When it comes to maintaining winter machinery, having a clear visual representation of its components can significantly enhance your ability to troubleshoot and repair. A well-organized reference can help users identify each piece and understand its function within the larger system. This knowledge is invaluable, especially during the colder months when reliable performance is crucial.

In this guide, we will explore a comprehensive outline of essential elements that make up a specific model of snow-clearing equipment. By delving into the intricate details of these components, users can gain insights into how they work together to ensure optimal operation. A thorough grasp of these individual parts not only aids in repairs but also empowers users to undertake maintenance with confidence.

Whether you are a seasoned technician or a homeowner preparing for the snowy season, familiarizing yourself with the structure and layout of your machine will streamline any repair processes. Understanding the intricacies of each component will help you keep your equipment in prime condition, ultimately enhancing its longevity and performance.

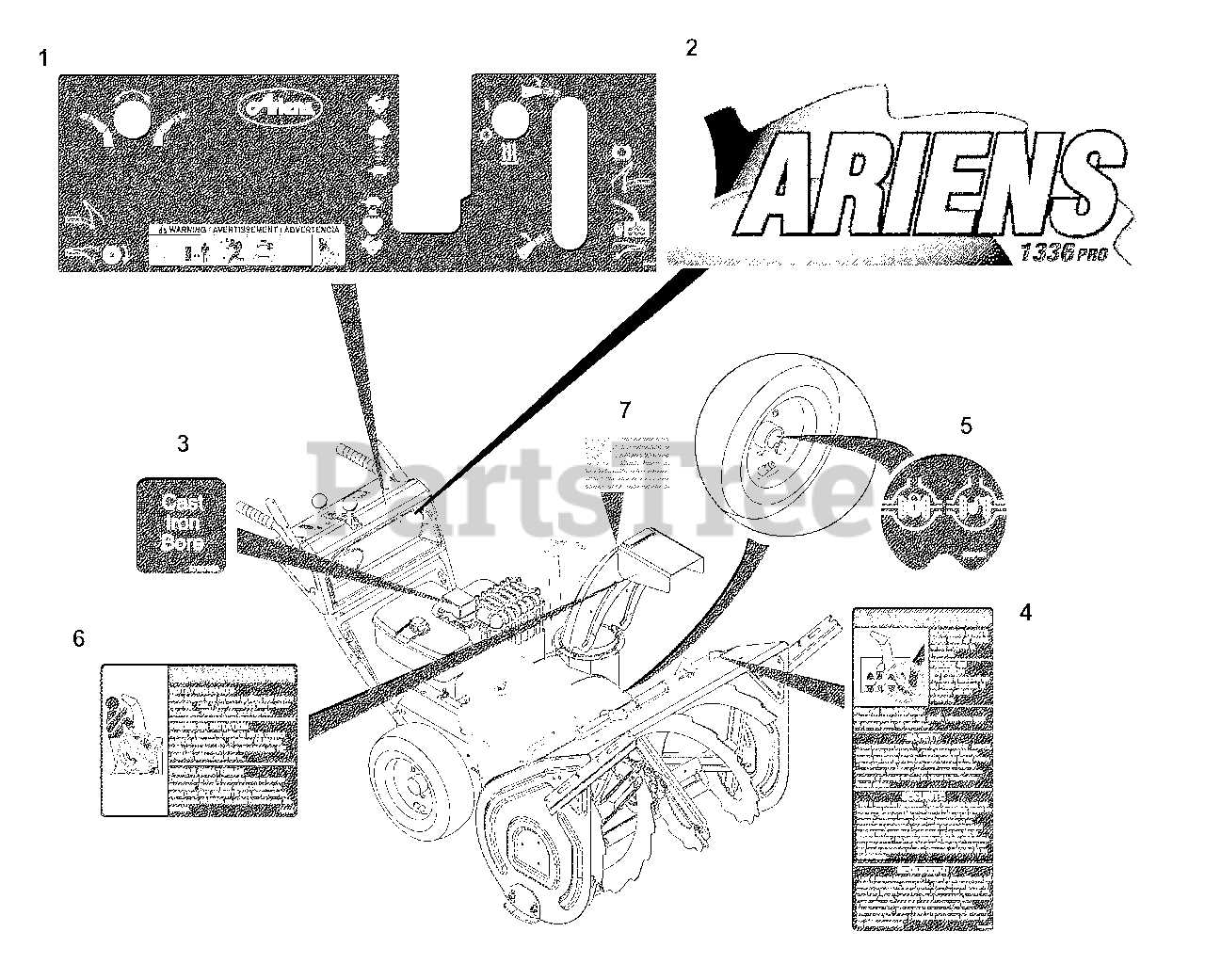

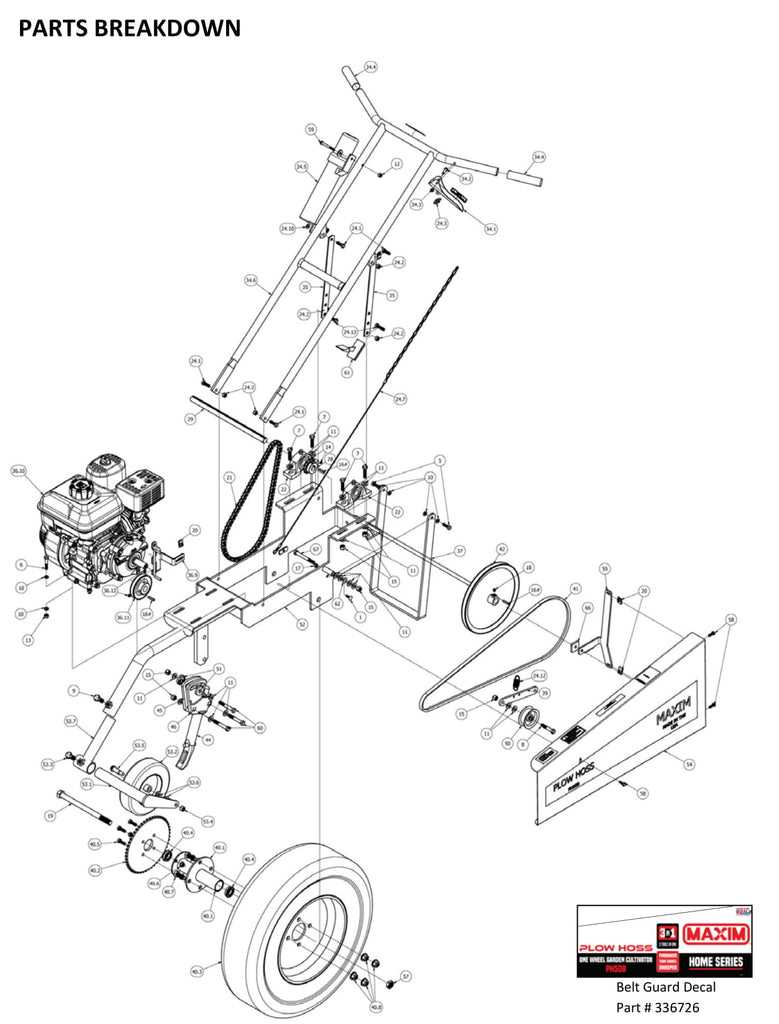

Ariens 926LE Overview

This section provides a comprehensive understanding of a specific model designed for snow management, ideal for both residential and commercial use. With its robust features and reliable performance, it stands out in its category.

The equipment is characterized by:

- Powerful engine for efficient snow clearing.

- Multiple speed settings to accommodate varying conditions.

- Ergonomic design for user comfort and ease of handling.

- Durable construction to withstand harsh weather elements.

When considering functionality, this machine excels in:

- Effective snow throwing distance.

- Ease of maneuverability in tight spaces.

- Maintenance features that enhance longevity.

- Intuitive controls for a smooth operation.

Overall, this model offers an excellent blend of power, efficiency, and user-friendly design, making it a top choice for those seeking reliable snow removal solutions.

Key Features of Ariens 926LE

This model stands out in its category, offering a blend of power and efficiency that caters to both residential and commercial needs. It boasts a variety of innovative features designed to enhance performance, ease of use, and overall reliability. Users can expect a machine that effectively tackles snow removal tasks with minimal effort, ensuring satisfaction in challenging winter conditions.

