The internal organization and functionality of agricultural machinery are crucial for ensuring efficient fieldwork. By examining the various elements that make up these machines, it’s easier to comprehend how they work together to perform essential tasks in the field.

Each piece of equipment is composed of multiple interconnected parts that must operate in harmony. The arrangement of these components directly affects the machine’s performance and durability. Understanding the layout and key mechanisms is vital for maintenance and repairs.

Proper care and timely replacement of worn-out components can significantly prolong the life of agricultural tools. By familiarizing yourself with the technical layout, you can ensure that your equipment remains in optimal condition, ready to meet the demands of the farm.

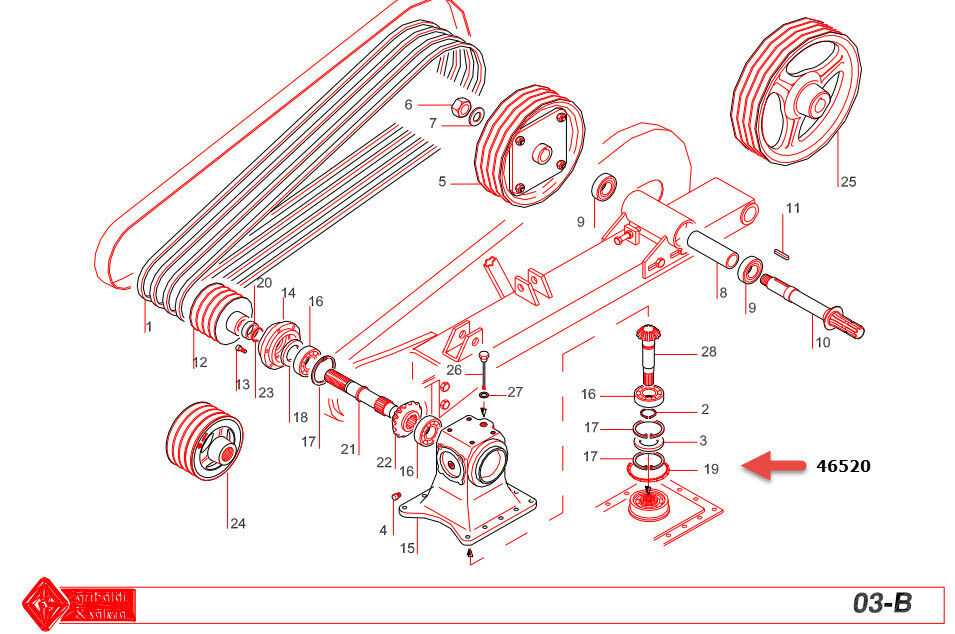

Understanding the Disc Mower Mechanism

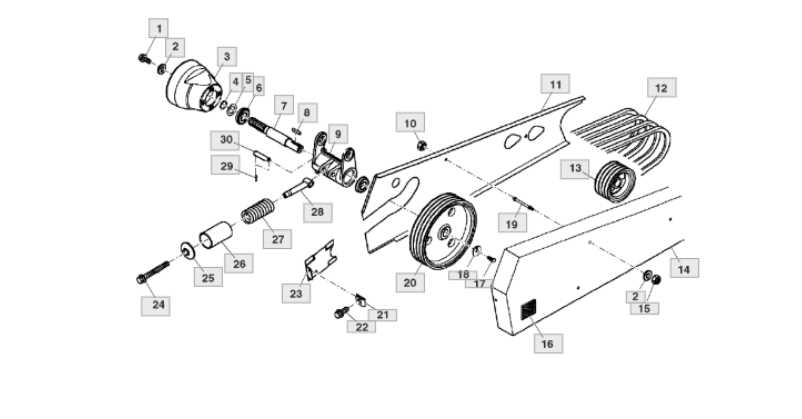

To comprehend how this cutting equipment functions, it’s essential to explore the core principles behind its operation. The system is designed to efficiently slice through vegetation, utilizing rotating elements to achieve a precise and even cut.

Key Rotating Elements

At the heart of the mechanism are rotating blades that spin at high speeds. These blades are responsible for shearing through plant material with minimal resistance, providing a smooth and consistent cutting action. The motion of these blades is powered by a central drive system, ensuring synchronization and efficiency.

