In the world of agricultural machinery, knowing the internal arrangement of key elements is essential for effective maintenance and troubleshooting. Each machine is made up of various interconnected systems that must work in harmony to ensure smooth operation. By exploring the relationships between these components, operators can maximize efficiency and extend the lifespan of their equipment.

Whether you’re a seasoned professional or a newcomer to agricultural machinery, having a clear overview of the mechanical structure is vital. It helps in identifying possible areas of wear and tear, replacing critical elements, and optimizing the overall performance of the equipment. Being familiar with the arrangement of these parts will ultimately save time and reduce downtime in the field.

Detailed knowledge of the internal structure ensures that the right procedures are followed when conducting repairs or replacements. It also assists in maintaining the integrity of the equipment and helps prevent potential issues before they occur. Proper understanding of this layout leads to improved productivity and less frequent maintenance cycles.

Understanding the Structure of Soil Savers

The efficiency of equipment designed to enhance the land’s condition relies on its well-thought-out structure. These systems consist of several key components working in harmony to provide optimal performance. Understanding how each section contributes to the overall mechanism allows users to maintain and adjust their tools effectively, ensuring durability and precision in every task.

Core Functional Elements

At the heart of these machines are specialized segments that engage with the ground to loosen and prepare it for further work. These elements must be strong and durable, capable of withstanding tough conditions. Proper alignment and calibration of these parts are crucial to avoid unnecessary wear and tear, thus ensuring long-lasting operation.

Support and Control Systems

Another essential part of the structure includes the supporting framework and the control systems that allow for adjustments. These components help the operator manage depth, angle, and pressure applied to the surface. Proper understanding of these systems enables smooth, consistent operation and allows the machine to perform efficiently across different types of terrain.

Main Components and Their Functions

Understanding the key elements of the system and their roles is essential for ensuring efficient operation and maintenance. Each part plays a crucial role in the overall performance, working together to achieve the desired result.

