Warranty options for additional peace of mind

Online Marketplaces

Numerous online platforms specialize in the sale of legitimate components. When exploring these options, keep the following in mind:

- Verify seller ratings and reviews to ensure credibility.

- Check for product authenticity guarantees.

- Compare prices to avoid overpaying.

By exploring these avenues, you can ensure that your equipment remains in peak condition with high-quality, genuine elements.