The operation of a heavy-duty diesel-powered system relies on the coordinated performance of various essential elements. Each component plays a crucial role in ensuring the entire mechanism runs smoothly and efficiently. To maintain this type of system, it is essential to have a thorough understanding of how all parts fit together and contribute to the overall function.

Comprehending the detailed layout of these components is key to troubleshooting issues and performing regular maintenance. Whether you’re a mechanic or an enthusiast, knowing how different sections interconnect allows for better performance and longevity of the system. This guide aims to shed light on the fundamental aspects and structure of a well-functioning setup.

Powerstroke Engine Overview

The engine at the heart of heavy-duty vehicles is designed to deliver both performance and durability. It’s built to handle intense workloads, offering the necessary balance between power output and efficiency. This type of motor stands out in its ability to perform under harsh conditions, supporting long hauls and large payloads with ease. The combination of strong materials and advanced technology allows it to remain reliable over extended periods.

Core Components and Functionality

Each unit integrates several key mechanisms working together to ensure smooth operation. High-pressure fuel systems, advanced air intake setups, and turbocharging contribute to the enhanced power output. Additionally, the intricate cooling and lubrication systems protect the motor from overheating and wear, ensuring longevity and consistent performance.

Durability and Efficiency

One of the key characteristics of this engine is its durability. It’s designed to withstand continuous use over long periods without significant performance drop. The efficiency of fuel consumption also plays a significant role, ensuring that despite its power, the motor doesn’t sacrifice cost-effectiveness. This combination makes it an ideal choice for heavy-duty applications.

Main Components of the 7.3 Diesel Engine

Diesel engines are built with a variety of vital elements that work together to ensure optimal performance. These units contribute to power generation, fuel efficiency, and overall durability. Understanding the essential pieces that form the foundation of a diesel motor allows for better maintenance and troubleshooting.

| Component | Description |

|---|---|

| Cylinder Block | The foundation of the motor, housing various moving parts and supporting key mechanisms for energy production. |

| Fuel Injection System | Responsible for delivering precise amounts of fuel to the combustion chamber for efficient operation. |

| Turbine | This part enhances air intake, allowing for greater fuel combustion and boosting performance. |

| Cooling System | Helps regulate temperature, preventing overheating during prolonged or intense use. |

| Exhaust Manifold | Directs exhaust gases away from the motor, ensuring clean operation and reducing back pressure. |

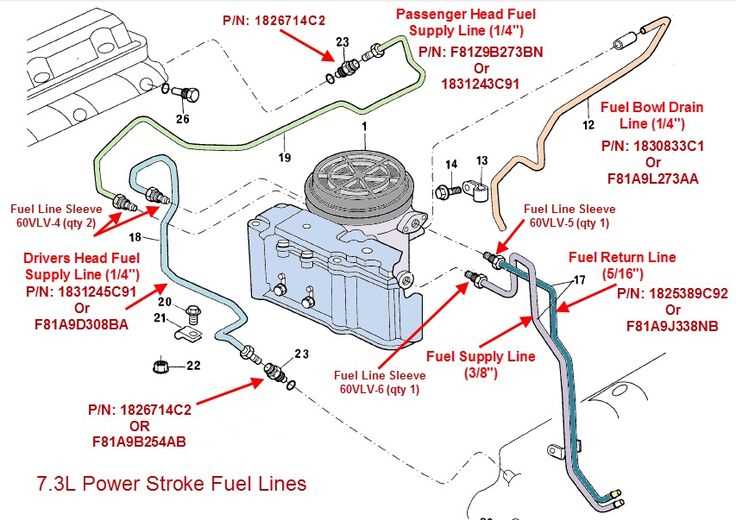

Fuel System and Its Role

The fuel system plays a critical role in ensuring that a vehicle operates efficiently. It is responsible for delivering the right amount of fuel to the combustion process, ensuring optimal performance and reliability. This system works in harmony with other components, contributing to smooth operation and fuel efficiency.

