When it comes to maintaining high-performance lawn care equipment, comprehending the intricate layout of essential components is crucial. This guide offers an in-depth look at the arrangement of various elements that contribute to optimal functionality and longevity.

Each segment plays a vital role, and identifying their specific placements can significantly enhance troubleshooting and repair processes. By acquiring knowledge of these configurations, operators can ensure that their machinery runs smoothly and efficiently.

Whether you are a professional landscaper or a dedicated homeowner, understanding the structure of your equipment will ultimately lead to better performance and satisfaction in your lawn maintenance endeavors. Delve into the details and empower yourself with the information needed to keep your machinery in top shape.

Dixie Chopper Magnum 2250 Overview

This section provides an insightful examination of a high-performance outdoor equipment model, renowned for its efficiency and durability. Designed for both professional and residential use, this machine stands out in its category due to its robust construction and advanced features.

The equipment is equipped with a powerful engine that ensures exceptional cutting capabilities, making lawn maintenance effortless. Its user-friendly design enhances maneuverability, allowing operators to navigate various terrains with ease.

In addition to performance, the focus on comfort and safety is evident in its ergonomic controls and reliable safety mechanisms. This combination of functionality and convenience makes it a favored choice among landscapers and homeowners alike.

Overall, this model represents a significant investment for those seeking a reliable solution for their lawn care needs, offering longevity and a high return on investment.

Understanding Parts and Functionality

Comprehending the components of a machine and their roles is essential for effective maintenance and operation. Each element contributes to the overall efficiency and performance, ensuring the system runs smoothly. A clear grasp of how these elements interact allows users to identify issues quickly and make informed decisions regarding repairs and upgrades.

Key elements serve distinct functions that enhance the machine’s capability. For instance, the power unit drives the entire system, while the cutting mechanism ensures precision in operation. Understanding these functionalities enables users to appreciate the importance of each component and its impact on the overall performance.

Moreover, regular inspection and knowledge of individual functionalities can prevent costly breakdowns. By recognizing wear and tear, operators can address problems proactively, thereby extending the lifespan of the equipment and maintaining optimal productivity.

