In the realm of machinery and equipment, comprehending the intricate arrangements of various elements is crucial for effective maintenance and repair. This section delves into the visual representation of these components, providing insight into their functionality and interconnections. A clear illustration can serve as a valuable guide for both seasoned technicians and novice users alike.

By examining the configuration of essential parts, one can gain a deeper appreciation for how each element contributes to the overall performance of the system. The clarity of such visuals not only aids in troubleshooting but also enhances the efficiency of any restoration efforts. Recognizing the relationships between different components can lead to more informed decisions during repairs.

Moreover, a detailed exploration of these layouts fosters a greater understanding of potential upgrades and modifications. With the right information at hand, users can navigate the complexities of their equipment with confidence, ensuring longevity and optimal function. This guide will illuminate the pathways through which these elements interact, empowering users to tackle any challenges that may arise.

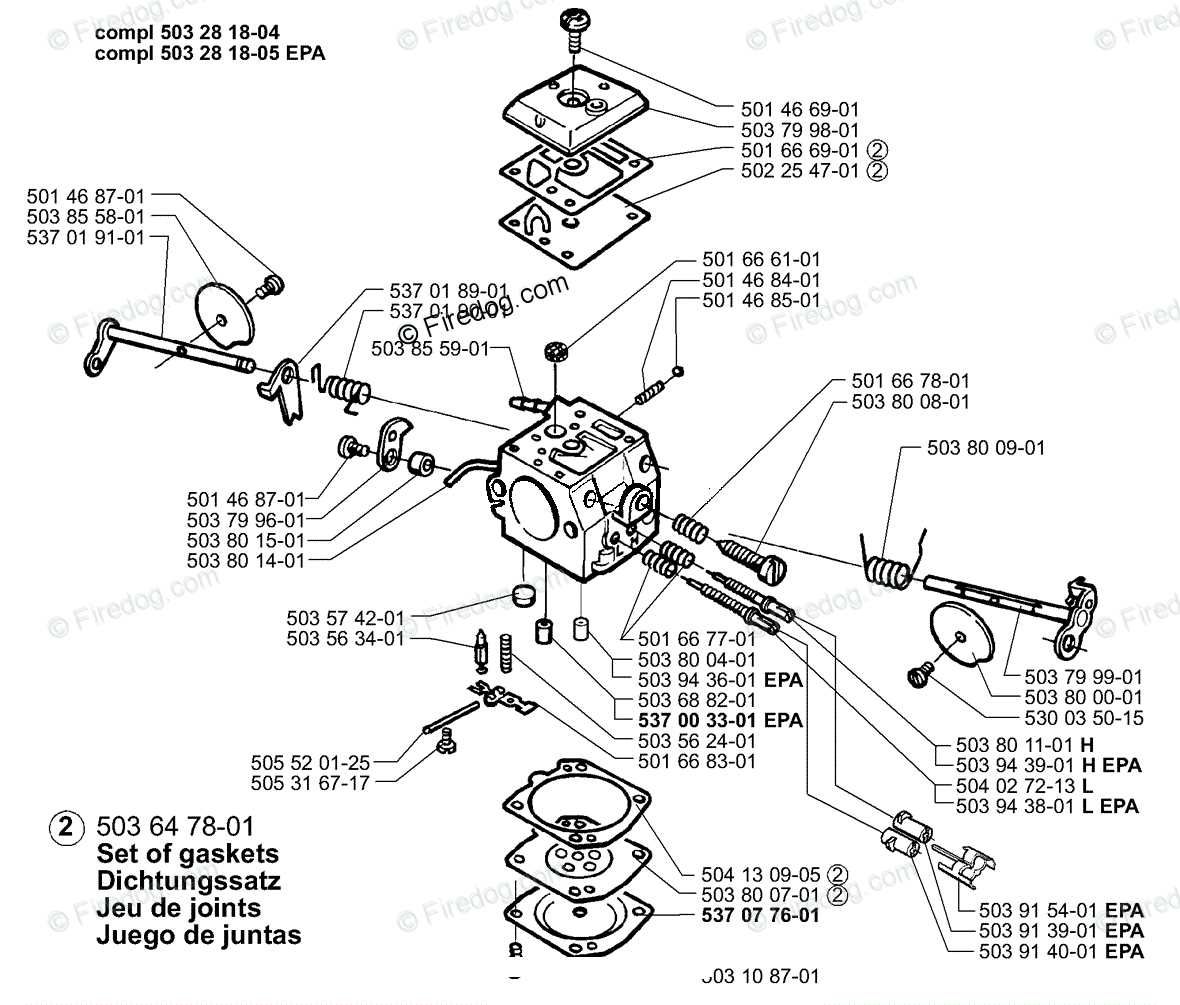

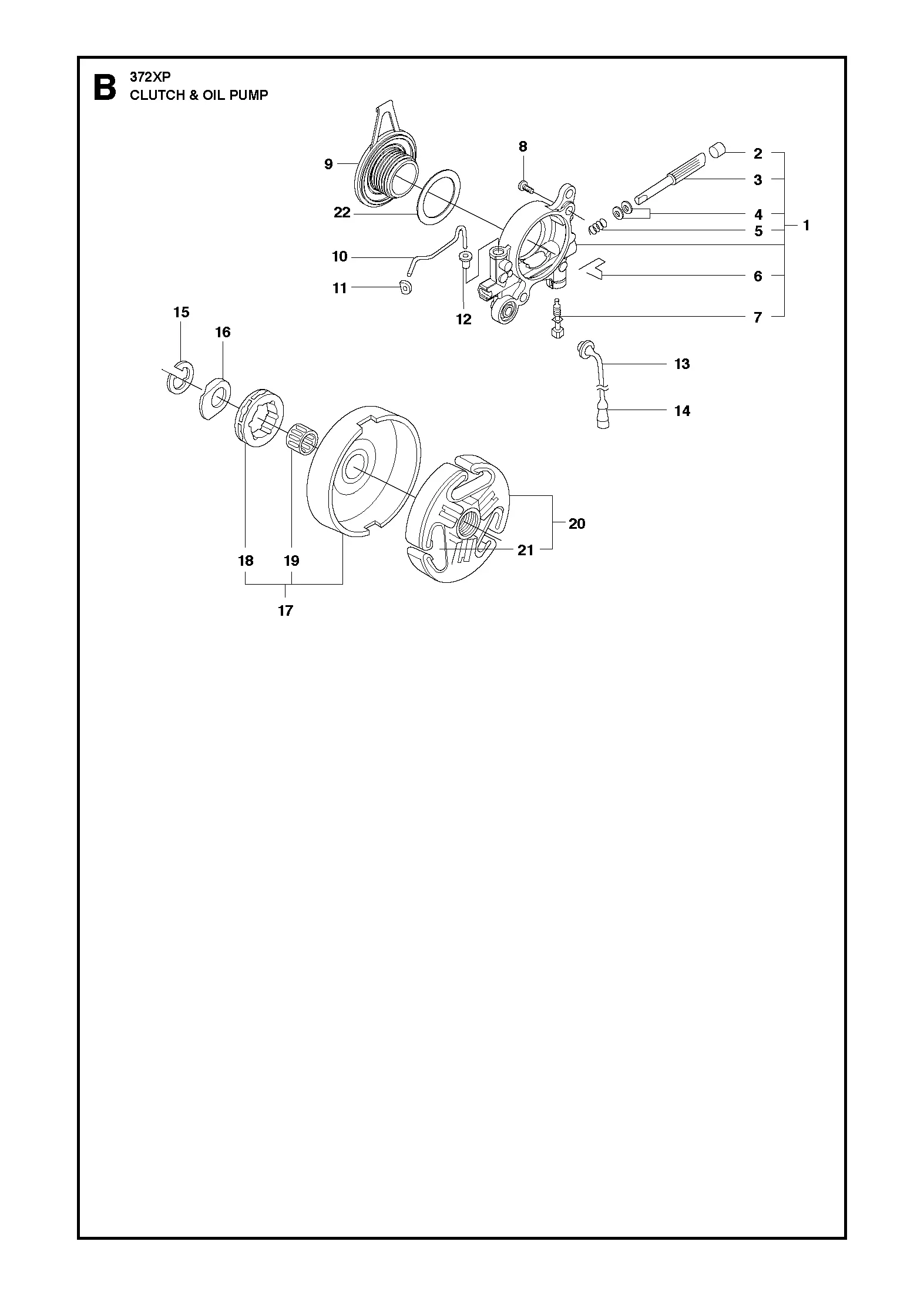

Understanding the 372XP Parts Diagram

Grasping the intricacies of a machinery breakdown can significantly enhance maintenance and repair efficiency. Familiarity with the components and their arrangements allows users to diagnose issues swiftly and understand how each part contributes to the overall functionality.

