The intricate design of modern shower systems plays a crucial role in ensuring user safety and comfort. A well-thought-out setup not only enhances the overall experience but also minimizes the risk of accidents, particularly those caused by unexpected temperature changes.

In this section, we will explore the various components that contribute to the efficiency and safety of these systems. By examining their functionality and interconnections, we aim to provide a comprehensive understanding of how each element works together to protect users from potential harm.

Through a detailed analysis, we can better appreciate the technology that underlies these essential home fixtures. This knowledge empowers consumers to make informed decisions and maintain their systems effectively, ensuring lasting performance and peace of mind.

Understanding Delta Scald Guard Components

In the realm of plumbing fixtures, ensuring safety and comfort is paramount. A crucial aspect of modern fixtures is the mechanism designed to prevent unexpected temperature fluctuations, thus enhancing user experience. This section will explore the key elements that contribute to this protective feature, allowing for a clearer understanding of its functionality and importance.

Key Elements of the System

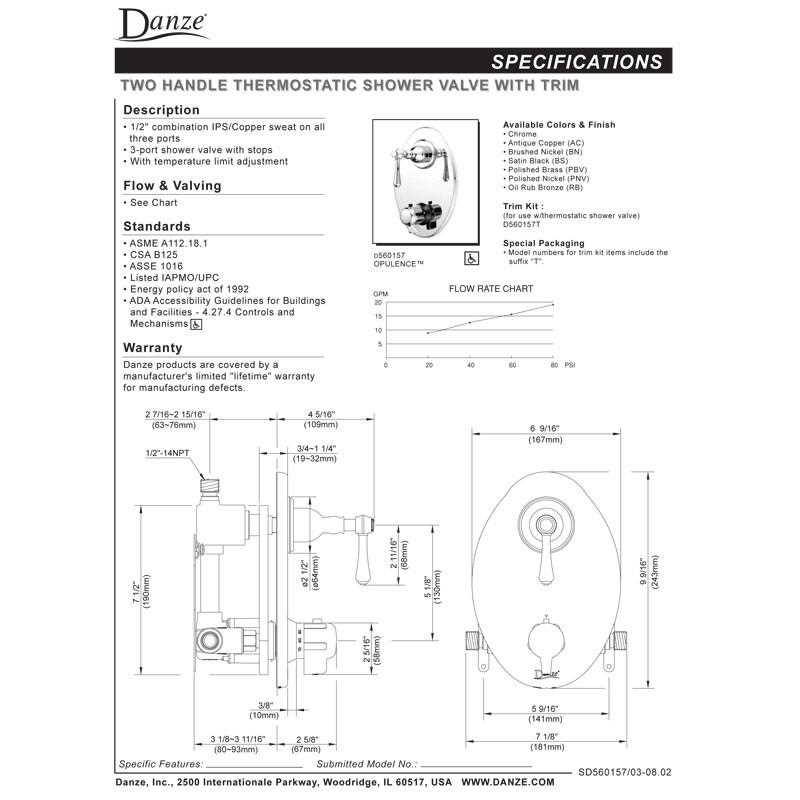

- Thermostatic Valve: Regulates water temperature to maintain consistency.

- Temperature Limit Stop: Prevents excessive heat by restricting maximum temperature.

- Pressure Balancing Mechanism: Ensures equal pressure for hot and cold water.

Benefits of These Components

- Enhances safety by reducing the risk of burns.

- Improves comfort through consistent temperature control.

- Increases reliability and longevity of the fixture.

How the Scald Guard Works

This mechanism is designed to enhance safety by regulating temperature, preventing sudden changes that could lead to discomfort or harm. It employs a system of controls that ensures a stable flow of water, allowing users to enjoy their experience without fear of unexpected surges in heat.

| Component | Function |

|---|---|

| Temperature Sensor | Monitors the water temperature and adjusts flow accordingly. |

| Mixing Valve | Balances hot and cold water to maintain a consistent temperature. |

| Flow Control | Regulates the amount of water that passes through the system. |

| Safety Stop | Limits maximum temperature to prevent burns. |

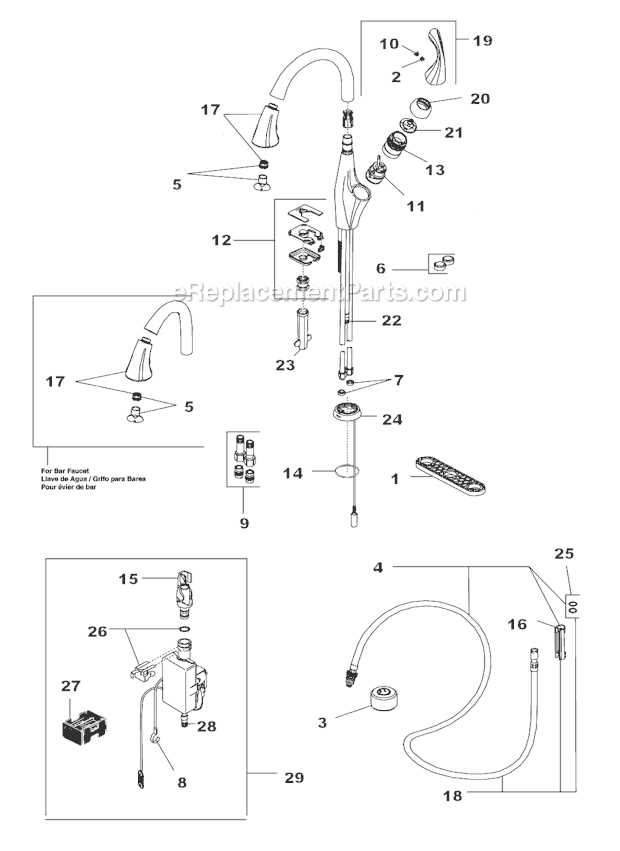

Identifying Parts in the Diagram

Understanding the components illustrated in a technical drawing is essential for effective maintenance and troubleshooting. By recognizing each element, users can ensure proper functionality and address any issues that may arise.