Key Components of the Magnum 2250

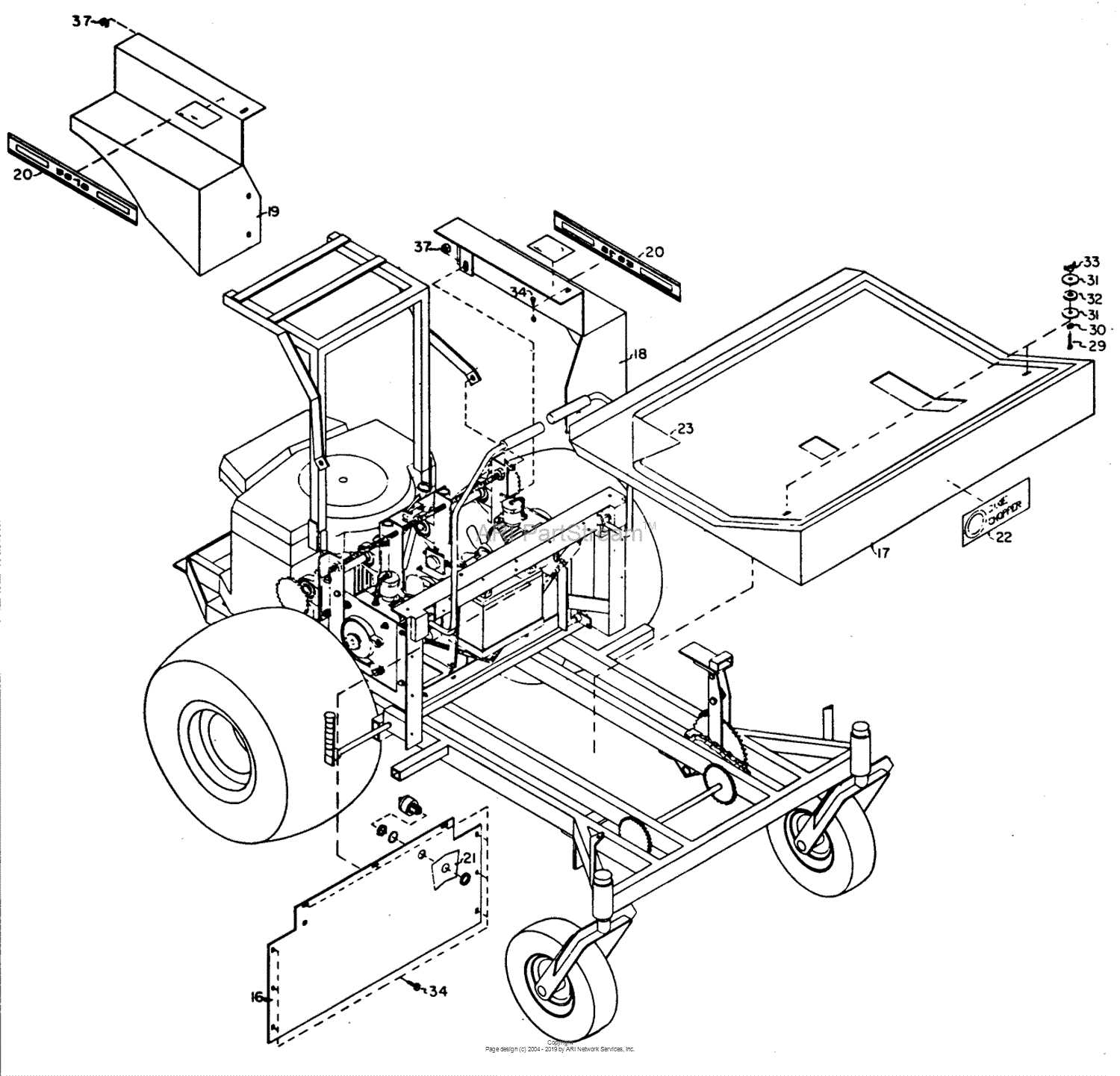

Understanding the essential elements of this powerful machine is crucial for both maintenance and optimal performance. Each part plays a significant role in ensuring efficient operation, contributing to the overall effectiveness of the equipment. A thorough grasp of these components enables users to make informed decisions regarding repairs and upgrades.

The engine serves as the heart of the system, providing the necessary power to tackle various tasks. Its efficiency and reliability are paramount, as they directly influence the machine’s performance in diverse conditions. Equally important is the cutting deck, which is designed to deliver precision and uniformity in grass cutting, ensuring a clean finish every time.

The drive system is another critical element, facilitating smooth movement and maneuverability across different terrains. This system includes various gears and belts that must be regularly inspected for wear and tear to maintain optimal functionality. Additionally, the control panel offers operators a user-friendly interface, allowing easy adjustments and monitoring of the machine’s status.

Lastly, the frame and chassis provide the structural integrity needed to withstand demanding use while ensuring stability and balance during operation. Each of these components works in harmony to enhance the overall performance and longevity of the equipment.

Maintenance Tips for Longevity

Ensuring the durability of your equipment involves consistent care and attention. Regular maintenance practices not only enhance performance but also extend the lifespan of your machinery. Below are essential tips to help you keep your device in optimal condition.

| Tip | Description |

|---|---|

| Regular Cleaning | Remove dirt and debris after each use to prevent buildup that can lead to rust and corrosion. |

| Inspect Components | Frequent checks on belts, blades, and other vital parts can help identify wear and prevent malfunctions. |

| Lubrication | Apply appropriate lubricants to moving parts to minimize friction and wear. |

| Check Fluid Levels | Ensure oil, fuel, and coolant levels are adequate to maintain smooth operation. |

| Follow Manufacturer Guidelines | Refer to the owner’s manual for specific maintenance schedules and recommendations. |

By following these practices, you can significantly enhance the efficiency and durability of your equipment, ensuring it serves you well for years to come.

Where to Find Replacement Parts

Locating components for your equipment can seem daunting, but there are several reliable avenues to explore. By utilizing a mix of online and local resources, you can ensure that you have access to the necessary items to keep your machinery running smoothly.

