In the realm of thermal management, a comprehensive grasp of essential elements is crucial for optimal functionality. This section aims to explore the intricate assembly that enables efficient temperature regulation within various environments.

Each element plays a pivotal role, contributing to the overall performance and reliability of the system. By examining these integral components, we can delve into their individual significance and the ultimate impact they have on energy efficiency and safety.

Whether for residential comfort or industrial applications, recognizing how these mechanisms interact is vital. A well-informed perspective empowers users to make better decisions regarding maintenance and enhancements, ensuring longevity and effectiveness.

Understanding Furnace Components

Grasping the various elements of a heating unit is essential for effective operation and maintenance. Each component plays a pivotal role in the overall functionality, contributing to efficiency and safety. A thorough comprehension of these elements not only aids in troubleshooting but also enhances performance longevity.

Key Elements of a Heating System

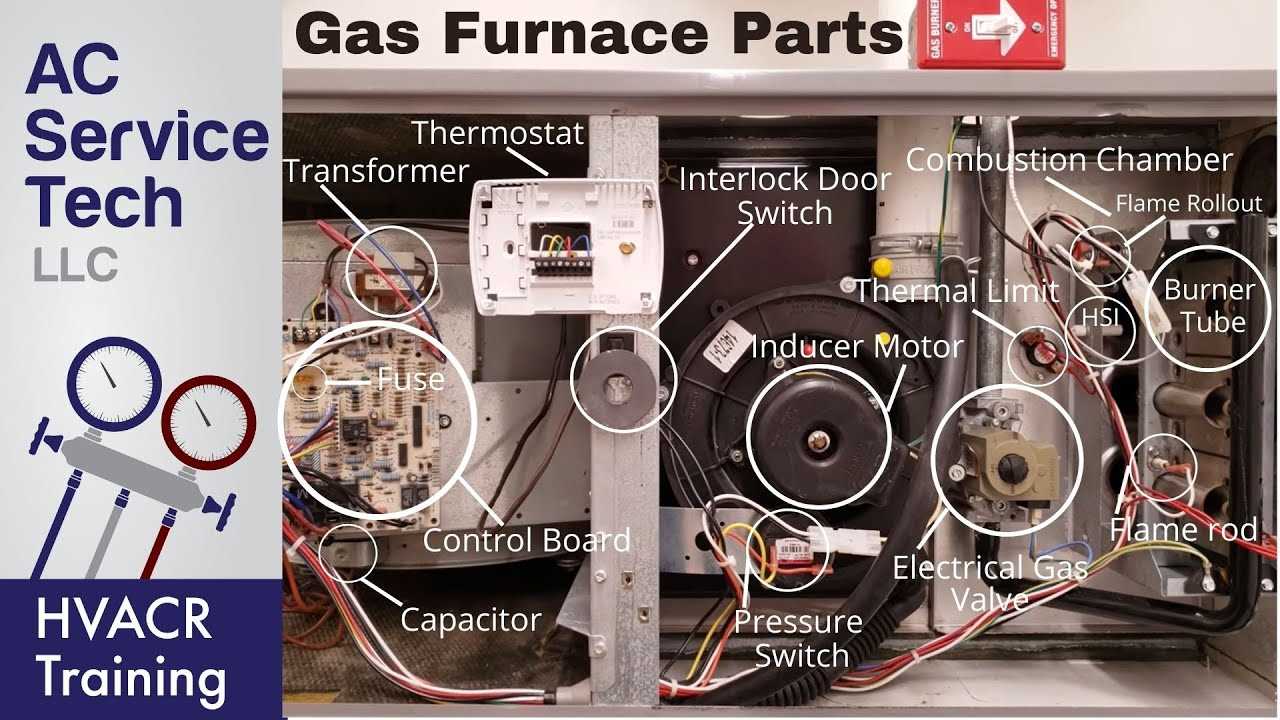

