In the realm of agricultural equipment, a thorough comprehension of the individual elements that make up a machine is essential for effective maintenance and operation. Familiarity with these components not only enhances performance but also prolongs the lifespan of the equipment. Whether you are a seasoned farmer or a newcomer to the field, grasping the intricacies of each section can lead to improved productivity and reduced downtime.

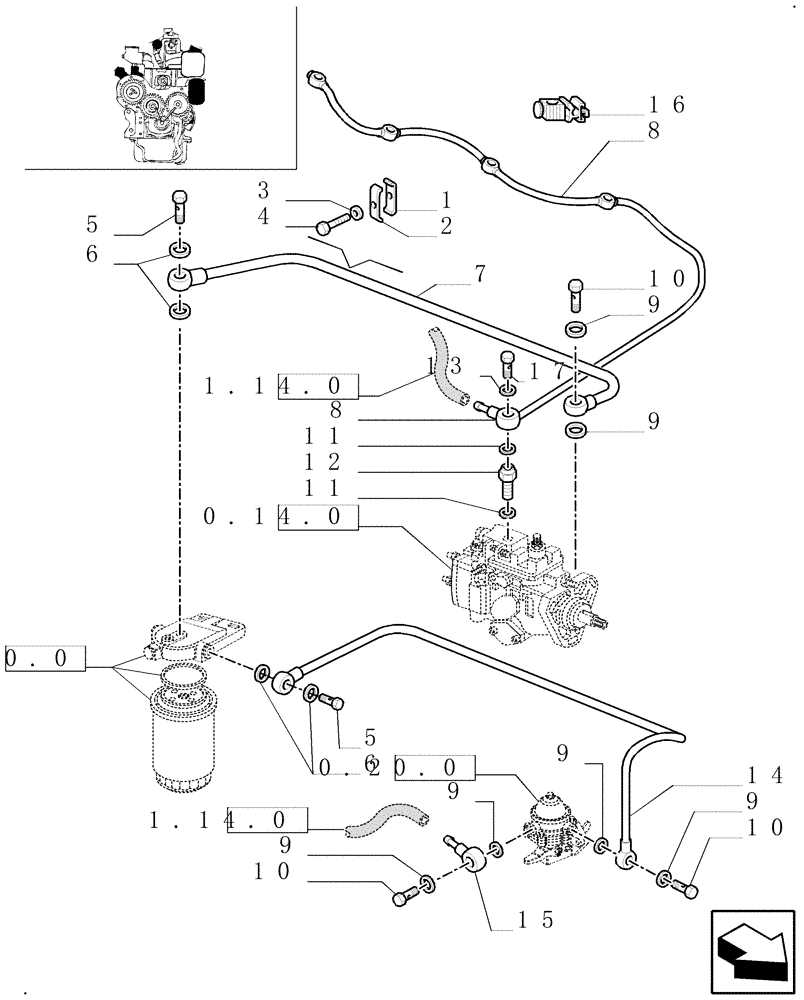

