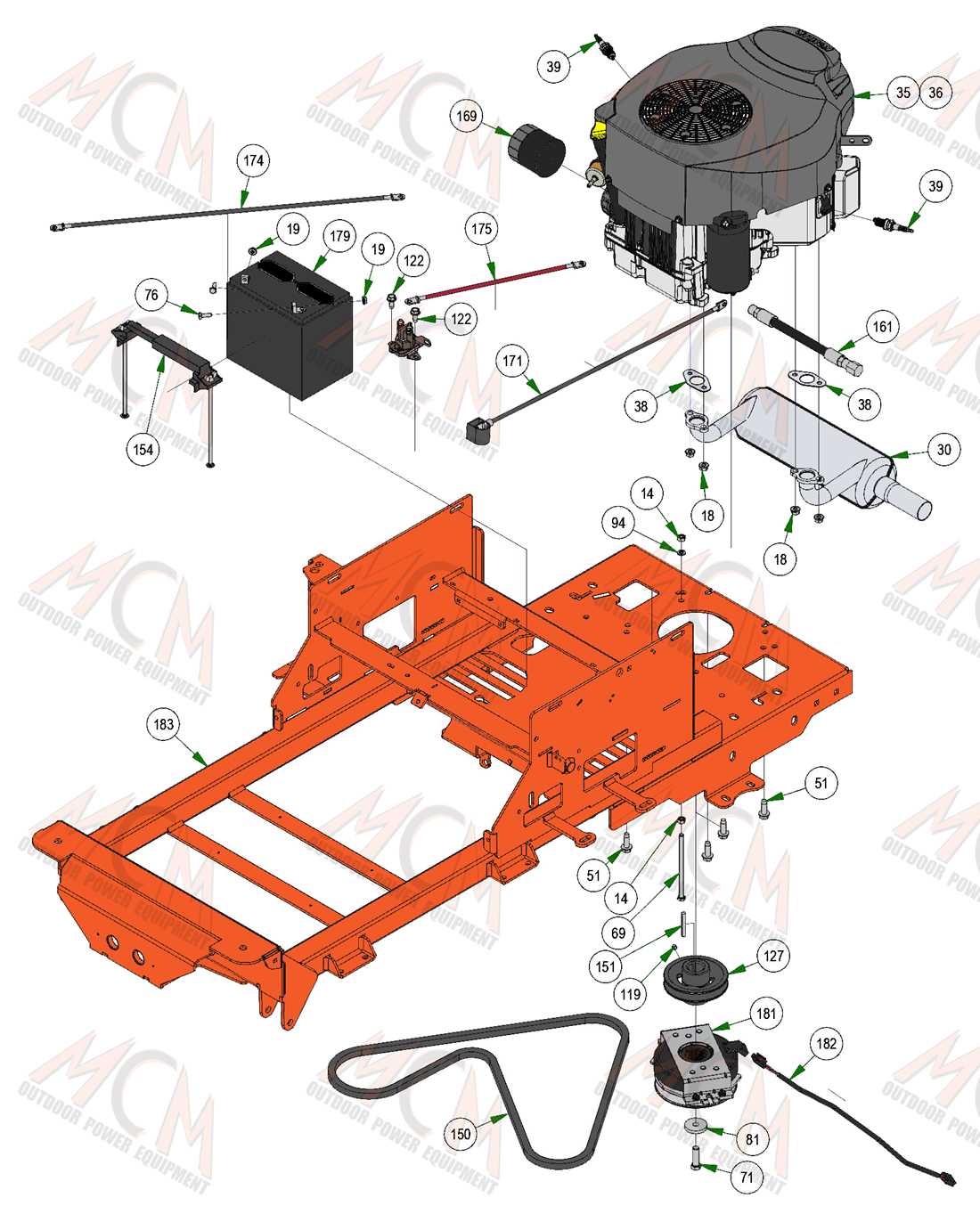

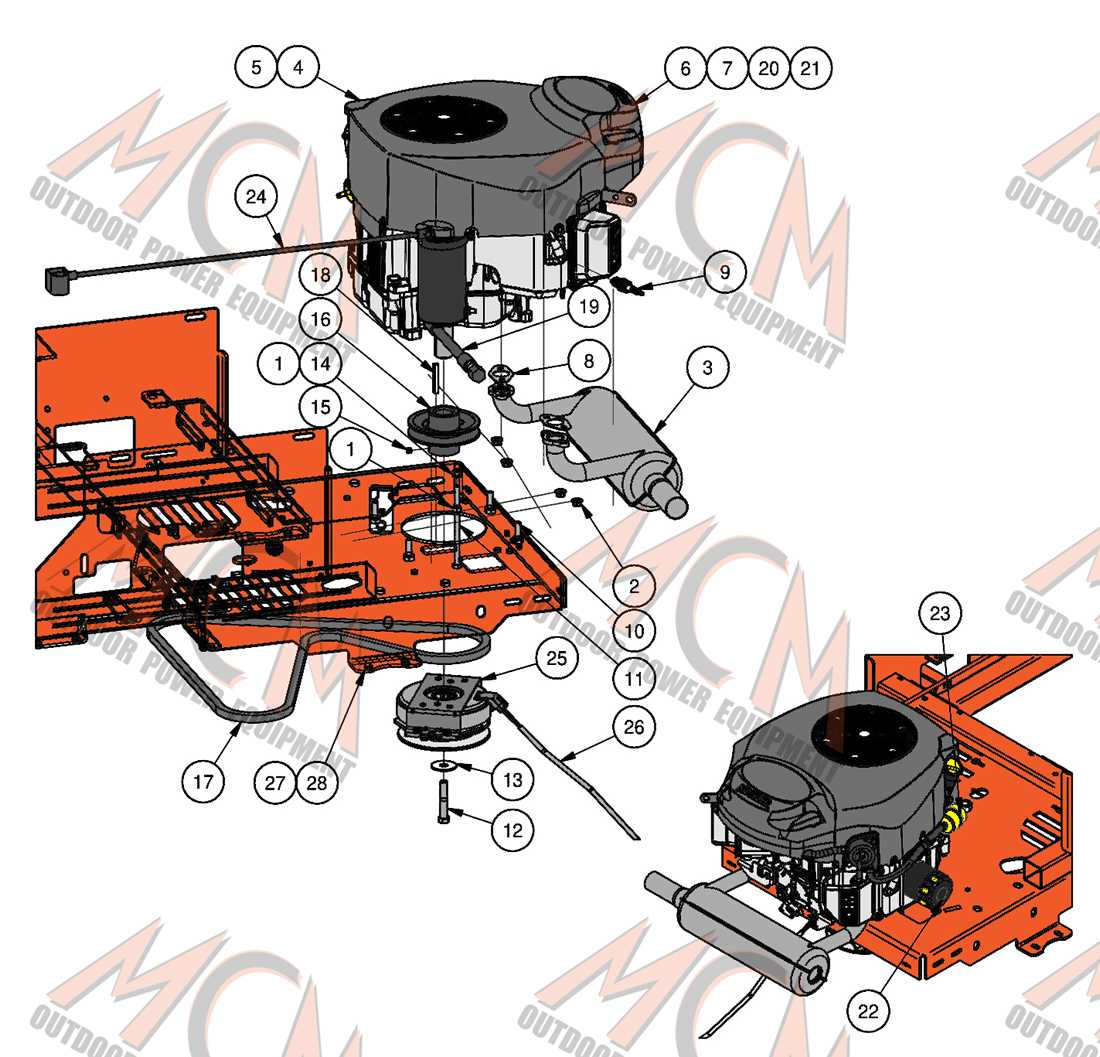

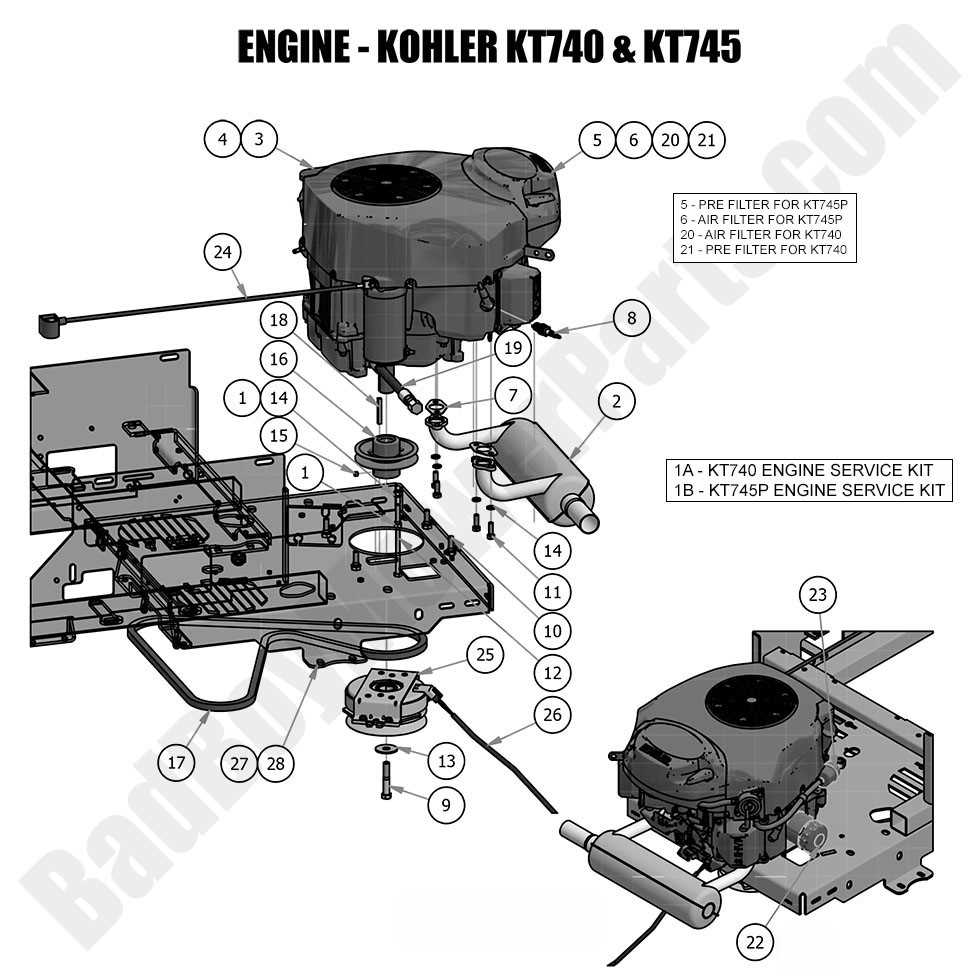

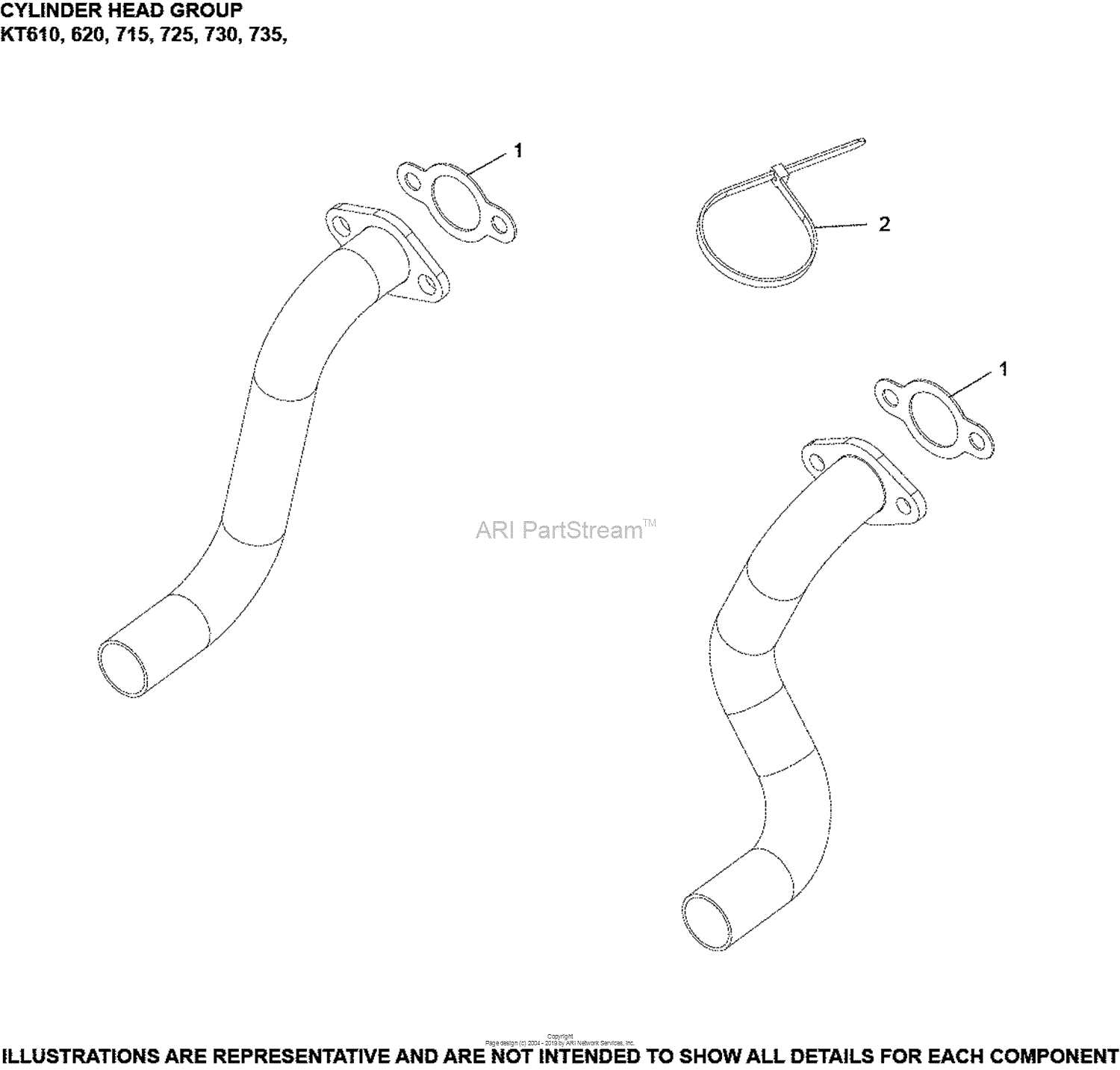

In the realm of mechanical systems, a comprehensive overview of individual elements plays a vital role in ensuring optimal functionality and maintenance. By visualizing the interconnection of various components, one can gain valuable insights into the operation and upkeep of the machinery. This understanding is essential for both troubleshooting and performing routine checks, ultimately extending the lifespan of the equipment.

