Effective management of gases in various applications requires a comprehensive understanding of the critical elements involved in the process. Each component plays a vital role in ensuring optimal performance, safety, and efficiency. By gaining insight into the intricate relationships between these elements, users can enhance their overall experience and achieve desired outcomes.

The arrangement and functionality of these elements are crucial for maintaining a consistent flow and pressure of the gas. Each section serves a specific purpose, contributing to the overall effectiveness of the system. Recognizing how these components interact will empower users to make informed decisions regarding their usage and maintenance.

In-depth knowledge of these essential elements not only aids in troubleshooting potential issues but also fosters a deeper appreciation for the technology involved. As users familiarize themselves with the configuration and roles of each part, they can better appreciate the sophistication of the entire system.

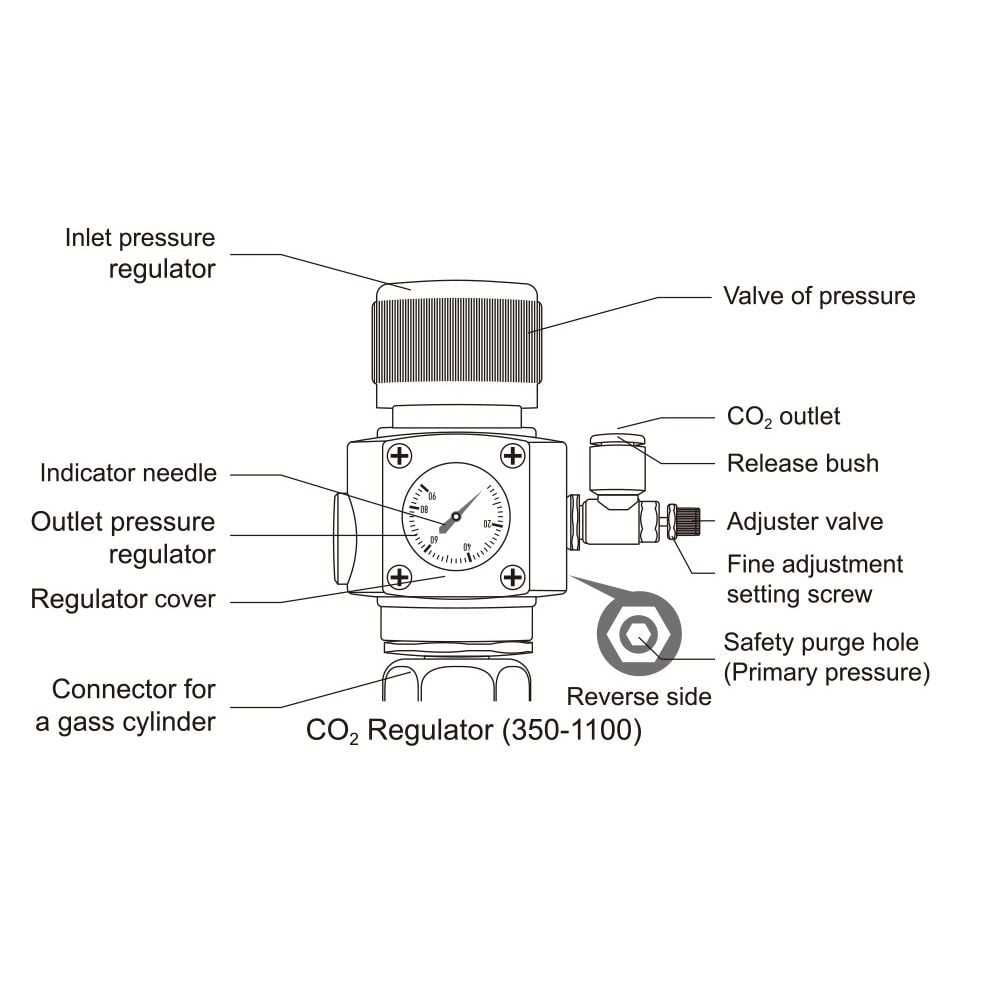

Understanding CO2 Regulator Components

In the realm of gas management systems, various elements work together to control the flow and pressure of gases. A clear comprehension of these components is essential for effective operation and maintenance. Each element plays a crucial role in ensuring stability and efficiency, contributing to the overall functionality of the setup.

