Exploring the inner workings of a specific trolling motor model reveals a wealth of components essential for its operation. This guide aims to provide an insightful look into the various elements that contribute to the functionality and efficiency of this propulsion system. By gaining familiarity with these components, users can enhance their understanding of maintenance and potential repairs.

Each component plays a crucial role in ensuring smooth operation, from the propeller to the control mechanisms. Knowledge of these individual parts not only aids in troubleshooting issues but also empowers users to make informed decisions regarding upgrades and modifications. A comprehensive overview of these elements will illuminate their significance in achieving optimal performance on the water.

By delving into the structure and functionality of this trolling motor, enthusiasts and anglers alike can develop a deeper appreciation for the technology that supports their adventures. Whether you are a seasoned user or new to the world of electric propulsion, this exploration will equip you with the essential information needed to navigate maintenance and enhance your boating experience.

This section will provide a comprehensive understanding of the features and components of a well-known trolling motor. Emphasizing its design and functionality, we will explore the essential elements that contribute to its performance on the water. The following headings will guide readers through various aspects of this equipment, enhancing their knowledge and usage experience.

Key Features

Understanding the fundamental characteristics of this device is crucial for potential users. It boasts a powerful thrust, efficient battery usage, and user-friendly controls that enhance overall navigation.

Specifications

| Attribute | Details |

|---|---|

| Thrust | 70 lbs |

| Voltage | 12V |

| Weight | Approximately 45 lbs |

| Shaft Length | Varies (36″, 42″, 48″) |

Key Features of the Edge 70

The model in question offers a variety of innovative characteristics designed to enhance the user experience and improve performance on the water. With its advanced functionalities and reliable construction, it stands out in its category, providing enthusiasts with the tools they need for successful outings.

Among its notable attributes, the following aspects contribute to its appeal:

| Feature | Description |

|---|---|

| Powerful Motor | Delivers robust thrust, ensuring efficient navigation and maneuverability. |

| Durable Construction | Built with high-quality materials to withstand harsh marine environments. |

| Adjustable Speed Settings | Allows for precise control over the boat’s pace, catering to various fishing techniques. |

| Easy Installation | Designed for straightforward mounting, facilitating quick setup and use. |

| Quiet Operation | Operates with minimal noise, ensuring a less intrusive experience for fish and other wildlife. |

Understanding Component Functionality

Grasping the roles and interactions of individual elements within a system is essential for effective operation and maintenance. Each component contributes to the overall performance and efficiency, impacting the functionality and reliability of the whole assembly. By analyzing how these parts work together, users can ensure optimal usage and address potential issues more effectively.

Key Elements Overview

Components vary in purpose, from providing energy to facilitating control and navigation. Understanding these elements allows users to appreciate their specific contributions and the way they influence overall system performance. For instance, propulsion mechanisms are crucial for movement, while control units ensure precise handling.

Interconnectivity and Impact

The interplay between different parts is vital. A malfunction in one area can affect others, leading to decreased performance or complete failure. Thus, recognizing the interconnected nature of components helps in troubleshooting and enhances user awareness of maintenance needs.

