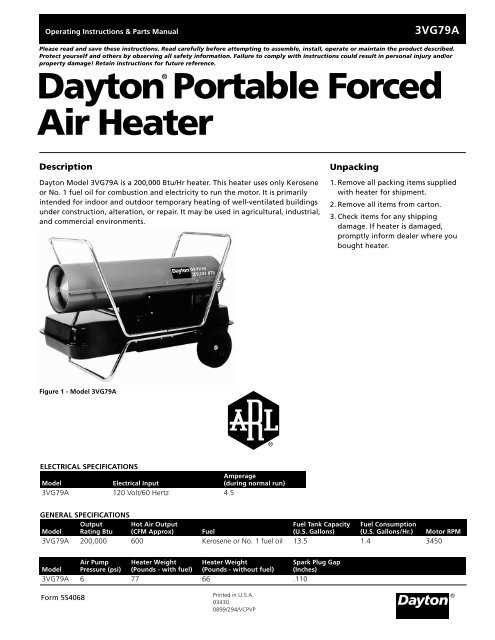

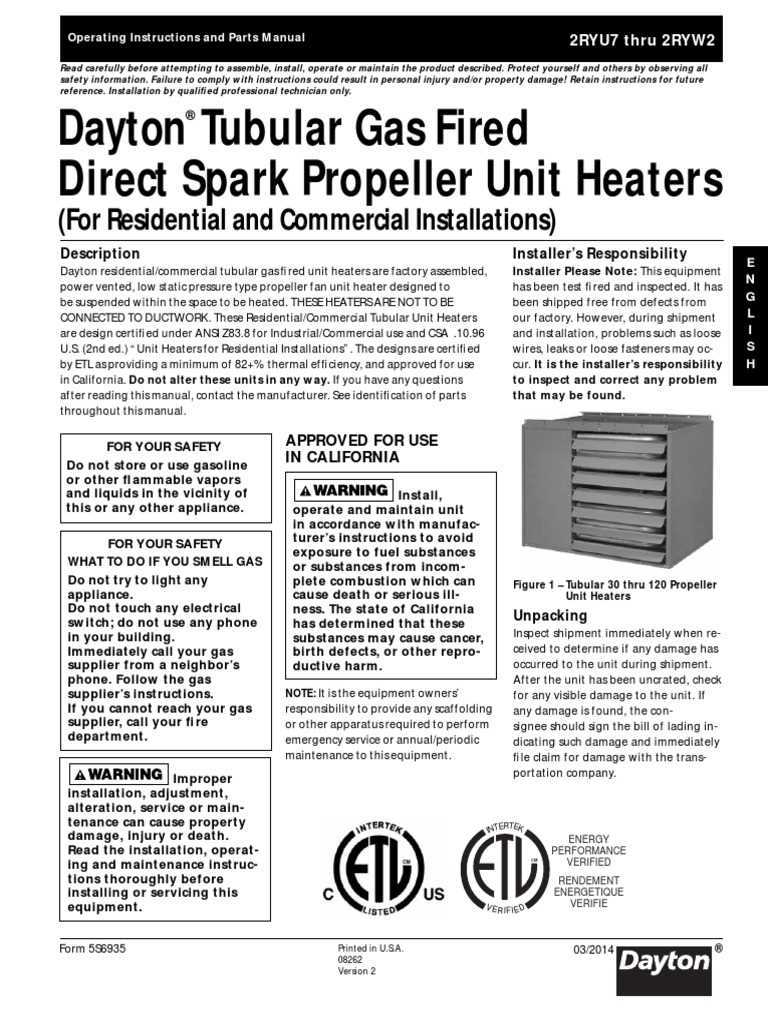

In any heating apparatus, a thorough comprehension of its individual components is crucial for optimal performance and maintenance. Each element plays a vital role in ensuring efficient operation and longevity, contributing to the overall functionality of the system.

Exploring these elements enables users to troubleshoot issues effectively and make informed decisions regarding repairs or replacements. This knowledge not only enhances the user experience but also promotes safety in handling the device.

To delve deeper into this subject, we will outline the key components, illustrating their interconnections and functions. This exploration will provide a comprehensive guide for those seeking to understand their heating systems better.