Drive System and Power Transfer

The power needed to operate the cutting system comes from a mechanical drive, which transfers energy from the machine’s engine to the cutting components. This setup ensures that each rotating element works in unison, maintaining the precision of the cut. Adjustments to speed and angle allow for flexibility, depending on the type of vegetation and desired result.

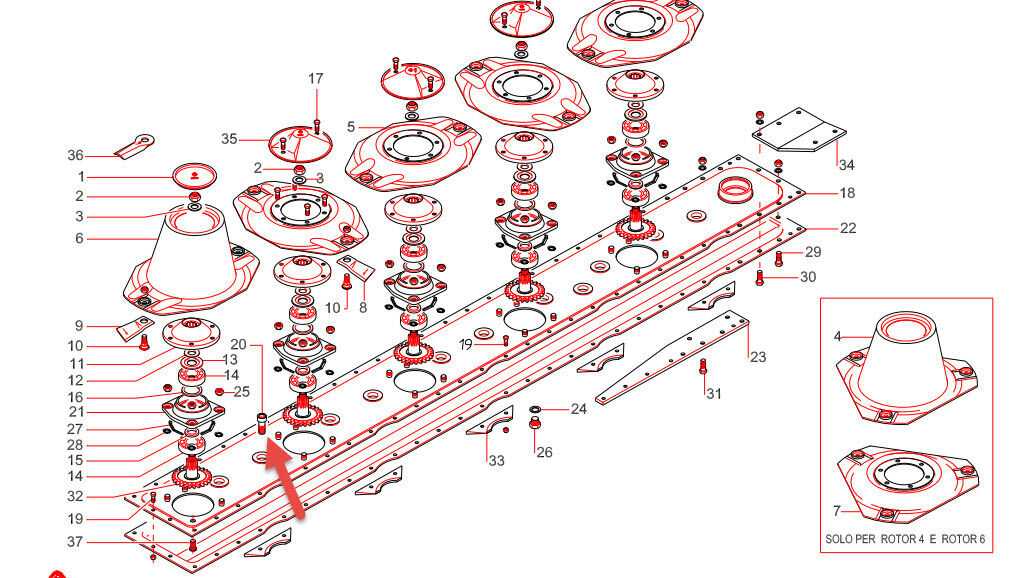

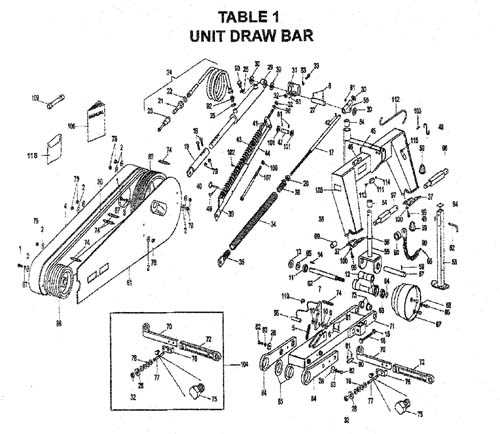

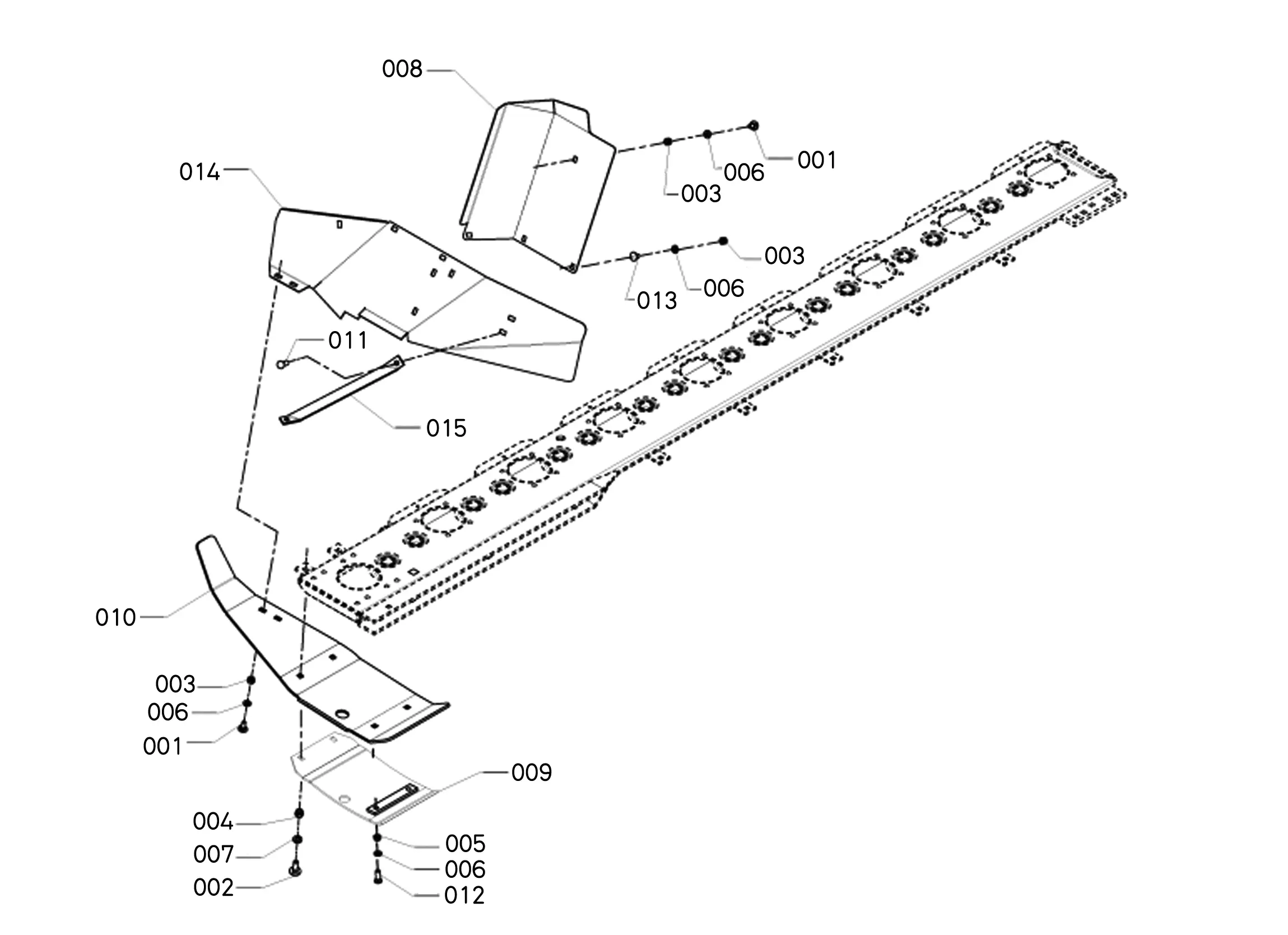

Main Components of the Kuhn Mower

The mechanism behind agricultural cutting tools consists of several critical elements that work together to ensure efficient and precise operation. Each part plays a key role in providing optimal performance during the cutting process, supporting both durability and ease of maintenance.

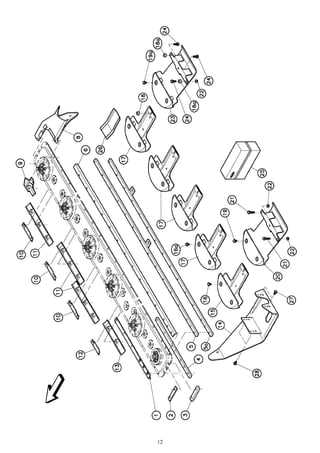

Cutting Assembly

The cutting assembly forms the heart of the equipment, responsible for ensuring smooth and consistent cutting of vegetation. It features multiple blades arranged to handle tough and dense crops, providing effective slicing through thick plant material. Regular maintenance is essential for these blades to retain their sharpness and functionality.

Drive System

The drive system connects the tractor to the equipment, allowing power to transfer seamlessly. This system ensures that the tool operates at the right speed and pressure for maximum efficiency. The components within the drive system are built for high performance and durability, ensuring that the tool remains reliable over time.

Functions of the Mower Blades

The cutting blades play a crucial role in the performance of agricultural equipment used for harvesting vegetation. These sharp edges ensure efficient cutting by slicing through dense growth, enabling smoother operation and higher productivity.

One key function is to provide clean and even cuts, which promotes healthier plant regrowth. Additionally, their design minimizes drag, allowing the machinery to operate with less effort and fuel consumption. This enhances the longevity of both the blades and the entire machine, reducing the frequency of maintenance.

Another essential function is to maintain balance and stability during operation. The precise construction of the blades ensures that the machine remains stable, even on uneven terrain, providing consistent performance and reducing wear on other components.