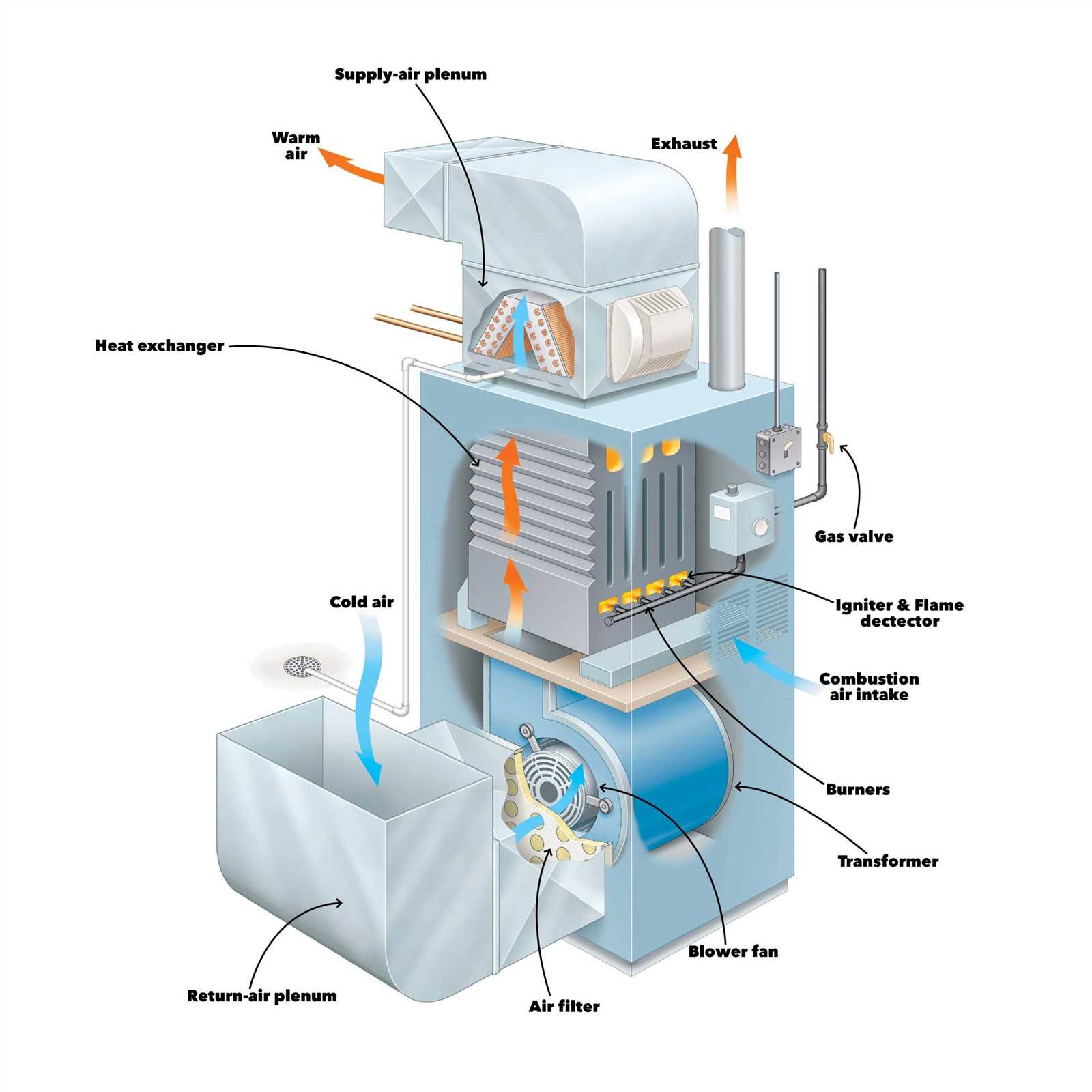

The main constituents include the heat exchanger, burner assembly, and control mechanisms. The heat exchanger is responsible for transferring heat, while the burner assembly ignites the fuel to create warmth. Additionally, control systems regulate the entire process, ensuring optimal temperature settings and safety protocols.

Importance of Maintenance

Regular upkeep of these components is crucial to prevent breakdowns and inefficiencies. Understanding their functions helps users recognize signs of wear or malfunction early, leading to timely repairs and ultimately extending the lifespan of the system.

Main Elements of a Furnace

Understanding the core components of a heating system is essential for grasping its functionality and efficiency. Each element plays a crucial role in ensuring that the entire mechanism operates smoothly and effectively, delivering optimal warmth and comfort.

Heating Source

The heating source is the heart of the system, where energy is converted into heat. Common types include gas burners, electric coils, and oil burners, each contributing differently to the overall performance. Efficiency and reliability are paramount when selecting the right source.