Powerful Engine Performance

The robust engine is a key highlight, delivering exceptional torque and speed to navigate through heavy snowfall. Its design ensures that it can handle various types of terrain, making it suitable for diverse environments. Additionally, the engine is built for durability, promising long-term operation without frequent maintenance.

User-Friendly Design

Ergonomics play a significant role in the functionality of this equipment. Features such as easy-start mechanisms, adjustable controls, and a comfortable handle contribute to a seamless user experience. The intuitive design allows operators to maneuver effortlessly, even in tight spaces, while the efficient snow discharge system ensures optimal performance with minimal blockage.

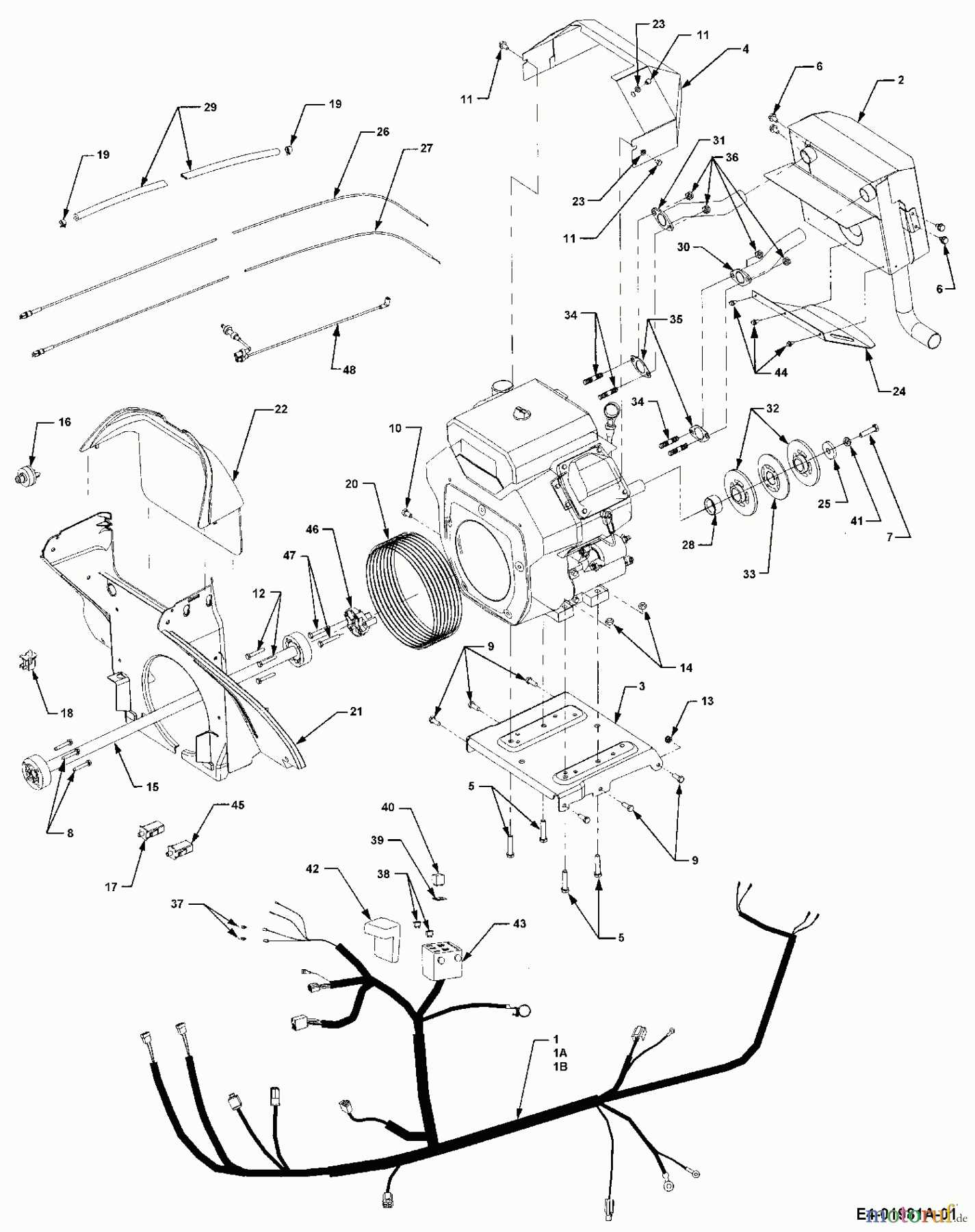

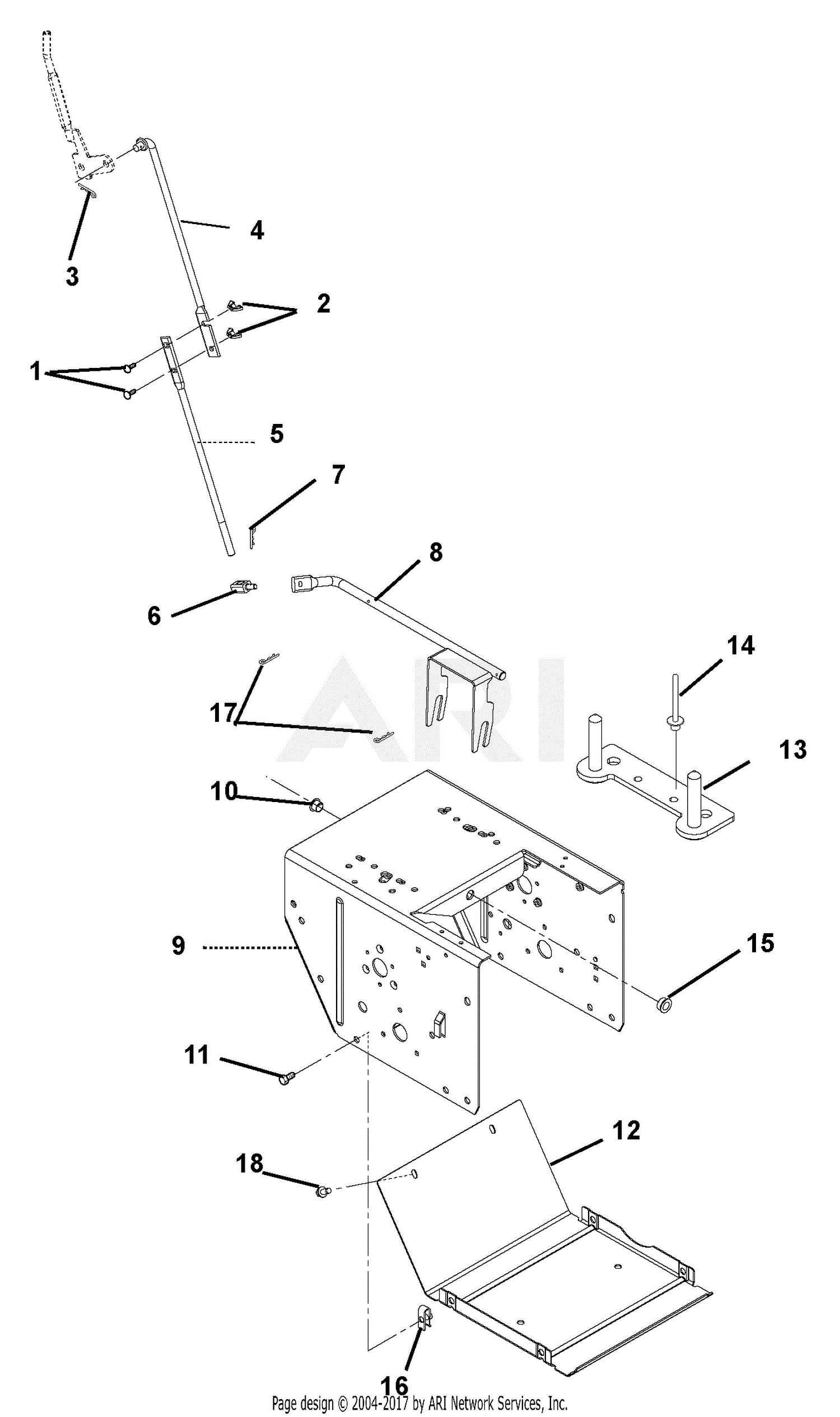

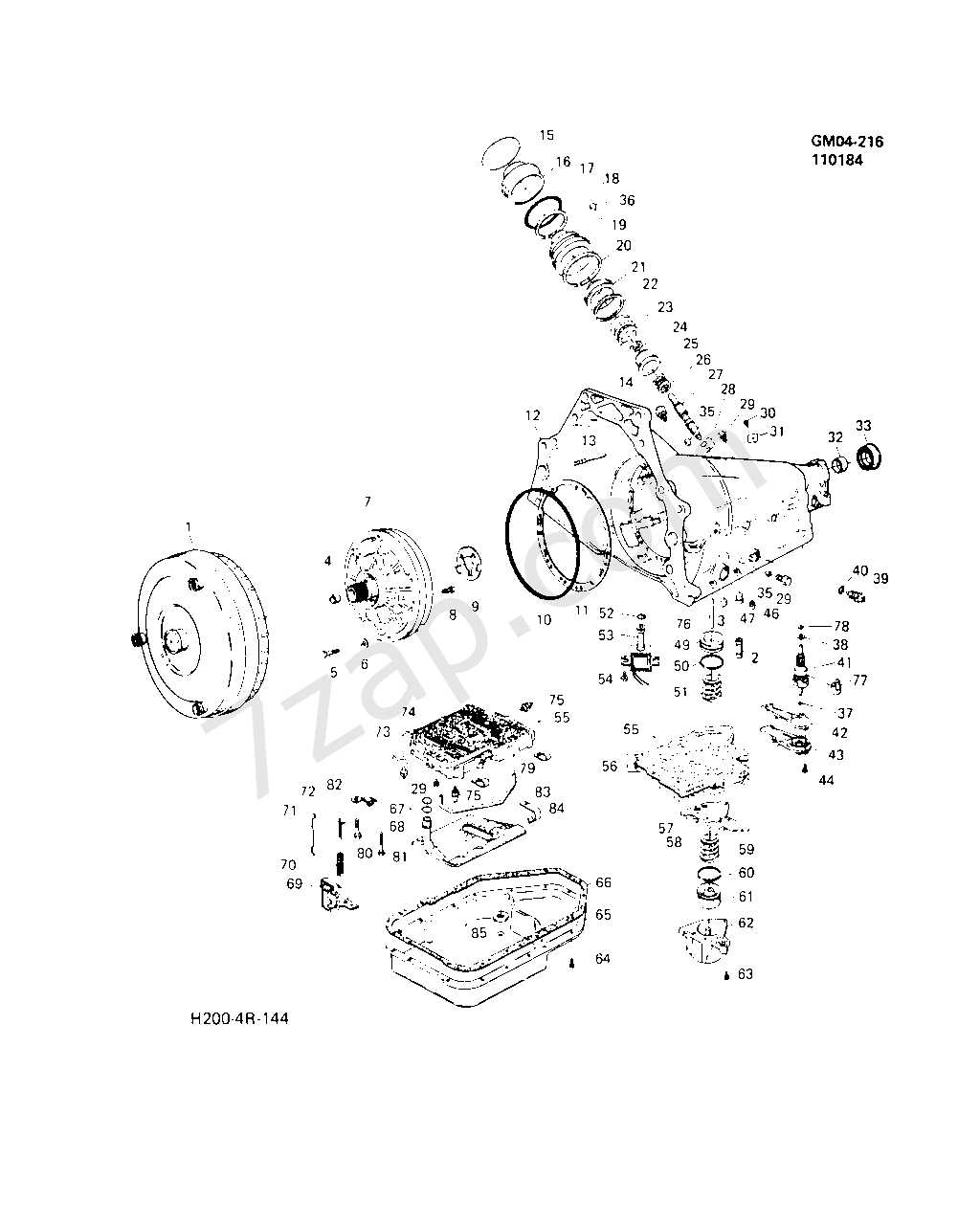

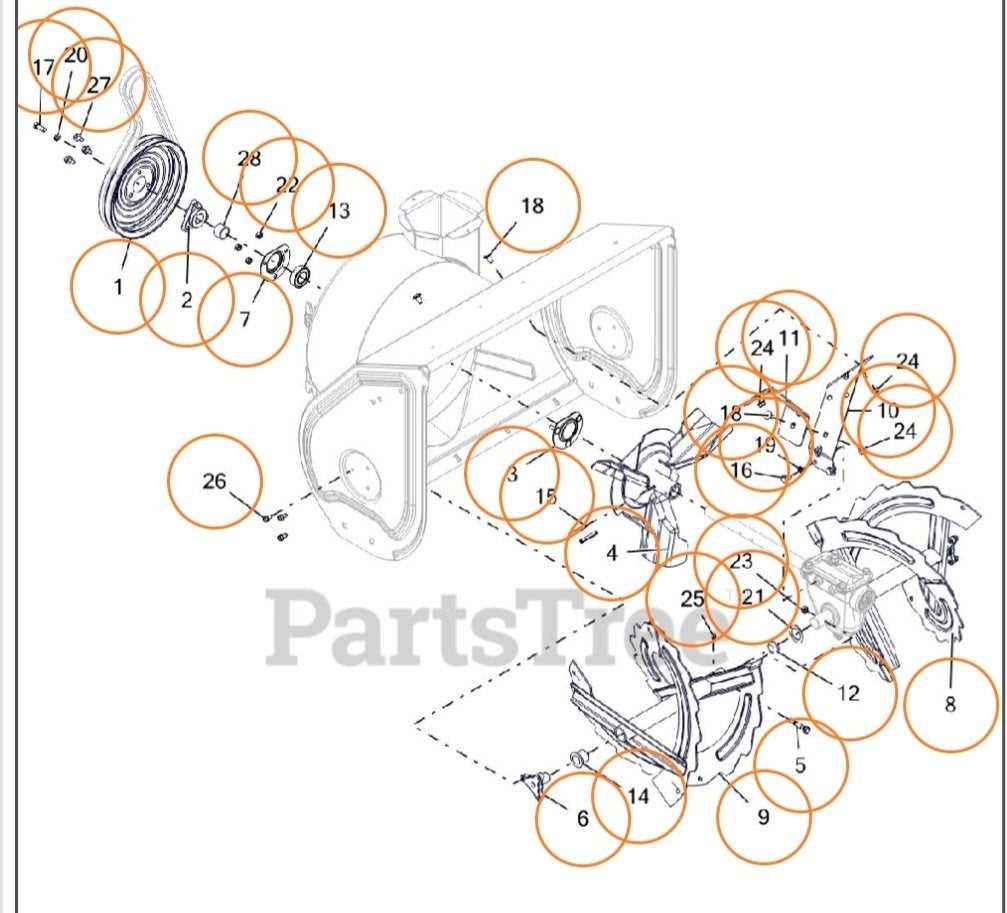

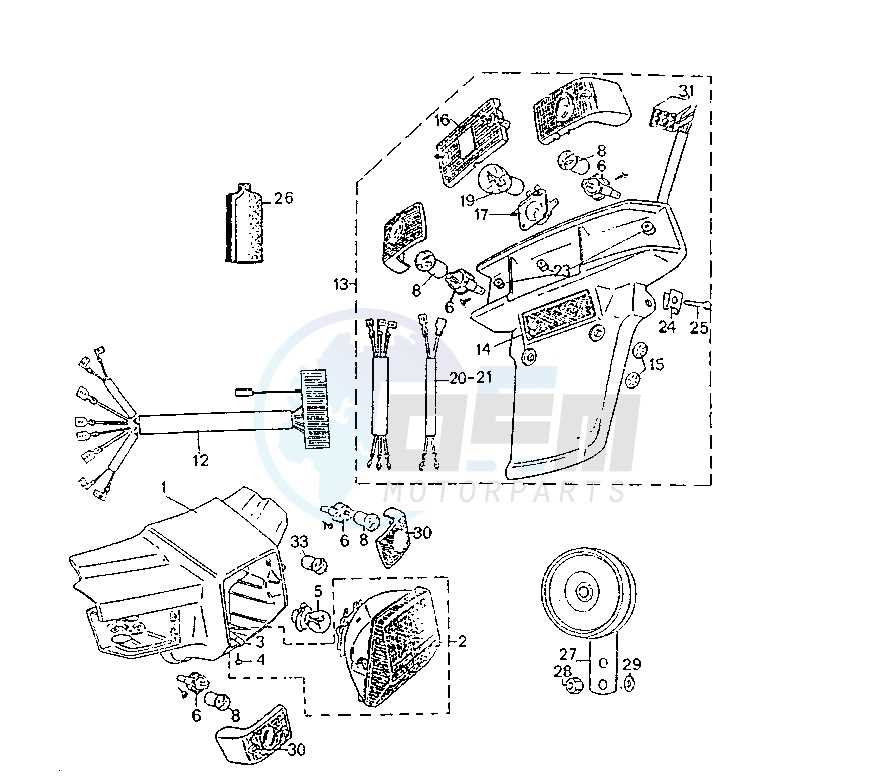

Understanding Parts Diagrams

Visual representations of components are essential tools for anyone seeking to comprehend the intricate systems of machinery. They simplify the complex, allowing users to identify individual elements and their relationships within the overall structure. Mastering these visuals can enhance maintenance efficiency and troubleshooting skills.

The Importance of Clarity

Clarity in these visuals ensures that users can quickly locate and differentiate between various components. Clear labeling and logical organization contribute to a more effective understanding of how each piece functions within the entire assembly.

Navigating the Visuals

Learning to navigate these illustrations involves recognizing common symbols and notation. Familiarity with these elements can ultimately streamline repair processes, reducing downtime and enhancing user confidence.

Importance of Accurate Diagrams

Having precise illustrations for mechanical components is crucial for effective maintenance and repair. These visuals serve as essential guides, allowing users to easily identify and understand each element’s function, placement, and relationship within the assembly.

Enhanced Understanding

Clear representations enable individuals to quickly grasp complex systems. By simplifying intricate details, users can approach repairs with confidence, reducing the likelihood of mistakes that could lead to further damage.

Efficient Repairs

When faced with a malfunction, accurate visual aids streamline the troubleshooting process. They facilitate quick identification of issues and guide users through each step of the repair, ultimately saving time and resources.

