In the realm of painting and coating, efficient equipment plays a crucial role in achieving optimal results. This section explores the intricate elements that make up a modern spray device, providing insight into their functionalities and interrelationships.

Each component is designed to work in harmony, ensuring seamless operation and consistent performance. By examining these vital pieces, users can enhance their understanding and maintenance of the equipment, ultimately leading to improved application quality.

To facilitate a deeper understanding, this exploration will delve into the various parts and their significance, equipping users with the knowledge to troubleshoot and optimize their spraying experience. Whether for professional use or DIY projects, knowing the inner workings of your device is the ultimate key to success.

Understanding Graco Truecoat 360

The innovative painting device has revolutionized the way enthusiasts and professionals approach their projects. With its advanced technology, it simplifies the application process, making it accessible to users at all skill levels. This tool offers a blend of efficiency and precision, enabling a smooth and even finish on various surfaces.

One of the key features of this equipment is its versatility. It allows for the use of different materials, catering to diverse painting needs. Whether tackling interior walls, furniture, or exterior surfaces, this device provides the necessary adaptability for various tasks.

Moreover, understanding the inner workings of this machine can significantly enhance user experience. Familiarity with its components and functionality not only aids in maintenance but also ensures optimal performance during operation. By knowing how each part contributes to the overall effectiveness, users can achieve superior results in their painting endeavors.

Additionally, proper handling and care of the equipment play a crucial role in prolonging its lifespan. Regular cleaning and attention to detail can prevent common issues and enhance the reliability of the device. This proactive approach ultimately leads to more successful projects and satisfied users.

In summary, mastering this advanced painting tool involves recognizing its strengths and understanding its operational mechanics. By doing so, users can maximize their painting capabilities and enjoy a more fulfilling experience with each application.

Key Features of the Truecoat 360

This advanced painting system is designed to provide exceptional performance and efficiency for a variety of applications. Its innovative design offers users a range of benefits that enhance both usability and results. Here are some of the standout characteristics that make this tool a top choice for professionals and DIY enthusiasts alike.

Efficiency and Versatility

- Rapid Coverage: Engineered to cover large areas quickly, reducing the time needed for projects.

- Multiple Spray Patterns: Capable of adjusting to different spraying needs, accommodating a variety of surfaces and finishes.

- Portable Design: Lightweight and easy to transport, making it ideal for both indoor and outdoor tasks.

User-Friendly Features

- Easy Setup: Quick assembly process that allows users to start painting in no time.

- Adjustable Settings: Customizable pressure and flow controls for precise application.

- Low Maintenance: Simple cleaning procedures ensure the tool remains in top condition with minimal effort.

With these remarkable features, this painting system not only improves productivity but also ensures high-quality finishes for all your projects.

Importance of Parts Diagrams

Understanding the structure and components of any machinery is crucial for effective maintenance and repair. Visual representations of various elements not only facilitate identification but also enhance the overall efficiency of troubleshooting processes. Such illustrations serve as valuable guides, ensuring that users can swiftly locate and replace any faulty components.

Benefits of Visual Guides

Visual aids provide numerous advantages in the realm of equipment management. They simplify complex processes and allow for easier comprehension of assembly and disassembly tasks. Additionally, they can help prevent errors during repairs, ultimately leading to improved longevity and performance of the machinery.

Key Features to Consider

| Feature | Description |

|---|---|

| Clarity | Illustrations should be clear and easy to interpret, highlighting all necessary components. |

| Detail | Comprehensive information about each part, including specifications and functions, enhances understanding. |

| Accessibility | Easy access to these resources enables users to refer to them whenever needed. |

| Update Frequency | Regular updates ensure that users have the latest information regarding components and their arrangements. |

Common Issues with Truecoat 360

When using a high-performance paint sprayer, users often encounter various challenges that can affect the quality of their work. Understanding these common problems can help in troubleshooting and ensuring optimal performance during projects.

| Issue | Possible Causes | Solutions |

|---|---|---|

| Uneven Spray Pattern | Clogged nozzle, improper technique | Clean the nozzle, adjust spraying distance |

| Paint Dripping | Overfilling, wrong pressure setting | Reduce paint volume, adjust pressure |

| Frequent Clogging | Using thick materials, debris | Thin paint appropriately, filter materials |

| Poor Finish Quality | Incorrect settings, environmental factors | Re-evaluate settings, check humidity |