Heat Exchanger

This component transfers heat generated by the heating source to the air or fluid circulating through the system. A well-designed heat exchanger maximizes heat transfer while minimizing energy loss, ensuring that the heated air is efficiently distributed throughout the space.

Functionality of Each Part

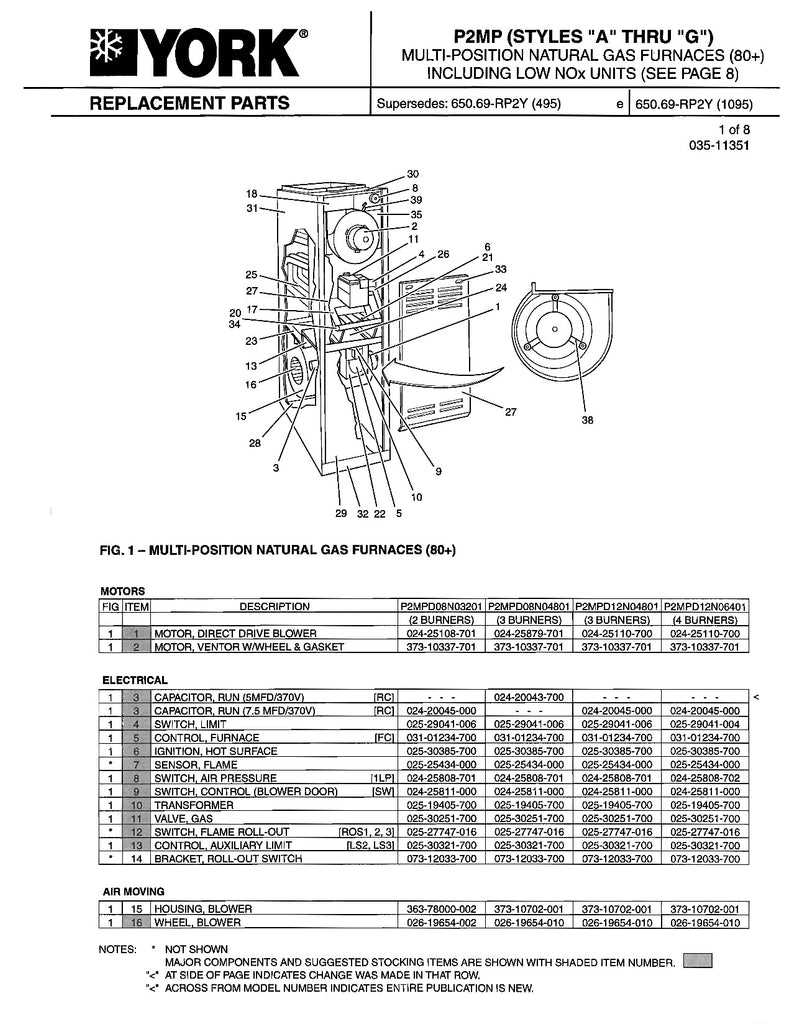

The various components of a heating system work in harmony to achieve optimal performance and efficiency. Understanding the role of each element is crucial for effective operation and maintenance. Each segment contributes uniquely to the overall functionality, ensuring safe and reliable heat generation.