Diagrams showcasing the arrangement of engine parts serve as invaluable resources for technicians and enthusiasts alike. These illustrations not only highlight the positioning of each element but also facilitate a clearer understanding of how they interact during operation. Whether for repairs or upgrades, having a detailed visual reference can significantly streamline the process, making it more efficient and effective.

Furthermore, these layouts empower users to identify potential issues swiftly, allowing for proactive measures to be taken before minor problems escalate into major repairs. As such, familiarity with these representations is crucial for anyone involved in the care and management of mechanical systems. By mastering the intricacies of component organization, one can enhance their expertise and contribute to the overall reliability of the machinery.

This section addresses frequent problems encountered in small engine systems and provides practical solutions. Understanding these issues is essential for effective maintenance and optimal performance.

Frequent Problems

- Engine Won’t Start

- Overheating Issues

- Fuel Leaks

- Poor Performance

Effective Solutions

-

Engine Won’t Start:

- Check the fuel level and ensure it is fresh.

- Inspect the spark plug for wear and replace if necessary.

- Examine the battery connections for corrosion or loose wires.

-

Overheating Issues:

- Clean the air filter to enhance airflow.

- Ensure the cooling fins are free from debris.

- Monitor the coolant levels and add if needed.

-

Fuel Leaks:

- Inspect fuel lines for cracks or damage.

- Tighten loose fittings to prevent leaks.

- Replace any faulty fuel connectors.

-

Poor Performance:

- Regularly change the oil and air filters.

- Ensure proper fuel type is being used.

- Adjust the carburetor settings as needed.

Key Components of KT745 Engine

The engine consists of several essential elements that contribute to its overall functionality and efficiency. Understanding these components is crucial for anyone looking to maintain or repair the system effectively.