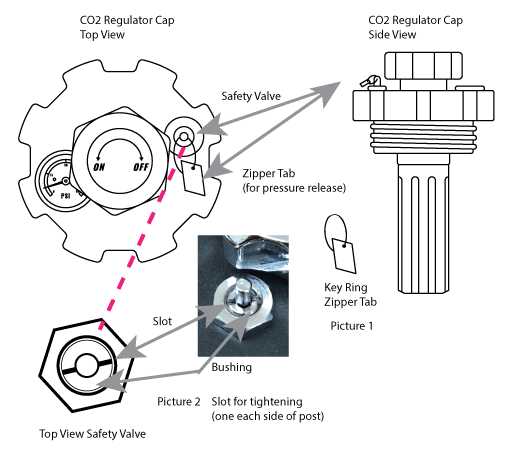

The primary component is responsible for managing pressure levels, facilitating a consistent release of gas. This element is vital in maintaining the desired pressure, preventing fluctuations that could affect performance. Furthermore, another key feature assists in the precise measurement and adjustment of the gas flow, allowing for tailored settings to meet specific requirements.

Moreover, an essential attachment enhances safety by providing a fail-safe mechanism. This feature is crucial for minimizing the risk of over-pressurization, ensuring that operations remain safe and reliable. Understanding these components enables users to troubleshoot effectively and optimize the overall performance of the system.

Importance of CO2 Regulation in Aquariums

Maintaining a balanced environment is crucial for the health and vitality of aquatic life. Proper management of carbon dioxide levels plays a vital role in fostering a thriving ecosystem within tanks. The appropriate concentration of this gas not only supports plant growth but also enhances the overall well-being of fish and other inhabitants.

Enhancing Plant Growth

Aquatic plants rely on specific gas levels to perform photosynthesis effectively. When the right amount of carbon dioxide is present, plants can convert light into energy, resulting in lush foliage and vibrant colors. Without sufficient levels, plants may struggle to thrive, leading to an unbalanced ecosystem.

Improving Fish Health

The presence of an optimal concentration of this essential gas is also beneficial for fish. Adequate levels contribute to a stable environment, reducing stress and promoting healthy behavior. Fish that thrive in a well-balanced setting exhibit better coloration, increased activity, and enhanced immune systems, ultimately leading to a more harmonious aquarium.