Key elements within the fuel system manage several important tasks:

- Transporting fuel from the tank to the combustion area

- Regulating fuel pressure to match engine demands

- Ensuring the proper mixture of air and fuel for efficient combustion

- Filtering out impurities to prevent damage to sensitive parts

The system’s proper functioning ensures that the vehicle can maintain its power and efficiency while also controlling emissions and fuel consumption.

Cooling Mechanism for Engine Efficiency

The cooling system plays a vital role in maintaining the overall performance of a vehicle. Proper temperature regulation is essential to prevent overheating, ensuring smooth and reliable operation during long drives or under heavy loads. Without an efficient cooling mechanism, excessive heat could damage critical components, leading to significant malfunctions.

| Component | Function |

|---|---|

| Radiator | Transfers excess heat away from the vehicle’s internal systems. |

| Water Pump | Circulates coolant throughout the system to maintain consistent temperature control. |

| Thermostat | Monitors and adjusts the flow of coolant to regulate optimal temperature. |

| Cooling Fan | Assists in expelling hot air from the radiator, boosting cooling performance. |

These components work together to sustain ideal operating conditions, preventing issues like overheating or wear on vital parts

Turbocharger and Boost Control in the 7.3

Turbocharging plays a crucial role in enhancing performance and efficiency by increasing the intake air pressure. This technology allows for improved combustion and power output, making it an essential component of high-performance vehicles. Effective boost control mechanisms are vital for maintaining optimal pressure levels and ensuring the system operates smoothly.

Components of the Turbocharging System

- Compressor Wheel

- Turbine Wheel

- Wastegate

- Boost Control Solenoid

Boost Control Mechanisms

Managing boost levels is critical for preventing overpressure situations. Common strategies include:

- Electronic Control Units (ECUs) that monitor and adjust parameters.

- Manual boost controllers for driver-adjustable settings.

- Wastegate actuation methods that regulate exhaust flow to the turbine.