This section will explore the key elements that make up the layout, enabling users to visualize the assembly and disassembly processes. Recognizing how different elements interact is crucial for effective troubleshooting and ensuring optimal performance.

| Component | Description | Function |

|---|---|---|

| Engine | The core unit that powers the machine. | Converts fuel into mechanical energy. |

| Cylinder | A cylindrical chamber within the engine. | Facilitates the combustion process. |

| Crankshaft | A rotating shaft connected to the engine. | Transforms linear motion into rotational motion. |

| Chain Brake | A safety mechanism for the chain. | Prevents accidental contact and injuries. |

| Air Filter | A component that cleans incoming air. | Ensures optimal engine performance by filtering debris. |

By delving into these details, users can develop a deeper understanding of how each piece plays a role in the operation of the machine. This knowledge is invaluable for effective maintenance practices, leading to improved reliability and longevity of the equipment.

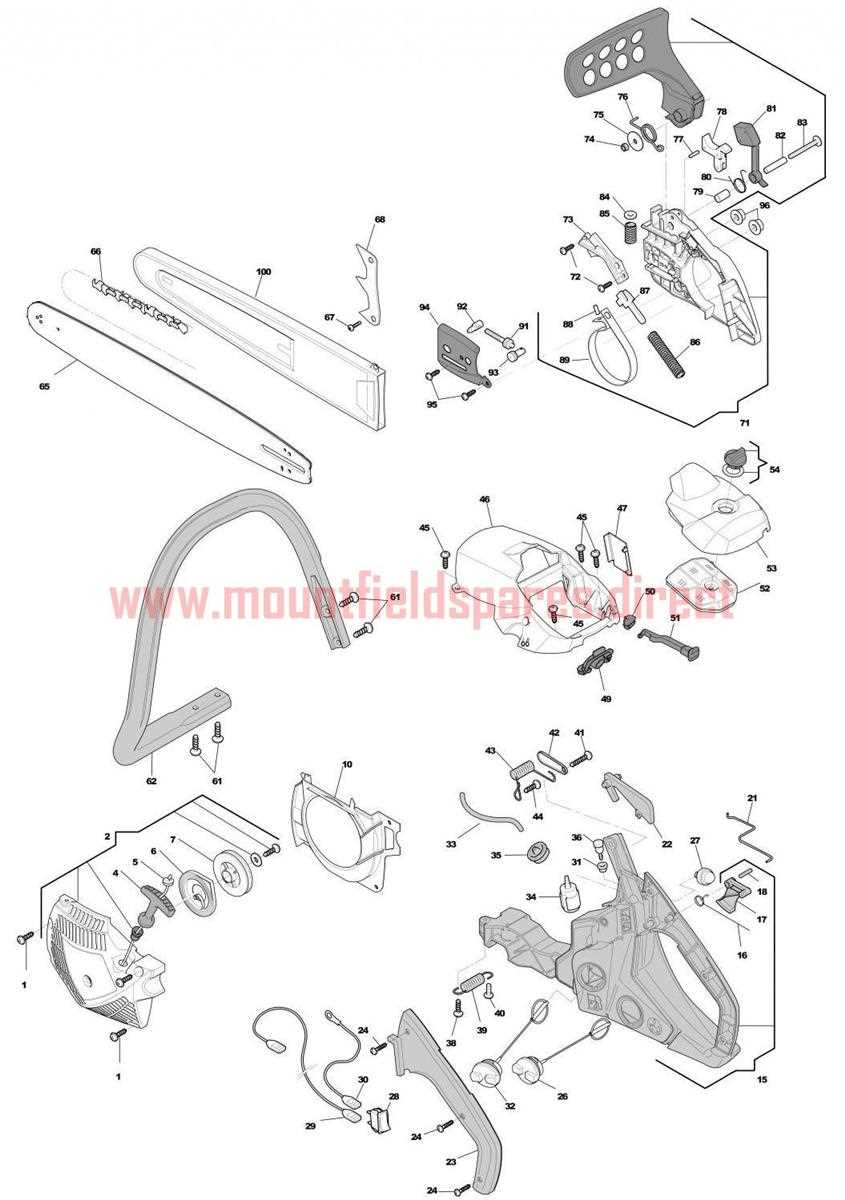