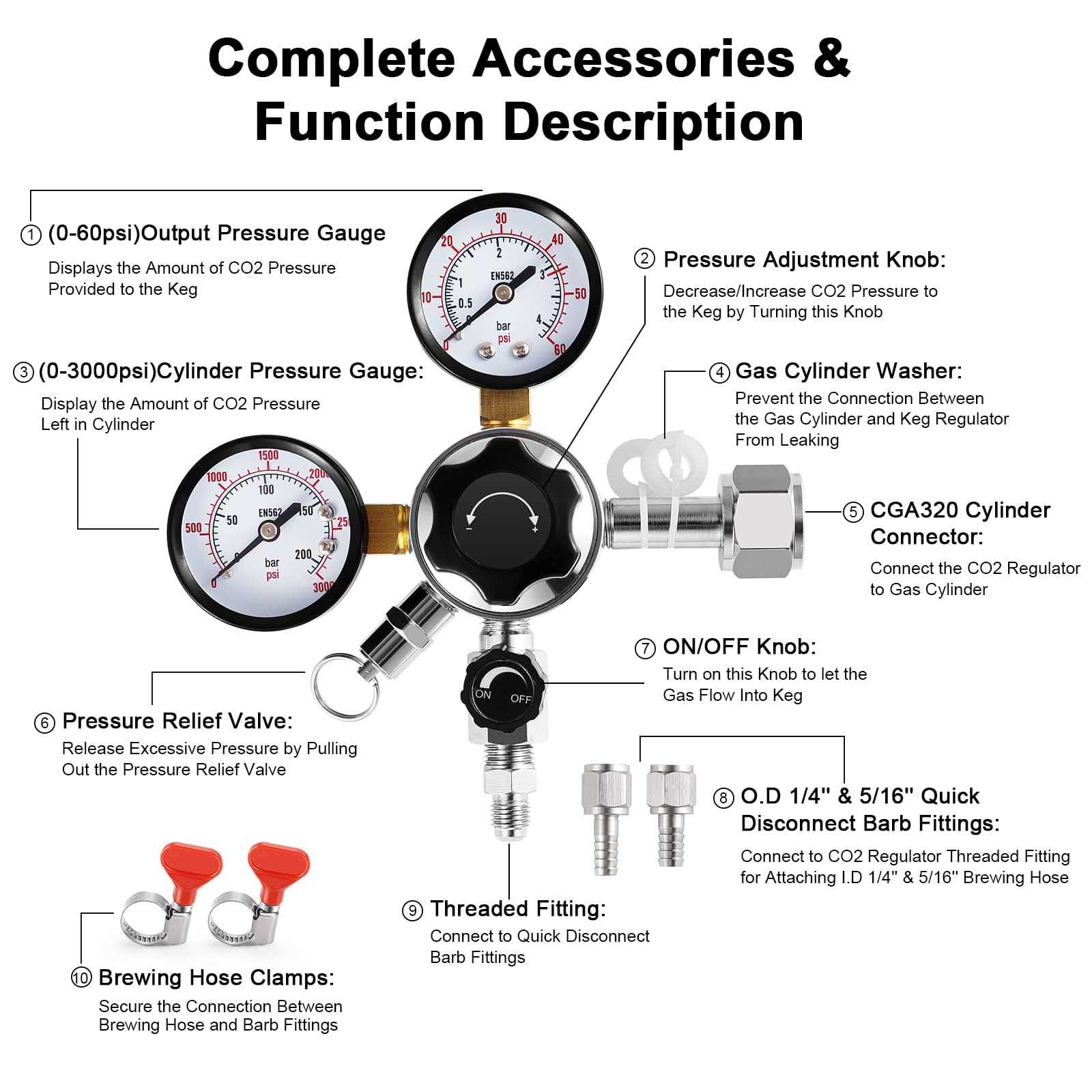

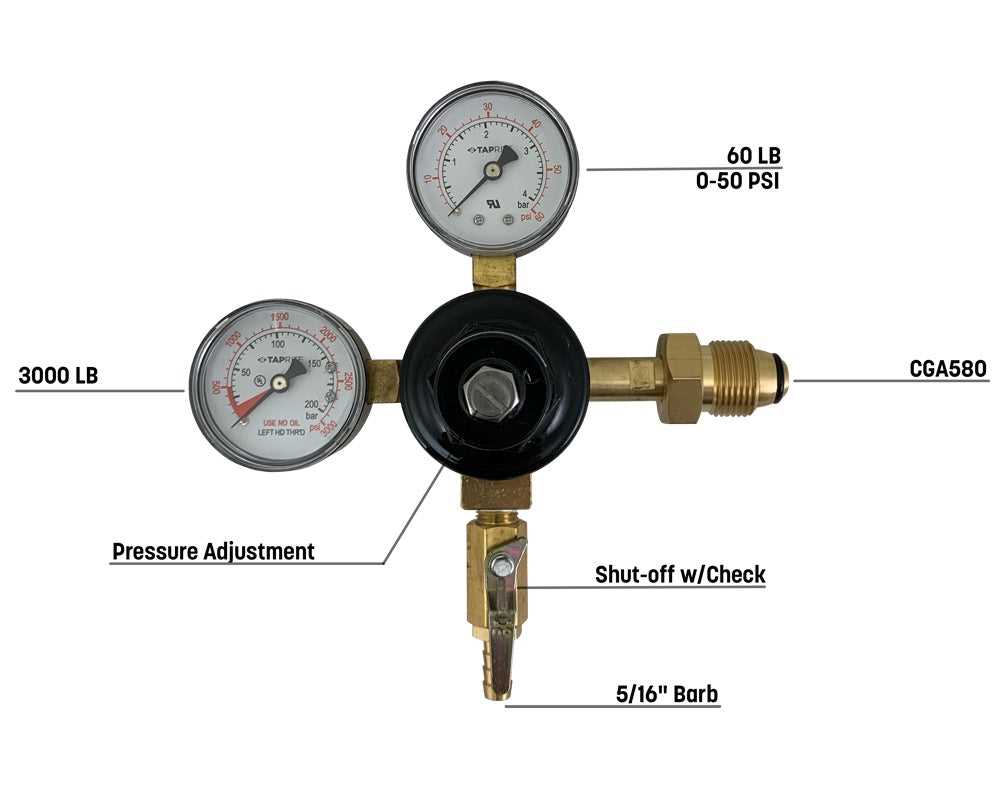

Key Parts of a CO2 Regulator

Understanding the essential components of a carbon dioxide management system is crucial for its effective operation. These elements work together to control the flow and pressure of the gas, ensuring optimal performance in various applications, such as aquariums, brewing, or industrial processes. Each element plays a vital role in the overall functionality and efficiency of the system.

Pressure Adjustment Mechanism

This feature allows users to set and modify the desired pressure level within the system. It ensures that the flow rate remains consistent, providing the necessary amount of gas for the specific application. The ability to fine-tune this aspect is critical for achieving optimal results and preventing system malfunctions.

Flow Control Valve

This component regulates the amount of gas released into the system. By controlling the flow rate, it helps maintain the desired pressure and prevents over-pressurization. A well-functioning valve is essential for ensuring a steady supply of gas, contributing to the overall efficiency and safety of the operation.

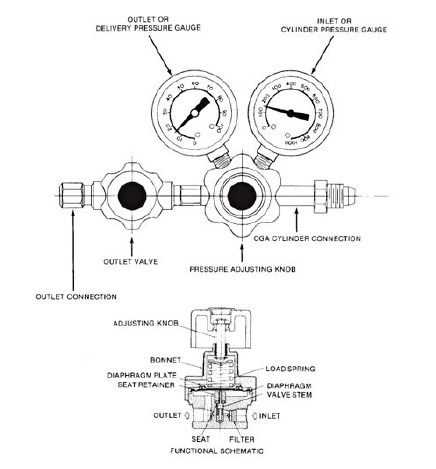

How a CO2 Regulator Functions

This device plays a crucial role in controlling the flow of a specific gas, ensuring it reaches the desired pressure for various applications. By precisely managing the release of the gas, it facilitates optimal performance in systems that require specific levels of pressure to operate efficiently.

The mechanism operates through a combination of components that work together seamlessly. The primary feature is the pressure control, which allows for the adjustment of the gas output to meet the needs of the system. Below is a table summarizing the main components and their functions:

| Component | Function |

|---|---|

| High-Pressure Gauge | Displays the pressure of the gas within the cylinder. |

