In the realm of plumbing technology, efficient waste removal is paramount. A well-designed mechanism ensures optimal functionality, maintaining hygiene and convenience in various settings. This system comprises several integral elements that work in harmony to achieve effective performance.

Each segment of this innovative assembly plays a crucial role, from controlling water flow to facilitating the flushing process. Understanding these components not only aids in troubleshooting but also enhances one’s appreciation for the engineering behind daily utilities. By grasping how these elements interact, users can make informed decisions regarding maintenance and upgrades.

This exploration delves into the intricate layout of these essential pieces, offering a comprehensive view of their arrangement and purpose. By familiarizing oneself with these configurations, individuals can better understand the mechanics at play, leading to improved management of their plumbing systems.

Understanding Flushometer Components

This section delves into the essential elements of a water control system commonly found in commercial restrooms. Each component plays a pivotal role in ensuring efficient operation, contributing to both performance and user satisfaction.

Key Elements and Their Functions

At the core of these systems are several crucial components that work in harmony. The valve regulates the flow of water, ensuring a precise amount is released during each use. Another significant part is the sensor, which detects when a user has finished, triggering the flushing mechanism automatically.

Maintenance and Care

Understanding these elements is vital for proper maintenance. Regular checks on the seal and diaphragm can prevent leaks and ensure longevity. Being aware of how each component functions allows for timely interventions and enhances overall efficiency.