- Official Manufacturer Website: Start by checking the manufacturer’s website, where you can often find an extensive catalog of available components along with direct purchase options.

- Authorized Dealers: Look for authorized dealers in your area. They typically stock genuine components and can provide expert advice tailored to your equipment.

- Online Retailers: Websites such as Amazon, eBay, and specialized equipment retailers often carry a wide selection of components. Be sure to read reviews and check seller ratings for reliability.

- Local Hardware Stores: Many local hardware or home improvement stores may carry basic components or can order specific items for you.

- Salvage Yards: Consider visiting salvage yards that specialize in machinery. You might find used components at a fraction of the cost.

- Community Forums and Groups: Engage with online communities or forums related to your equipment. Members often share insights about where to source components and may even have spare parts available for sale or trade.

By exploring these various options, you can easily find the necessary items to maintain your equipment’s performance and longevity.

Common Issues and Troubleshooting

Maintenance of outdoor power equipment often reveals a range of typical problems that users may encounter. Identifying these issues early can prevent more significant complications and extend the life of the machinery.

Engine Starting Problems: A common challenge is difficulty in starting the engine. This can be due to a faulty ignition system, fuel blockages, or issues with the battery. Ensure all connections are secure and that the fuel is fresh.

Uneven Cutting: If the cutting blades are not providing a uniform finish, it could be related to blade dullness, misalignment, or variations in wheel height. Regularly inspect and sharpen blades to maintain optimal performance.

Overheating: Machines may overheat during operation, often caused by insufficient oil levels or debris blocking the cooling system. Regular checks of fluid levels and cleaning around the engine can mitigate this risk.

Excessive Vibration: Unusual vibrations might indicate loose components or worn-out parts. Tightening fasteners and inspecting parts for wear can help address this issue.

By regularly inspecting and addressing these common problems, users can ensure smoother operation and longevity of their equipment.

Comparative Analysis with Other Models

This section focuses on evaluating the features and performance of a specific model in relation to its peers. Understanding how different machines stack up against one another provides valuable insights for potential buyers and users. Key areas of comparison include efficiency, durability, and overall user experience.

When assessing various models, several critical factors emerge:

- Performance: How well does the machine operate under various conditions compared to its competitors?

- Durability: What materials and construction methods are used, and how do they affect longevity?

- Maintenance: How easy is it to service and obtain replacement components?

- User Comfort: What ergonomic features are available to enhance the user experience?

- Price Point: How does the cost compare to similar models, and does it offer good value?

For example, when comparing performance, certain models may excel in speed and cutting precision, while others may offer better fuel efficiency. Durability can vary significantly based on the materials used, with some brands prioritizing heavy-duty construction to withstand tough conditions.

Maintenance considerations also play a crucial role; ease of accessing components can save time and effort in the long run. User comfort is another vital aspect, as ergonomic designs can significantly enhance the usability of the equipment during prolonged operation.

Ultimately, a comprehensive analysis allows consumers to make informed decisions by weighing the pros and cons of each model. This approach ensures that the chosen equipment aligns well with the user’s specific needs and expectations.

Customer Reviews and Feedback

Gathering insights from users provides valuable perspectives on product performance and reliability. Customer opinions often highlight strengths and weaknesses, helping potential buyers make informed decisions. In this section, we explore various experiences shared by individuals who have utilized this equipment.

Many users appreciate the efficiency and power of the machine, noting its ability to handle tough tasks with ease. Comments often reflect satisfaction with its durability and overall design, which contributes to a seamless mowing experience. Users frequently mention how well it performs on different terrains, enhancing its appeal for both residential and commercial use.

However, some feedback indicates areas for improvement. A few customers have pointed out the need for better customer support and availability of replacement components. Additionally, there are remarks about the initial learning curve associated with its operation, particularly for those new to such machinery.

Overall, the feedback collected paints a comprehensive picture, showcasing both the advantages and challenges associated with this product. It serves as a reminder of the importance of user reviews in guiding future customers towards making the right choice.