In the realm of farming equipment, comprehending the intricate layout of various elements is essential for effective maintenance and repair. By visualizing the assembly of these machines, users can gain insight into the functionality and interconnection of each component, ensuring optimal performance in the field.

Exploring the configuration of these devices enables operators to identify critical sections and address potential issues before they escalate. This knowledge fosters a deeper appreciation of the machinery’s design and enhances troubleshooting capabilities.

Whether you’re a seasoned farmer or a newcomer to agricultural tasks, delving into the specifics of your equipment can lead to improved efficiency and longevity. Understanding how each piece works together serves as the ultimate guide to mastering your agricultural tools.

Understanding the Farmall H Model

The iconic tractor model has played a significant role in agricultural history, showcasing a combination of durability and efficiency. Designed for various farming tasks, it remains a favorite among enthusiasts and professionals alike. This section delves into the unique features and characteristics that define this remarkable machinery.

Key Features

- Robust engine design

- Reliable transmission system

- Versatile attachments for different tasks

- Ergonomic operator layout

Applications

This tractor model is well-suited for:

- Tilling and plowing fields

- Hauling materials and equipment

- Supporting livestock management

- Maintaining large properties

Its adaptability to various farming operations highlights its importance in modern agriculture.

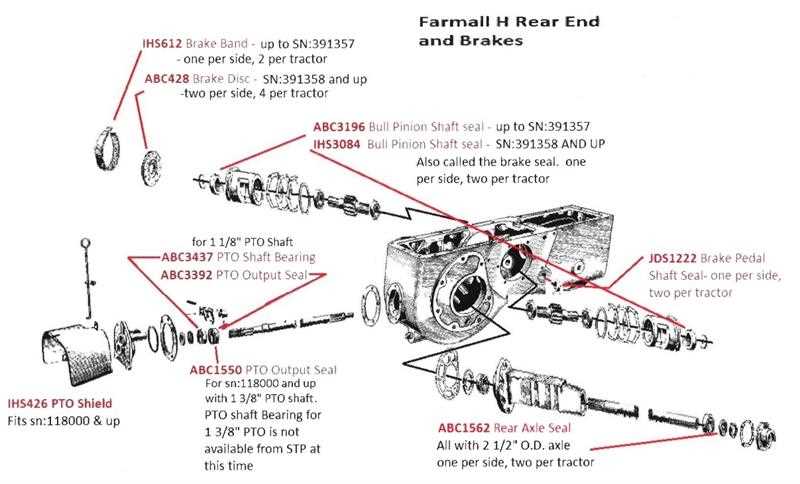

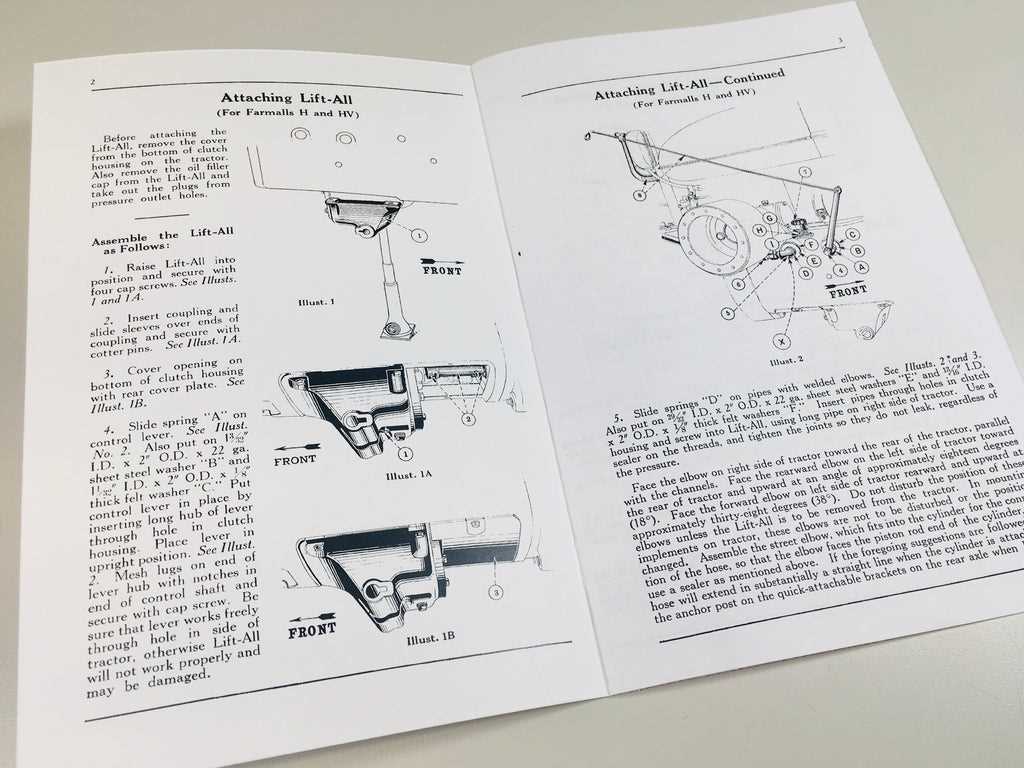

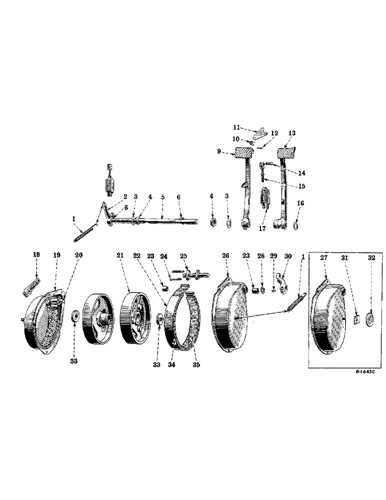

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding the structure and functionality of machinery. These illustrations serve as essential tools for maintenance, repair, and assembly, enabling users to navigate complex systems with ease.

One of the primary advantages of these visual aids includes:

- Enhanced Clarity: Clear visuals simplify the identification of individual elements, making it easier to locate and understand each piece’s function.

- Efficient Troubleshooting: When issues arise, having a visual reference allows for quicker diagnosis and resolution, saving time and reducing frustration.

- Accurate Reassembly: Following repairs or upgrades, these illustrations help ensure that every component is returned to its rightful place, maintaining the integrity of the machine.

- Improved Communication: For teams working on projects, these visuals facilitate better collaboration, ensuring everyone is on the same page regarding components and their arrangement.

In addition, utilizing visual guides can significantly enhance the learning experience for individuals unfamiliar with the equipment. They provide a structured way to absorb information, making complex systems more approachable.

Overall, these resources are invaluable for anyone involved in the upkeep and operation of machinery, promoting efficiency, accuracy, and safety in all tasks related to equipment management.

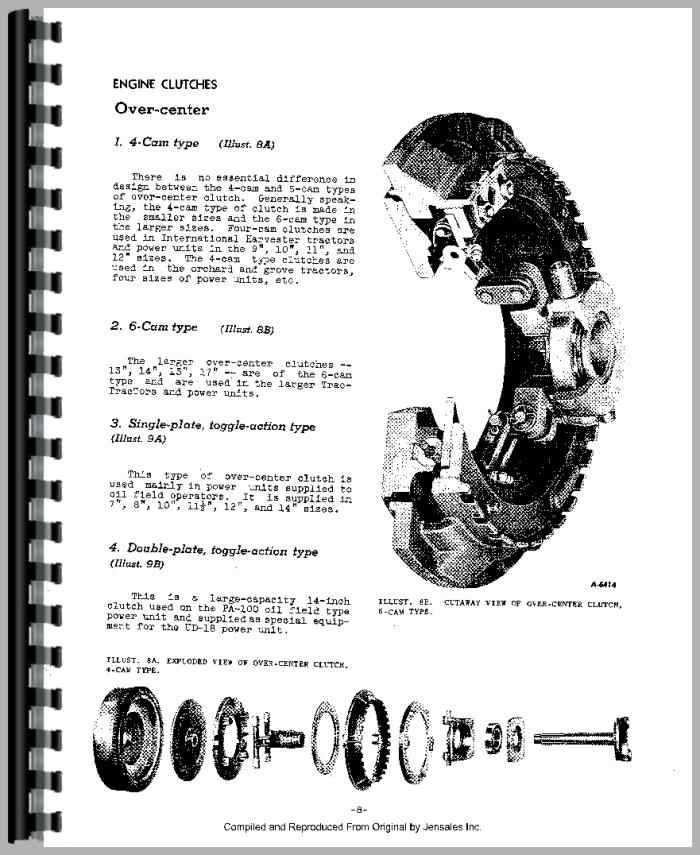

Identifying Key Components of the Tractor

Understanding the essential elements of a tractor is crucial for effective maintenance and operation. These components work together to ensure optimal performance and efficiency in various agricultural tasks. Familiarity with each element can greatly enhance the user’s ability to troubleshoot and perform necessary repairs.

Engine: The heart of the machine, responsible for generating power. It is vital to monitor its performance and ensure regular maintenance to avoid breakdowns.

Transmission: This system transfers power from the engine to the wheels, enabling movement. Different types of transmissions affect speed and torque delivery.

Hydraulic System: Essential for powering attachments and implements, this system allows for versatile functionality. Regular checks can prevent hydraulic failures.

Chassis: The frame provides structural support for all components. A robust chassis is key to stability and durability on rough terrain.