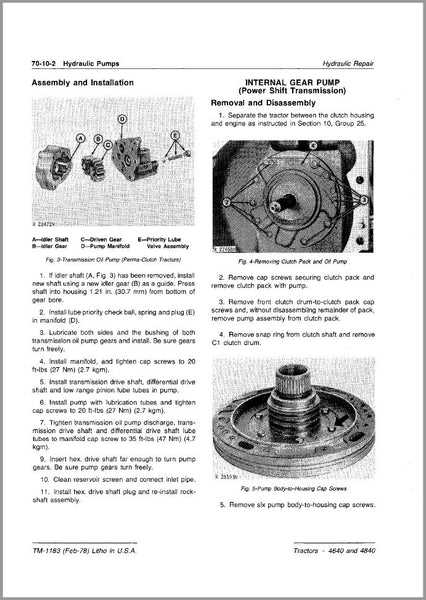

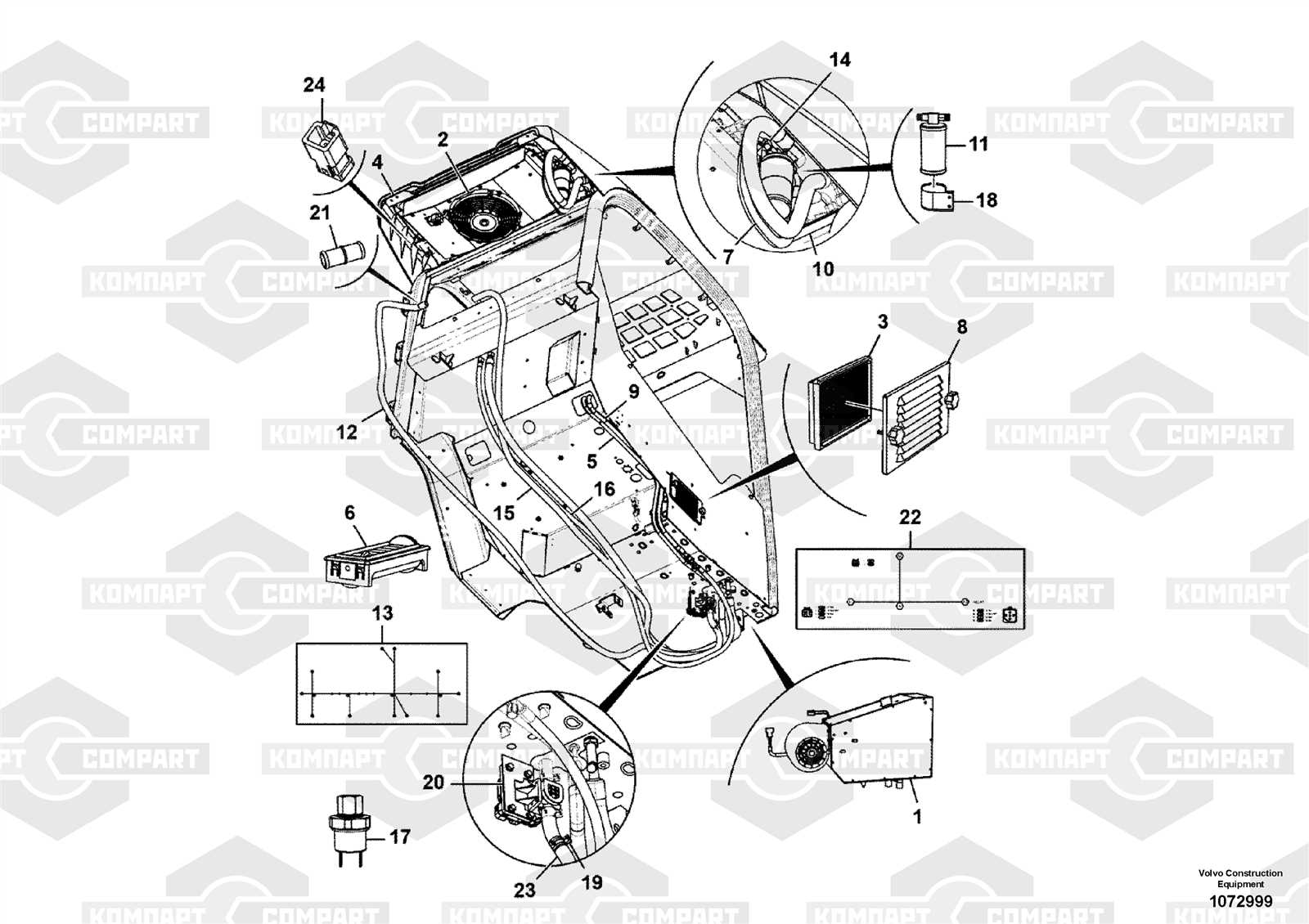

Visual representations of machinery layouts serve as invaluable resources for identifying various sections and their respective roles. By exploring these schematics, operators can better understand how different parts interact and contribute to the overall functionality of the equipment. This knowledge empowers users to troubleshoot issues efficiently and execute repairs with confidence.