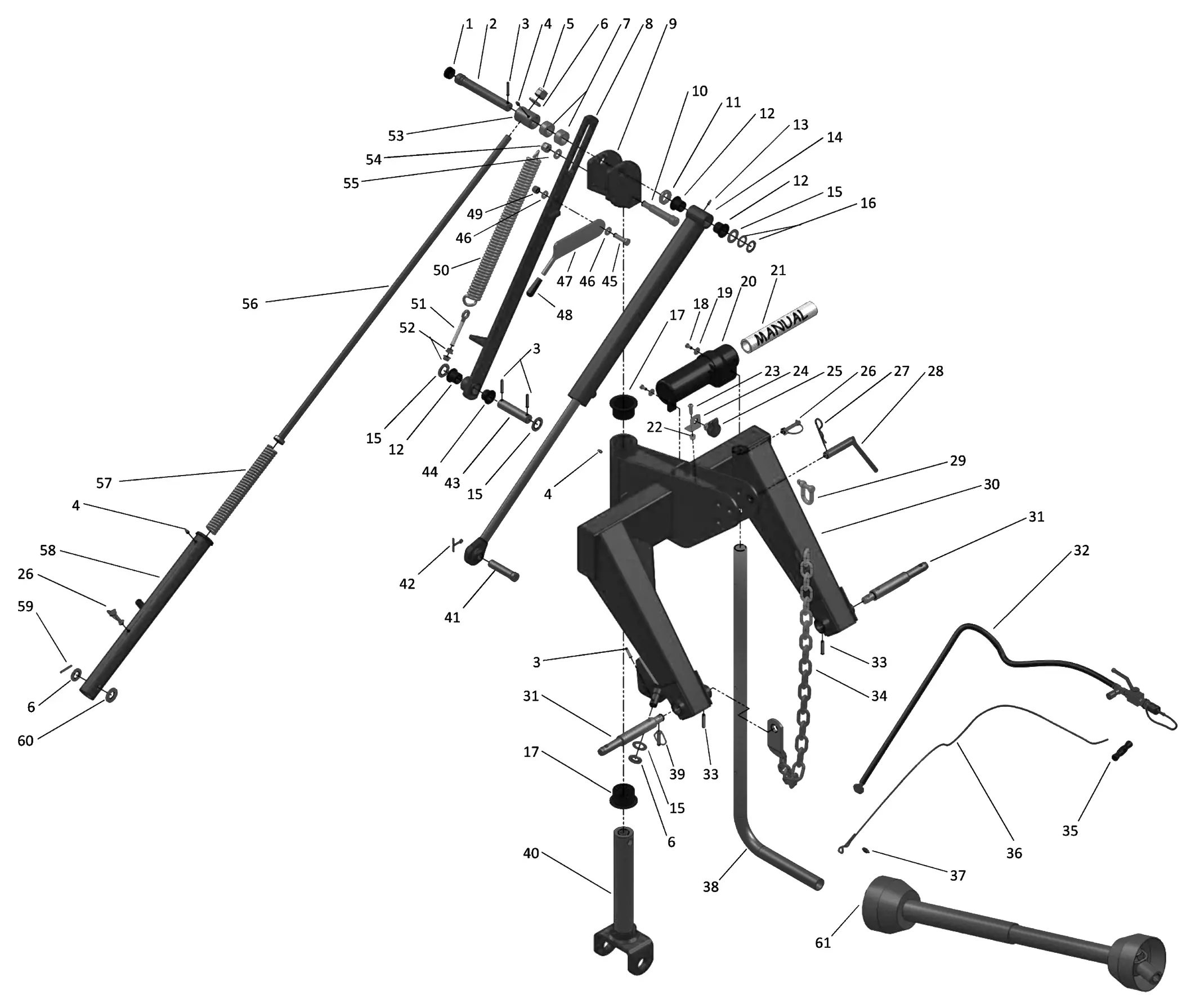

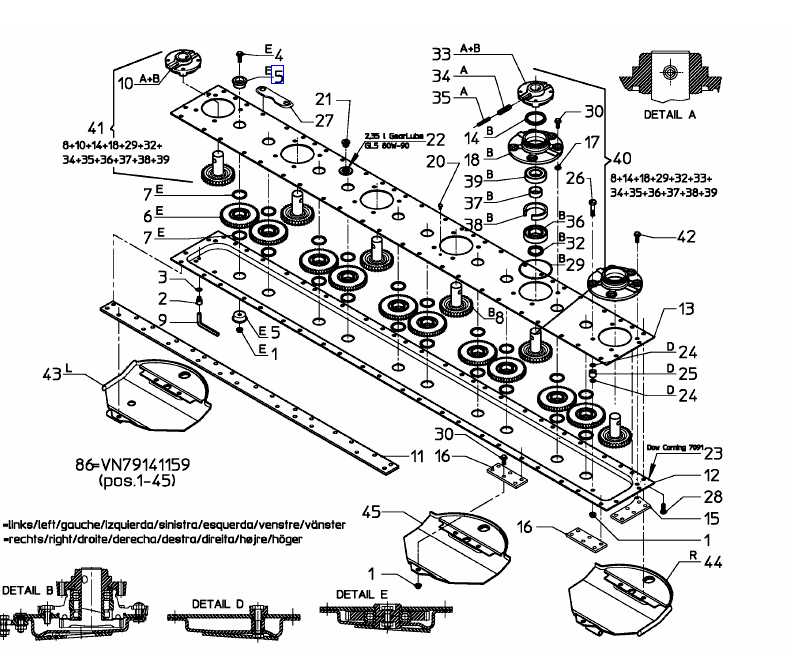

Drive System and Its Role

The drive mechanism is a critical component, ensuring the efficient transfer of power throughout the machine. It enables smooth operation by coordinating movement and energy distribution, allowing various parts to function together seamlessly.

Main Components of the Drive System

The system includes several key elements, such as shafts, gears, and belts, which work in unison to deliver consistent performance. Each component plays a role in maintaining speed, force, and accuracy during operation.

Importance of Maintenance

Proper upkeep of the drive system is crucial for prolonging the machine’s lifespan and preventing breakdowns. Regular checks on lubrication, alignment, and wear help ensure that the system operates efficiently and avoids costly repairs.

How to Maintain Cutting Discs

Ensuring the longevity and optimal performance of your agricultural cutting tools requires regular care and attention. Routine upkeep will not only extend the life of the components but also improve efficiency during use.

Regular Cleaning and Inspection

After each use, it’s important to clean the blades thoroughly to remove any debris or grass buildup. Inspect for any signs of wear, such as dull edges or cracks, as these can affect performance and may lead to further damage.

- Clear off dirt, grass, and other residues immediately after use.

- Check for visible damage, like dents or bent components.

- Lubricate moving parts regularly to reduce friction.

Sharpening and Replacement

