The complexity of aerial equipment demands a thorough comprehension of its various elements. Proper maintenance and repair rely on an in-depth understanding of how these components interact with one another. This section aims to provide insights into the essential features of this specialized machinery, enhancing operational safety and efficiency.

Within this realm, visual representations play a crucial role in facilitating understanding. Illustrations that delineate the structure and functionality of individual elements enable operators and technicians to quickly identify issues and implement necessary solutions. By dissecting these intricate systems, we can gain clarity on their operation and improve troubleshooting capabilities.

Furthermore, knowledge of the various segments that comprise this machinery is vital for ensuring optimal performance. Each component serves a unique function, contributing to the overall effectiveness of the equipment. This guide will delve into the specific features and configurations, ensuring that users are well-equipped to manage and maintain their machinery effectively.

Understanding Altec Bucket Trucks

The equipment designed for elevated work provides significant advantages across various industries. These machines are essential for tasks that require reaching considerable heights, enabling operators to perform maintenance, installations, and inspections safely and efficiently.

Key features and components of these elevated work platforms include:

- Structure: Robust frameworks ensure stability and durability under various operating conditions.

- Height Capability: Models are available that reach impressive vertical distances, accommodating different job requirements.

- Articulation: Flexible designs allow for maneuverability in tight spaces, enhancing accessibility.

- Control Systems: User-friendly interfaces simplify operation, allowing for precise movements.

Understanding the critical components is vital for efficient operation and maintenance:

- Boom: The extendable arm that provides vertical reach.

- Platform: The area where operators stand to perform their tasks.

- Stabilizers: Outriggers that ensure stability during operation.

- Hydraulic System: The mechanism that powers the movement of the boom and platform.

Proper maintenance of this equipment is crucial for safety and longevity:

- Regular inspections help identify wear and tear.

- Routine servicing of hydraulic systems ensures optimal performance.

- Keeping the control systems updated enhances operational efficiency.

In summary, these elevated work platforms play a vital role in modern industry, and a thorough understanding of their construction and functionality is essential for maximizing their effectiveness.

Importance of Quality Parts

The integrity of any machinery relies heavily on the components utilized in its assembly. Ensuring that each element meets high standards of excellence not only enhances performance but also extends the lifespan of the equipment. High-quality materials contribute to overall safety and reliability, crucial for efficient operations in demanding environments.

Using superior components reduces the likelihood of malfunctions, which can lead to costly downtime and repairs. When every piece functions optimally, operators can trust their machinery to perform under pressure, ultimately boosting productivity. Moreover, reliable components often provide better energy efficiency, which translates to lower operational costs.

Investing in premium materials pays dividends in the long run. Organizations that prioritize quality are likely to experience fewer breakdowns and less frequent replacements, leading to enhanced profitability. In competitive industries, maintaining high performance through quality construction can set a business apart from its peers.

Key Components of Bucket Trucks

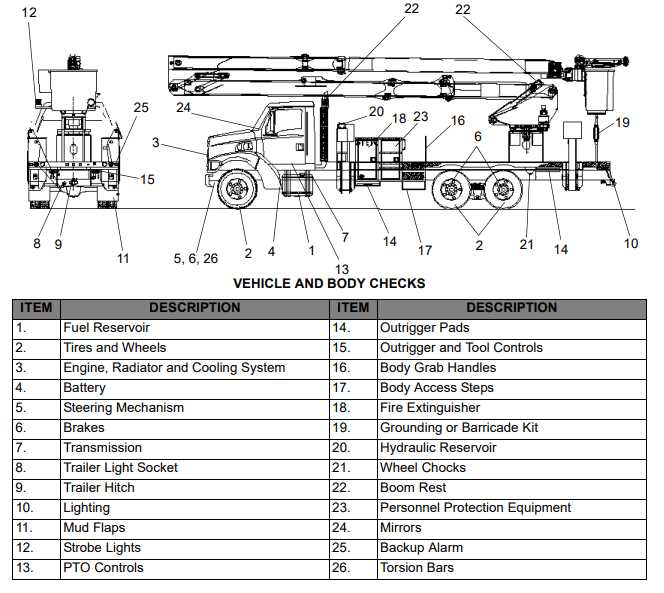

Understanding the essential elements of aerial lift vehicles is crucial for their effective operation and maintenance. These vehicles are designed to elevate personnel and equipment to various heights, making specific components integral to their functionality and safety. Each element plays a vital role in ensuring that these machines perform efficiently and safely in various work environments.