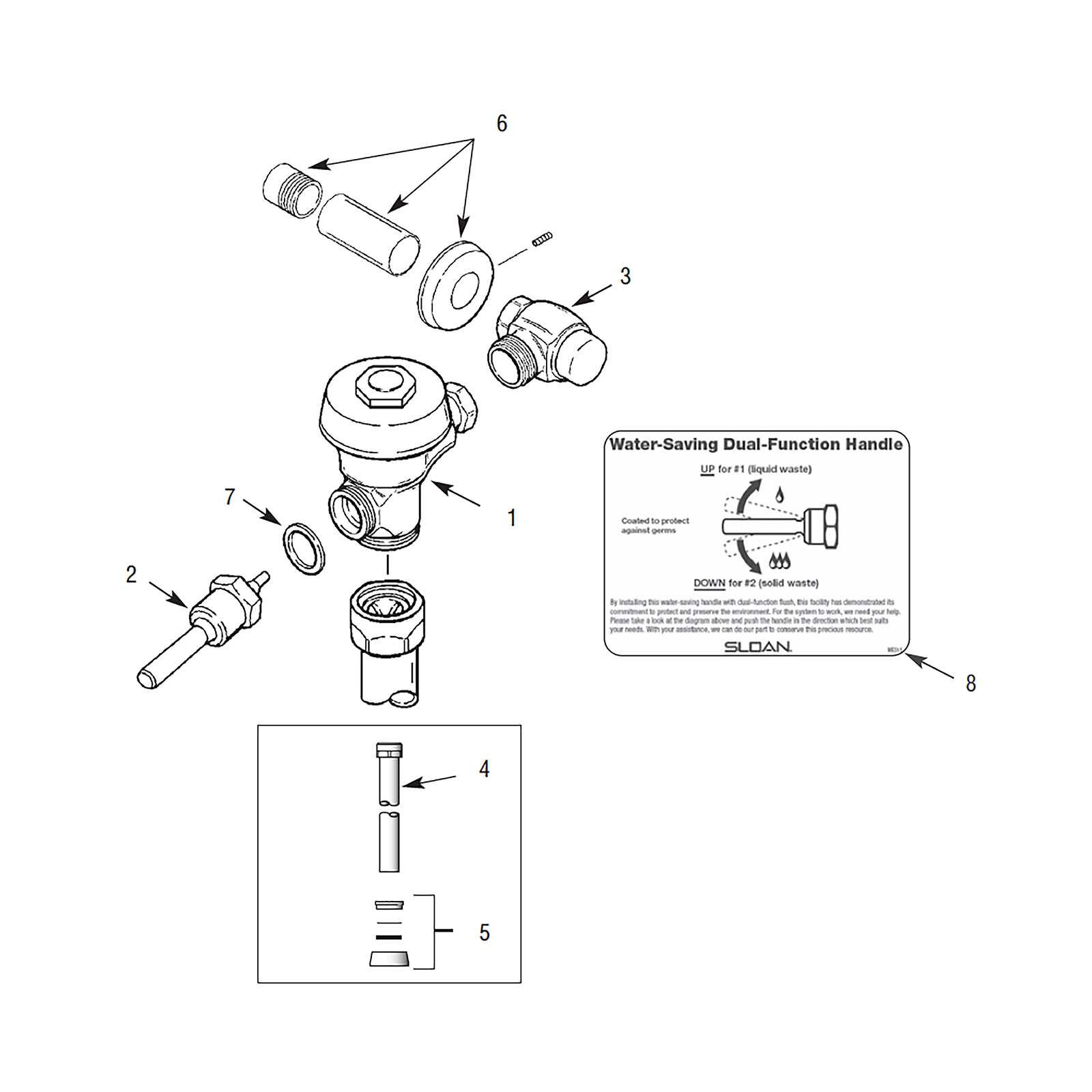

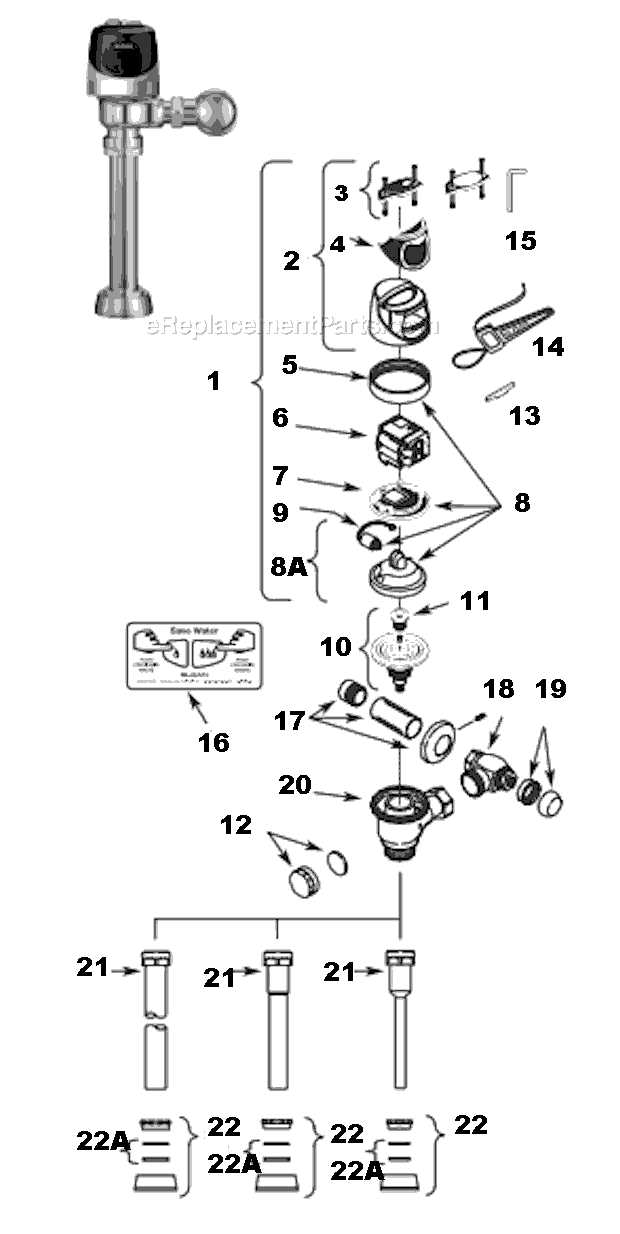

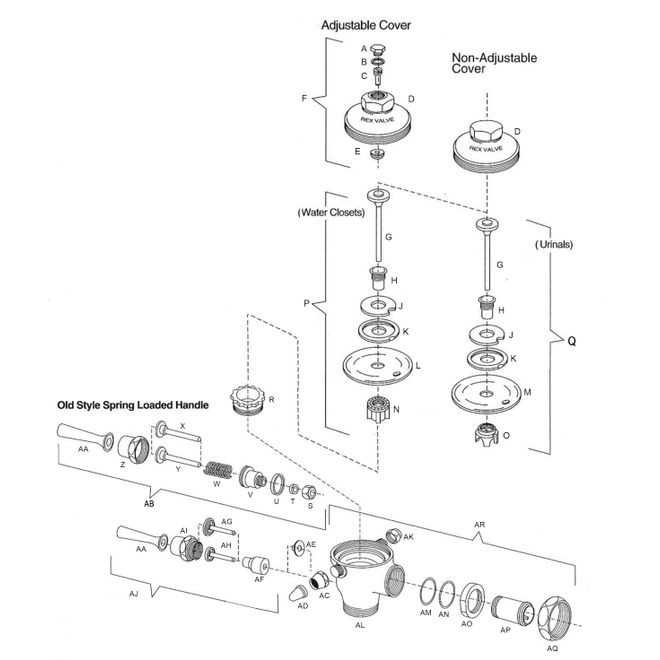

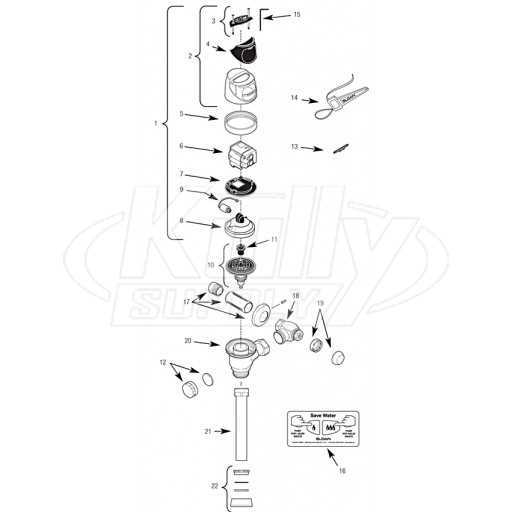

Key Parts of a Flushometer

Understanding the essential components of a toilet flushing mechanism is crucial for effective maintenance and repair. Each element plays a significant role in ensuring proper functionality and efficiency during use. Knowledge of these components can help in troubleshooting issues and enhancing performance.

One vital element is the valve assembly, which controls the flow of water during the flushing process. This component is responsible for initiating the release of water from the supply line, enabling the flushing action. The diaphragm, often part of the valve assembly, helps maintain pressure and ensures a consistent flow rate.

Another important feature is the handle or actuator, which allows users to engage the flushing mechanism easily. This component’s design can vary, but its primary function remains the same: to trigger the release of water with minimal effort.

The supply tube is equally critical, delivering water from the source to the flushing system. Its size and condition can greatly influence the effectiveness of the entire mechanism. Additionally, the water filter, if present, helps prevent debris from entering the system, ensuring smooth operation.

Finally, the seat and seal are fundamental in preventing leaks and maintaining water pressure within the system. Their integrity is essential for optimal performance, and regular inspection can help identify potential issues before they escalate.

Functionality of Flushometer Systems