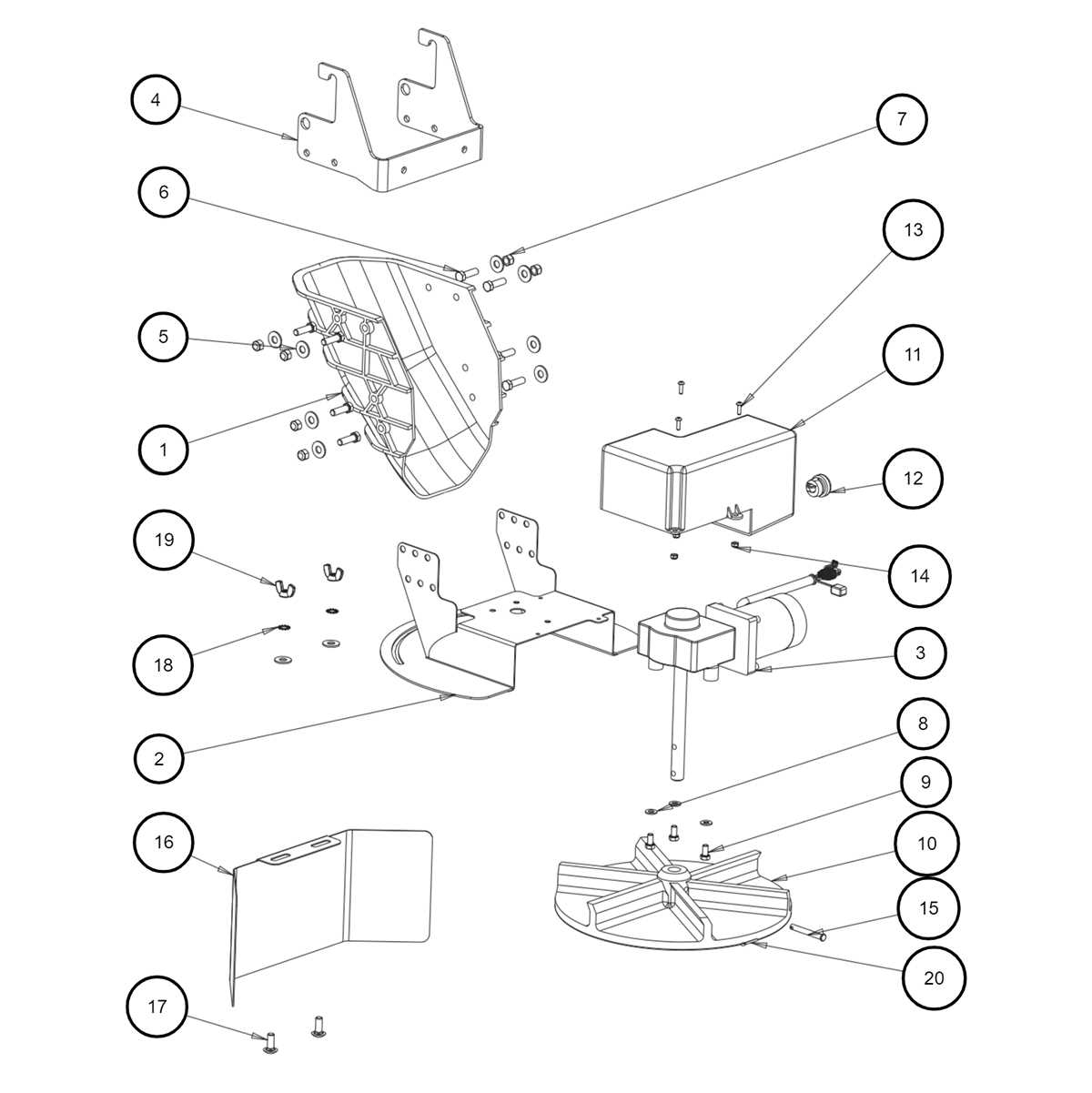

Common Replacement Parts

In the maintenance of outdoor power equipment, certain components often require substitution to ensure optimal performance. Regularly replacing these elements can prevent malfunctions and extend the lifespan of the machinery.

- Engines: Key for reliable operation, often needing new filters or gaskets.

- Belts: Crucial for power transmission, they may wear out and need replacement.

- Blades: Essential for cutting efficiency, dull blades should be sharpened or replaced periodically.

- Wheels: Wear and tear can lead to reduced mobility, necessitating new wheels or bearings.

- Spark plugs: Vital for ignition, these components often require regular checks and replacements.

Identifying these commonly replaced elements can significantly enhance maintenance routines and performance levels.

Where to Find Diagrams Online

Locating detailed visuals for machinery components has become increasingly convenient through various online resources. These platforms provide essential information for maintenance, repair, and assembly tasks.

- Manufacturer Websites: Official sites often host a wealth of technical resources.

- Online Retailers: E-commerce platforms frequently feature schematics alongside product listings.

- Specialty Forums: Communities focused on specific equipment types can be invaluable for sharing resources.

- Technical Documentation Sites: Websites dedicated to manuals and guides often contain useful illustrations.

By exploring these avenues, users can easily access the visuals needed for effective equipment management.

Maintenance Tips for Longevity