As you delve into the specifics of your machinery, you will uncover a wealth of information that can significantly aid in maintenance practices. Engaging with these visual aids not only simplifies complex processes but also enhances your ability to make informed decisions regarding repairs and upgrades. Embracing this knowledge is a key step toward ensuring that your agricultural endeavors are met with success.

Understanding New Holland TN65 Components

Gaining insight into the various elements that comprise agricultural machinery is essential for optimal performance and maintenance. Each component plays a vital role, contributing to the overall efficiency and functionality of the equipment. Familiarity with these parts aids in troubleshooting and ensuring longevity.

Key Elements of the Machinery

The following are some of the critical components commonly found in this type of agricultural machinery:

| Component | Description |

|---|---|

| Engine | The powerhouse that drives the entire machine, providing necessary horsepower. |

| Transmission | Responsible for transferring power from the engine to the wheels or attachments. |

| Hydraulics | Facilitates the movement of various implements through fluid power. |

| Chassis | The structural framework that supports all components and provides stability. |

Importance of Regular Maintenance

Consistent upkeep of these components is crucial to avoid unexpected breakdowns and ensure peak operational efficiency. Regular inspections and timely replacements can significantly enhance performance and extend the life of the machinery.

Importance of Parts Diagrams

Understanding the intricate details of machinery is crucial for effective maintenance and repair. Visual representations serve as essential tools that facilitate this comprehension, enabling users to identify components and their relationships within a complex system. These illustrations not only enhance clarity but also streamline the process of troubleshooting and assembly.

Enhanced Accuracy: Visual aids promote precision during repairs. By clearly illustrating the location and orientation of each element, users can ensure they are working with the correct pieces, minimizing errors and avoiding potential damage.

Efficient Communication: When collaborating with technicians or discussing issues with support staff, having a visual reference allows for more effective communication. Describing problems becomes simpler when both parties can refer to the same illustration.

Time-Saving: Familiarity with visual references can significantly reduce downtime. Technicians can quickly locate and replace worn or damaged elements, allowing for a more efficient workflow.

In summary, utilizing visual representations greatly enhances the overall maintenance experience, ensuring machinery operates smoothly and effectively.

Common Issues with TN65 Parts

Understanding the frequent complications associated with various components of agricultural machinery can significantly enhance maintenance practices and extend the equipment’s lifespan. Each element may encounter specific challenges that, if not addressed promptly, could lead to more serious malfunctions.

Wear and Tear

One of the most prevalent concerns involves the natural deterioration of components over time. Regular usage can lead to a decline in performance, particularly in high-stress areas. Inspections should be conducted routinely to identify signs of fatigue or damage, allowing for timely replacements and minimizing downtime.

Hydraulic System Failures

Hydraulic issues are often reported, stemming from leaks or blockages within the system. These failures can result in a loss of power or erratic operation. It is essential to monitor fluid levels and inspect hoses and fittings for signs of wear. Maintaining the hydraulic system is critical for ensuring optimal functionality and preventing extensive repairs.

How to Read a Parts Diagram

Understanding a schematic representation of components is essential for effective maintenance and repairs. These visual aids provide a clear overview of various elements and their interconnections, making it easier to identify specific pieces and their functions. Familiarity with these representations allows for more efficient troubleshooting and ordering of replacements.

Key Elements of the Representation

Each visual schematic typically includes several important features:

| Element | Description |

|---|---|

| Labels | Indicate the names or codes of individual components. |

| Connections | Show how different elements are linked together, often using lines or arrows. |

| Reference Numbers | Provide a unique identifier for each part, usually corresponding to a list for ordering. |

| Legend | Explains any symbols or color codes used in the schematic. |

Tips for Effective Reading

To navigate these representations successfully, follow these tips:

- Start by examining the legend to understand the symbols used.

- Identify the main components and their reference numbers.

- Trace the connections to visualize how elements interact.

- Take note of any grouped components for ease of understanding.

Finding Replacement Parts Online

In today’s digital age, sourcing components for machinery has become remarkably convenient. With just a few clicks, enthusiasts and professionals alike can locate the necessary items to keep their equipment running smoothly. Whether you are dealing with wear and tear or seeking upgrades, the online marketplace offers a plethora of options to suit various needs.