These innovative water control devices play a crucial role in the efficient operation of restroom facilities. Designed to deliver a precise volume of water to ensure effective waste removal, they enhance sanitation while minimizing water consumption. The mechanism is typically activated by a user-initiated action, which triggers the release of water into the fixture.

Understanding the components and their functions is essential for effective maintenance and troubleshooting. Below is a table summarizing the key elements involved in the operation of these systems:

| Component | Function |

|---|---|

| Control Valve | Regulates water flow based on pressure and user activation. |

| Actuator | Initiates the flushing process by opening the valve. |

| Reservoir | Holds the water supply until needed for flushing. |

| Flush Volume Regulator | Ensures a consistent volume of water is used with each flush. |

| Overflow Tube | Prevents water from spilling over and maintains a safe water level. |

The coordinated functioning of these elements allows for a reliable and efficient system, contributing to water conservation and improved hygiene standards in public and private restrooms alike.

Maintenance Tips for Flushometers

Regular upkeep is essential to ensure efficient operation and longevity of restroom flushing systems. By following a few simple practices, you can prevent common issues and maintain optimal performance.

Routine Inspection

Conducting frequent checks can help identify potential problems before they escalate. Look for signs of leaks, unusual noises, or inconsistent flushing. A proactive approach can save time and money on repairs in the long run.