Electrical System: This system controls the lighting, ignition, and various electronic components. Maintaining the battery and wiring is crucial for reliable operation.

Wheels and Tires: Critical for traction and mobility, these components need to be suited for the specific terrain and workload. Proper inflation and tread conditions are important for safety and efficiency.

By understanding these primary parts, users can delve deeper into the workings of their machinery and ensure it operates at its ultimate potential.

Common Issues and Solutions

Every machinery owner encounters specific challenges that can hinder performance and efficiency. Understanding these common problems and knowing how to address them is essential for maintaining optimal operation. Below are some frequent issues faced by users, along with effective solutions to enhance reliability and functionality.

One prevalent issue is overheating, which can occur due to low coolant levels or a malfunctioning thermostat. To resolve this, regularly check and refill coolant, and inspect the thermostat for proper operation. If overheating persists, consider cleaning the radiator to ensure efficient heat dissipation.

Another frequent concern is difficulty in starting the engine. This may be attributed to a weak battery or faulty ignition system. Regularly testing the battery and ensuring clean, secure connections can help. Additionally, inspect spark plugs and replace them if worn to improve starting reliability.

Transmission problems, such as slipping or difficulty shifting gears, are also common. These issues can often be traced to low fluid levels or contaminated fluid. Regularly check and change the transmission fluid to maintain smooth operation and prevent potential damage.

Finally, unusual noises during operation can indicate underlying issues. These could range from loose components to worn bearings. Conduct regular inspections and address any loose parts promptly. If noise persists, consider consulting a professional for a thorough examination.

Where to Find Parts for Farmall H

Locating essential components for vintage machinery can be a rewarding endeavor, especially for enthusiasts and restorers. With the right resources, one can ensure their equipment runs smoothly and efficiently.

Online Resources

- Specialty websites dedicated to vintage machinery

- Online marketplaces like eBay and Craigslist

- Forums and community groups focused on machinery restoration

Local Options

- Tractor salvage yards

- Local agricultural supply stores

- Community events or swap meets

Maintenance Tips for Longevity

Ensuring the extended lifespan of your machinery requires diligent care and regular attention. By implementing systematic maintenance routines, you can significantly enhance performance and reduce the likelihood of costly repairs.

Regular Inspections

Conduct routine checks to identify wear and tear before it escalates. Focus on critical components, ensuring they operate smoothly.

Fluid Management

Keep fluids at optimal levels and replace them according to the manufacturer’s guidelines. This is vital for the overall health of your equipment.

| Maintenance Task | Frequency |

|---|---|

| Oil Change | Every 50 hours |

| Filter Replacement | Every 100 hours |

| Battery Check | Monthly |

Upgrading Your Farmall H Equipment

Enhancing the performance of your vintage agricultural machinery can significantly improve efficiency and productivity on your land. By focusing on modernizing key components, you can ensure that your equipment runs smoother and lasts longer, all while maintaining its classic charm. This guide explores various upgrades that can breathe new life into your machinery, making it more reliable and user-friendly.

Key Upgrades to Consider

When it comes to modernization, several areas offer great potential for improvement. From engine enhancements to better transmission options, each upgrade contributes to a more efficient operation.

| Upgrade Type | Description | Benefits |

|---|---|---|

| Engine Tune-Up | Improving fuel efficiency and power output. | Increased horsepower and reduced fuel consumption. |

| Transmission Update | Installing a more modern gearbox for smoother shifting. | Enhanced driving experience and better control. |

| Brake System Improvement | Upgrading to hydraulic brakes for better stopping power. | Increased safety and responsiveness. |

| Lighting Enhancement | Replacing old bulbs with LED lighting. | Better visibility and energy efficiency. |

Maintaining Classic Appeal

While upgrading is essential, it’s important to retain the character of your vintage machine. Choosing components that are compatible with the original design can help maintain its aesthetic while providing the benefits of modern technology. This balance ensures that you enjoy improved performance without sacrificing the essence of what makes your machinery special.

Resources for Restoration Projects

Embarking on a restoration journey can be both rewarding and challenging. Having access to reliable materials, tools, and community support can significantly enhance the process. Below are some valuable resources to aid in your restoration endeavors.

Online Communities and Forums

- Restoration Forums: Joining dedicated forums allows you to connect with fellow enthusiasts, share experiences, and seek advice.

- Social Media Groups: Platforms like Facebook and Reddit have groups where members post tips, photos, and resources related to restoration projects.

- YouTube Channels: Numerous creators share detailed videos covering techniques, tips, and restoration walkthroughs.

Suppliers and Catalogs

- Local Salvage Yards: These places can be treasure troves for finding rare components and materials at a fraction of the cost.

- Online Retailers: Websites specializing in vintage machinery often provide a wide array of supplies and components.

- Catalogs and Manuals: Reference guides can provide crucial information on specifications and compatible materials.