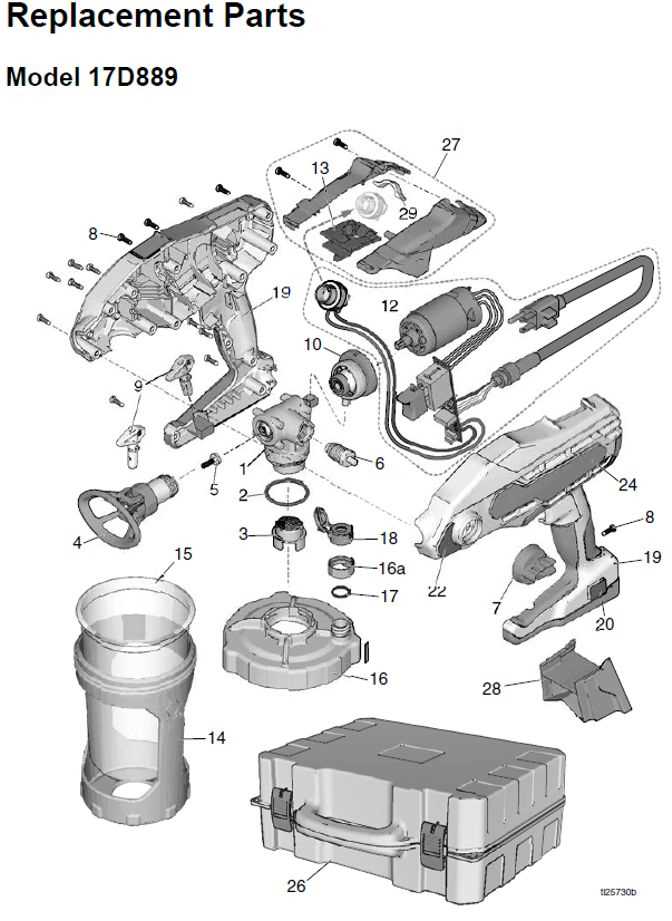

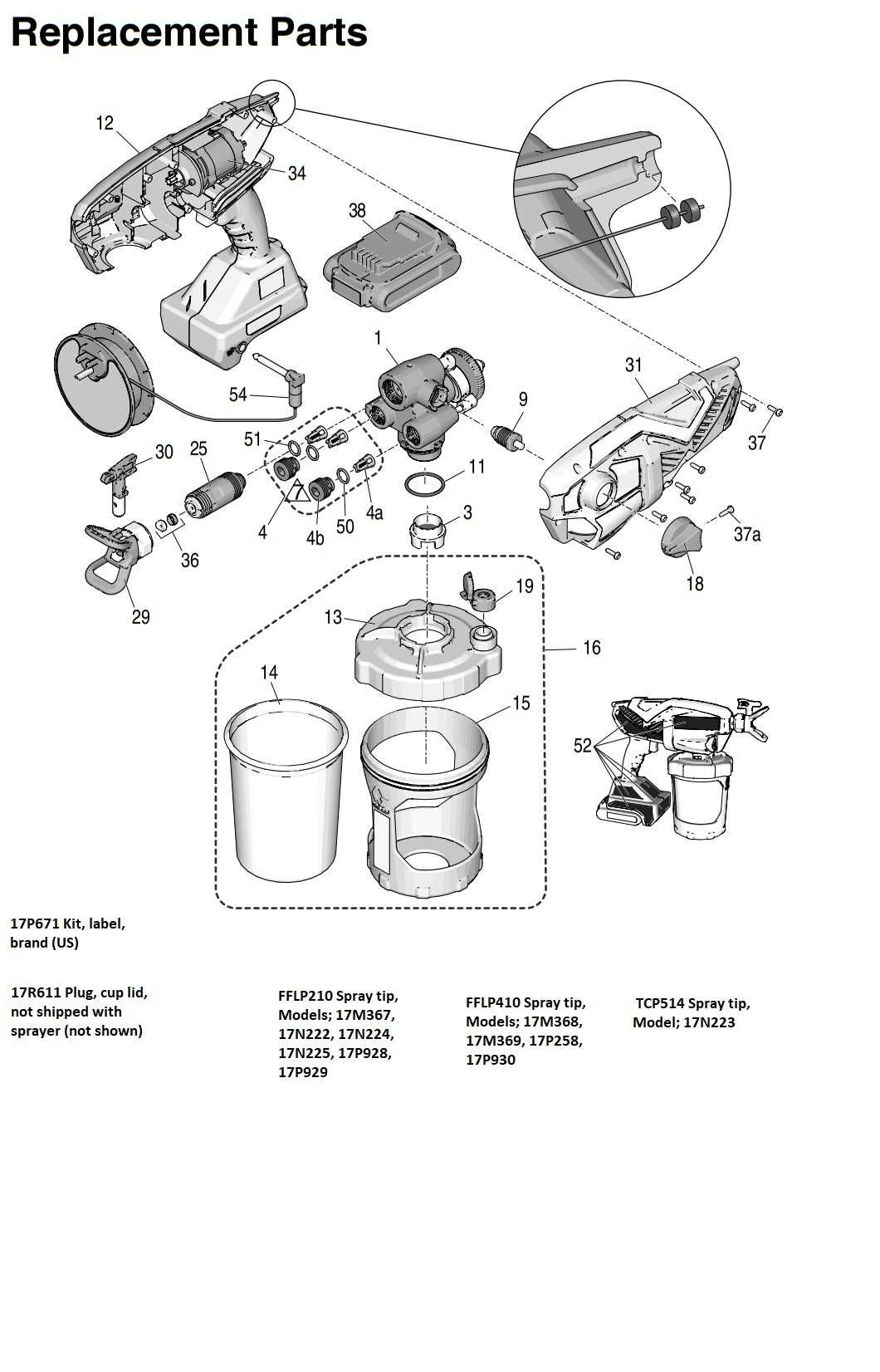

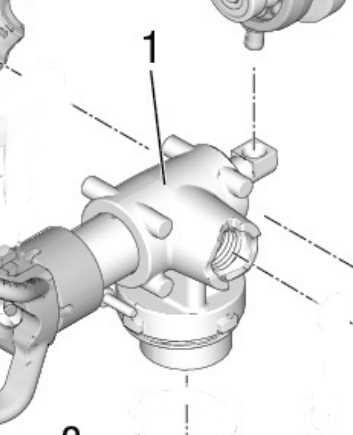

Essential Replacement Parts Overview

Understanding the key components of a spray device is crucial for maintaining its optimal performance. This section highlights the vital elements that may require attention over time to ensure consistent and effective operation. Knowing which parts are essential can help users make informed decisions when it comes to upkeep and repairs.

Common Components

Several integral pieces contribute to the functionality of the equipment. Nozzles are among the most frequently replaced items, as they can wear out or become clogged, impacting spray patterns. Additionally, filters play a significant role in preventing debris from interfering with the application process, necessitating regular replacement to maintain efficiency.

Maintenance Tips

Regular inspection of seals and gaskets is essential to prevent leaks and ensure the integrity of the device. Keeping a set of replacement items on hand can minimize downtime and enhance overall performance. Users are encouraged to consult the manufacturer’s guidelines for specific recommendations on maintenance intervals and best practices.

How to Access Parts Diagrams

Accessing technical illustrations of components is crucial for effective maintenance and repairs. These resources provide a visual representation of individual elements, enabling users to understand the assembly and identify necessary replacements. This section will guide you through the steps to obtain these valuable references.

Online Resources

Numerous websites offer comprehensive resources where you can find detailed illustrations. Searching for manufacturer-specific sites is a great starting point. Often, these platforms provide downloadable materials or interactive guides, which can enhance your understanding of each component’s function and placement.

User Manuals and Documentation

Another reliable source is the user manuals that come with the equipment. These documents frequently include sections dedicated to visual aids, showcasing the arrangement and specifics of each part. Referencing these manuals can be immensely helpful when troubleshooting or replacing components, ensuring you have the correct information at your fingertips.