Over time, the cutting edges may become dull, leading to inefficient operation. Sharpening or replacing them is essential for maintaining productivity.

- Use proper sharpening tools to restore the sharpness of the edges.

- Replace any worn-out or broken components to ensure smooth operation.

- Regularly check and tighten all fasteners to avoid any loosening during use.

Identifying Wear on Mower Parts

Understanding the signs of deterioration in essential components is crucial for maintaining optimal performance. Regular inspection helps to identify any wear that may affect efficiency and safety during operation. Being aware of potential issues allows for timely interventions, reducing the risk of malfunction and extending the lifespan of the equipment.

Common Signs of Wear

Several indicators can signify that components are beginning to show wear. These include visual inspections and performance assessments. Look for uneven surfaces, unusual noises, and changes in cutting efficiency. Early detection of these signs can prevent more significant issues down the line.

Maintenance Recommendations

To ensure longevity, it is essential to adopt regular maintenance practices. Cleaning after use, lubricating moving parts, and replacing worn components promptly are critical steps. A systematic approach to maintenance will enhance performance and reliability.

| Indicator | Possible Cause | Action Required |

|---|---|---|

| Uneven Cuts | Worn blades or uneven alignment | Sharpen or replace blades |

| Strange Noises | Lack of lubrication or damaged bearings | Lubricate or replace bearings |

| Decreased Performance | Blocked or damaged components | Inspect and clear obstructions |