Lift Mechanism

The lift mechanism is one of the primary features of these vehicles, allowing for vertical movement. It typically consists of a hydraulic system that powers the boom, enabling it to extend and retract smoothly. This mechanism must be reliable and strong enough to support both the weight of the personnel and any additional tools or equipment required for the task at hand.

Platform and Safety Features

The platform serves as the work area for operators, making its design crucial for safety and accessibility. Equipped with guardrails and harness attachment points, it ensures that personnel can work securely at heights. Additionally, safety features such as emergency shut-off systems and stability indicators are integrated to enhance operational safety and prevent accidents.

Common Issues and Solutions

In the realm of aerial work platforms, operators often encounter various challenges that can hinder performance and safety. Addressing these common problems not only enhances the functionality of the equipment but also extends its lifespan. Below are some frequently observed issues along with effective solutions to ensure smooth operation.

Frequent Problems

| Issue | Description | Solution |

|---|---|---|

| Hydraulic Leaks | Fluid loss can lead to reduced lifting capacity and potential safety hazards. | Inspect hoses and fittings regularly; replace damaged components immediately. |

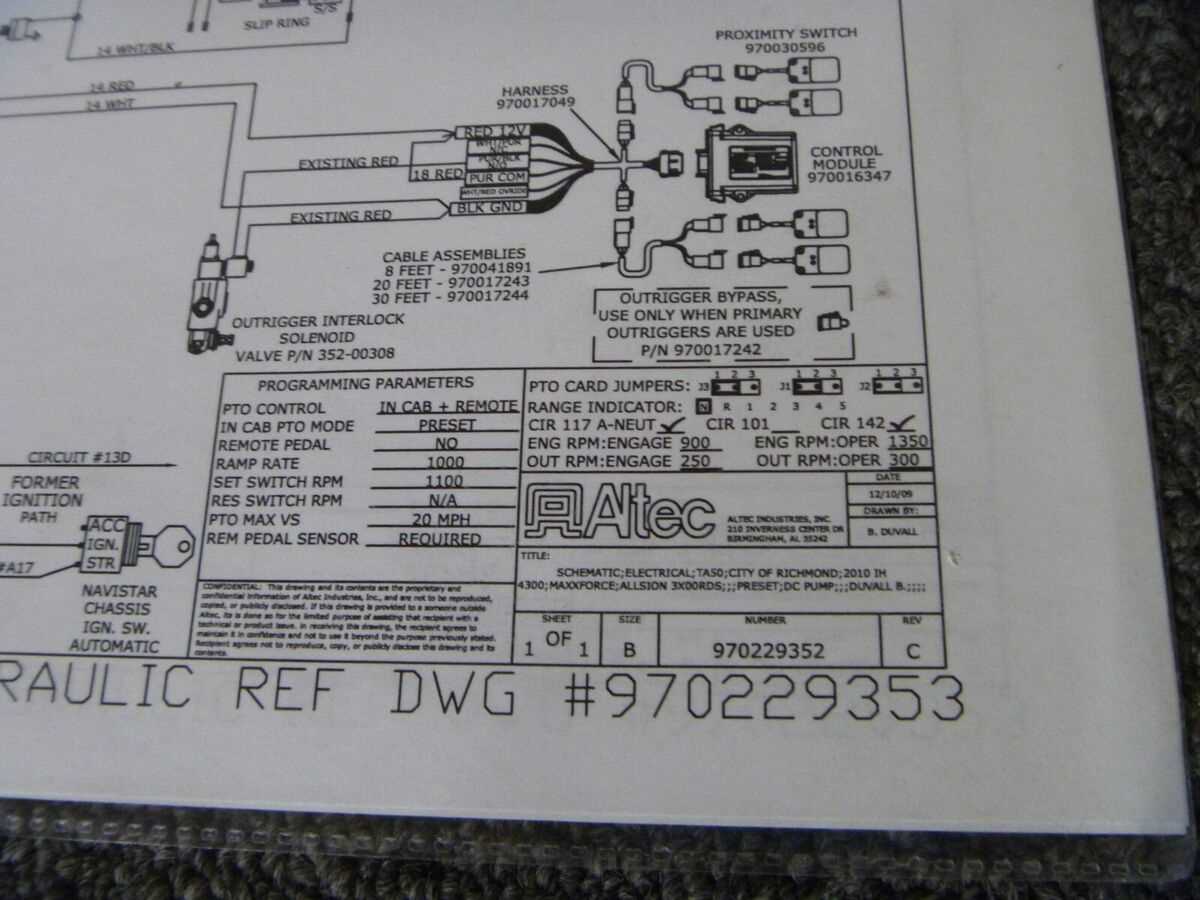

| Electrical Failures | Malfunctions in the electrical system can disrupt control operations. | Check connections and fuses; ensure proper wiring and grounding. |