Each part plays a significant role in the engine’s operation, ensuring optimal performance and longevity. Below is a detailed overview of the primary elements that make up this engine.

| Component | Description |

|---|---|

| Cylinder Block | The main structure housing the cylinders, providing support for various engine components. |

| Piston | A moving part that compresses the fuel-air mixture and transfers energy to the crankshaft. |

| Crankshaft | A shaft that converts the linear motion of the pistons into rotational motion to power the machinery. |

| Camshaft | A component that operates the intake and exhaust valves, regulating the engine’s airflow. |

| Fuel System | Includes the fuel tank, lines, and injectors, responsible for delivering fuel to the engine. |

| Ignition System | Consists of spark plugs and coils that ignite the fuel-air mixture, initiating combustion. |

| Cooling System | A network of components that prevents the engine from overheating, ensuring efficient operation. |

Maintenance Tips for Longevity

Ensuring the durability of machinery requires regular upkeep and attention to detail. By implementing a series of strategic practices, one can significantly extend the operational lifespan of their equipment. This section explores essential care techniques that contribute to long-term performance.

Regular Cleaning: Keeping components free from dirt and debris is crucial. Accumulated grime can lead to wear and malfunction. Employ a suitable cleaning method to maintain optimal functionality.

Frequent Inspections: Periodically examining the equipment for signs of wear and tear can help identify potential issues before they escalate. Look for cracks, loose parts, or any irregularities that may hinder performance.

Lubrication: Applying the right lubricants to moving parts reduces friction and prevents overheating. Consult the manufacturer’s guidelines to choose the appropriate substances for each component.

Timely Replacements: Replacing worn or damaged parts promptly can prevent further complications. Maintain an inventory of critical components to ensure swift action when necessary.

Follow Manufacturer Guidelines: Adhering to the recommended maintenance schedule and practices provided by the manufacturer is essential for preserving functionality. This will help in understanding the specific needs of the equipment.

How to Read Parts Diagrams

Understanding visual representations of components is essential for effective maintenance and repair. These illustrations provide a detailed view of individual elements and their relationships within a system. Familiarity with the layout and symbols used can significantly enhance your ability to identify necessary components.

Key Elements to Consider

- Symbols: Recognize common icons and their meanings, as they denote specific elements or functionalities.

- Labels: Pay attention to written identifiers that clarify the roles of various components.

- Connections: Observe how parts are interconnected, as this often indicates assembly order or functionality.

Steps for Effective Interpretation

- Start by familiarizing yourself with the overall layout.

- Identify the key symbols and labels to understand each component’s function.

- Trace connections to see how elements work together within the system.

- Consult the accompanying documentation for additional context or specifications.

Where to Find Replacement Parts

Locating suitable components for machinery maintenance can enhance performance and extend longevity. There are several avenues to explore when seeking these essential items, ensuring you find reliable options that meet your requirements.

- Authorized Dealers: Visiting certified retailers can provide assurance of quality. These locations often stock genuine items that meet manufacturer specifications.

- Online Retailers: Numerous e-commerce platforms offer a wide range of components. Look for reputable websites with positive reviews and detailed product descriptions.

- Local Repair Shops: Engaging with nearby service centers can be beneficial. Technicians may have access to or knowledge of specific items that can suit your needs.

- Manufacturer Websites: Exploring the official sites may reveal catalogues of available components, including compatibility information and purchasing options.

- Aftermarket Suppliers: Consider alternative providers that offer comparable items, often at competitive prices. Ensure they have a good reputation to avoid low-quality options.

Taking the time to explore these sources will help you find the right solutions for your equipment, ultimately ensuring efficient operation and minimizing downtime.

Installation Guidelines for New Parts

When integrating new components into a system, it is crucial to follow systematic procedures to ensure proper functionality and longevity. This section outlines essential practices for effective installation, focusing on preparation, execution, and verification steps.

Begin by reviewing the specifications and compatibility of the components being installed. Ensure that all necessary tools are available and that the workspace is clean and organized. This preparation phase is vital for a smooth installation process.

During installation, handle each component with care, following the manufacturer’s recommendations. Secure all connections tightly but avoid over-torquing, which can lead to damage. Take your time to position each part correctly, as misalignment can cause operational issues.

After completing the installation, it is essential to conduct thorough checks to confirm that everything is functioning as intended. Look for any signs of leaks, vibrations, or irregular noises, and make adjustments if necessary. Document the installation process for future reference, noting any challenges encountered and solutions implemented.