This section provides an in-depth exploration of a particular type of mechanical assembly widely utilized in agricultural and industrial applications. Understanding the various elements that comprise this assembly is essential for maintenance, troubleshooting, and optimizing performance.

By analyzing the intricate layout of components, users can gain valuable insights into their functionality and interrelations. Such knowledge is crucial for technicians and operators who strive to ensure efficient operation and longevity of the machinery.

In this article, we will delve into the intricacies of these components, highlighting their roles and how they contribute to the overall performance of the machinery. The information presented will serve as a useful reference for those looking to enhance their understanding of this essential system.

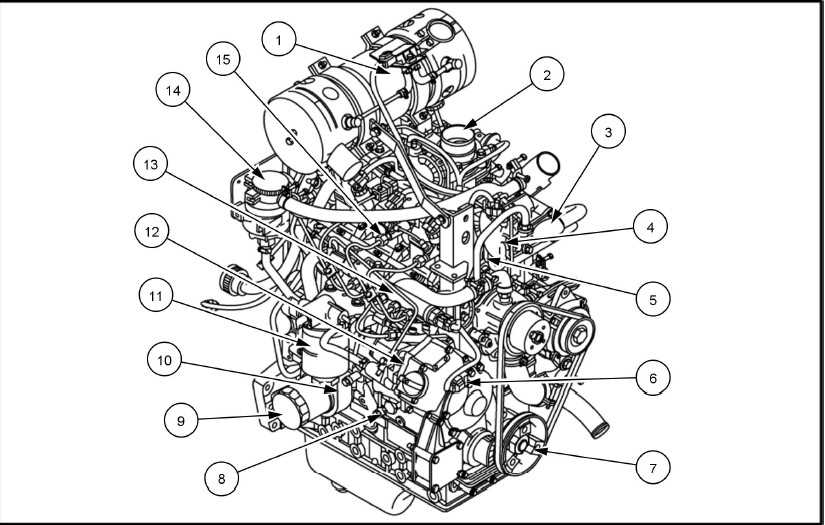

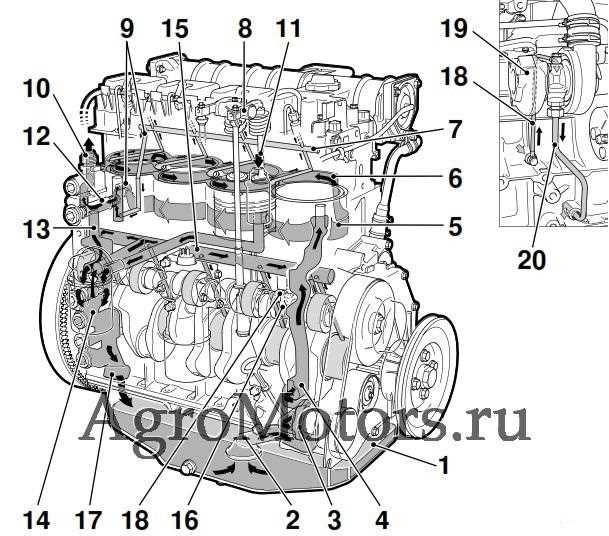

Understanding Deutz 1011 Engine Components

The study of mechanical systems involves exploring the various elements that contribute to their functionality and efficiency. In the context of a specific model, recognizing each component’s role is crucial for effective maintenance and troubleshooting. This section aims to shed light on the vital constituents of this particular system, illustrating how they work together to achieve optimal performance.

Central to the operation of this assembly is the core mechanism that facilitates movement and energy conversion. This fundamental unit interacts with a series of supporting mechanisms that enhance its capabilities. These include components designed for cooling, lubrication, and fuel delivery, each performing essential tasks to ensure smooth operation.

Understanding these elements helps users appreciate the complexity and ingenuity involved in the design. For instance, the cooling system prevents overheating, while the lubrication components minimize friction and wear. Additionally, fuel delivery systems ensure efficient operation by maintaining the appropriate flow and mixture of fuels, critical for sustaining power output.