| Wear and Tear on Components | Regular usage can result in degradation of key parts, affecting efficiency. | Conduct routine maintenance checks; replace worn-out parts as necessary. |

| Stability Issues | Uneven surfaces can compromise the stability of the platform. | Always deploy outriggers on stable ground; avoid working on slopes. |

Preventive Measures

Implementing preventive strategies can significantly reduce the likelihood of encountering issues. Regular inspections, adhering to maintenance schedules, and proper operator training are essential for optimal performance. By taking these proactive steps, operators can ensure safer and more efficient use of their equipment.

Reading Parts Diagrams Effectively

Understanding technical illustrations is essential for anyone involved in maintenance or repair tasks. These visual aids provide crucial information about components, their relationships, and assembly processes, making it easier to identify specific elements and navigate complex systems. Mastering the skill of interpreting these illustrations can significantly enhance efficiency and accuracy in various technical projects.

Key Elements to Focus On

When analyzing technical illustrations, it’s important to pay attention to the various symbols and notations used. Different shapes often represent different types of components, while lines can indicate connections or paths. Familiarizing oneself with these elements allows for quicker identification of necessary items, leading to more effective troubleshooting and repairs.

Utilizing Legends and Annotations

Most illustrations come with legends or notes that clarify the meanings of specific symbols and markings. Taking the time to read these annotations can provide invaluable insights into the layout and function of each component. This understanding not only facilitates the repair process but also helps in acquiring the right replacements or upgrades when needed.

By enhancing your skills in reading technical illustrations, you can ensure that maintenance and repair tasks are completed accurately and efficiently.

Maintenance Tips for Longevity

Ensuring the durability and efficiency of your aerial work platform requires consistent care and attention. By implementing regular maintenance practices, you can extend the lifespan of the equipment and enhance its performance. Adopting a proactive approach not only minimizes the risk of unexpected failures but also contributes to overall safety and operational effectiveness.

Regular Inspections

Conduct thorough assessments on a routine basis to identify any signs of wear or damage. Check critical components such as hydraulic systems, electrical connections, and structural integrity. Early detection of potential issues can prevent more severe complications in the future.