Understanding Dayton Heater Components

Gaining insight into the various elements that constitute a heating device is essential for effective maintenance and troubleshooting. Each component plays a crucial role in the overall functionality, ensuring optimal performance and safety. By familiarizing oneself with these integral parts, one can enhance the longevity and efficiency of the unit.

Key Components Overview

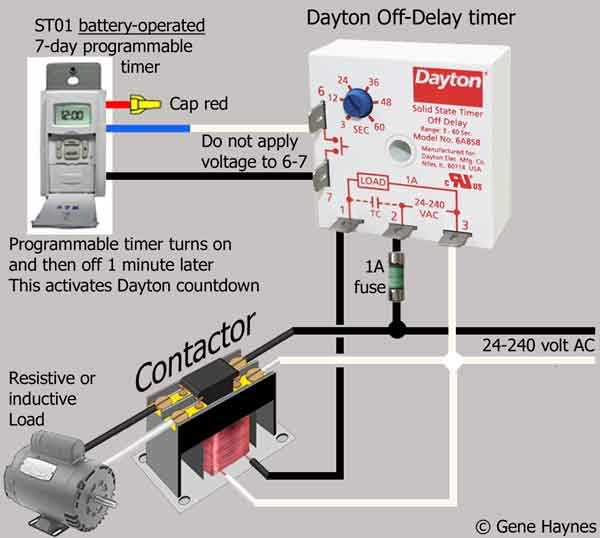

- Power Supply: Provides the necessary energy for operation, often involving electrical connections.

- Heating Element: The core component responsible for generating heat through resistance.

- Thermostat: Regulates the temperature by controlling the power supply to the heating element.

- Blower or Fan: Distributes warm air throughout the space, improving comfort levels.

- Control Panel: Allows users to set preferences and monitor operational status.

Maintenance and Care Tips

- Regularly check and clean the heating element to prevent buildup and ensure efficiency.

- Inspect electrical connections for signs of wear or damage to avoid safety hazards.

- Test the thermostat periodically to ensure accurate temperature readings.

- Keep the blower or fan free from obstructions to maintain optimal airflow.

- Review the control panel for any error codes or alerts that may indicate maintenance needs.

Understanding these essential components can significantly enhance the functionality and reliability of your unit, ultimately leading to a more comfortable environment.

Importance of Accurate Diagrams

Precise representations play a crucial role in various fields, providing clarity and guidance for assembly, maintenance, and troubleshooting processes. They serve as visual aids that enhance understanding and facilitate efficient communication among users and technicians. A well-constructed illustration can significantly reduce errors and save time, leading to improved overall performance.

When dealing with complex systems, having accurate schematics ensures that each component’s function and placement are clearly understood. This clarity is essential not only for professionals but also for DIY enthusiasts who may lack extensive experience. Consequently, the reliability of the information conveyed through these visuals is paramount.

| Benefits | Description |

|---|---|

| Clarity | Enhances understanding of complex systems. |

| Efficiency | Reduces time spent on repairs and assembly. |

| Accuracy | Minimizes the likelihood of errors during installation or maintenance. |

| Accessibility | Makes information available to users of varying expertise. |

In conclusion, the significance of well-designed representations cannot be overstated. They are indispensable tools that empower users to engage confidently with their equipment, ultimately enhancing functionality and longevity.

Common Issues with Heater Parts

When it comes to thermal devices, various challenges can arise due to wear and tear or environmental factors. Understanding these issues can help users maintain optimal performance and extend the lifespan of their equipment. Identifying and addressing common problems early can prevent further complications and ensure safe operation.

Electrical Failures

One of the most frequent challenges involves electrical components. These may suffer from short circuits, loose connections, or complete failures, leading to inefficiency or total malfunction. Regular inspections and testing of wiring and electrical systems can help detect issues before they escalate.

Thermal Control Malfunctions

Another prevalent issue is related to temperature regulation mechanisms. Sensors or thermostats may become unresponsive or inaccurately gauge the surrounding temperature. This can result in improper heating cycles, causing discomfort and increased energy consumption. Periodic calibration and replacement of faulty sensors can help maintain effective thermal management.