Cleaning and Replacement

Keep the components clean to ensure smooth functionality. Mineral deposits can accumulate, affecting performance. Use a soft cloth and appropriate cleaning solutions. If any elements show signs of wear or damage, replace them promptly. Regular replacements of seals and washers can help maintain a tight seal and prevent leaks.

By implementing these maintenance tips, you can enhance the reliability and efficiency of your flushing systems, ensuring a better experience for users.

Common Flushometer Issues

Maintaining proper functionality in restroom fixtures is crucial for both hygiene and efficiency. Various complications can arise that affect their operation, often leading to inefficiencies or water wastage. Understanding these frequent challenges can aid in troubleshooting and ensuring optimal performance.

Leaking Valves: One of the most prevalent issues is leakage from the control valve. This can occur due to worn-out seals or improper installation, resulting in continuous water flow. Regular inspection and timely replacement of seals can mitigate this problem.

Insufficient Water Flow: Another common concern is inadequate water pressure during flushing. This can stem from blockages in the supply line or sediment build-up within the system. Ensuring that the water supply is unobstructed and maintaining cleanliness can help restore proper flow.

Unresponsive Mechanism: Occasionally, the flushing mechanism may fail to activate. This could be caused by a malfunctioning diaphragm or internal components that have become damaged over time. Routine maintenance checks can help identify issues early and ensure smooth operation.

Noise During Operation: Excessive noise during the flushing process can be a sign of air in the lines or faulty components. Identifying the source of the noise is essential, as it may indicate underlying problems that require immediate attention.

By recognizing these common challenges and addressing them promptly, users can enhance the functionality and longevity of their restroom fixtures, ensuring a better experience for all. Regular maintenance and awareness are key to preventing minor issues from escalating into significant problems.