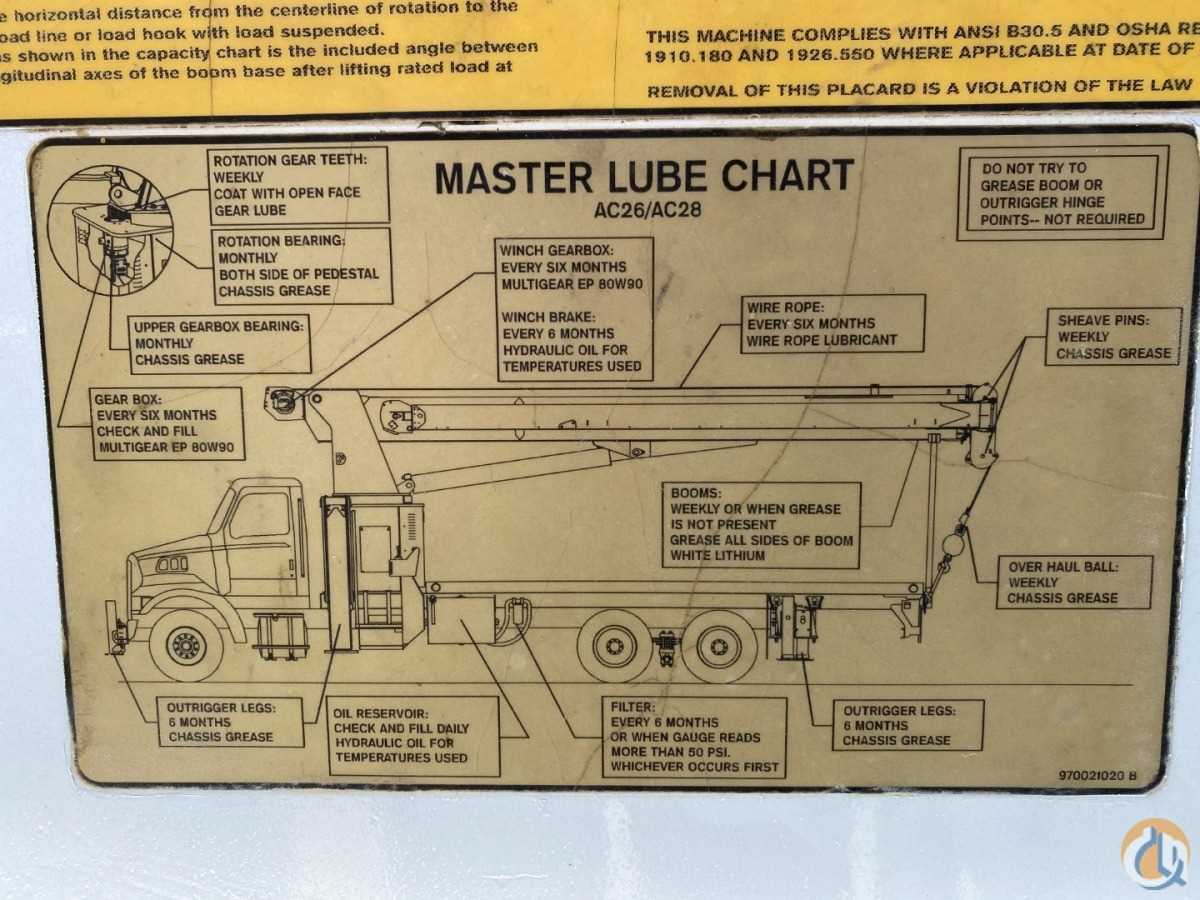

Proper Cleaning and Lubrication

Maintain cleanliness by removing dirt and debris from all surfaces. This practice helps to prevent corrosion and ensures smooth operation. Additionally, apply suitable lubricants to moving parts to reduce friction and wear, promoting optimal functionality and longevity.

Upgrading Your Bucket Truck

Enhancing your elevating work platform can significantly improve its functionality, efficiency, and safety. Regular upgrades not only extend the lifespan of the equipment but also ensure it meets current operational standards. This section outlines key considerations and steps for effectively modernizing your equipment.

When planning upgrades, it is essential to evaluate the specific needs of your operations. Consider the following aspects:

- Performance Improvements: Assess if your machinery can handle more demanding tasks or if it requires a boost in power.

- Safety Enhancements: Explore options for adding safety features such as improved harness systems, emergency stop controls, or better stabilization.

- Technological Advances: Investigate new technologies, like automation systems or telematics, to enhance monitoring and performance tracking.

- Comfort and Usability: Think about the operator’s experience and comfort, potentially integrating ergonomic designs and user-friendly interfaces.

After identifying the areas for improvement, consider the following steps:

- Research: Gather information on the latest innovations and best practices in the industry.

- Consult Experts: Engage with professionals who specialize in equipment upgrades to gain insights and recommendations.

- Budgeting: Establish a budget that accommodates both immediate enhancements and future needs.

- Implementation: Plan a schedule for the upgrades to minimize downtime and disruption to operations.

Investing in modernization not only boosts efficiency but also contributes to the overall safety and effectiveness of operations. Proper planning and execution can lead to substantial benefits in productivity and worker satisfaction.

Where to Find Replacement Parts

Finding suitable components for your equipment is essential for maintaining its performance and safety. Various resources are available for those in search of high-quality replacements that can ensure longevity and reliability.

Authorized Dealers: One of the best options for sourcing genuine replacements is through authorized distributors. These establishments often carry a wide range of items tailored specifically for your equipment, ensuring compatibility and adherence to manufacturer standards.

Online Marketplaces: Numerous online platforms provide an extensive selection of components. Websites dedicated to industrial supplies often feature detailed product descriptions, customer reviews, and competitive pricing, making it easier to compare and select the right items.

Local Supply Stores: Visiting local supply stores can be beneficial as well. Many of these shops stock essential components and have knowledgeable staff who can assist in identifying the right items for your needs.

Surplus Auctions: Another avenue worth exploring is surplus auctions or liquidation sales. These events can offer significant savings on quality components, though it may require some diligence to ensure the items meet your specifications.

By utilizing these resources, you can effectively find the components you need to keep your equipment in optimal condition.