| Low-Pressure Gauge | Indicates the pressure of the gas as it exits the device. |

| Control Knob | Allows users to adjust the output pressure as needed. |

| Safety Release Valve | Prevents over-pressurization by releasing excess gas. |

| Connection Fittings | Ensures secure attachment to gas supply and delivery lines. |

In essence, the efficient operation of this mechanism is essential for maintaining the desired levels of gas in various environments, making it a vital tool in numerous fields.

Common Issues with CO2 Regulators

Understanding the frequent challenges associated with gas pressure management devices is essential for ensuring optimal performance. These components play a crucial role in controlling the flow and pressure of gas, making it vital to address any problems promptly. Below are some typical issues that users may encounter, along with their potential causes and solutions.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Inconsistent Pressure | Faulty seals, leaks, or damaged components | Inspect for leaks and replace damaged parts |

| Difficulty in Adjusting Flow | Blocked pathways or malfunctioning adjustment knobs | Clean the pathways and check adjustment mechanisms |

| Unusual Noise | Loose fittings or internal wear | Tighten fittings and replace worn internal parts |

| Fluctuating Readings | Inaccurate gauge or temperature fluctuations | Calibrate the gauge and monitor temperature |

Maintenance Tips for CO2 Systems

Ensuring optimal performance of carbon dioxide systems requires regular upkeep and attention. By following a set of maintenance practices, users can prolong the lifespan of their equipment, improve efficiency, and prevent common issues that may arise over time.

Here are some essential maintenance recommendations:

- Regular Inspections: Conduct frequent checks on all components to identify any signs of wear, leaks, or damage. Early detection can prevent more significant problems.

