The inner workings of a fastening device can often be intricate, featuring a variety of essential elements that contribute to its overall functionality. Grasping how these components interact is vital for anyone looking to maintain or troubleshoot such tools effectively.

Familiarity with the individual elements not only enhances your ability to perform repairs but also aids in the optimization of the device’s performance. Whether it’s a matter of replacing a worn-out component or simply understanding the mechanics, having a clear overview of these parts is crucial.

By examining the specific roles of each piece, users can ensure that their fastening device operates smoothly and efficiently. This knowledge empowers individuals to address issues proactively, thus extending the lifespan of their equipment and ensuring consistent results in their tasks.

Understanding Stapler Mechanism Functionality

Grasping the inner workings of a fastening device reveals the intricacies behind its efficiency. Each component plays a crucial role in ensuring smooth operation, enabling the secure binding of sheets. This section delves into the essential elements that contribute to the effective performance of such tools.

At the heart of the mechanism are several key components, each designed to fulfill a specific function:

- Base: This foundational element provides stability during operation, allowing for accurate placement of materials.

- Lever: The lever is pivotal for the manual force application necessary to drive the fastener through the sheets.

- Channel: This component guides the fastener, ensuring it is aligned correctly for efficient penetration.

- Spring: A spring mechanism facilitates the return motion of the lever, preparing the device for the next action.

- Fastener Holder: This part stores the fasteners, allowing for seamless replenishment and ensuring consistent performance.

Understanding how these components interact is vital for troubleshooting and maintenance. A well-maintained fastening device can enhance productivity and prolong its lifespan, making familiarity with its mechanism beneficial for any user.

Identifying Common Parts and Their Roles

Understanding the components of a fastening device is crucial for effective usage and maintenance. Each element plays a specific role that contributes to the overall functionality of the tool. Familiarity with these features enables users to troubleshoot issues and ensure optimal performance.

The following list outlines some of the most common elements found in these devices, along with their respective functions:

- Handle: The main grip area that allows for manual operation, facilitating the application of force.

- Chamber: The space where fasteners are loaded, enabling smooth dispensing during use.

- Feed Mechanism: This component transports the fasteners from the chamber to the firing position, ensuring consistent delivery.

- Release Button: A safety feature that allows the user to reset or clear any jammed fasteners.

- Guide Rail: Helps align fasteners accurately during application, promoting precision.

- Spring Mechanism: Provides the necessary tension for the release of fasteners, aiding in the speed of operation.

By recognizing these essential components and their roles, users can enhance their understanding of the tool’s operation and improve their overall efficiency in various tasks.