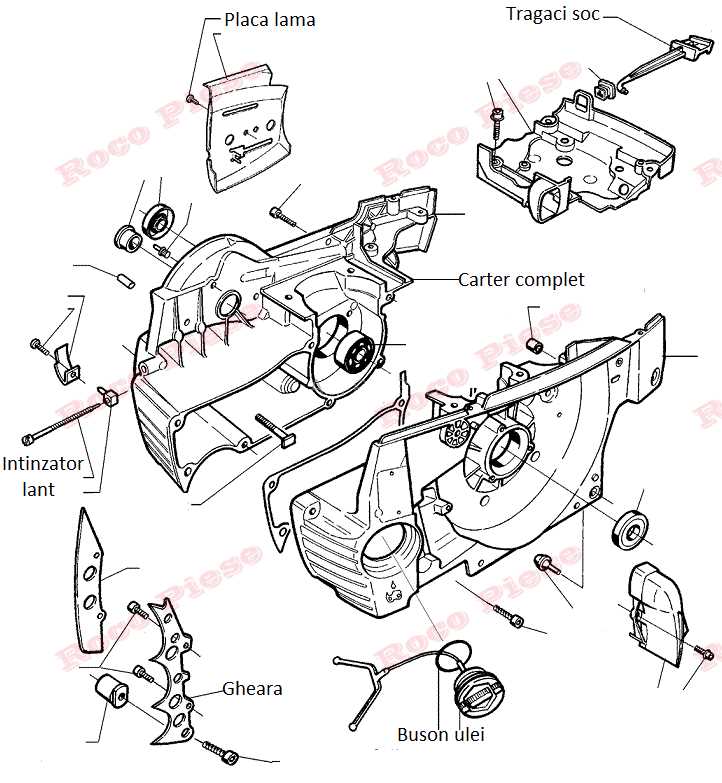

Key Components of the 372XP Model

This section delves into the essential elements that contribute to the overall functionality and performance of the model. Each component plays a vital role in ensuring efficiency and reliability, making it crucial to understand their individual characteristics and interconnections.

Core Elements

The primary parts that make up the unit include the engine, cutting system, and housing. Each of these elements is engineered to work in harmony, providing the user with optimal power and control.

| Component | Function |

|---|---|

| Engine | Delivers power and performance for cutting tasks. |

| Cutting System | Ensures precision and efficiency in operation. |

| Housing | Protects internal components and provides structural integrity. |

Additional Features

Beyond the main components, several auxiliary features enhance usability and safety. These include vibration dampening systems, ergonomic handles, and fuel management mechanisms. Together, they improve the overall user experience and extend the longevity of the equipment.