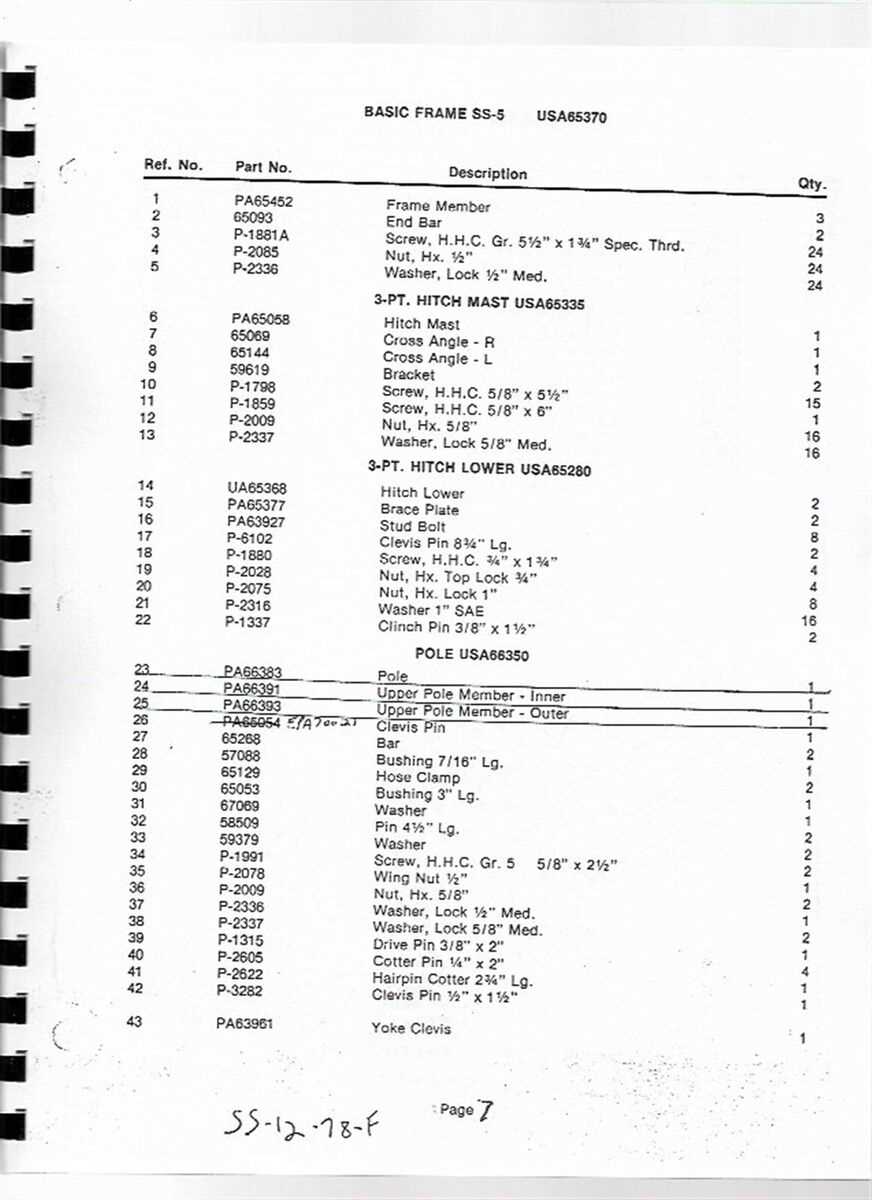

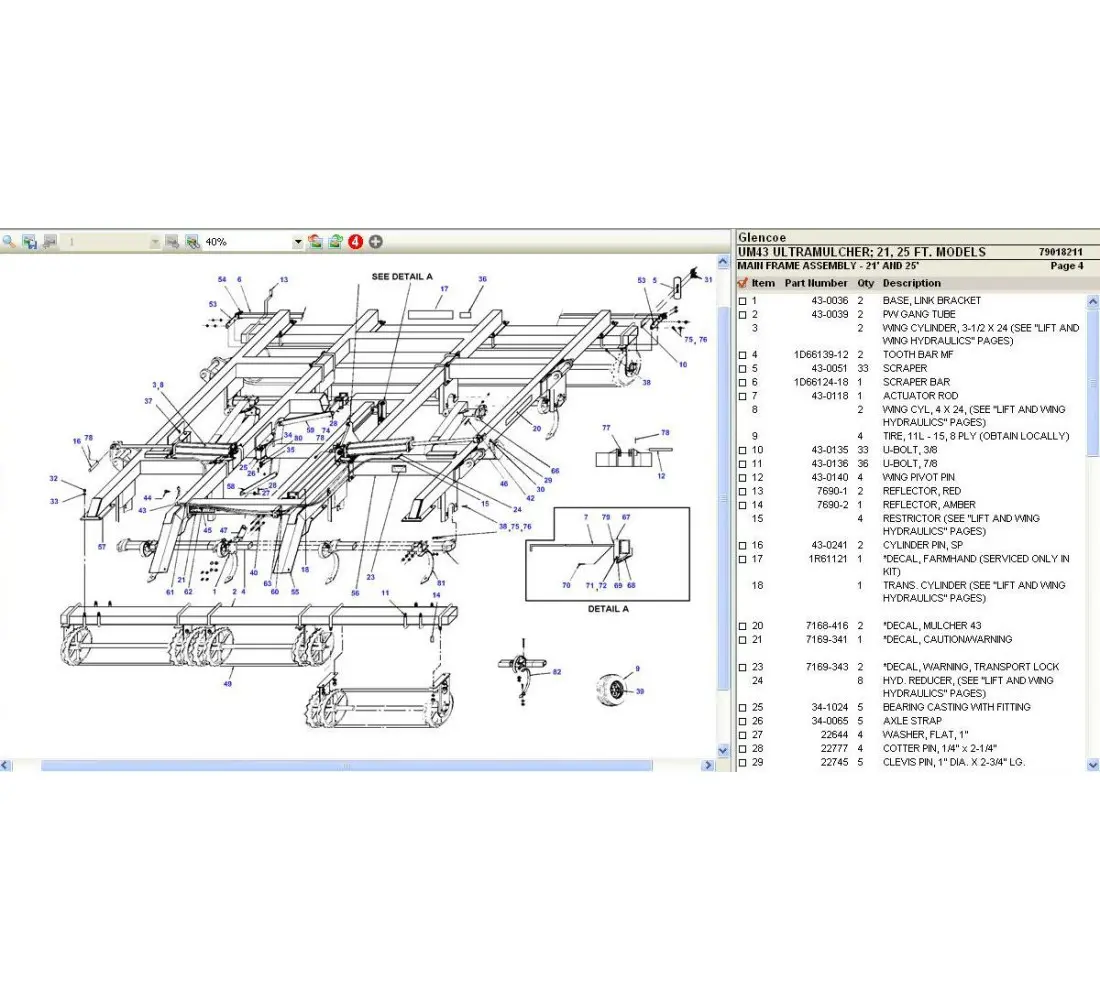

Frame: The structure provides a solid foundation for the entire setup, supporting the weight and distribution of all other components. Its durability ensures stability during operation, preventing unnecessary movement or damage.

Shanks: These are critical in the process, interacting directly with the surface to perform the necessary actions. Their design allows them to withstand pressure while maintaining the desired depth and precision.

Blades: These components are responsible for cutting through and preparing the material, ensuring smooth and consistent movement. Their sharpness and positioning directly affect efficiency.

Hitch: The connection point between the machine and the towing vehicle, this part ensures secure attachment and enables smooth transitions when in motion. It also allows for adjustments to improve control and maneuverability.

How to Identify Key Parts

Understanding the structure and function of essential components is critical for ensuring the effective operation of equipment. Each element plays a unique role, and being able to recognize these parts can help maintain functionality and prevent breakdowns.

- Frame: This is the primary support, holding all other elements in place. It is vital for the overall stability and durability of the machine.

- Blades: These are responsible for engaging with the material, cutting or shaping it as required. Regular inspection ensures they remain sharp and aligned.

- Discs: These rotating elements assist in processing by moving materials efficiently through the system. Look for signs of wear to prevent operational delays.

