In the realm of machinery, a thorough comprehension of individual elements is crucial for optimal performance and maintenance. Each segment plays a vital role in the seamless operation of the entire system. Gaining insights into these components not only enhances troubleshooting skills but also empowers enthusiasts and professionals alike to execute precise repairs and upgrades.

Visual representations serve as invaluable tools for deciphering complex assemblies. By breaking down intricate structures into understandable segments, these illustrations facilitate a clearer understanding of how each piece interacts within the broader mechanism. This knowledge is essential for anyone looking to delve deeper into the workings of their equipment.

Furthermore, familiarity with various configurations and functionalities enables users to make informed decisions regarding modifications and enhancements. Recognizing the significance of each component paves the way for improved efficiency and longevity, ultimately leading to a more satisfying experience with one’s machinery.

Understanding Century Motor Components

Comprehending the essential elements of mechanical devices is crucial for their efficient operation and maintenance. Each component plays a specific role, contributing to the overall functionality and reliability of the system. A thorough grasp of these elements enables users to diagnose issues, perform repairs, and optimize performance.

Core Elements of these systems include energy converters, transmission mechanisms, and control units. Each part must work harmoniously to ensure seamless operation. For instance, energy converters transform input into usable power, while transmission mechanisms facilitate the movement of this power to various functional areas.

Furthermore, control units govern the operation, allowing for adjustments and monitoring. Understanding how these components interact can significantly enhance the user’s ability to maintain and troubleshoot the system. With the right knowledge, individuals can achieve greater efficiency and longevity from their equipment.

Common Parts in Century Motors

Understanding the essential components of machinery is crucial for effective maintenance and operation. This knowledge not only enhances performance but also ensures longevity and reliability of the equipment. Various elements work together, each playing a specific role in the overall functionality of the system.