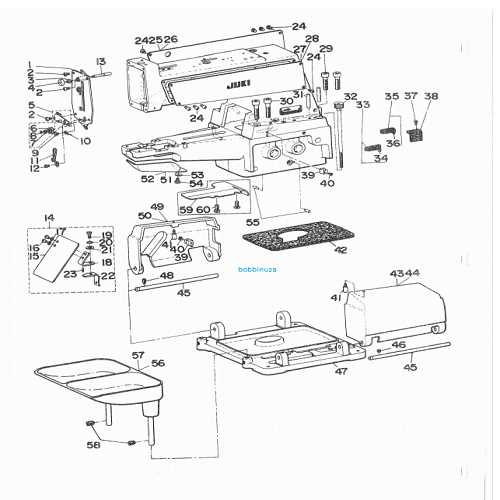

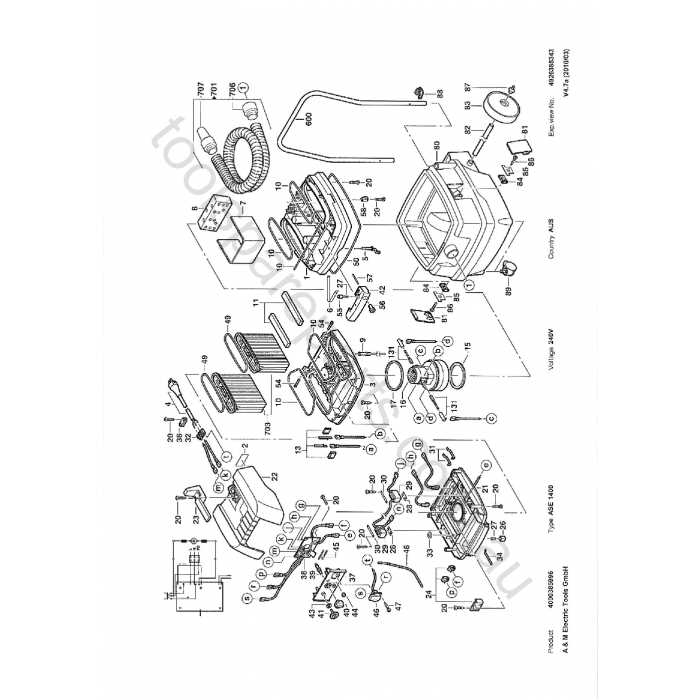

How to Read the Diagram Effectively

Understanding visual representations of mechanical components is crucial for successful assembly and maintenance. These illustrations provide a clear overview of each element’s placement and function, enabling users to navigate complex structures with confidence.

Familiarize Yourself with Symbols

Each visual guide utilizes a specific set of symbols to represent various components. Before diving in, take time to study the accompanying legend or key. This will help you decode the symbols quickly, ensuring you can identify parts accurately and efficiently.

Follow the Flow of the Image

When analyzing the layout, focus on the sequence depicted in the illustration. Start from one end and move systematically to the other, tracing connections and interactions. This approach will provide a comprehensive understanding of how each piece works in relation to the entire assembly.

Common Issues with 372XP Parts

When working with machinery, it’s not uncommon to encounter various challenges that can affect performance and longevity. Understanding the frequent complications associated with components can aid in effective troubleshooting and maintenance, ensuring optimal operation.

Frequent Problems

Components may experience wear and tear over time, leading to inefficiencies or malfunctions. Here are some typical issues:

| Component | Common Issues | Possible Solutions |

|---|---|---|

| Fuel System | Clogs, leaks, inconsistent fuel flow | Regular cleaning, replace worn seals |

| Ignition | Misfiring, starting difficulties | Inspect spark plug, replace faulty wiring |

| Chain | Wear, tension loss | Regular adjustments, replacement when necessary |

Preventive Measures

To minimize these issues, routine inspections and maintenance are crucial. Keeping components clean and replacing worn items promptly can greatly enhance performance and extend the lifespan of the equipment.

Where to Find Replacement Parts

Locating suitable components for your equipment can be a straightforward process when you know where to look. Various sources offer a wide range of options, ensuring you can find the right items to keep your machinery in optimal condition.

Online Retailers: Numerous e-commerce platforms specialize in providing a vast selection of items for maintenance and repair. These sites often include detailed descriptions and specifications, allowing you to easily compare alternatives and make informed choices.

Local Dealers: Authorized distributors in your area can be a reliable resource. They often carry a selection of genuine components and can offer expert advice tailored to your specific needs.

Specialty Stores: Stores focusing on outdoor equipment and machinery often have knowledgeable staff who can help you find what you need. They may also stock hard-to-find items that are not readily available online.

Online Marketplaces: Platforms that facilitate user-to-user transactions can also be beneficial. You might discover pre-owned items in good condition, often at a fraction of the original price.

Forums and Community Groups: Engaging with online communities dedicated to your equipment type can yield valuable insights. Members often share recommendations and sources for quality replacements, helping you connect with reputable suppliers.