- Axle: The connecting piece that supports the rotation of other components. Ensuring it is free of obstructions guarantees smooth movement.

- Fasteners: Nuts, bolts, and screws hold various parts together. Tightening them regularly helps prevent unnecessary vibrations or loosening during operation.

By familiarizing yourself with these key components, routine checks and repairs become easier, ensuring the machine functions optimally for an extended period.

Maintenance Tips for Optimal Performance

Regular care and attention are key to ensuring long-lasting efficiency and smooth functionality of any equipment. By adhering to simple maintenance practices, you can extend the lifespan of your machinery and avoid unexpected breakdowns.

Regular Inspection and Cleaning

Frequent inspections are vital for identifying wear and tear before they escalate into more significant problems. Keep the components clean by removing debris and buildup that could hinder proper operation.

- Check for loose bolts or connections

- Ensure moving parts are free of obstructions

- Wipe down surfaces to prevent corrosion

Lubrication and Adjustments

Proper lubrication of mechanical parts is essential to minimize friction and prevent premature wear. Adjustments should also be made periodically to maintain alignment and smooth operation.

- Use the recommended lubricant for your equipment

- Apply oil or grease to moving parts regularly

- Check for proper alignment of key components

By following these tips, your equipment will remain in excellent condition, helping to ensure consistent and reliable performance throughout its use.