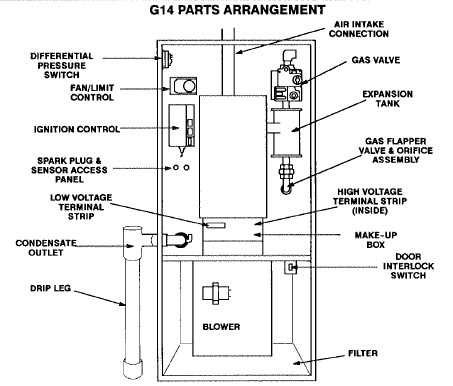

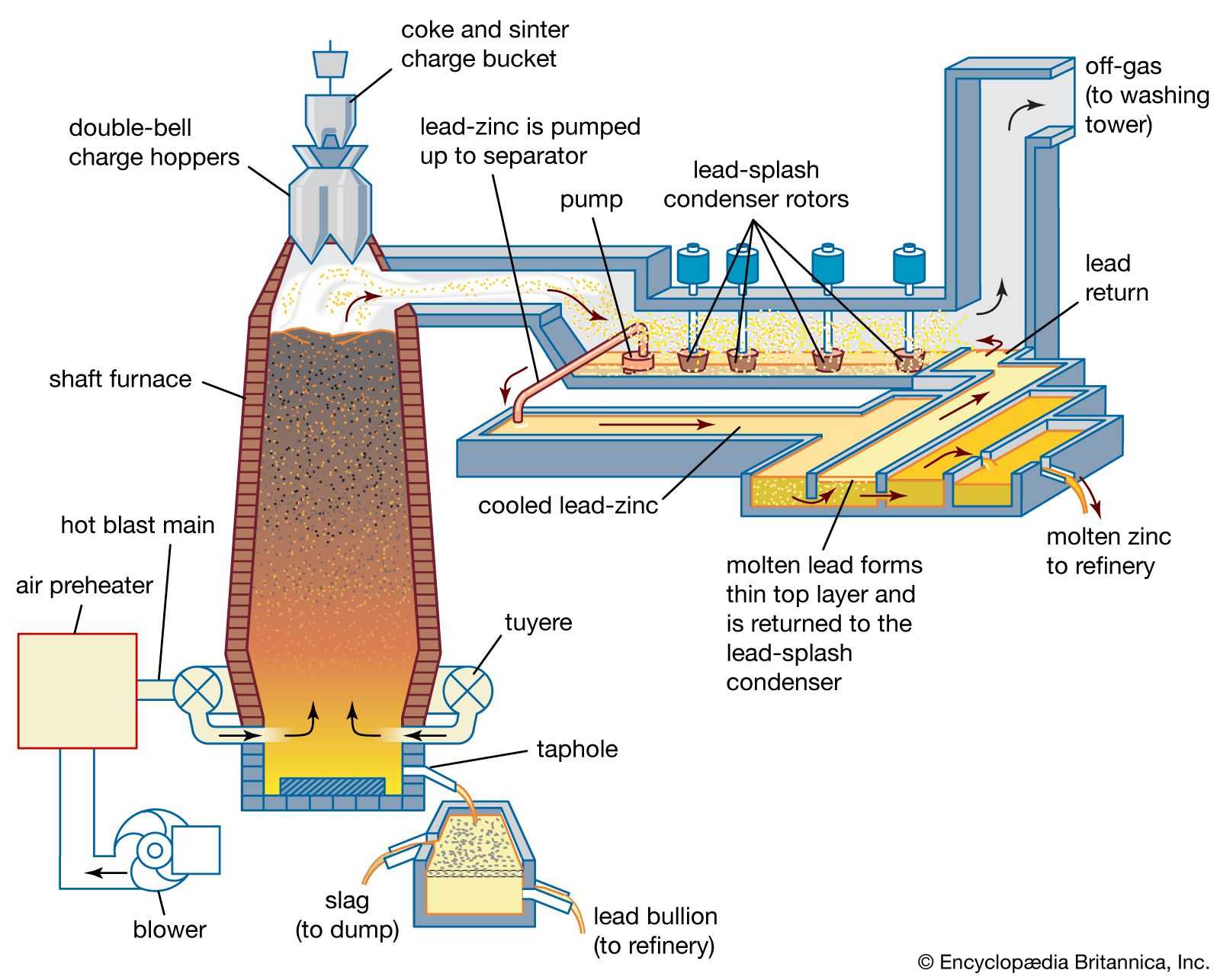

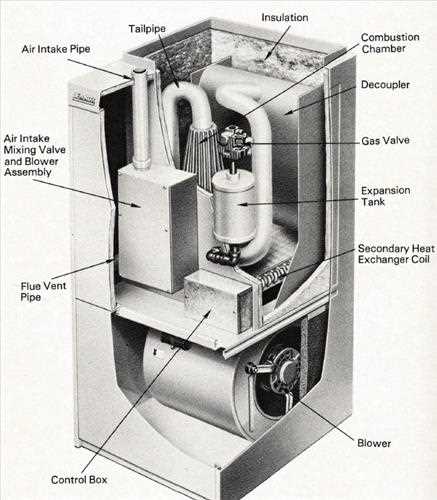

Combustion Chamber: This is where the fuel undergoes combustion. It is designed to withstand high temperatures while maximizing the efficiency of the fuel used.

Heat Exchanger: This element transfers heat from the combustion process to the air or water that circulates through the system. Its design allows for maximum heat transfer while minimizing energy loss.