Ensuring the extended lifespan of outdoor machinery requires consistent care and attention. By following a systematic approach to maintenance, you can enhance performance and minimize potential issues. Here are some essential practices to consider for optimal functionality.

Regular Inspections

- Check for any signs of wear or damage.

- Inspect belts and cables for fraying or corrosion.

- Ensure all fasteners are secure to avoid operational problems.

Routine Cleaning

- Remove debris from air filters to promote airflow.

- Clean the exterior and undercarriage to prevent rust and buildup.

- Regularly wash and dry components to maintain their integrity.

Incorporating these practices into your maintenance routine will contribute significantly to the longevity and reliability of your equipment, allowing for effective performance season after season.

Assembly and Disassembly Guide

This section provides a comprehensive overview for assembling and disassembling equipment, ensuring a seamless experience whether you are maintaining or upgrading components. Understanding the process is crucial for efficient handling and longevity of the machinery.

Preparation Steps

Before beginning, gather all necessary tools and ensure you have a clear workspace. Identifying each component beforehand can significantly simplify the procedure. Always refer to the manufacturer’s instructions to avoid any potential issues.

Disassembly Process

Follow these steps to safely disassemble the equipment:

| Step | Description |

|---|---|

| 1 | Disconnect power supply and remove any attachments. |

| 2 | Carefully unscrew and detach parts, keeping them organized. |

| 3 | Inspect components for wear and document any findings. |

Once disassembled, follow the reverse order for assembly, ensuring all components are securely fastened and properly aligned.