Replacing Worn or Damaged Elements

Over time, various components in agricultural equipment may experience wear and tear, leading to decreased efficiency. Ensuring these elements are in optimal condition is crucial for maintaining peak performance. By regularly inspecting and replacing any compromised parts, you can extend the overall lifespan of your machinery and avoid costly downtime.

Identifying Signs of Wear

It’s important to recognize the early signs of deterioration, such as cracks, bending, or loss of sharpness in key components. These indicators often suggest the need for immediate replacement to maintain the proper functioning of the equipment. Regular visual checks can help prevent further damage and improve operational safety.

Replacement Process Overview

When replacing a damaged part, it’s essential to follow proper procedures to ensure the new element fits correctly and operates as intended. Below is a general guide for replacing common parts:

| Component | Common Issue | Replacement Tips | |||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Blades | Dullness or cracks | Ensure the blade is compatible with the model; tighten all fasteners securely. | |||||||||||||||||||||||||||

| Fasteners | Corrosion or loosening | Use high-grade bolts and apply thread-locking compounds to prevent future loosening. | |||||||||||||||||||||||||||

| Hinges | Stiffness or misalignment | Lubricate

Common Issues and TroubleshootingWhen using agricultural equipment, users may encounter several recurring problems that can impact performance and efficiency. Addressing these issues promptly can ensure longevity and optimal operation. This section highlights frequent challenges and offers guidance on how to resolve them effectively.

By performing regular inspections and addressing issues early, users can maintain high performance and reduce the need for costly repairs. Compatibility with Other Equipment

When integrating new machinery with existing tools, ensuring proper interaction is essential for optimal performance. It is crucial to understand how different systems can work together seamlessly, offering versatility and reducing the need for additional equipment. This section explores how one piece of machinery can be paired effectively with other components, ensuring maximum efficiency and cost savings. Key Considerations for Equipment PairingTo guarantee smooth operation between various devices, compatibility factors such as size, connection types, and operational settings must be reviewed. Proper alignment of mechanical and electrical specifications is important to prevent wear and tear or functionality issues. Common Pairings

Below is a table showcasing popular equipment pairings, with each combination offering specific benefits based on user needs:

Proper Storage and Handling GuidelinesMaintaining equipment in optimal condition requires careful attention to its storage and handling. To prevent damage and ensure long-term performance, following proper guidelines is essential. These practices not only preserve the functionality of the machinery but also extend its lifespan and reliability. Storage location plays a crucial role in safeguarding the components from external elements such as moisture, extreme temperatures, and dust. Keep the equipment in a dry, cool place, away from direct sunlight or areas with high humidity to avoid rust or deterioration. When handling, always use proper lifting techniques to prevent unnecessary strain or potential damage to sensitive parts. Ensure all moving components are securely stored to avoid unnecessary wear. If disassembling is required, take note of the sequence to avoid confusion during reassembly. Regular maintenance checks should be part of the storage routine. Inspect for any signs of wear or potential issues that could compromise the system’s integrity. Addressing small problems early on prevents costly repairs later. Upgrading and Customizing Your Soil SaverEnhancing and tailoring your agricultural tool can significantly improve its performance, versatility, and durability. Whether you’re looking to increase efficiency, adapt to specific tasks, or simply upgrade worn-out components, making adjustments to the machine can offer a range of benefits for your farming operations. With the right modifications, you can extend its lifespan and ensure optimal functionality for various soil management activities. Key Modifications for Enhanced PerformanceOne of the most common upgrades involves improving the cutting or tilling efficiency. Upgrading the blades or discs can lead to better soil penetration and more even processing. Additionally, enhancing the frame or adding stabilizers can provide greater control and reduce wear on other components, leading to a smoother operation. Customizing for Specific Tasks

Depending on the type of soil and tasks you frequently handle, customizing your equipment to suit these needs can bring substantial improvements. Adding accessories like depth control systems or adjustable tines can help optimize the tool’s adaptability. These adjustments allow for precise adjustments, making it easier to manage different soil conditions and achieve the desired results. |