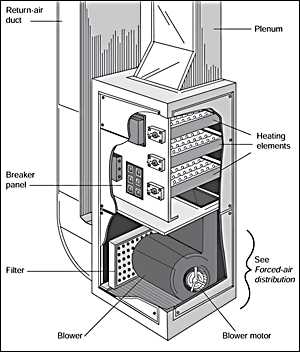

Blower: The blower plays a pivotal role in circulating air throughout the system. It ensures that warm air reaches the desired spaces quickly and efficiently, maintaining a comfortable environment.

Thermostat: This device acts as the brain of the system, regulating temperature by signaling when to activate or deactivate the heating cycle based on the desired settings.

Safety Valve: This critical component ensures safe operation by releasing excess pressure, preventing potential hazards and maintaining system integrity.

Fuel Supply System: Responsible for delivering fuel to the combustion chamber, this system ensures a consistent and controlled flow, essential for efficient operation.

Flue System: This part safely expels combustion byproducts outside the structure, preventing harmful gases from accumulating indoors and ensuring compliance with safety standards.

Common Types of Furnaces

Heating systems play a crucial role in maintaining comfort within residential and commercial spaces. Different types of heating units offer varying efficiencies, fuel sources, and operational characteristics, catering to diverse needs and preferences. Understanding these variations can help users make informed decisions about which system best suits their requirements.

Gas-Powered Systems

Gas-powered heating units are among the most popular choices due to their efficiency and cost-effectiveness. They utilize natural gas or propane as fuel, providing rapid heating and often featuring advanced technology for precise temperature control. One major advantage is their lower environmental impact compared to some other energy sources, making them a favored option for eco-conscious consumers.

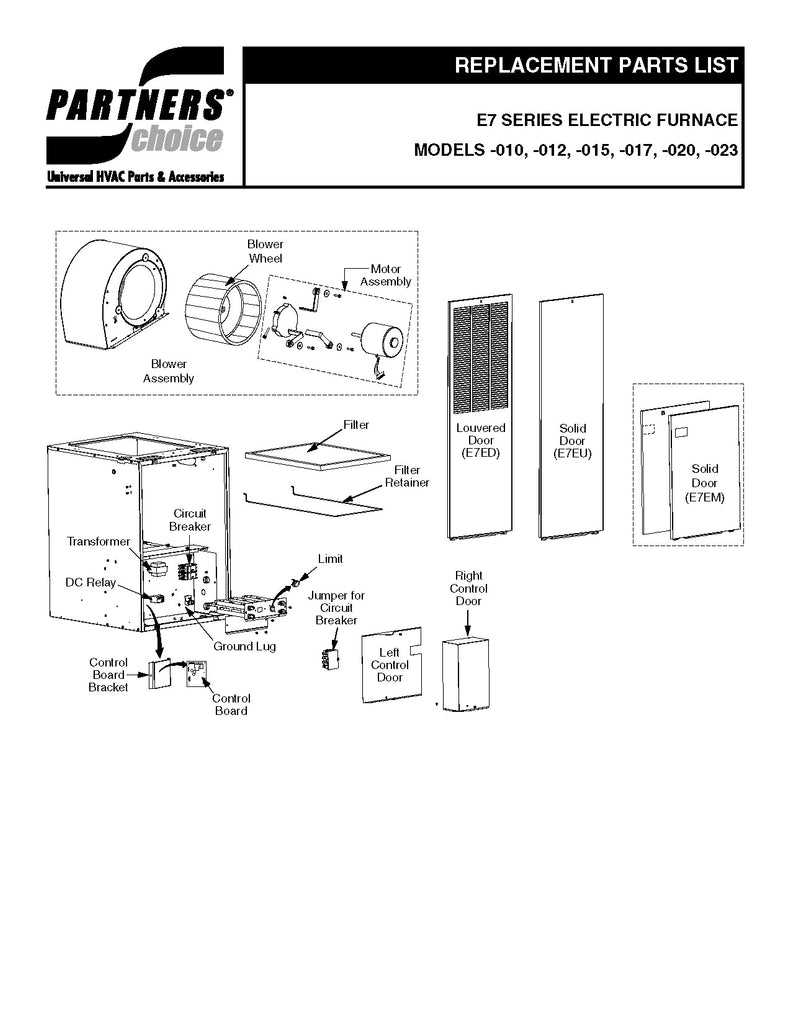

Electric Heating Units

Electric heating systems are known for their convenience and ease of installation. They rely on electricity to generate heat, eliminating the need for fuel storage or combustion. While they may have higher operational costs in areas with expensive electricity rates, they are often praised for their ability to deliver consistent warmth and are particularly suitable for smaller spaces.

