In any gardening device, it is crucial to understand how the individual components interact to ensure smooth and efficient operation. Whether you’re maintaining your own backyard or working on a larger project, having a clear overview of the mechanical structure is essential for keeping everything in top shape.

When working with outdoor machinery, knowing how each element fits together can save time and prevent unnecessary repairs. Understanding the placement and function of these elements is key to extending the lifespan of your machine and avoiding costly breakdowns.

In the following sections, we will explore the intricate connections that make your garden tool work efficiently. This knowledge will help you identify potential issues and maintain your equipment with confidence.

Understanding the Structure of a Yard Maintenance Machine

Every garden tool designed for keeping your yard in top condition consists of numerous components that work together to ensure smooth operation. Grasping the layout and function of each element allows for easier maintenance, troubleshooting, and even enhancing the tool’s lifespan.

Key Mechanical Elements

The machine’s core consists of an engine, blade system, and drive mechanisms, all playing crucial roles in maintaining efficiency. The power source drives the cutting blades, while the drivetrain manages movement across your lawn. Regular upkeep of these mechanisms ensures they remain in excellent working condition, reducing potential downtime.

Auxiliary Components

In addition to the primary mechanisms, there are auxiliary elements that support functionality, such as adjustable height systems, wheels for mobility, and safety switches. Ensuring these components are properly cared for contributes to overall performance and user safety during operation.

Common Issues with Lawn Mower Components

Mechanical garden tools are designed for long-lasting performance, but over time, wear and tear on various elements can lead to malfunctions. Understanding the common problems that arise can help in diagnosing and fixing issues efficiently.

Engine-Related Problems

One of the most frequent challenges involves engine performance. Common symptoms include difficulty starting, reduced power output, or unusual sounds during operation. These issues can stem from fuel supply interruptions, clogged air filters, or faulty ignition components.

Blade and Cutting Mechanism Issues

The cutting system is another critical area prone to wear. Dull or damaged blades can lead to uneven cutting or missed sections, while mechanical failures in the driving mechanism may result in reduced cutting efficiency. Regular maintenance of these parts ensures smoother operation.

| Component |

Common Problem |

Possible Cause |

| Engine |

Won’t start |

How to Replace Key Mower Parts

Maintaining your equipment in top condition requires periodic replacement of vital components. By ensuring timely changes of these essential elements, you can extend the life of your machine and keep it operating smoothly. In this guide, we’ll walk through the steps to replace some of the most critical elements of your machine.

The process involves attention to detail and understanding how different pieces function together. Below is a general overview of the main items you may need to replace, along with their corresponding actions.

| Component |

Steps to Replace |

| Blades |

Start by removing the safety key or disconnecting the spark plug. Using the appropriate tools, unscrew the blade bolt, carefully remove the old blade, and install the new one, ensuring it’s aligned properly. |

| Drive Belt |

First, disengage the deck and carefully remove any covers or guards. Then, remove the old belt from its pulleys and replace it

Choosing the Right Blades for Your Mower

Selecting the appropriate cutting components for your outdoor equipment is crucial for maintaining efficient performance and ensuring a clean cut. The right choice impacts the quality of your grass and the lifespan of your machinery, making it essential to understand the various options available and how they align with your specific needs.

Types of Blades

Different types of cutting tools are designed for specific functions. Some are ideal for bagging, others for mulching, while a few are meant for heavy-duty cutting in tough terrain. Understanding the unique advantages of each will help you make an informed decision.

| Blade Type |

Purpose |

Features |

| Standard |

General cutting |

Straight edge for clean, basic cuts |

| Mulching |

Chopping grass into fine clippings |

Curved edges to enhance the shredding process |

| High-lift |

Bagging a

Maintenance Tips for a Grass-Cutting Machine

Regular upkeep is essential for ensuring that your equipment remains efficient and lasts for many seasons. Proper care not only improves performance but also helps prevent unexpected breakdowns during crucial tasks. By adhering to simple maintenance routines, you can keep your tool running smoothly and avoid costly repairs.