Moreover, an awareness of each part’s location and function can significantly aid in diagnosing issues. By grasping how these elements fit together, individuals can more effectively identify potential problems and execute repairs. Knowledge of these components not only enhances operational efficiency but also extends the lifespan of the entire system.

Overview of Engine Functionality

This section provides a comprehensive look at the operational principles of a typical power unit found in various applications. Understanding how these systems work is crucial for anyone interested in mechanical engineering or maintenance. The focus will be on the essential components and their roles in converting fuel into mechanical energy efficiently.

Key Components and Their Roles

At the heart of the system lies the core mechanism, which orchestrates the combustion process. Fuel is mixed with air and ignited, resulting in a rapid expansion of gases. This expansion creates pressure that drives pistons, which are connected to a crankshaft. The movement of the pistons is translated into rotational motion, allowing the unit to perform work. Each element within the assembly is designed to withstand extreme conditions and contribute to the overall efficiency and reliability of the operation.

Efficiency and Performance Considerations

Efficiency in these units is paramount, as it directly affects fuel consumption and overall performance. Factors such as air-fuel mixture ratios, combustion chamber design, and exhaust management all play significant roles. By optimizing these parameters, operators can achieve better fuel economy and reduce emissions, making the system more environmentally friendly while enhancing power output.

Common Parts and Their Roles

In any mechanical system, various essential components work together to ensure efficient operation. Each element plays a crucial role in maintaining balance, movement, and the overall functionality of the unit. Understanding the purpose and interaction of these components helps with both maintenance and troubleshooting.

- Pistons: These are responsible for transferring energy from one medium to another, helping to power the movement within the system.

- Cooling Unit: Helps in managing temperature, ensuring that the entire mechanism doesn’t overheat during operation.

- Valves: These regulate the flow of different substances, ensuring that various sections of the system receive what they need at the right time.

- Fuel Distributor: This part ensures that the energy source is delivered consistently to different areas for optimal function.

- Exhaust Unit: Allows for the removal of unwanted materials, maintaining a clean and efficient cycle of operation.

- Step

Importance of Accurate Diagrams

Precision in technical illustrations is crucial for the effective understanding and maintenance of mechanical systems. These visuals serve as essential tools for technicians and engineers, providing clear representations of components and their interconnections. When accuracy is prioritized, the likelihood of errors during assembly or repair significantly decreases.

Clear illustrations enhance communication among team members, ensuring that everyone involved shares a common understanding of the layout and functionality of the system. This clarity is vital, especially in complex machinery where multiple elements must work in harmony.

Furthermore, detailed representations allow for better training of personnel, facilitating a quicker learning curve for new technicians. As they familiarize themselves with the configuration and operation of various components, they become more efficient in their roles. Ultimately, investing in precise illustrations leads to improved performance and longevity of mechanical systems.

Maintenance Tips for Engine Longevity

Ensuring the durability and efficiency of a mechanical unit requires regular upkeep and attention. By following best practices, you can significantly extend its lifespan and maintain optimal performance. Here are essential guidelines to keep in mind.

- Perform regular oil changes to keep the lubrication system functioning smoothly.

- Check and replace filters to prevent dirt and debris from contaminating vital components.

- Monitor fluid levels, including coolant and transmission fluid, to prevent overheating and mechanical failure.

- Inspect belts and hoses for wear and tear, replacing them as needed to avoid breakdowns.

- Ensure that all connections and fittings are secure to prevent leaks and maintain pressure.

In addition to routine checks, adopting a proactive approach can also be beneficial.

- Schedule regular inspections by a qualified technician to identify potential issues before they escalate.

- Keep a log of maintenance activities to track performance and identify trends over time.

- Utilize high-quality fluids and components that meet the manufacturer’s specifications.

By adhering to these practices, you can ensure that your machinery operates efficiently and remains reliable for years to come.