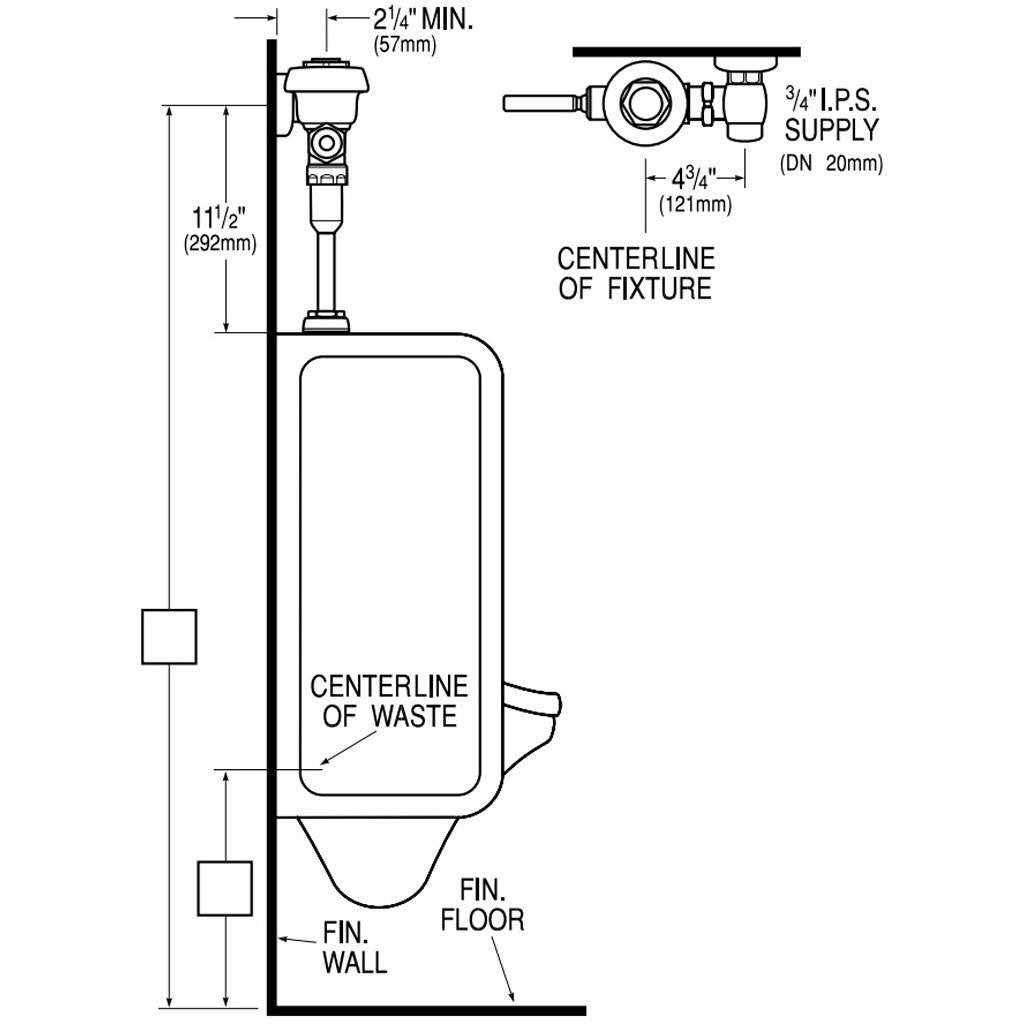

Installation Guidelines for Flushometer Units

Setting up a water management system requires careful planning and execution to ensure efficient operation and longevity. This section outlines essential steps and considerations for the successful installation of these units, focusing on optimal functionality and maintenance ease.

Preparation Before Installation

Prior to commencing the installation process, it is crucial to gather all necessary tools and materials. Follow these preliminary steps:

- Review the manufacturer’s instructions for specific guidelines.

- Gather tools such as wrenches, screwdrivers, and measuring devices.

- Ensure you have the correct unit size for your application.

- Inspect the installation site for any potential issues, including pipe alignment and accessibility.

Step-by-Step Installation Process

Once preparations are complete, proceed with the installation by following these steps:

- Shut off the water supply to prevent any leaks during the setup.

- Install the mounting bracket securely according to the specifications.

- Connect the inlet and outlet connections, ensuring tight seals to avoid leaks.

- Attach the flushing mechanism, making sure it is aligned properly with the mounting bracket.

- Adjust any necessary settings, such as flow rate and timing features, if applicable.

- Restore the water supply and conduct a test flush to verify proper operation.

- Check for any leaks and make adjustments as needed.

By following these guidelines, you can ensure that your installation is both effective and reliable, promoting efficient water usage and user satisfaction.

Flushometer vs. Traditional Toilets

This section explores the differences between modern flush systems and conventional water closets. Each design has its unique characteristics, advantages, and disadvantages, catering to various preferences and needs in restroom facilities.

Design and Mechanism

- Modern Systems: Typically utilize a pressure-assisted mechanism, providing a powerful and efficient flush.

- Conventional Units: Rely on gravity to facilitate waste removal, often requiring a larger volume of water for effective flushing.

Water Efficiency

- Modern Flush Systems: Generally consume less water per flush, making them environmentally friendly.

- Traditional Water Closets: May use more water, leading to higher consumption and costs over time.

In summary, both options offer distinct functionalities and efficiencies, allowing users to choose based on their specific needs and environmental considerations.

Choosing the Right Flushometer Model

Selecting the appropriate model for your toilet system involves several key considerations that ensure optimal performance and efficiency. It’s essential to assess the specific needs of your restroom environment, taking into account factors such as water pressure, fixture compatibility, and intended usage frequency.

One important aspect is understanding the flow rate requirements of your installations. Different systems offer varying rates, which can affect how effectively they operate in high-traffic areas versus more residential settings. Ensuring the selected model meets these demands will lead to improved user satisfaction and reduced maintenance issues.

Another critical factor is the type of valve technology used. Options range from manual to sensor-activated mechanisms, each with distinct advantages depending on your operational preferences and hygiene standards. Sensor-based models often enhance user experience and conserve water, making them suitable for modern facilities.

Compatibility with existing plumbing is also vital. Prior to making a choice, evaluate the dimensions and connections of your current setup to avoid potential installation challenges. Consulting with a plumbing professional can provide additional insights into which models will seamlessly integrate with your system.

Lastly, consider the brand reputation and warranty offerings. Investing in a reliable manufacturer with positive reviews can ensure longevity and effective support, ultimately contributing to the overall success of your restroom solutions.