Check the Engine Oil – Consistently monitor the oil level and change it at recommended intervals to ensure the motor operates effectively. Fresh oil reduces friction and extends the life of the engine.

Sharpen the Blades – Dull blades tear grass rather than cutting it cleanly, which can harm your lawn’s health. Sharpen the cutting edges regularly to maintain a clean, uniform cut.

Clean the Undercarriage – Grass clippings and debris can accumulate beneath the deck, causing blockages and affecting performance. Clean the underside of the machine after each use to prevent buildup.

Inspect the Air Filter – A clogged air filter restricts airflow to the engine, reducing efficiency. Check and clean or replace the filter as needed to keep the machine running at its best.

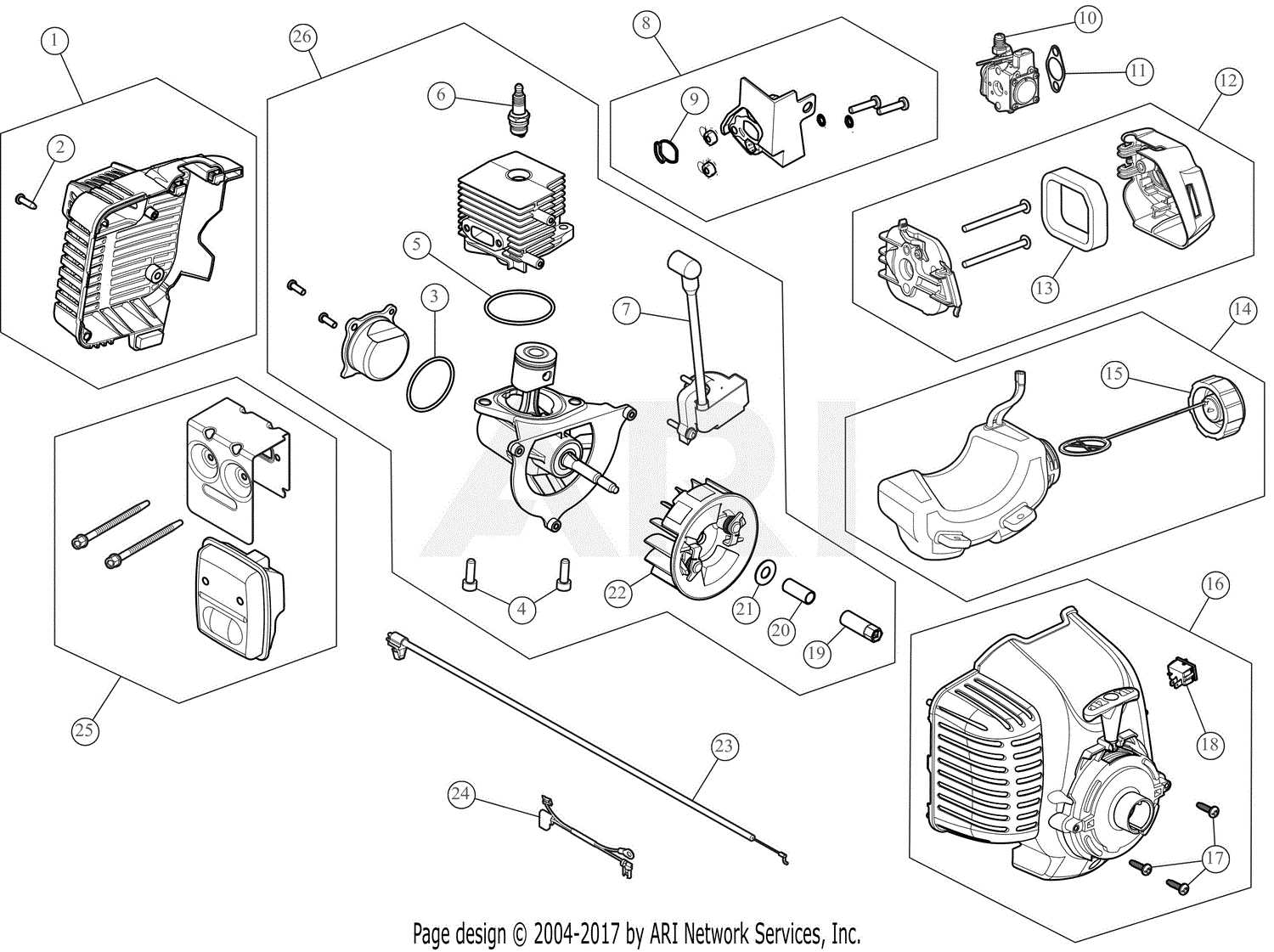

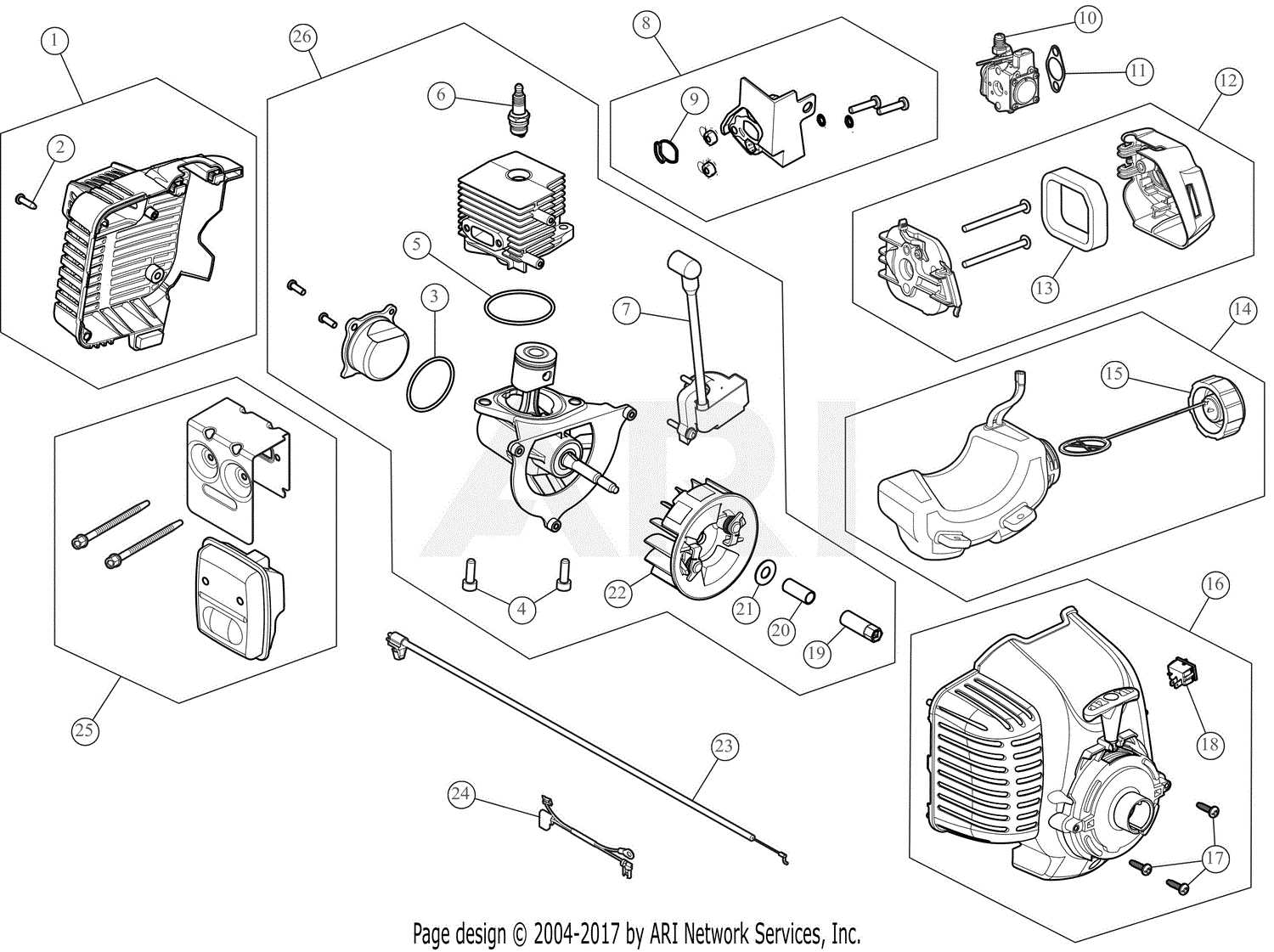

Identifying Engine Parts on a Bolens Mower

Understanding the components of your machinery is essential for effective maintenance and troubleshooting. Each element plays a crucial role in ensuring optimal performance and longevity. Familiarizing yourself with these elements can enhance your ability to diagnose issues and perform repairs efficiently.

Key Components to Recognize

- Engine Block: The main structure housing various elements, providing strength and stability.

- Crankshaft: Converts linear motion into rotational motion, driving the machine’s power.

- Camshaft: Regulates the opening and closing of valves, controlling airflow into and out of the combustion chamber.

- Fuel System: Includes the fuel tank, filter, and carburetor, responsible for supplying the engine with the necessary fuel mixture.

- Ignition System: Comprises components like the spark plug and ignition coil, essential for starting the engine.

Maintenance Tips for Engine Components

- Regularly check and clean the air filter to ensure proper airflow.

- Inspect the fuel lines for leaks and wear, replacing them if necessary.

- Keep the ignition system clean and properly adjusted to enhance starting efficiency.

- Monitor the oil level and quality, changing it as needed to protect internal components.