Each type of heating solution presents unique benefits and challenges, emphasizing the importance of evaluating specific needs and conditions before making a selection.

How to Maintain Furnace Parts

Regular upkeep of heating systems is essential for optimal performance and longevity. This involves a series of tasks aimed at ensuring every component functions efficiently, preventing unexpected breakdowns and costly repairs.

First, inspect filters frequently. Clogged filters can restrict airflow, leading to reduced efficiency. Replace them every one to three months to maintain proper circulation.

Second, check the burners for any signs of dirt or wear. Cleaning these regularly ensures complete combustion, improving energy usage. Address any buildup immediately to avoid issues.

Finally, consider scheduling a professional inspection annually. Technicians can identify potential problems early and provide comprehensive maintenance that enhances the overall functionality of your system.

Safety Features in Modern Furnaces

In today’s heating systems, a range of innovative safety mechanisms are implemented to ensure optimal performance and protect users. These advancements not only enhance efficiency but also prioritize user well-being by minimizing potential hazards associated with heating equipment.

One of the essential components is the automatic shut-off system. This feature activates when it detects irregularities, such as overheating or gas leaks, effectively preventing dangerous situations. Additionally, modern models often incorporate flame sensors that monitor the burner’s activity, ensuring it operates safely and extinguishing the flame if necessary.

Moreover, ventilation controls play a crucial role in maintaining air quality and preventing the buildup of harmful gases. By ensuring proper airflow, these controls significantly reduce the risk of asphyxiation or other respiratory issues. Another important aspect is the use of over-temperature protection, which automatically regulates the temperature to avoid excessive heat that could lead to fires or equipment damage.

Finally, regular maintenance reminders and diagnostics enhance reliability, allowing users to address potential issues before they escalate. With these advanced safety features, modern heating systems provide peace of mind while delivering comfort in homes and buildings.

Signs of Wear and Tear

Recognizing the indicators of degradation is crucial for maintaining optimal performance in heating systems. Over time, various components can exhibit signs that suggest they are reaching the end of their effective lifespan. Timely identification of these symptoms can prevent larger issues and ensure efficient operation.

Common Indicators

Visual inspections often reveal discoloration, rust, or cracks in housing materials. Additionally, unusual noises during operation, such as rattling or hissing, may signal underlying problems. Frequent cycling on and off can also indicate stress on the system, requiring attention.

Performance Changes

Decreased efficiency, such as rising energy bills or inconsistent temperature control, can point to wear in essential elements. If the system struggles to maintain desired conditions, it may be time to delve deeper into potential replacements or repairs to restore functionality.

Upgrading Furnace Components

Enhancing the efficiency and performance of heating systems can significantly impact comfort and energy consumption. This section explores various methods to improve essential elements, leading to a more reliable and effective operation.

Benefits of Upgrading

Modernizing key elements offers numerous advantages:

- Increased energy efficiency

- Improved heating consistency

- Extended lifespan of the system

- Lower maintenance costs

- Enhanced safety features

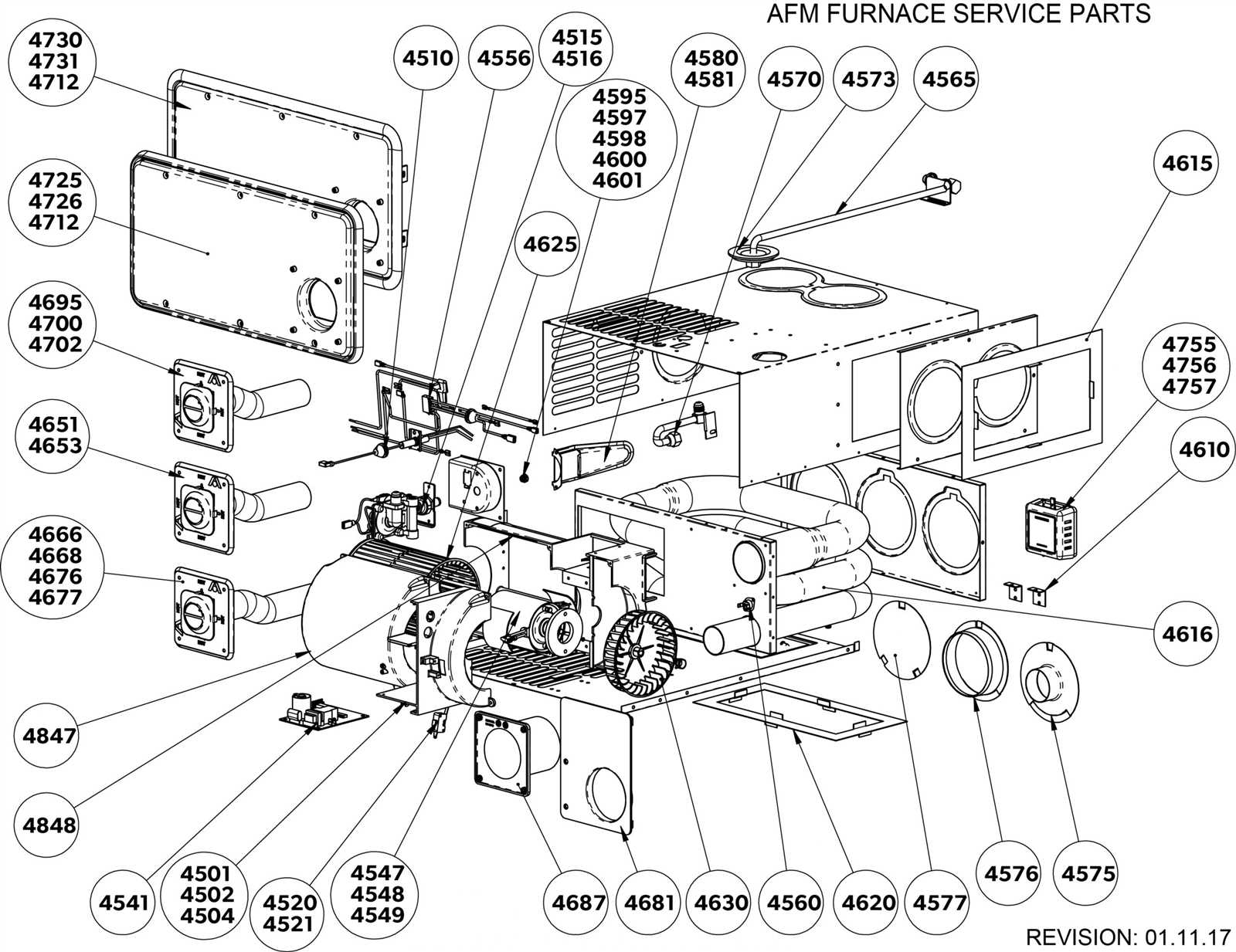

Key Components to Consider

When planning enhancements, focus on these crucial elements:

- Burner System: Upgrading to a high-efficiency burner can optimize fuel usage and reduce emissions.

- Heat Exchanger: Replacing an outdated heat exchanger can improve heat transfer and reduce energy loss.

- Blower Motor: Installing a variable-speed motor can enhance airflow control and decrease noise levels.

- Thermostat: A smart thermostat can optimize temperature management and provide remote access for convenience.

- Insulation: Improving insulation around ducts and the unit can prevent heat loss and increase overall system efficiency.

Investing in these upgrades not only enhances performance but also contributes to long-term savings and environmental sustainability.

Impact of Design on Efficiency

The configuration of thermal systems plays a crucial role in their overall performance and energy consumption. By optimizing the structure and layout, manufacturers can significantly enhance operational effectiveness, reduce energy waste, and lower environmental impact. A well-considered design not only improves functionality but also contributes to cost savings and sustainability.

Key Design Elements

- Material Selection: The choice of materials affects heat retention and transfer, impacting efficiency.

- Insulation: High-quality insulation minimizes heat loss, leading to lower energy requirements.

- Airflow Management: Efficient airflow paths enhance combustion processes and overall performance.

- Size and Scale: Proper sizing ensures optimal operation, preventing excess energy use.

Benefits of Efficient Design

- Reduced Energy Costs: Efficient systems require less energy to operate, resulting in lower utility bills.

- Improved Longevity: Thoughtful design contributes to the durability and lifespan of the equipment.

- Lower Environmental Impact: Enhanced efficiency leads to decreased emissions and resource consumption.

- Increased User Comfort: Effective thermal management ensures consistent temperatures, enhancing user experience.