Replacing Faulty Components Effectively

Maintaining optimal functionality in equipment often requires the timely replacement of defective elements. This process not only enhances performance but also prolongs the lifespan of the device. Understanding the correct approach can make the task more efficient and reduce the likelihood of future issues.

| Component | Symptoms of Failure | Replacement Tips |

|---|---|---|

| Thermostat | Inconsistent temperature control | Ensure power is off; calibrate before installing a new unit. |

| Fan | Unusual noises or lack of airflow | Inspect connections; lubricate or replace as necessary. |

| Ignitor | Failure to start | Check for cracks; use a multimeter to test continuity. |

Step-by-Step Assembly Guide

This section will provide a comprehensive approach to assembling your equipment effectively and efficiently. By following these clear instructions, you will ensure that every component fits perfectly, contributing to optimal performance.

Preparation Phase

Begin by gathering all necessary components and tools. Ensure your workspace is clean and organized, allowing for a smooth assembly process. Familiarize yourself with each item and its function within the overall system.

Assembly Process

Start by connecting the main structure, followed by the integration of secondary components. Secure each part carefully, checking alignment and fit at every step. Once fully assembled, conduct a thorough inspection to guarantee everything is correctly installed before proceeding to the operational stage.

Identifying Parts by Function

Understanding the various components of an apparatus is crucial for effective maintenance and troubleshooting. Each element serves a unique role, contributing to the overall functionality of the system.

Main Components

- Power Supply: Provides the necessary energy to operate.

- Control System: Regulates performance and settings.

- Heating Element: Generates the required thermal energy.

- Safety Mechanisms: Ensures safe operation and prevents hazards.

Additional Elements

- Fan: Circulates air for even distribution.

- Thermostat: Monitors and adjusts temperature levels.

- Vents: Facilitates proper airflow and exhaust.

By familiarizing oneself with these components, one can better assess functionality and address potential issues efficiently.

Maintaining Your Dayton Heater

Regular upkeep is essential for ensuring optimal performance and longevity of your heating equipment. By following a few simple practices, you can enhance efficiency and prevent potential breakdowns. This section provides guidance on routine care and inspection procedures to keep your system running smoothly.

1. Routine Inspections: Schedule periodic checks to identify any wear or damage. Look for signs of corrosion, loose connections, or unusual noises that may indicate underlying issues. Early detection can save time and repair costs.

2. Cleaning Components: Accumulated dust and debris can hinder functionality. Ensure that all accessible elements are cleaned regularly. Pay special attention to filters and vents, as these are crucial for maintaining airflow and efficiency.

3. Lubrication: Many mechanical parts require lubrication to function properly. Consult your manual for recommended intervals and specific points that need attention. Proper lubrication can reduce friction and extend the lifespan of moving parts.

4. Professional Servicing: Consider engaging a certified technician for comprehensive maintenance. A professional can perform detailed inspections, ensure safety standards are met, and address complex issues that may not be apparent during routine checks.

5. Seasonal Preparation: Before peak usage seasons, conduct a thorough evaluation. This includes testing the system, checking for any leaks, and confirming that all controls are functioning correctly. A proactive approach will help you avoid unexpected failures when you need your equipment the most.

By adhering to these maintenance tips, you can enjoy reliable warmth and peace of mind throughout the colder months. Regular attention will help preserve the integrity of your system, ensuring it operates efficiently for years to come.

Resources for Troubleshooting Problems

When faced with malfunctions in heating appliances, having access to reliable resources can significantly aid in identifying and resolving issues. Whether you are a DIY enthusiast or seeking professional help, various tools and references are available to streamline the troubleshooting process.

Online Guides and Manuals

One of the most effective ways to troubleshoot is to consult user manuals and online guides. These resources often provide detailed information on common issues and their solutions. Look for:

- Manufacturer websites for downloadable manuals

- Forums and community boards where users share experiences

- Video tutorials demonstrating repair techniques

Diagnostic Tools

Utilizing diagnostic tools can enhance your ability to pinpoint problems. Some valuable tools include:

- Multimeters for checking electrical components

- Thermometers to assess temperature outputs

- Pressure gauges for evaluating airflow

By leveraging these resources and tools, you can effectively navigate issues and ensure optimal performance of your heating systems.