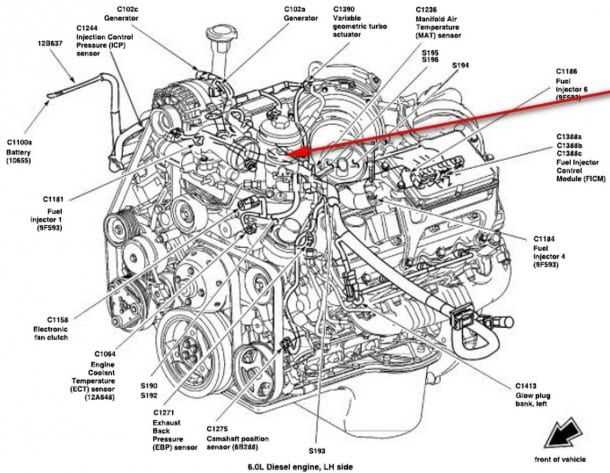

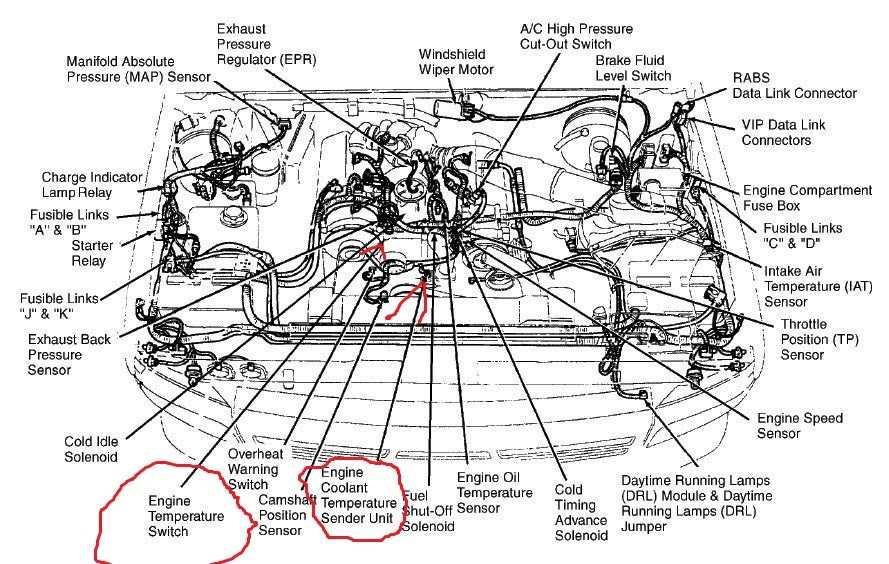

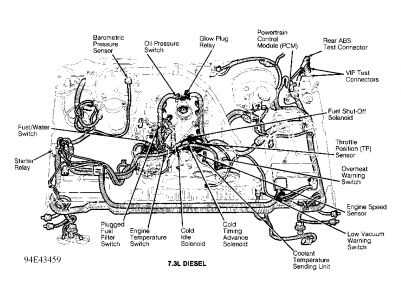

Electrical System and Engine Sensors

The electrical framework in modern vehicles plays a vital role in ensuring optimal performance and efficiency. This intricate network is responsible for powering various components and facilitating communication between different systems. A reliable electrical setup is crucial for the seamless operation of the vehicle’s functionalities.

One of the key elements of this system includes sensors that monitor critical parameters and provide real-time data to the control unit. These devices are designed to detect changes in various conditions, such as temperature, pressure, and airflow. By continually gathering this information, they enable the system to make necessary adjustments to maintain peak performance.

Among the various sensors, the temperature sensor measures the heat levels of different components, ensuring that they operate within safe limits. The pressure sensor monitors the pressure of fluids, which is essential for optimal operation. Additionally, the mass airflow sensor evaluates the air intake, playing a crucial role in fuel efficiency and combustion quality.

The control module acts as the brain of the electrical network, processing data from the sensors and making real-time decisions to adjust operations. This interaction between sensors and the control module is fundamental for enhancing performance and reducing emissions.

Overall, the integrity and functionality of the electrical setup and sensors are indispensable for the smooth operation of the vehicle, highlighting the importance of regular maintenance and timely replacements when necessary.

Lubrication Process in the 7.3 Powerstroke

The lubrication process is crucial for ensuring optimal functionality and longevity of mechanical systems. Proper lubrication minimizes friction between moving components, reduces wear, and helps maintain temperature stability. This section explores the fundamental aspects of the lubrication system, highlighting its significance in maintaining efficiency and reliability.

The system utilizes a pump to circulate lubricant throughout the internal components. This fluid is drawn from a reservoir and delivered under pressure to critical areas, where it forms a protective film. As the lubricant flows, it also carries away contaminants and dissipates heat, contributing to a cleaner and cooler operation.

An important element of this process is the filtration system, which traps debris and prevents it from circulating back into the system. Regular maintenance, including fluid changes and filter replacements, ensures that the lubrication system remains effective over time. Understanding the intricacies of this system is essential for any operator aiming to enhance performance and reduce the likelihood of mechanical failures.

Intake and Exhaust Systems Explained

The intake and exhaust mechanisms play a crucial role in the overall performance of any vehicle. They are responsible for managing the flow of air and gases, ensuring that the combustion process occurs efficiently. Understanding how these systems operate can significantly enhance maintenance and optimization efforts.

Understanding the Intake System

The intake system’s primary function is to facilitate the entry of air into the combustion chamber. This process is essential for maintaining optimal performance and fuel efficiency. Key components of the intake system include:

- Air Filter: Prevents contaminants from entering the system.

- Intake Manifold: Distributes air evenly to each cylinder.

- Throttle Body: Regulates airflow based on the driver’s input.

By ensuring that clean, cool air enters the combustion chamber, the intake system helps enhance the combustion process, leading to improved power and efficiency.

Exploring the Exhaust System

The exhaust system is responsible for expelling the gases produced during combustion. An efficient exhaust system minimizes back pressure, which can enhance overall performance. Key components include:

- Exhaust Manifold: Collects exhaust gases from the cylinders.

- Catalytic Converter: Reduces harmful emissions before release.

- Muffler: Reduces noise produced by the exhaust gases.

A well-functioning exhaust system not only helps in reducing emissions but also improves engine efficiency by allowing for a smoother exit of gases.