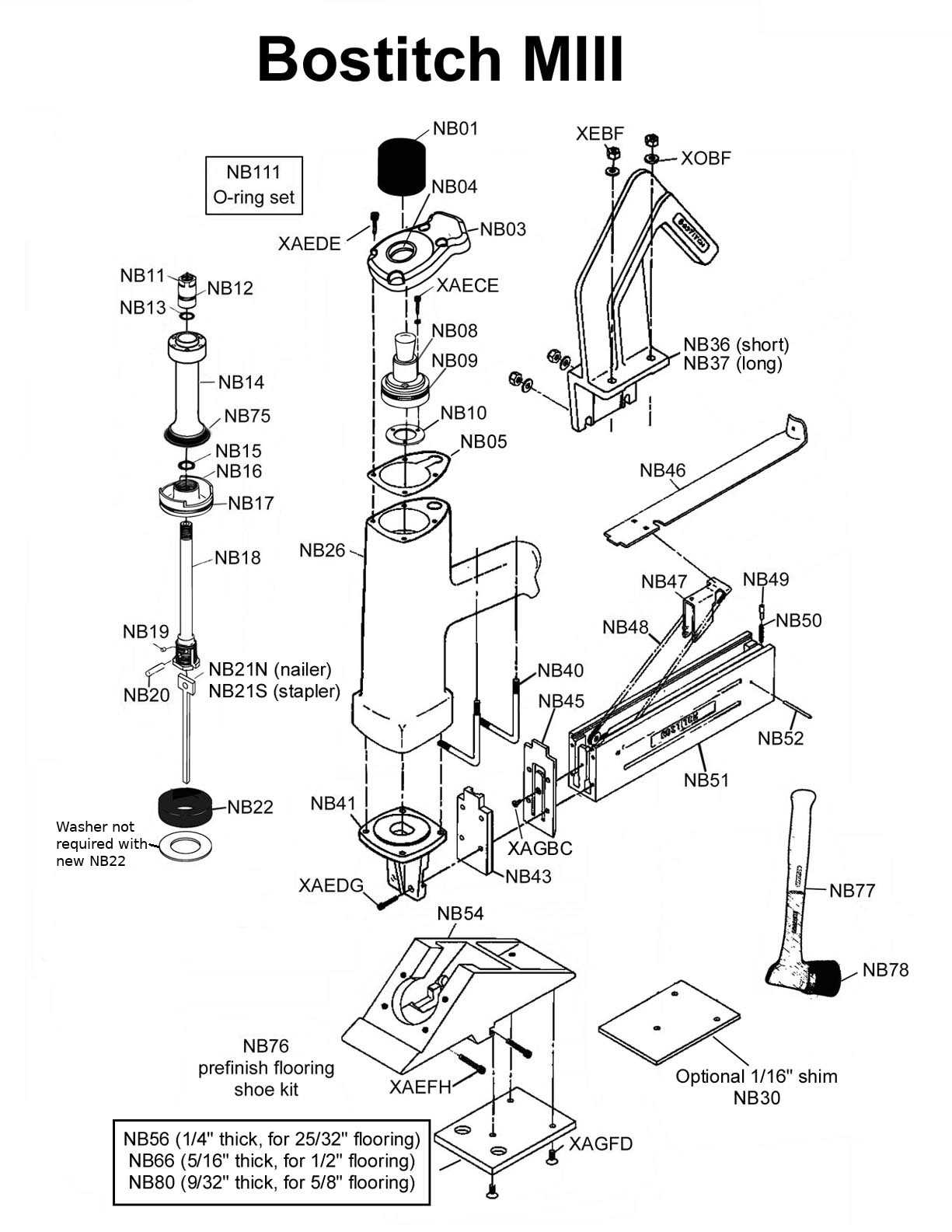

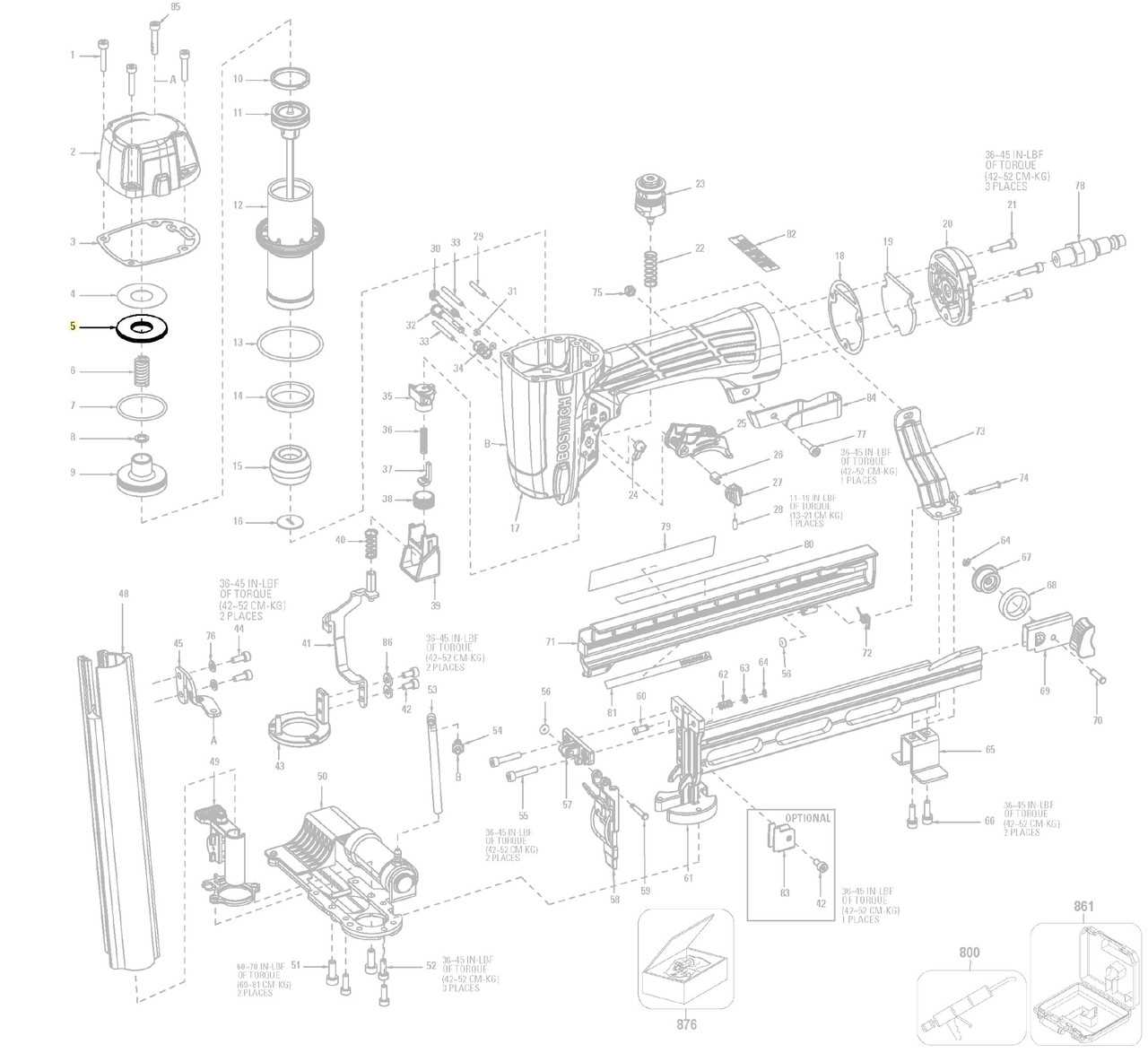

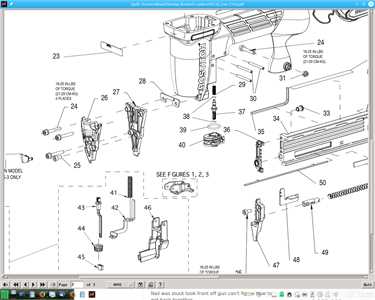

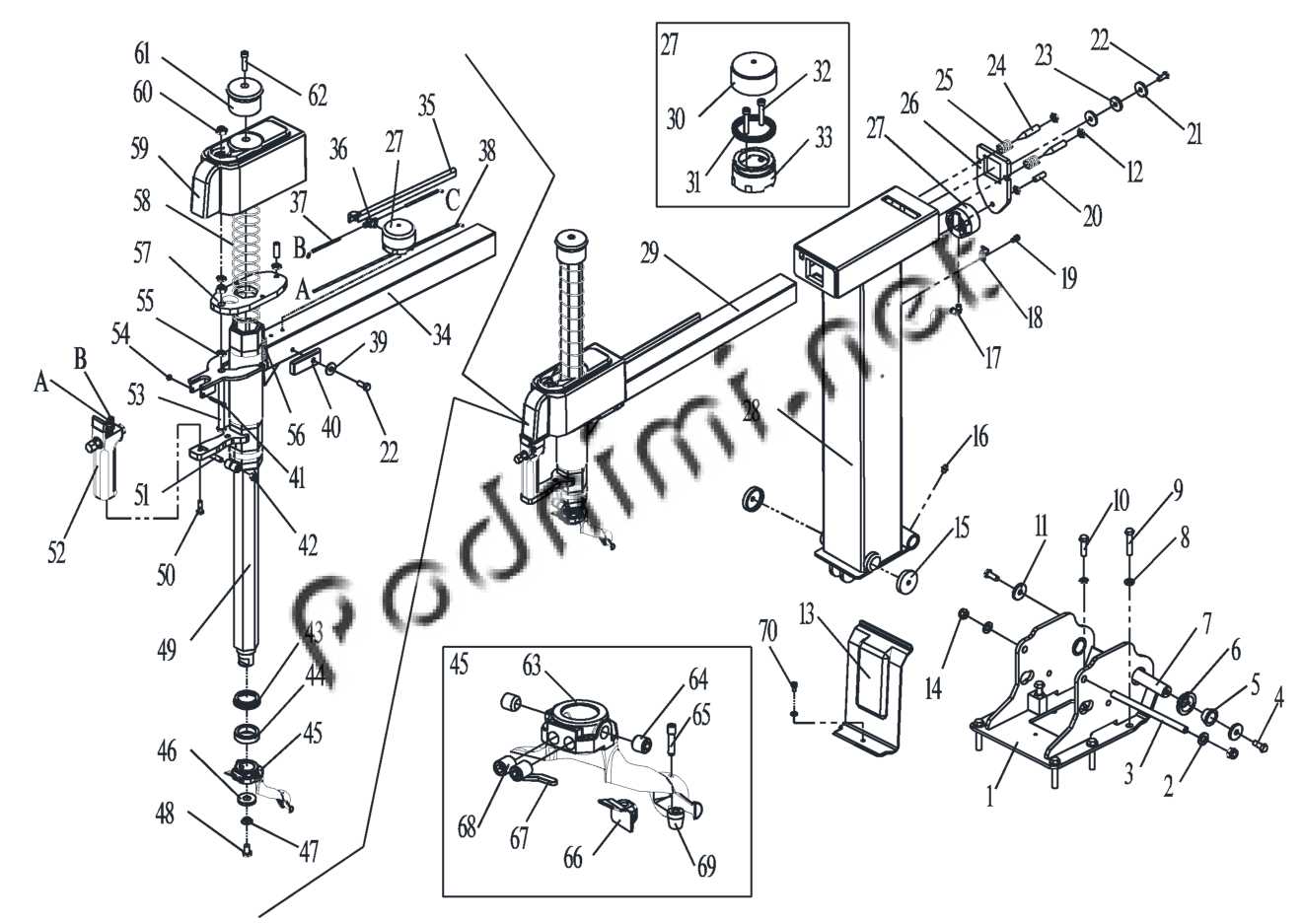

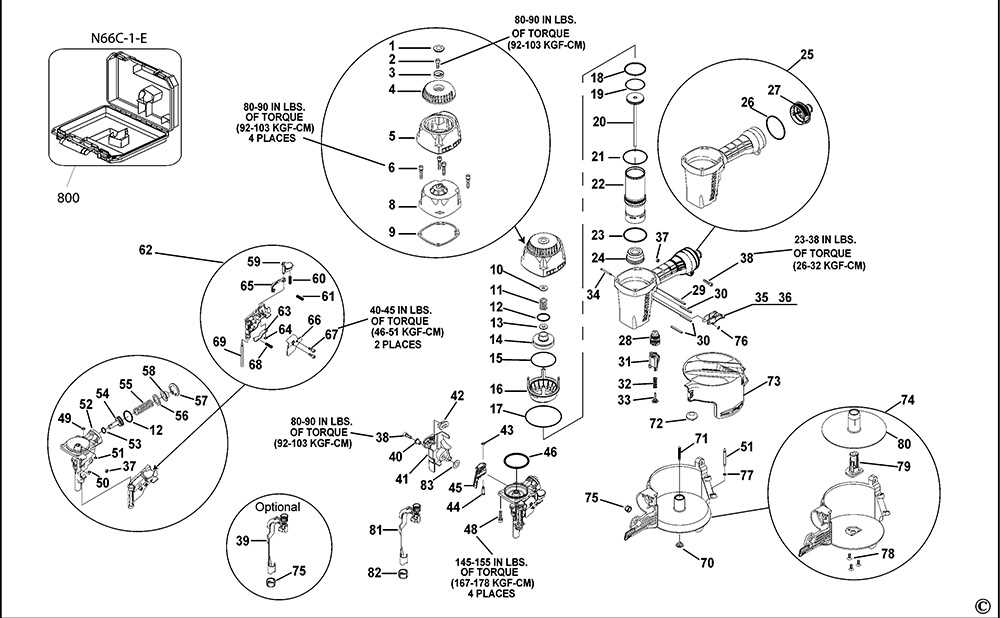

Detailed Parts Diagram Analysis

Understanding the intricate components of a fastening device is essential for effective maintenance and troubleshooting. Each element plays a crucial role in the overall functionality, ensuring smooth operation and reliability. A comprehensive analysis of these components allows users to grasp their significance and interrelations.

To facilitate better understanding, let’s break down the primary elements involved:

- Body Frame: The main structure that houses all other components.

- Pressure Mechanism: Responsible for applying the necessary force to drive the fastener into the material.

- Loading Chamber: Where the fasteners are stored before being dispensed.

- Actuation Lever: The control mechanism that triggers the fastening action.

- Guide Track: Ensures precise alignment of the fasteners during operation.

In addition to these components, several smaller yet vital elements contribute to the overall performance:

- Spring: Provides the necessary tension for the actuation mechanism.

- Safety Guard: Prevents accidental activation during handling.

- Adjustment Knob: Allows for customization of depth and pressure settings.

- Release Button: Facilitates easy unloading of fasteners.

By examining these components in detail, users can enhance their understanding of the device’s mechanics, which is pivotal for effective repairs and optimal use.

How to Maintain Stapler Components

Proper care of fastening devices is essential for their longevity and efficiency. Regular maintenance not only ensures smooth operation but also helps prevent common issues that can disrupt workflow. This guide outlines effective practices for keeping these mechanisms in optimal condition.

Regular Cleaning: Accumulated debris and dust can hinder performance. Use a soft cloth to wipe down exterior surfaces and a small brush to remove particles from the interior. Ensure that the feeding mechanism is free of obstructions to promote seamless function.