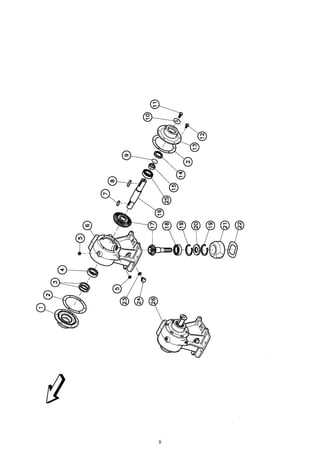

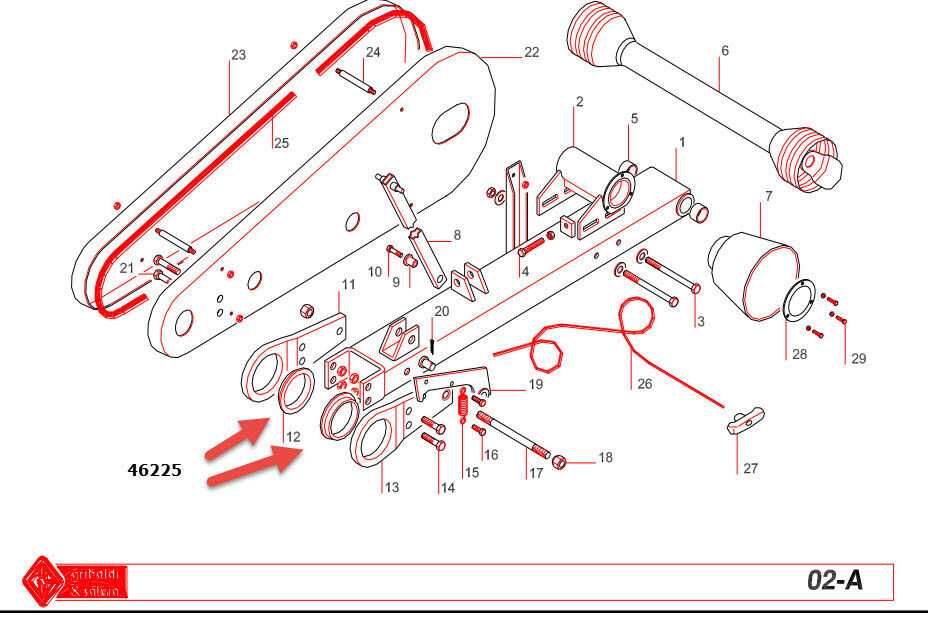

Replacing Gearbox Components

When it comes to maintaining agricultural machinery, ensuring the optimal function of transmission elements is crucial. These components play a vital role in transferring power effectively, and replacing them when necessary can enhance performance and prolong the equipment’s lifespan.

Identifying Issues is the first step in the replacement process. Common signs of wear may include unusual noises, vibrations, or a noticeable decrease in efficiency. Regular inspections can help in early detection, preventing further damage.

Disassembly involves carefully removing the affected components. Start by ensuring the machine is powered down and secured. Utilize appropriate tools to detach the gearbox from its housing, taking note of the arrangement of each part for reassembly.

Once disassembled, select high-quality replacements that match the specifications of the original components. Using incompatible parts can lead to inefficiency and increased wear. After acquiring the new pieces, proceed to reassemble the gearbox, ensuring all connections are secure.

Finally, test the functionality of the equipment post-replacement. Monitor its operation for any irregularities. Regular maintenance and timely replacement of transmission elements will significantly contribute to the overall efficiency and reliability of the machinery.

Troubleshooting Common Mower Issues

Identifying and resolving frequent challenges with your cutting equipment can significantly enhance its efficiency and longevity. Various factors can contribute to performance issues, and understanding these can help you maintain optimal functionality.

Uneven Cutting: If your equipment is leaving patches of uncut grass, check the blade height settings. Adjusting them to ensure uniformity can often resolve this issue. Additionally, inspect the cutting edges for wear or damage, as sharp blades are crucial for a clean cut.

Stalling: Frequent stalling may indicate a problem with fuel flow or engine performance. Ensure that the fuel tank is adequately filled and that the fuel filter is clean. If these components are in good condition, consider examining the spark plug for any signs of wear or fouling.

Vibration: Excessive vibration during operation can signal an unbalanced blade or loose components. Inspect the blades for any signs of damage and ensure all mounting hardware is securely fastened. Balancing the blades can help minimize vibrations and improve overall performance.

Difficulty Starting: If your equipment struggles to start, examine the battery and electrical connections. Corroded terminals or a weak battery can hinder the starting process. Additionally, ensure the ignition system is functioning correctly, as faulty ignition components can lead to starting difficulties.