- Clean Components: Keep all parts free from dirt and debris. Use a soft cloth or brush to clean fittings and connections, ensuring smooth operation.

- Check Seals and Gaskets: Inspect seals and gaskets regularly for integrity. Replace any that show signs of deterioration to prevent gas leaks.

- Monitor Pressure Levels: Regularly check the pressure levels within the system. Ensure they are within recommended ranges to maintain performance.

- Calibrate Equipment: Periodically calibrate any measurement tools to ensure accuracy in readings. This helps maintain the system’s efficiency.

- Store Properly: When not in use, store equipment in a cool, dry place away from direct sunlight. This helps to protect sensitive components.

Implementing these maintenance practices will contribute to the longevity and reliability of your carbon dioxide systems, ensuring they function effectively and efficiently.

CO2 Regulator Setup and Installation

Setting up your carbon dioxide control system is essential for maintaining optimal conditions in your aquatic environment. Proper installation ensures efficient delivery and helps prevent leaks, which can lead to ineffective operation. This section provides a comprehensive guide to assist you in configuring your system accurately.

Begin by gathering all necessary components and tools. Familiarize yourself with the different elements of the system, including the delivery mechanism and the connection fittings. Ensure that all components are clean and in good condition to facilitate a seamless setup.

Once you have all your materials ready, start by securely attaching the primary unit to your gas source. Tighten all connections to avoid potential leaks, and utilize thread seal tape where necessary to enhance sealing. Following this, connect the delivery tubing to the designated outlet, ensuring it is firmly attached to prevent any disconnection during operation.

After everything is connected, check for any leaks by turning on the gas supply slowly and observing for bubbles around the fittings. If any leaks are detected, turn off the gas and make the necessary adjustments. Finally, calibrate the output settings according to the specific requirements of your aquatic environment, ensuring optimal levels for the health of your inhabitants.

Comparing Different CO2 Regulator Models

When it comes to selecting a device for managing gas pressure, various models offer distinct features that cater to different needs. Understanding the nuances between these options can significantly enhance your overall experience and efficiency in usage. Each variant presents its own set of functionalities, precision levels, and ease of use, making it essential to consider what aligns best with your specific requirements.

First and foremost, the design of the devices plays a crucial role in their performance. Some models prioritize simplicity, providing a user-friendly interface that allows for quick adjustments. In contrast, others incorporate advanced features, such as multiple pressure settings and built-in safety mechanisms. This diversity ensures that users can choose a model that fits their comfort level and technical expertise.

Moreover, the materials used in construction can vary significantly. Higher-end options often utilize durable materials that promise longevity and resistance to wear and tear. On the other hand, more economical choices may sacrifice some robustness for affordability. This factor can influence not only the initial investment but also long-term maintenance and reliability.

Finally, it’s important to consider the compatibility of these devices with various systems. Some models are designed to integrate seamlessly with specific setups, while others offer universal compatibility. Assessing the compatibility with your existing equipment is vital for achieving optimal performance and avoiding potential issues down the line.

Upgrading Your CO2 System Components

Enhancing the efficiency and performance of your gas distribution system can significantly improve overall results. By carefully selecting and replacing specific elements, you can ensure optimal functionality, reliability, and longevity of your setup. This section will explore various ways to elevate your system through component upgrades.

Identifying Key Components for Enhancement

To achieve maximum efficiency, it’s essential to evaluate the main elements of your system. Consider focusing on the following:

- Pressure control devices

- Connection fittings

- Delivery mechanisms

- Measurement tools

- Sealing components

Benefits of Upgrading Specific Elements

Each component plays a crucial role in the overall performance. Upgrading these parts can lead to several advantages:

- Improved Accuracy: Enhanced measurement devices ensure precise gas flow and pressure, reducing waste.

- Increased Durability: High-quality materials in replacement fittings can withstand wear and tear better than standard options.

- Enhanced Safety: Newer technology can provide better leak prevention and system monitoring capabilities.

- Optimized Performance: Upgraded delivery mechanisms can improve gas distribution efficiency, resulting in better results.

In summary, investing in quality replacements and enhancements can lead to a more effective and reliable gas management system.