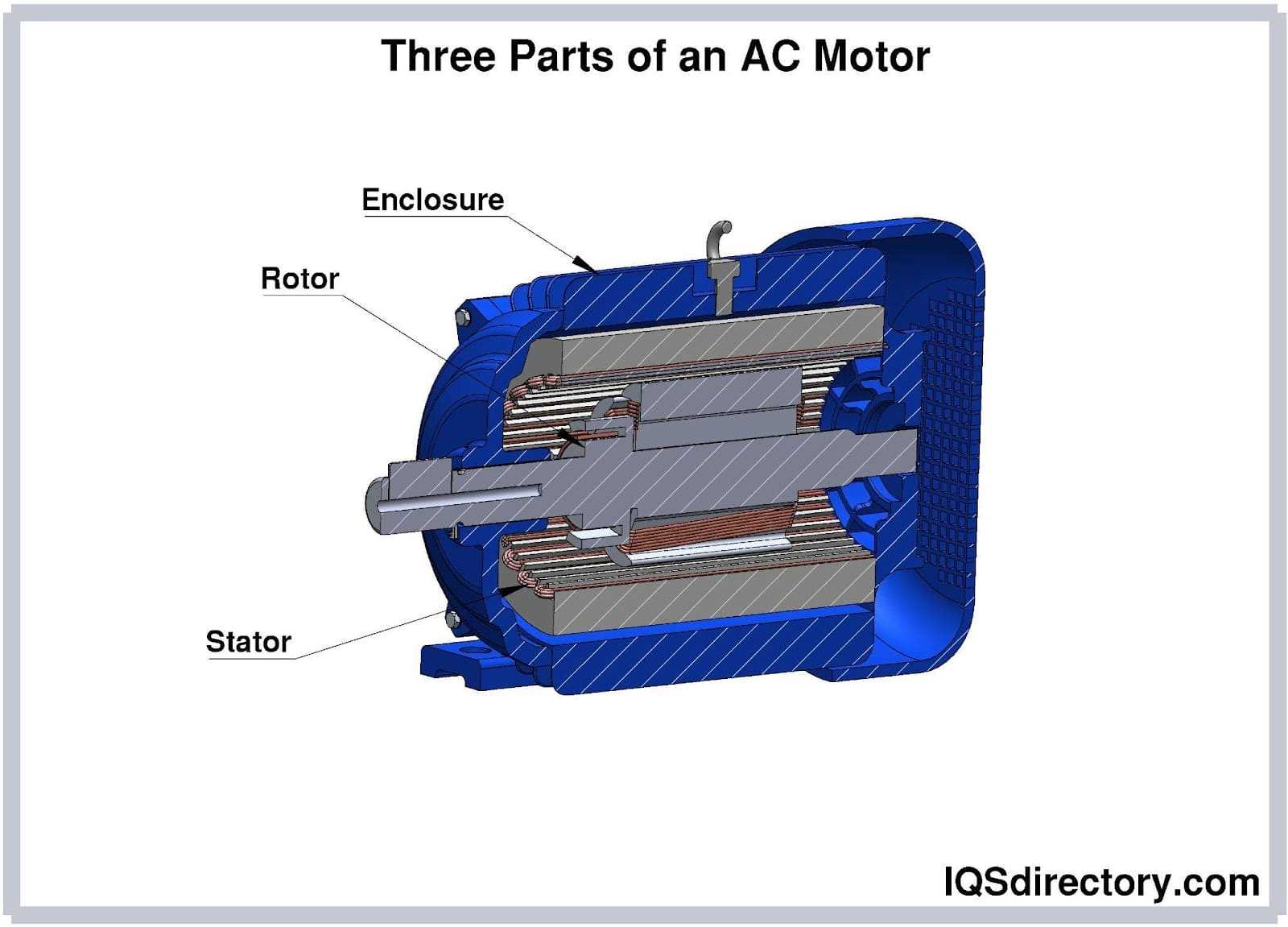

Among the frequently encountered components, the rotor stands out as a pivotal part responsible for generating motion. Coupled with this is the stator, which provides the necessary magnetic field for operation. Another key element is the bearing, crucial for reducing friction and supporting rotating parts.

Additionally, winding serves as the conductor through which electrical current flows, facilitating energy transfer. The housing protects these internal components from external elements, ensuring safety and durability. Lastly, capacitors and switches play essential roles in controlling the electrical flow, contributing to the efficiency and functionality of the machinery.

In summary, a thorough grasp of these fundamental elements allows users to optimize performance and address any issues that may arise during operation. Familiarity with these components not only aids in troubleshooting but also enhances overall understanding of the equipment’s mechanics.