Maintenance Tips for Truecoat 360

Ensuring the longevity and optimal performance of your painting equipment requires regular upkeep. Proper maintenance not only enhances efficiency but also prevents potential issues that could arise from neglect. Here are some essential practices to keep your device in top shape.

Regular Cleaning

After each use, thoroughly clean the components to remove any paint residue. Use appropriate solvents and brushes to ensure that all parts are free from clogs. Pay special attention to the nozzle and filters, as these areas are prone to buildup. Regular cleaning prevents performance degradation and extends the life of the equipment.

Routine Inspections

Conduct frequent inspections of your apparatus for wear and tear. Check seals, hoses, and connections for any signs of damage. Replacing worn parts promptly can prevent more significant issues and maintain the functionality of the device. Keeping an eye on these components ensures that your equipment operates smoothly during projects.

Where to Buy Replacement Components

Finding the right components for your equipment is essential for maintaining optimal performance and longevity. Whether you’re in need of a nozzle, filter, or any other essential part, there are various sources available that cater to your requirements.

Authorized Dealers

One of the most reliable options is to purchase from authorized dealers. These vendors are officially recognized and often provide genuine components that ensure compatibility and quality. You can locate authorized sellers through the manufacturer’s website, which typically includes a list of trusted partners.

Online Marketplaces

Another convenient option is to explore online marketplaces. Websites like Amazon or eBay offer a vast array of replacement parts, often at competitive prices. When using these platforms, it’s important to check seller ratings and reviews to ensure you are buying from reputable sources. Always confirm compatibility with your specific model before making a purchase.

In addition to these options, local hardware stores may carry some essential items, allowing for immediate access without the wait for shipping. By exploring these avenues, you can easily find the components you need to keep your equipment running smoothly.