Identifying Parts in Diagrams

Understanding the components illustrated in technical visuals is crucial for effective maintenance and troubleshooting. Familiarizing oneself with these representations enhances the ability to locate and recognize individual elements, facilitating smoother operations. This process involves studying the layout and symbols used to denote each item within the schematic.

Visual cues play a significant role in identifying various components. Each symbol or shape typically corresponds to a specific function or feature, making it easier to differentiate between them. Contextual knowledge about the machinery can further aid in interpretation, allowing users to link the visual information with practical applications.

Moreover, comparing similar visuals can deepen understanding. Analyzing multiple examples of schematics helps develop a mental map of how components interact within the overall structure. This knowledge proves invaluable during repairs or upgrades, ensuring that users can effectively address any issues that may arise.

Replacement Procedures for Key Components

Maintaining optimal functionality in machinery often requires the timely replacement of essential elements. This section outlines effective methods for substituting critical components to ensure smooth operation and longevity. Understanding the correct procedures not only enhances performance but also minimizes the risk of malfunctions.

Preparation and Safety Measures

Before commencing any replacement process, it is crucial to implement appropriate safety protocols. Always disconnect power sources and allow the system to cool down. Gather the necessary tools and replacement items, ensuring they meet the required specifications. This preparatory phase lays the groundwork for a successful procedure.

Step-by-Step Replacement Process

Once the preparation is complete, follow these steps for a seamless transition:

- Remove the Existing Component: Carefully detach the old item by loosening any fasteners and disconnecting associated connections.

- Inspect Surrounding Areas: Before installation, examine the nearby sections for wear or damage, addressing any issues to prevent future complications.

- Install the New Component: Align the new piece accurately, ensuring it fits snugly into its designated space. Secure it with the appropriate fasteners.

- Test Functionality: After installation, reconnect power and conduct tests to confirm that the replacement operates correctly.

Adhering to these procedures can significantly enhance the reliability of your machinery and extend its service life.

Frequently Asked Questions About Parts

This section aims to address common inquiries regarding components and their functionality within machinery systems. Understanding the intricacies of these elements is crucial for effective maintenance and operation. Here, we provide clarity on frequent concerns and misconceptions.

Common Queries

Many individuals encounter similar questions when dealing with various elements of machinery. Below are some of the most frequently asked questions along with their answers.

Question Answer What should I consider when selecting components? It’s essential to assess compatibility, durability, and specific application requirements before making a choice. How can I ensure the longevity of my components? Regular maintenance and adhering to manufacturer guidelines are key to extending the lifespan of any machinery element. Where can I find reliable information on replacements? Consulting reputable manufacturers, official manuals, and authorized distributors will provide accurate information on suitable replacements. Is it necessary to use original components? While original parts are recommended for optimal performance, high-quality aftermarket alternatives can also be effective if compatible. Additional Considerations

When dealing with machinery components, always keep in mind the importance of regular inspections and timely replacements to avoid unexpected failures.

Resources for Further Information

For those seeking to deepen their understanding of machinery and its components, a variety of materials are available. These resources can offer valuable insights into the intricacies of mechanical systems, enhancing both knowledge and practical skills.

Online Databases: Numerous digital platforms host extensive information regarding various mechanical models. These databases provide technical specifications, maintenance guidelines, and user manuals that can be beneficial for both novices and experts alike.

Industry Publications: Journals and magazines dedicated to mechanical engineering often feature articles and case studies that explore advancements and best practices within the field. Subscribing to these publications can keep individuals informed about the latest trends and innovations.

Workshops and Seminars: Participating in hands-on workshops and educational seminars can greatly enhance practical knowledge. These events often include demonstrations and expert talks, providing attendees with direct experience and insights from seasoned professionals.

Manufacturer Websites: Many manufacturers maintain informative websites that detail their offerings. These sites typically include FAQs, instructional videos, and customer support resources to assist users in navigating their products effectively.

Forums and Community Groups: Engaging with online communities and forums dedicated to mechanical interests can foster discussion and knowledge sharing. Participants can seek advice, share experiences, and learn from one another, creating a rich learning environment.