How to Read Motor Diagrams

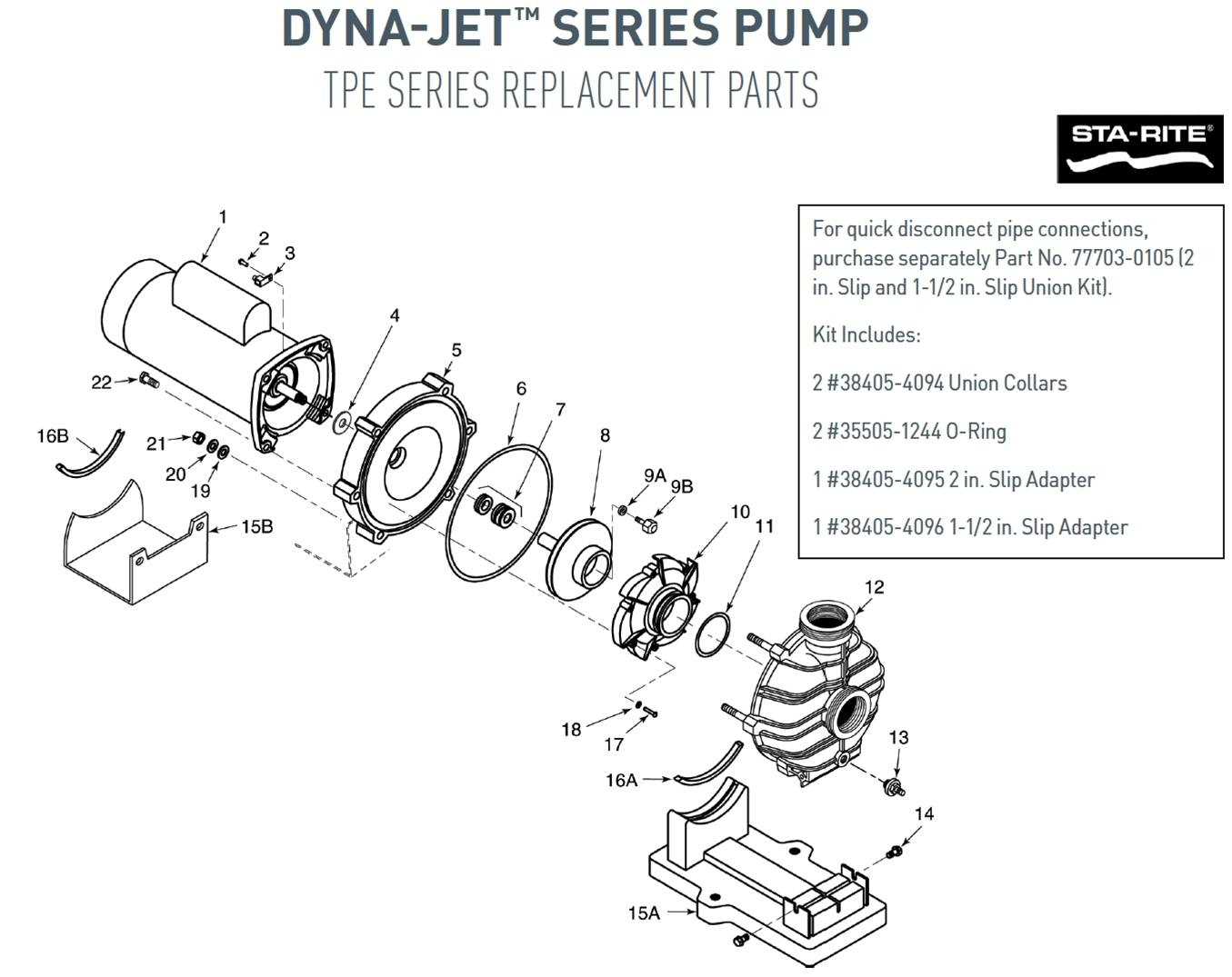

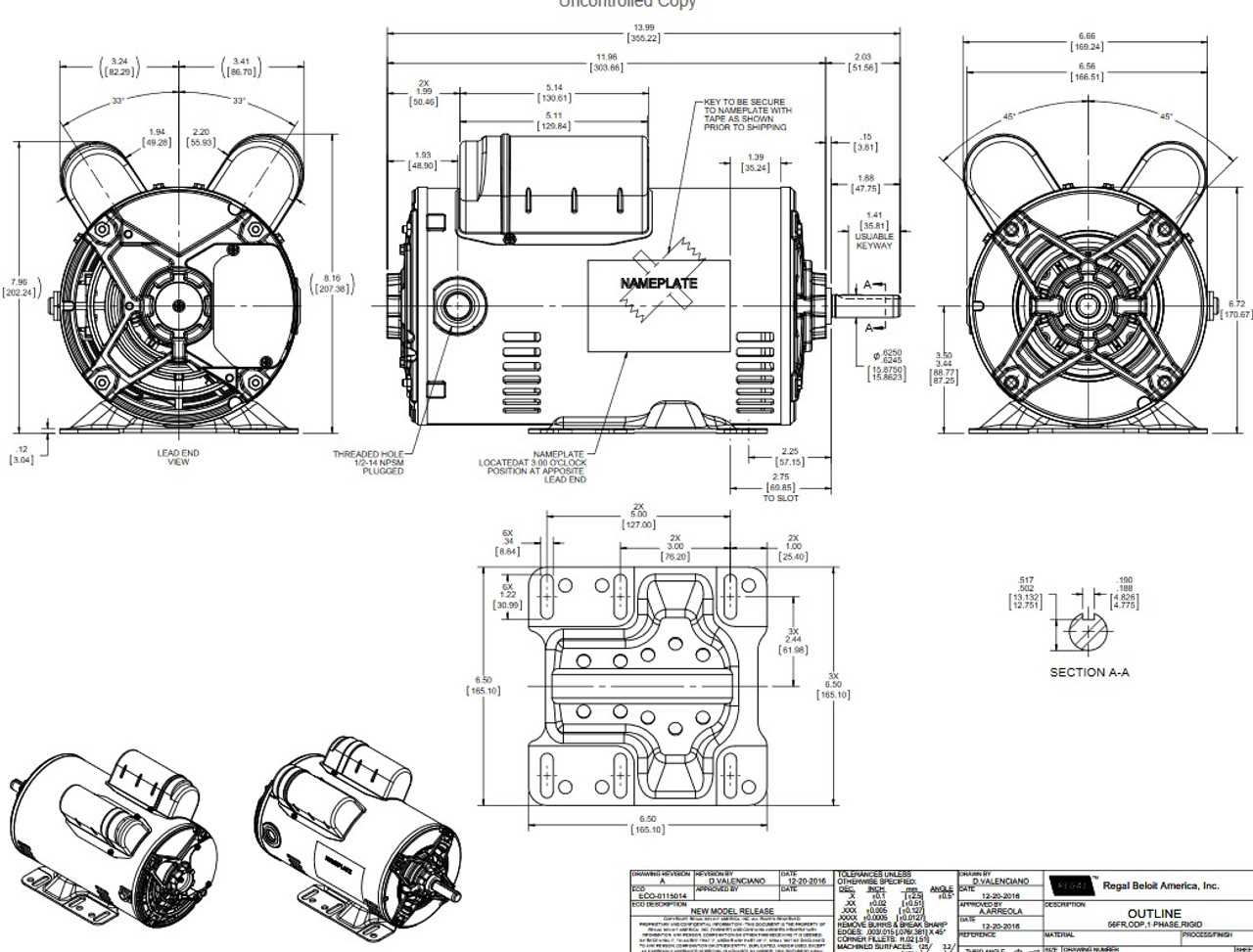

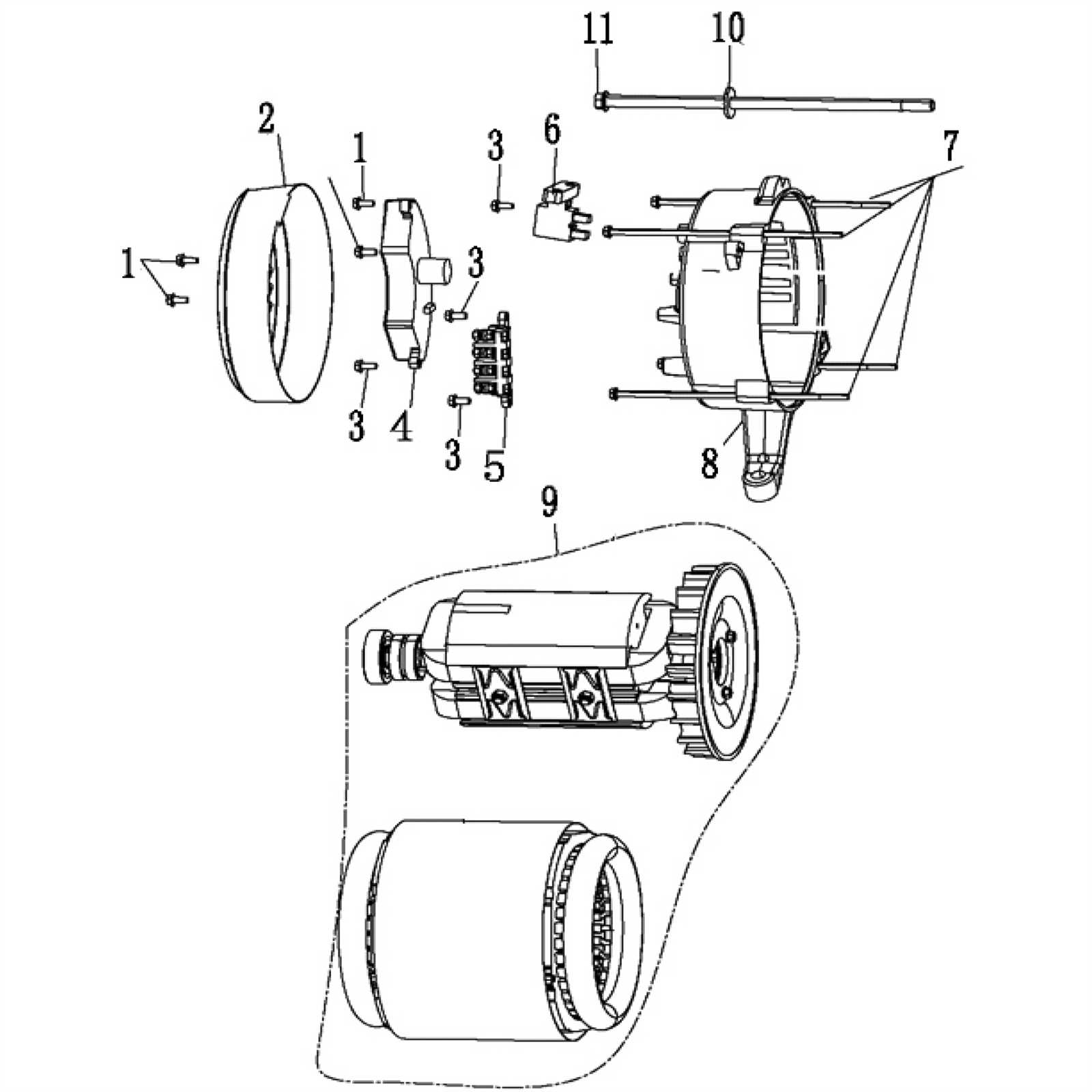

Understanding the intricacies of mechanical illustrations is essential for anyone involved in machinery maintenance or repair. These visuals provide crucial information about components, their connections, and operational principles. Mastering how to interpret these representations can significantly enhance troubleshooting and assembly tasks.

Identifying Symbols and Components

Each visual representation uses specific symbols to denote various elements. Familiarize yourself with these icons, as they are standardized across many industries. Common symbols often include representations for switches, connectors, and power sources. Recognizing these will allow you to quickly ascertain the layout and functionality of the system.

Following Connections and Flow

Once you identify the components, pay attention to the lines connecting them. These lines often indicate the flow of energy or signal. Solid lines typically represent physical connections, while dotted lines may indicate control signals. Following these pathways can help you understand how different parts interact within the larger system, leading to effective troubleshooting and repair.

Importance of Accurate Schematics

Precise representations are essential in any technical field, as they serve as the foundation for understanding complex systems. These visual aids facilitate communication among engineers, technicians, and other stakeholders by providing a clear framework to follow during assembly, maintenance, or troubleshooting. Without such clarity, the risk of errors increases significantly, leading to inefficiencies and potential hazards.