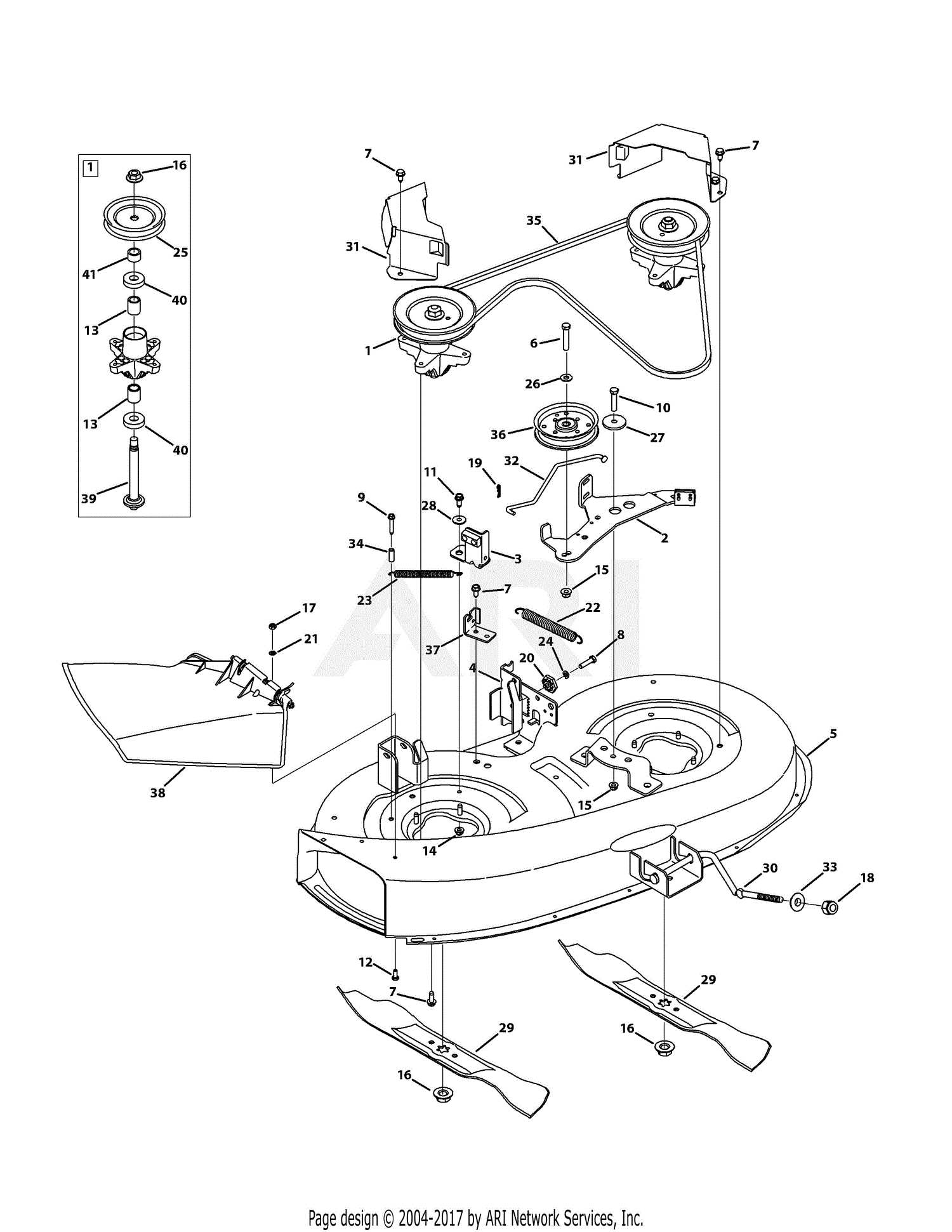

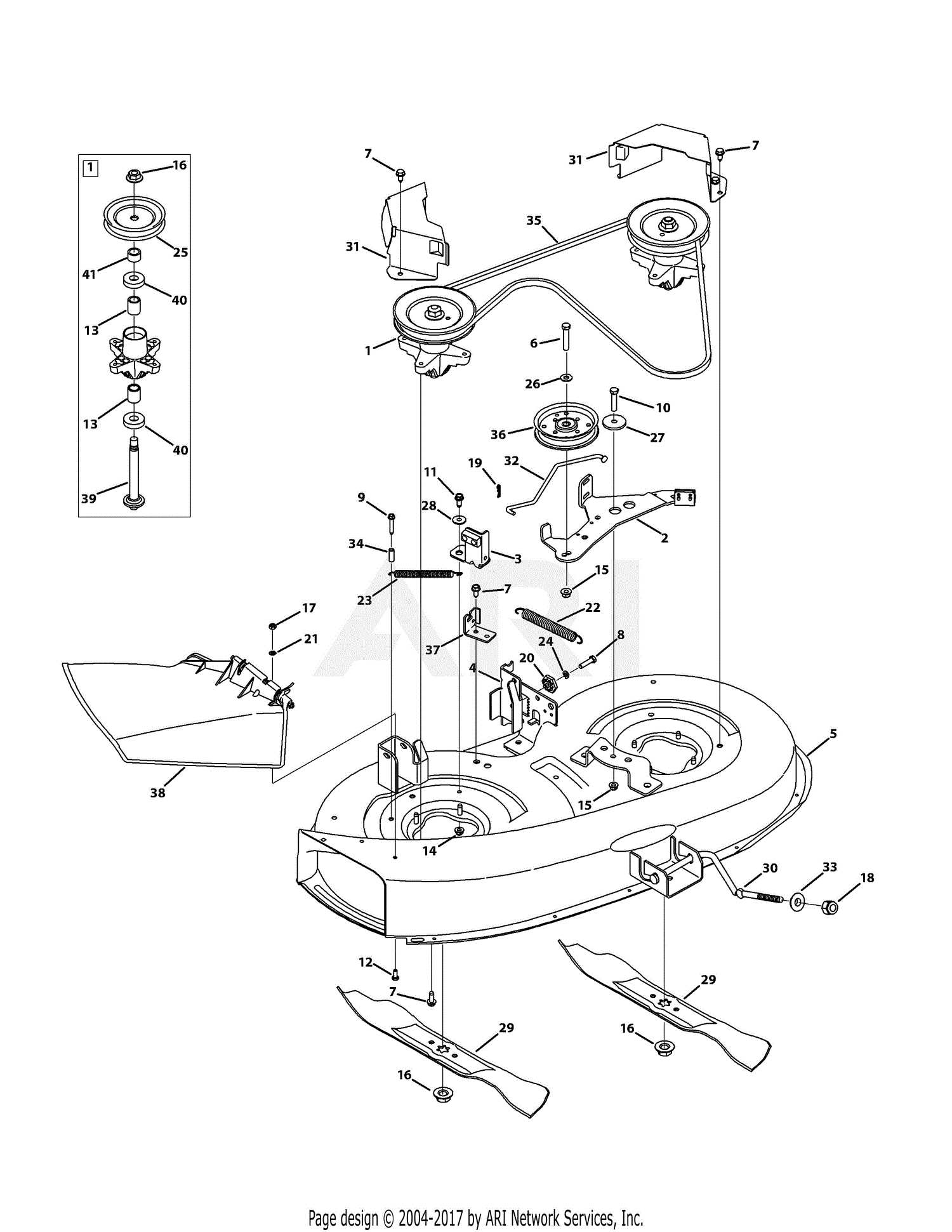

Bolens Mower Belt System Overview

The belt mechanism is a crucial component that ensures efficient power transmission within the cutting apparatus. Understanding its configuration and function can enhance performance and maintenance efforts.

Key Components

- Drive Belts: These are responsible for transferring power from the engine to the cutting blade.

- Pulleys: They guide and support the belts, ensuring smooth operation.

- Idler Arms: These maintain proper tension on the belts to prevent slippage and wear.

Functionality and Maintenance

The efficiency of the belt mechanism directly influences the effectiveness of the cutting tool. Regular inspections and replacements are necessary to maintain optimal function. Here are some maintenance tips:

- Check for wear and tear on belts regularly.

- Ensure that pulleys are aligned and free of debris.

- Adjust tension as needed to prevent slippage.

Safety Precautions When Working on Lawn Mowers

Ensuring safety while performing maintenance on outdoor equipment is crucial to prevent accidents and injuries. Adhering to recommended precautions can significantly reduce risks associated with mechanical tasks. Proper awareness and preparation will lead to a safer working environment.

Before starting any repair or upkeep, it is essential to take several safety measures:

| Precaution |

Description |

| Wear Protective Gear |

Always wear gloves, safety goggles, and sturdy footwear to protect against sharp objects and debris. |

| Disconnect Power Source |

Before working on any equipment, ensure that the power source is completely disconnected to avoid accidental starts. |

| Work in a Ventilated Area |

Perform maintenance in a well-ventilated space to prevent inhalation of harmful fumes or gases. |

| Follow Manufacturer Instructions |

Refer to the equipment manual for specific guidelines and safety information related to maintenance tasks. |

| Keep Workspace Clean |

Maintain a tidy work area to reduce the risk of tripping or losing tools during repairs. |

By following these guidelines, individuals can enhance their safety and efficiency while handling outdoor machinery.