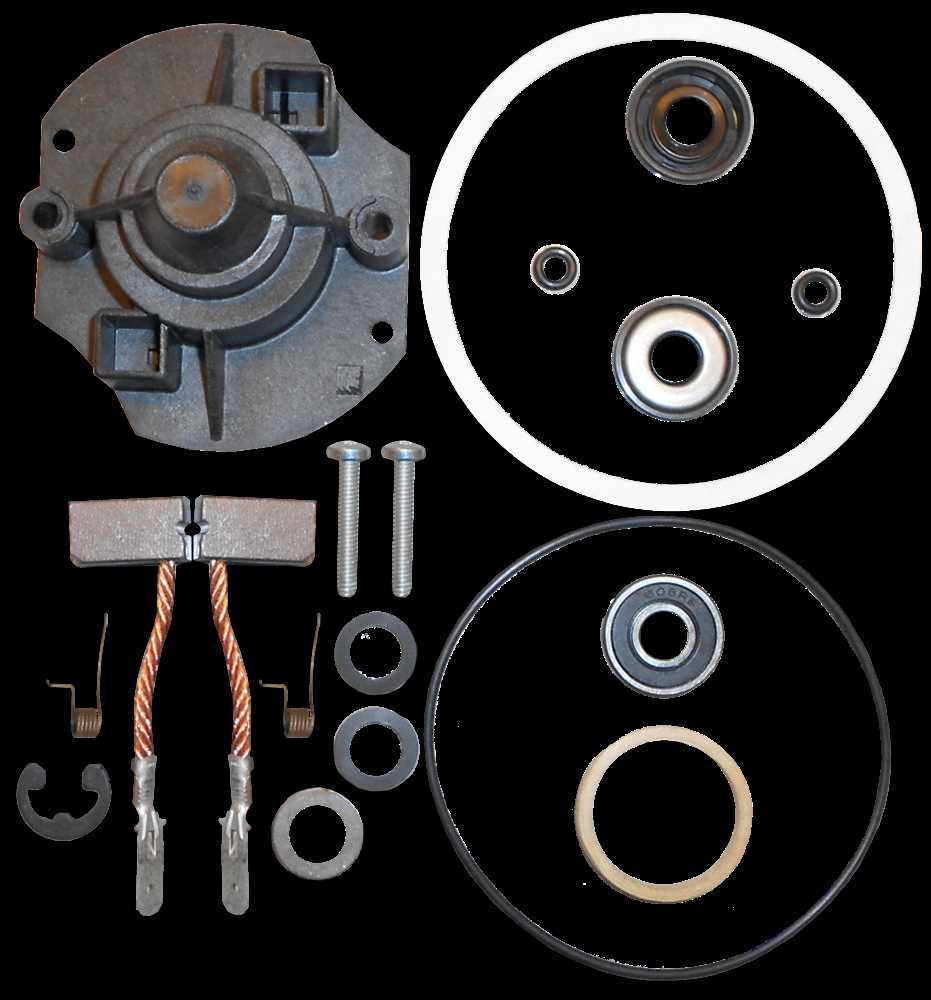

Common Replacement Parts Explained

When it comes to maintaining and enhancing the performance of electric propulsion systems, understanding the essential components is crucial. This section delves into frequently needed components that ensure optimal functioning, longevity, and efficiency of your equipment. Regularly replacing worn-out elements can significantly improve performance and reliability, making it vital for users to be familiar with these key components.

Motor Components

Propellers are among the most commonly replaced elements, as they directly influence thrust and maneuverability. Over time, wear and tear from exposure to water and debris can diminish their effectiveness, necessitating replacement to maintain optimal performance.

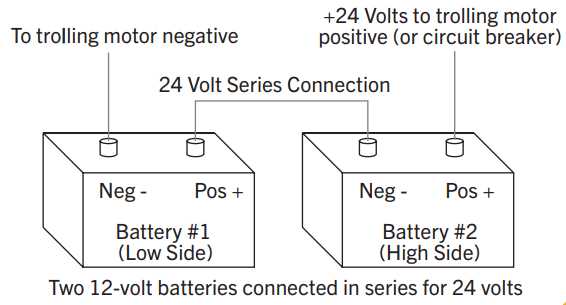

Electrical Parts

Batteries play a crucial role in power delivery and operational longevity. A decline in battery capacity can lead to reduced efficiency and shorter operational times. Ensuring that the right specifications are met when selecting replacements is vital for continued performance. Additionally, circuit breakers are essential for preventing overloads and protecting the electrical system from potential damage.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your equipment requires consistent care and attention. Regular maintenance practices not only enhance performance but also extend the lifespan of your device. By following a few key guidelines, you can keep your system in optimal condition, preventing premature wear and costly repairs.

Regular Inspection

Conducting frequent checks is essential for identifying potential issues before they escalate. Look for signs of wear, corrosion, or damage, particularly in areas subjected to frequent use. A proactive approach can save time and resources in the long run.

Cleaning and Storage

Proper cleaning after each use is vital. Remove any debris or residue that may accumulate during operation. Additionally, storing the equipment in a dry, protected environment prevents damage from moisture and dust, further enhancing its longevity.