Utilizing Online Marketplaces

Numerous platforms cater to those in search of mechanical components. These websites not only provide a wide selection but also allow users to compare prices and read reviews. Searching with specific keywords related to your machinery can yield the best results. Additionally, filtering options can help narrow down choices based on brand, type, and compatibility.

Connecting with Communities

Online forums and social media groups dedicated to machinery and equipment can be invaluable resources. Engaging with fellow users can lead to recommendations for reliable suppliers. Networking with experienced individuals can also provide insights into the best practices for purchasing and installing new components. By leveraging these community connections, you can ensure you are making informed decisions when acquiring replacements.

Maintenance Tips for TN65 Machinery

Regular upkeep is essential for ensuring optimal performance and longevity of your agricultural equipment. By following specific guidelines, operators can prevent breakdowns and enhance efficiency. This section outlines key practices to maintain machinery effectively.

Routine Inspections

Conducting frequent evaluations of machinery components can help identify wear and tear before it escalates. Focus on checking the fluid levels, belts, and filters. Timely replacements can save both time and costs in the long run.

Proper Lubrication

Keeping moving parts well-lubricated is crucial for reducing friction and preventing damage. Use high-quality lubricants as specified in the manual. Regularly scheduled lubrication will enhance the lifespan and performance of your equipment.

Comparing OEM and Aftermarket Parts

When it comes to maintaining and repairing machinery, users often face a choice between original components and those produced by third-party manufacturers. This decision can significantly impact performance, longevity, and overall satisfaction. Understanding the distinctions between these options is crucial for making an informed choice that meets specific needs and budgetary constraints.

Advantages of Original Components

Original equipment manufacturers typically guarantee that their components meet strict quality standards. These items are specifically designed to fit seamlessly within the machinery, often resulting in enhanced reliability and performance. Additionally, using original parts may ensure that warranties remain valid and that the machinery operates as intended over its lifespan.

Benefits of Third-Party Alternatives

On the other hand, aftermarket options often present a more budget-friendly alternative without sacrificing quality. Many independent manufacturers produce reliable components that can match or even exceed the performance of originals. These alternatives may offer a wider variety of choices, allowing users to find specific features or enhancements that cater to unique operational needs.

Using Diagrams for Troubleshooting

Visual representations play a crucial role in diagnosing issues effectively. By providing a clear overview of components and their interconnections, these illustrations can simplify complex problems, making it easier to identify faults and determine solutions.

When faced with a malfunction, utilizing visual aids can enhance your troubleshooting process in several ways:

- Clarity: Detailed sketches help clarify the layout and function of various elements, reducing confusion.

- Identification: Quickly pinpoint problematic areas by referencing specific parts, saving time during inspections.

- Organization: Visuals can help organize your approach, allowing for a systematic examination of each section.

- Documentation: They serve as an excellent reference for future maintenance, ensuring consistent practices.

To maximize the benefits of these visual tools, consider the following steps:

- Familiarize yourself with the overall layout depicted in the illustrations.

- Identify the specific area where issues are suspected.

- Trace connections and components logically to isolate the source of the problem.

- Cross-reference findings with manufacturer guidelines to ensure accuracy.

By integrating visual aids into your troubleshooting toolkit, you can enhance your efficiency and accuracy, ultimately leading to faster resolutions and improved equipment performance.

Resources for TN65 Owners

For enthusiasts and operators, having access to reliable materials and guides is essential for maintaining and enhancing the functionality of their machinery. This section offers various tools and references that can help streamline the upkeep process and ensure optimal performance.

| Resource Type | Description | Link |

|---|---|---|

| User Manual | A comprehensive guide detailing operational procedures and maintenance tips. | Download User Manual |

| Maintenance Guides | Step-by-step instructions for regular servicing and repairs. | View Maintenance Guides |

| Online Forums | A community platform for sharing experiences and solutions. | Join Online Forums |

| Supplier Contacts | List of recommended suppliers for parts and accessories. | View Supplier Contacts |