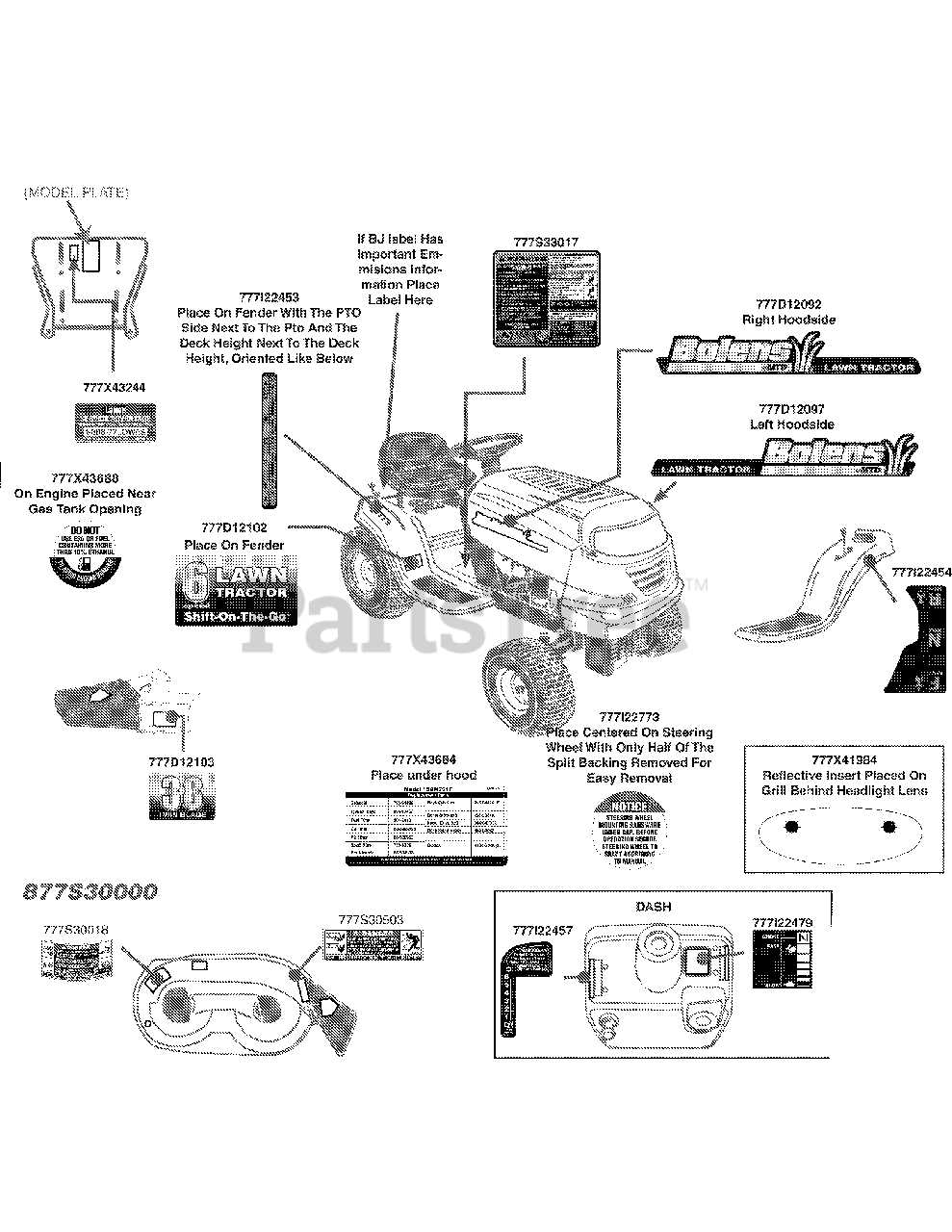

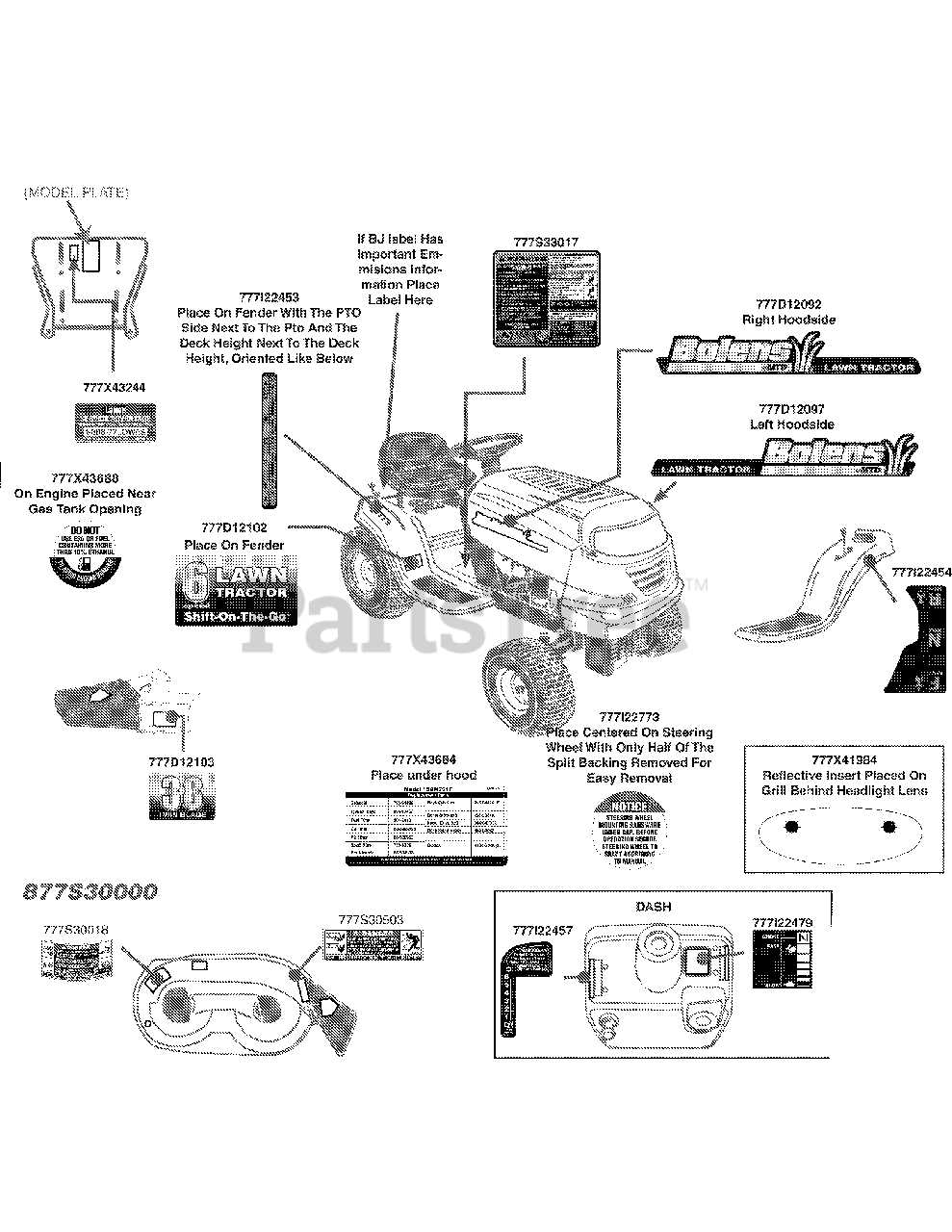

Where to Find Bolens Mower Parts Diagrams

For those seeking detailed illustrations of components for their garden equipment, various resources are available that can simplify the process. These visual aids not only enhance understanding but also facilitate effective repairs and maintenance, ensuring optimal performance of your equipment.

Online Resources

The internet offers a wealth of platforms where you can access comprehensive visuals. Websites dedicated to outdoor machinery often provide searchable databases, allowing users to easily locate specific models and their respective components. Additionally, manufacturer websites can be a reliable source for official illustrations and information.

Community Forums and Support Groups

Joining online forums and support groups can be particularly beneficial. Enthusiasts and experienced users frequently share their knowledge and resources, including links to useful visuals. Engaging with a community can also provide insights into troubleshooting and tips for your specific equipment.

|

|