In the realm of machinery and equipment, the efficient operation of devices heavily relies on their user interfaces. These interfaces are designed to enhance maneuverability and precision, ensuring that tasks are completed with minimal effort and maximum control. A thorough exploration of these essential elements reveals the intricate connections that contribute to overall functionality.

By dissecting the various elements involved in the manipulation of tools, one can gain insight into how each component works in harmony to facilitate user interaction. Understanding these individual pieces is crucial for both troubleshooting and maintenance, as each part plays a significant role in the system’s performance. This knowledge empowers users to optimize their experience and prolong the lifespan of their equipment.

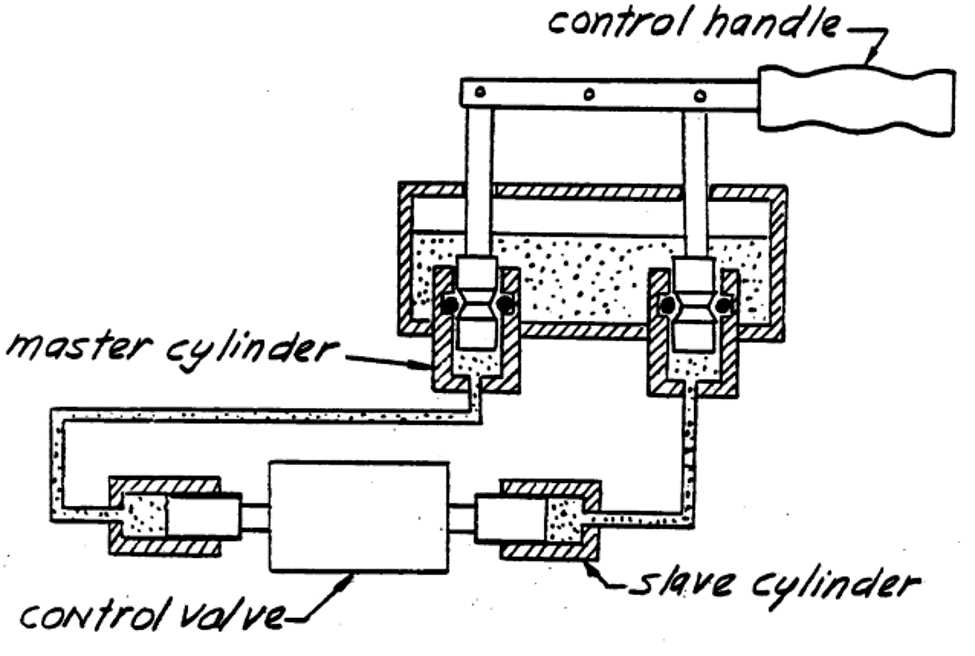

Moreover, an illustrative representation of these components serves as a valuable reference for both novices and experienced operators. Such visual aids clarify the relationships between the parts, highlighting their functions and interdependencies. Whether for educational purposes or practical application, this detailed overview enriches the comprehension of the overall mechanism.

Understanding Altec Pistol Grip Controls

This section explores the intricacies of specific manipulation devices used in various equipment, highlighting their essential components and functionalities. A thorough comprehension of these mechanisms can enhance user experience and operational efficiency.

Key Components

The effectiveness of these manipulation devices relies on several crucial elements. Each part plays a unique role in ensuring seamless operation and responsiveness, contributing to overall performance.

| Component | Function |

|---|---|

| Trigger | Initiates action and controls speed. |

| Handle | Provides grip and stability during operation. |

| Switch | Allows for directional control and adjustments. |

Benefits of Understanding Functionality

Grasping how these devices operate ultimately leads to improved handling and safety. Users can make informed decisions when utilizing equipment, ensuring optimal results.

Key Components of the Control System

The functionality of a sophisticated manipulation system relies on several essential elements that work in harmony. Understanding these integral components is crucial for effective operation and maintenance. Each part plays a distinct role, contributing to the overall performance and reliability of the mechanism.

Primary Elements

The main elements include actuators, sensors, and interface units. Actuators are responsible for executing movements, while sensors provide critical feedback on the system’s status. Interface units facilitate user interactions, ensuring seamless communication between the operator and the system.

Supportive Mechanisms

In addition to primary elements, supportive mechanisms such as power supply units and safety features enhance the system’s efficiency. The power supply ensures consistent energy flow, while safety mechanisms protect against malfunctions, ultimately securing the operation during various tasks.

Importance of Accurate Parts Diagrams

Having precise illustrations of components is crucial in various fields, particularly in maintenance and assembly tasks. Such visual representations provide a clear understanding of how individual elements fit together and function within a larger system. This clarity is essential for technicians and engineers, enabling them to perform their duties effectively and efficiently.

Benefits of Detailed Illustrations

- Enhanced Understanding: Clear visuals help users grasp complex structures quickly.

- Efficient Troubleshooting: Identifying issues becomes simpler when each element is labeled accurately.

- Streamlined Assembly: Precise guides ensure that all components are placed correctly, reducing errors.

- Improved Communication: Illustrations facilitate clearer discussions among team members regarding repairs or upgrades.

Consequences of Inaccurate Visuals

- Increased Risk of Errors: Misunderstandings about component placement can lead to critical mistakes.

- Wasted Time: Technicians may spend excessive time trying to decipher unclear representations.

- Higher Costs: Errors resulting from inaccuracies can lead to expensive repairs or replacements.

- Reduced Safety: Poorly illustrated components may contribute to hazardous situations during operation.

In summary, accurate representations of components are vital for efficient operation and maintenance. Investing in high-quality visuals not only aids in daily tasks but also enhances overall productivity and safety.