Key Components

- Temperature Control Mechanism

- Water Flow Regulator

- Connection Fittings

- Sealing Gaskets

Tips for Recognition

- Refer to the legend for symbol explanations.

- Compare the components with physical counterparts.

- Use magnification for detailed examination.

Common Issues with Scald Guards

Temperature control devices are essential for maintaining safe water conditions. However, various problems can arise, affecting their performance and user safety.

- Inconsistent Temperature: Fluctuations in water temperature can occur due to faulty mechanisms or blockages.

- Leakage: Wear and tear can lead to leaks, compromising effectiveness and safety.

- Obstructions: Mineral buildup can hinder proper function, necessitating regular maintenance.

- Improper Installation: Incorrect setup may result in ineffective performance and safety hazards.

- Component Wear: Over time, components can degrade, affecting overall reliability.

Addressing these issues promptly can ensure the ultimate safety and comfort in water usage.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your plumbing fixtures requires regular care and attention. By following a few essential maintenance practices, you can significantly extend the lifespan of your equipment and enhance its functionality. This guide outlines key strategies to keep your installations in prime condition.

| Tip | Description |

|---|---|

| Regular Cleaning | Use mild detergents and soft cloths to prevent buildup of mineral deposits and soap scum. |

| Inspect Seals | Check the integrity of seals and gaskets periodically to prevent leaks and water damage. |

| Temperature Control | Avoid exposing fixtures to extreme temperatures to minimize wear and tear on materials. |

| Use Appropriate Tools | When performing maintenance, use tools specifically designed for plumbing tasks to avoid damage. |

| Professional Servicing | Schedule regular inspections by qualified technicians to identify potential issues early. |

By adhering to these guidelines, you can ensure that your fixtures remain functional and visually appealing for years to come.

Installing a Scald Guard System

Implementing a temperature control mechanism in your plumbing setup is essential for ensuring safety and comfort. This process typically involves a few key components designed to regulate water temperature and prevent accidental burns.

Begin by gathering all necessary tools and materials, including the temperature regulator, fittings, and any required seals. Carefully shut off the water supply to your system before starting the installation. Follow the manufacturer’s instructions for connecting the regulator, ensuring all connections are secure to avoid leaks.

Once the mechanism is in place, restore the water supply and check for proper function. Test the system by adjusting the temperature settings to confirm that it operates smoothly and maintains a safe range. Regular maintenance checks will help ensure ongoing efficiency and safety.

Upgrading Your Shower Components

Enhancing your shower experience can significantly transform your daily routine. By modernizing key fixtures, you can achieve improved functionality, aesthetic appeal, and energy efficiency. This section explores various components that can be upgraded to elevate your bathing environment.

Benefits of Upgrading

- Improved water flow and pressure

- Enhanced energy efficiency

- Modern aesthetic appeal

- Increased comfort and convenience

Components to Consider

- Showerhead: Opt for a high-efficiency model that offers adjustable settings.

- Faucet: Upgrade to a more ergonomic design that matches your style.

- Valves: Consider replacing old valves for better temperature control.

- Shower Arm: A stylish arm can enhance the overall look and feel.

- Wall Panels: Update to waterproof materials that are easy to clean and maintain.

Investing in these improvements not only elevates the aesthetics of your bathroom but also contributes to a more enjoyable and efficient bathing experience.

Safety Standards for Shower Fixtures

When it comes to installing and maintaining shower systems, adherence to safety standards is critical to ensure user protection. These standards serve to regulate temperature control, water flow, and emergency response features, all of which are essential for preventing accidents. Every fixture must be carefully evaluated to meet both local building codes and broader safety regulations. This involves more than just basic functionality; it includes the user’s experience and safety, particularly in residential and public settings.

Temperature Control and Prevention

A primary safety concern is the prevention of water temperature fluctuations. Many regulatory bodies emphasize the need for precise temperature regulators to avoid unexpected surges of hot or cold water, which can lead to discomfort or harm. Thermostatic valves are typically used to maintain stable water temperatures, ensuring a consistent, safe experience. In environments like hospitals or care homes, such features are even more crucial, given the heightened vulnerability of certain users.

Compliance and Installation Practices

To remain compliant, shower fixtures must undergo routine inspections and meet specific installation standards. For example, plumbing codes often require that systems include anti-scald devices and emergency shut-off mechanisms. These not only protect users but also prevent water wastage in case of system failures. Additionally, regular maintenance ensures that all safety components function correctly, minimizing risks of accidents and extending the life of the fixtures.

Where to Find Replacement Parts

Locating appropriate components for maintaining or repairing specific fixtures can sometimes be challenging, especially if the exact model is no longer available. However, there are numerous reliable sources where compatible items can be found, ensuring that even older or rare models remain functional.

Authorized Dealers and Online Stores

Many manufacturers offer direct access to components through certified retailers or online platforms. These suppliers often carry a wide range of replacement items, allowing customers to quickly identify what is needed. In addition, online marketplaces can provide access to third-party suppliers and used pieces.

Local Hardware Stores

For those who prefer in-person shopping, local hardware stores can also be a valuable resource. Staff at these stores are often knowledgeable and can assist in identifying the correct items. Many stores also offer the option to order parts that are not immediately available in-store.

| Source |

|---|