| Maintenance Task | Frequency | Notes |

|---|---|---|

| Visual Inspection | Before each use | Check for damage or wear |

| Cleaning | After each use | Remove debris and residue |

| Lubrication | Monthly | Ensure moving parts operate smoothly |

| Battery Check | Every three months | Inspect for corrosion and charge levels |

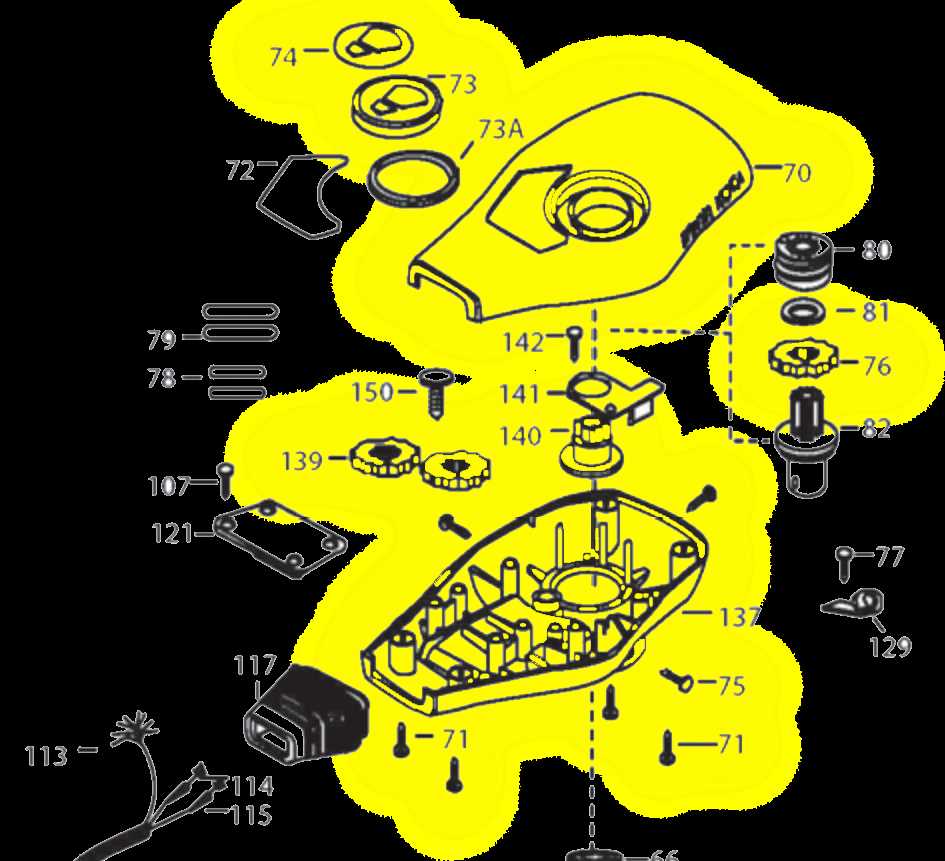

How to Access the Parts Diagram

Finding a visual representation of components can be essential for understanding assembly and maintenance. This guide provides simple steps to locate a comprehensive view of the elements for a specific model.

- Visit the official manufacturer’s website.

- Navigate to the support or resources section.

- Look for links labeled as “Technical Documents” or “Manuals.”

- Use the search feature to enter the model name.

- Download or view the available schematic files.

Additionally, consider exploring online forums and user communities. These platforms often share valuable insights and resources.

- Utilize social media groups dedicated to the model.

- Check out video tutorials that may visually guide you through the parts.

- Look for downloadable resources from third-party websites.

By following these steps, you can easily find a clear illustration that assists in identifying and replacing components when necessary.

Troubleshooting Common Issues

Understanding the frequent challenges that may arise with your equipment can help enhance its performance and longevity. This section aims to provide insights into typical problems users encounter, along with practical solutions to address them effectively.

Electrical Issues

One of the most prevalent concerns involves electrical malfunctions. Users may experience unresponsive controls or inconsistent operation. These issues can stem from several sources, including faulty wiring or connections.

| Issue | Possible Cause | Solution |

|---|---|---|

| No response from controls | Disconnected wiring | Check all connections and ensure they are secure. |

| Inconsistent operation | Faulty circuit board | Inspect the circuit board for damage; replace if necessary. |

Mechanical Problems

Another area to consider is mechanical difficulties, which can affect the smooth operation of the system. Common symptoms include unusual noises or jerky movements during operation.

| Issue | Possible Cause | Solution |

|---|---|---|

| Unusual noises | Worn bearings | Lubricate or replace bearings to eliminate noise. |

| Jerky movements | Debris in the mechanism | Clean the moving parts to ensure free movement. |

Where to Find Authentic Parts

Finding genuine components for your equipment is crucial for maintaining optimal performance and longevity. Quality replacements ensure that your system operates efficiently, preventing potential issues down the line. Here are some reliable avenues to explore for sourcing authentic elements.

- Manufacturer’s Website: Always start with the official website of the manufacturer. They typically offer the most reliable and high-quality replacements.

- Authorized Retailers: Check with authorized dealers or retail outlets that specialize in marine accessories. These locations often carry a range of original components.

- Online Marketplaces: Websites like Amazon or eBay can be useful, but make sure to verify the seller’s ratings and reviews to ensure authenticity.

- Marine Supply Stores: Local marine supply shops are great for finding original items, and the staff can often provide valuable advice on compatibility.

- Forums and Online Communities: Engaging with online forums dedicated to boating can lead to recommendations for trustworthy suppliers.

By exploring these options, you can ensure that you acquire authentic components that meet the standards required for your system, ultimately enhancing its performance and reliability.