Lubrication: Periodically apply a suitable lubricant to moving parts. This reduces friction and wear, enhancing the device’s overall efficiency. Be careful not to over-lubricate, as excess oil can attract dust and grime.

Inspection of Components: Routinely check for signs of wear or damage. Examine springs, levers, and guides for any signs of deterioration. If any component appears compromised, consider replacing it to avoid further issues.

Storage Considerations: Proper storage is crucial. Keep the device in a dry, cool environment, away from direct sunlight. This prevents materials from degrading and maintains the integrity of the fastening apparatus.

Troubleshooting Common Stapler Issues

Addressing frequent challenges encountered with fastening devices can enhance their functionality and extend their lifespan. By understanding these typical problems, users can efficiently resolve issues and maintain optimal performance.

One common concern is when the mechanism fails to secure sheets together. This may be due to misalignment or a jam in the feeding path. To rectify this, inspect the loading area for any obstructions and ensure that the fasteners are correctly positioned.

Another issue arises when the device does not puncture through the paper effectively. This often results from using the wrong type or size of fasteners. Confirm that the selected fasteners are compatible with the specific model in use.

Additionally, if the fastening mechanism feels unusually stiff, it may indicate a need for lubrication. Applying a suitable lubricant to the moving parts can alleviate friction and improve operation.

Lastly, if the device produces an inconsistent output, it might require a thorough cleaning. Dust and debris can accumulate over time, leading to performance issues. Regular maintenance, including cleaning the internal components, can significantly enhance reliability.

Replacement Parts and Compatibility Guide

Ensuring optimal performance of your fastening device often requires the replacement of specific components. Understanding the compatibility of these elements is crucial for maintaining functionality and longevity. This guide aims to provide insights into the essential components and their suitability for various models, helping users make informed decisions during repairs or upgrades.

When considering replacements, it is important to identify the correct components that fit your model. Below is a list of common elements and factors to consider:

- Compatibility: Always check if the component is designed for your specific model to avoid functionality issues.

- Quality: Opt for high-quality replacements to ensure durability and efficient operation.

- Specifications: Review technical specifications such as size, material, and design to ensure a proper fit.

- Brand Variations: Some brands may offer similar components that can work interchangeably, but it is essential to verify compatibility.

Below are some frequently replaced elements and their general descriptions:

- Spring Mechanism: Vital for the device’s operation, this component can wear out over time, necessitating replacement.

- Push Lever: This part is crucial for the functionality of the device, and ensuring it is in good condition is important for performance.

- Safety Features: Components related to safety are essential to ensure user protection; check for wear regularly.

- Loading Mechanism: Efficient loading is key; if this component becomes faulty, it may lead to jamming or inefficient performance.

Before purchasing replacements, consult user manuals or manufacturer guidelines for detailed compatibility information. This ensures that you select the right components that meet your specific requirements.

Tips for Choosing Quality Fasteners

Selecting high-quality fasteners is crucial for ensuring durability and reliability in various projects. The right fasteners not only contribute to the structural integrity of the assembly but also affect the overall performance of the final product. Here are some essential considerations to keep in mind when making your choice.

Understand the Material

The material of the fasteners plays a significant role in their strength and suitability for specific applications. Common materials include:

- Steel: Known for its strength, it is suitable for heavy-duty applications.

- Stainless Steel: Resistant to corrosion, making it ideal for outdoor use.

- Brass: Offers excellent corrosion resistance and aesthetic appeal.

Consider the Size and Type

Choosing the right size and type of fastener is essential for a secure fit. Consider the following:

- Length: Ensure the fastener is long enough to penetrate the materials being joined.

- Diameter: A thicker fastener provides more strength but may require larger pre-drilled holes.

- Head Style: Different head styles, such as flat or round, can influence the fastener’s performance and appearance.

Upgrading Your Stapler Performance

Enhancing the functionality of your fastening tool can lead to increased efficiency and productivity. By focusing on specific components and making strategic improvements, you can ensure that your device operates smoothly and reliably.

Here are several ways to boost the effectiveness of your fastening equipment:

- Replace Worn Components: Regularly check and swap out old or damaged pieces to maintain optimal performance.

- Utilize Quality Fasteners: Choose high-quality staples that are compatible with your device to improve fastening reliability.

- Adjust Tension Settings: If available, modify the tension settings to accommodate various materials and thicknesses.

- Perform Routine Maintenance: Clean and lubricate moving parts to ensure smooth operation and prevent jams.

- Explore Upgraded Models: Consider investing in a newer model with advanced features for enhanced efficiency.

By implementing these strategies, you can significantly improve the performance of your fastening tool, making it more effective and easier to use for a variety of tasks.