Accurate schematics not only enhance comprehension but also streamline processes. They allow users to identify components and their interrelations, which is crucial for effective repairs and modifications. Moreover, these representations serve as invaluable references, ensuring that all involved parties are aligned on specifications and expectations.

| Benefits of Accurate Schematics | Description |

|---|---|

| Clarity | Offers a clear understanding of the system layout and function. |

| Efficiency | Reduces time spent on repairs and maintenance by providing clear guidance. |

| Safety | Minimizes the risk of accidents by ensuring correct assembly and operation. |

| Consistency | Ensures that all modifications and repairs adhere to the same standards. |

Ultimately, investing in high-quality schematics pays off by fostering a more reliable and productive environment. Clarity in design and communication paves the way for innovation and improvement, empowering teams to tackle challenges effectively.

Troubleshooting with Diagrams

Effective problem-solving often hinges on visual aids that clarify complex systems. Utilizing graphical representations can significantly enhance understanding, enabling individuals to identify issues more efficiently. By analyzing these visuals, users can pinpoint malfunctioning components and devise appropriate solutions without extensive trial and error.

Identifying Issues

Visual schematics serve as a roadmap for diagnosing problems. By following the layout, one can systematically eliminate potential causes of failure. Each section offers insights into how elements interact, revealing possible points of failure and helping to streamline the troubleshooting process.

Implementing Solutions

Once a problem is identified, graphical representations assist in planning corrective actions. Users can refer back to the illustrations to ensure that replacements or repairs align with the original design. This method minimizes the risk of further complications and promotes effective restoration of functionality.

Replacement Parts for Century Motors

Ensuring optimal performance of your machinery often requires the timely replacement of specific components. Understanding the available options is crucial for maintaining efficiency and longevity.

When looking for substitutes, consider the following factors:

- Quality: Always opt for high-quality alternatives to avoid premature failures.

- Compatibility: Ensure that the replacements fit perfectly with your existing setup.

- Availability: Check local suppliers or online retailers for stock levels.

Commonly needed components include:

- Bearings: Essential for smooth operation and minimizing friction.

- Gaskets: Vital for preventing leaks and maintaining pressure.

- Seals: Help to protect internal mechanisms from contaminants.

- Brushes: Crucial for electrical connectivity and performance.

- Switches: Important for controlling the power supply effectively.

By keeping these considerations in mind, you can ensure your equipment remains in top condition for years to come.

Maintenance Tips for Motor Longevity

Proper upkeep is essential for ensuring the extended life of any machinery. Regular attention to various aspects can significantly reduce wear and tear, leading to improved performance and reliability over time. This section outlines key practices that can help achieve optimal functioning and longevity.

Regular Inspection

- Conduct frequent checks for any signs of wear, leaks, or unusual noises.

- Inspect electrical connections to ensure they are secure and free from corrosion.

- Examine belts and hoses for fraying or cracking.

Lubrication

- Utilize appropriate lubricants to reduce friction and prevent overheating.

- Follow the manufacturer’s recommendations regarding lubrication intervals.

- Pay special attention to high-friction areas that require regular maintenance.

By adhering to these maintenance practices, you can significantly enhance the durability and functionality of your equipment, ensuring it performs at its best for years to come.

Resources for Motor Diagrams

Accessing accurate schematics is essential for anyone involved in machinery maintenance or repair. A variety of platforms provide valuable information that can assist both professionals and enthusiasts in understanding components and their configurations. Below are some recommended sources that can enhance your knowledge and support your projects.

- Manufacturer Websites: Many producers offer downloadable blueprints directly on their sites, ensuring you have the latest versions.

- Online Forums: Communities dedicated to machinery often share insights and links to useful resources, including detailed layouts and user experiences.

- Technical Manuals: These documents typically contain comprehensive information, including assembly layouts and troubleshooting tips.

- Educational Platforms: Websites that focus on technical education frequently provide access to instructional materials and interactive schematics.

Utilizing these resources can greatly enhance your understanding and facilitate more effective repairs and maintenance. Always ensure that the information is up to date and applicable to your specific needs.