How to Read Control Schematics

Understanding technical blueprints is essential for effective troubleshooting and maintenance. These visual representations convey critical information about the components and their interconnections, enabling users to grasp the overall system functionality.

Familiarize Yourself with Symbols

Each illustration uses specific icons to represent different elements. Learning these symbols is crucial, as they provide a universal language that simplifies complex interactions within the system.

Trace the Connections

Follow the pathways between components to comprehend how they interact. Identifying these links will help you delve deeper into the operation, revealing how signals and energy flow throughout the assembly.

Common Issues with Pistol Grip Parts

In any machinery relying on hand-held mechanisms, certain challenges can arise that may affect performance and usability. These difficulties often stem from wear and tear, misalignment, or manufacturing defects. Understanding these issues is essential for maintenance and ensuring smooth operation.

Wear and Tear: Frequent use can lead to degradation of materials, which may result in reduced responsiveness or malfunction. Components made from less durable materials tend to show signs of fatigue over time.

Misalignment: Proper alignment is crucial for optimal functioning. Components may shift due to external forces or improper installation, leading to inefficiencies or operational failures. Regular checks can help identify and rectify these issues before they escalate.

Manufacturing Defects: Occasionally, items may come from production with inherent flaws. These defects can manifest as irregular shapes, inadequate fitting, or subpar materials, ultimately compromising performance. Vigilant inspection during procurement can mitigate such risks.

In conclusion, recognizing and addressing these common challenges is vital for maintaining efficiency and prolonging the lifespan of hand-held devices.

Maintenance Tips for Longevity

Ensuring the durability of your equipment requires regular care and attention. By following a systematic maintenance routine, you can significantly extend the life of your tools and enhance their performance. Here are some essential practices to consider for optimal upkeep.

Regular Inspection

- Conduct frequent visual checks for signs of wear or damage.

- Look for loose components that may need tightening or replacement.

- Ensure all moving parts are free of obstructions and properly aligned.

Cleaning and Lubrication

- Clean the exterior regularly to prevent buildup of dirt and grime.

- Use appropriate cleaning solutions to avoid damage to sensitive surfaces.

- Apply lubricant to moving parts as specified in the user manual to reduce friction.

By integrating these practices into your routine, you can maintain optimal functionality and ensure a longer lifespan for your equipment.

Comparing Altec with Other Brands

When evaluating various manufacturers in the equipment sector, it is essential to consider how each brand stands out in terms of performance, design, and user experience. Different companies offer unique features that cater to diverse needs, making it crucial for users to understand the strengths and weaknesses of each option available in the market.

Key factors to examine include:

- Build Quality: The materials and craftsmanship can greatly affect durability and reliability.

- User Ergonomics: Comfort and ease of use play a significant role in efficiency and operator satisfaction.

- Technology Integration: Advanced features and smart technologies can enhance functionality and performance.

- Service and Support: Availability of customer service and replacement parts can influence long-term user experience.

- Price Point: Cost-effectiveness is always a consideration, impacting purchasing decisions.

Several brands in this sector have established themselves as leaders by excelling in one or more of these areas. For instance:

- Brand A: Known for exceptional durability, making it a favorite among heavy users.

- Brand B: Offers cutting-edge technology that attracts tech-savvy operators.

- Brand C: Focuses on user-friendly designs, enhancing comfort during prolonged use.

By assessing these factors, users can make informed decisions that align with their specific requirements and preferences, ensuring they select the most suitable equipment for their tasks.

Upgrades and Modifications Available

Enhancing functionality and performance through various upgrades and modifications can significantly improve user experience. Whether for precision, comfort, or efficiency, these enhancements can be tailored to individual preferences and needs.

Here are some popular options to consider:

- Ergonomic Enhancements: Improve user comfort with specially designed grips that reduce strain during prolonged use.

- Customizable Controls: Allow for the adjustment of buttons and switches, making it easier to access essential functions quickly.

- Durability Upgrades: Use high-quality materials to ensure that components withstand wear and tear, extending the lifespan of the device.

- Precision Modifications: Incorporate advanced mechanisms that enhance accuracy and responsiveness, ideal for tasks requiring fine control.

In addition to these modifications, users may also explore:

- Weight Adjustments: Adding or removing weights to achieve the desired balance for better handling.

- Color and Aesthetic Changes: Personalizing the appearance through various finishes or coatings, reflecting individual style.

- Smart Technology Integration: Implementing modern tech solutions, such as Bluetooth connectivity for seamless interaction with other devices.

Ultimately, selecting the right upgrades can transform the overall experience, making it more efficient and tailored to specific tasks.

Resources for Further Learning

Enhancing your understanding of specific components and their functionalities can significantly benefit your overall knowledge. The following resources provide valuable insights and detailed information on various aspects related to mechanical assemblies and operational mechanisms.

- Books:

- “Fundamentals of Mechanical Components” by John Doe

- “Understanding Mechanical Systems” by Jane Smith

- “Advanced Assembly Techniques” by Alex Johnson

- Online Courses:

- Forums and Communities:

- Engineering Stack Exchange – A Q&A platform for technical inquiries.

- Reddit – Engineering – A community for sharing insights and experiences.

- LinkedIn Groups – Connect with professionals and engage in discussions.

- Videos:

- YouTube – Search for tutorials and demonstrations related to mechanisms.

- Khan Academy – Offers educational videos on engineering principles.

- TED Talks – Inspirational talks by experts in technology and design.

Exploring these resources can deepen your understanding and proficiency in the subject, paving the way for further exploration and mastery of mechanical concepts.