Benefits of Using Original Components

Utilizing authentic parts in machinery and equipment can significantly enhance performance and longevity. These components are specifically designed to fit seamlessly and function optimally, ensuring that the overall system operates at its best. Below are some key advantages of opting for original pieces instead of generic alternatives.

Quality Assurance

Original components are manufactured to meet strict quality standards. This guarantees:

- Durability and reliability

- Consistent performance under various conditions

- Reduced risk of failure and associated costs

Perfect Compatibility

Using genuine parts ensures that each element works in harmony with the others. Benefits include:

- Improved efficiency and functionality

- Minimized risk of compatibility issues

- Enhanced safety during operation

Overall, investing in original components is a wise choice for maintaining optimal performance and prolonging the lifespan of your machinery.

Maintenance Tips for 372XP Users

Proper upkeep of your equipment is essential for ensuring optimal performance and longevity. Regular attention to maintenance tasks can prevent breakdowns and enhance efficiency, making your experience more enjoyable and productive. Here are some valuable tips to help you care for your machine effectively.

| Task | Frequency | Details |

|---|---|---|

| Clean Air Filter | After every 5 hours of use | Remove debris and ensure proper airflow to maintain engine efficiency. |

| Check Fuel System | Every month | Inspect for leaks and replace fuel filters as necessary to prevent clogs. |

| Inspect Spark Plug | Every 20 hours of use | Clean or replace to ensure proper ignition and engine performance. |

| Sharpen Cutting Tools | As needed | Keep blades sharp for efficient cutting and reduced strain on the engine. |

| Examine Cables and Hoses | Every season | Look for wear and tear, replacing any damaged components to avoid failures. |

| Lubricate Moving Parts | Every 10 hours of use | Apply suitable lubricant to reduce friction and wear on components. |

By following these guidelines, users can ensure that their machinery remains in top condition, ready for any task at hand. Consistent maintenance not only improves performance but also extends the life of your equipment, providing better value in the long run.

Comparing 372XP with Other Models

This section explores the distinctions and similarities between a specific model and its competitors in the market. By analyzing features, performance, and user experience, we aim to provide a clearer understanding of how this particular unit stacks up against others.

Key Features and Performance

When assessing various models, several critical aspects come into play:

- Power Output: Different units offer varying horsepower and torque, impacting overall performance.

- Weight: The weight of a machine can affect maneuverability and ease of use.

- Fuel Efficiency: Comparing fuel consumption rates helps determine operational costs over time.

- Durability: Material quality and construction methods play a significant role in longevity and reliability.

User Experience and Applications

Users often consider how a model performs in real-world scenarios:

- Ease of Use: Controls, handling, and maintenance requirements are crucial for user satisfaction.

- Versatility: The ability to handle various tasks is a significant advantage for many operators.

- Feedback and Reviews: Customer opinions provide insights into reliability and effectiveness.

In summary, a thorough comparison reveals not only the strengths and weaknesses of each model but also helps potential buyers make informed decisions based on their specific needs and preferences.

Expert Advice on Repairs and Upgrades

Maintaining and enhancing your equipment requires a solid understanding of its components and their functionality. Proper guidance can make the difference between a simple fix and a complicated overhaul. This section offers insights into effective maintenance practices and upgrade strategies, ensuring optimal performance and longevity.

When approaching repairs, it’s crucial to identify the underlying issues accurately. Common problems may stem from wear and tear or improper usage. Regular inspections can help detect these issues early, allowing for timely interventions. Moreover, utilizing high-quality replacement components can significantly improve reliability.

| Common Issues | Recommended Actions |

|---|---|

| Worn-out components | Replace with OEM parts for best performance. |

| Poor performance | Check for clogs and clean or replace filters. |

| Noise during operation | Inspect and lubricate moving parts to reduce friction. |

Upgrades can also enhance the capabilities of your machinery. Investing in modern technologies or superior materials can lead to increased efficiency and effectiveness. Prioritize modifications that align with your specific operational needs and budget.

Lastly, always consult with experts or refer to detailed manuals before undertaking any significant work. Their experience can provide valuable insights and prevent costly mistakes. Whether repairing or upgrading, informed decisions will ensure your equipment remains in peak condition.