Understanding the inner workings of various mechanical systems can provide valuable insight into how individual elements interact. Whether you’re a seasoned technician or simply a curious enthusiast, exploring the structure and function of these systems is key to maintaining and optimizing their performance.

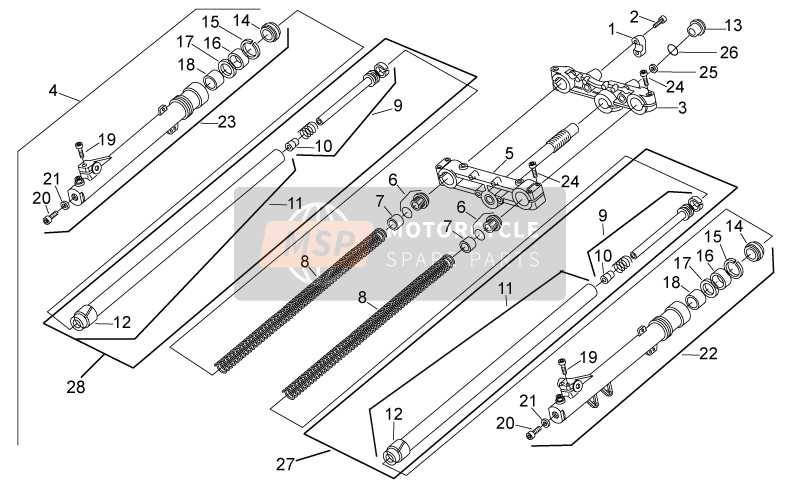

This section delves into the intricate assembly of a classic spring-powered mechanism, detailing its main features and how each component contributes to the overall operation. The focus will be on the internal structure, ensuring clarity and precision in describing the essential elements involved in proper function.

With this guide, you’ll gain a clearer understanding of how various mechanical elements interact, assisting you in troubleshooting, repairs, and maintenance. Let’s explore the construction, ensuring you are well-equipped with the knowledge needed for effective handling and care.

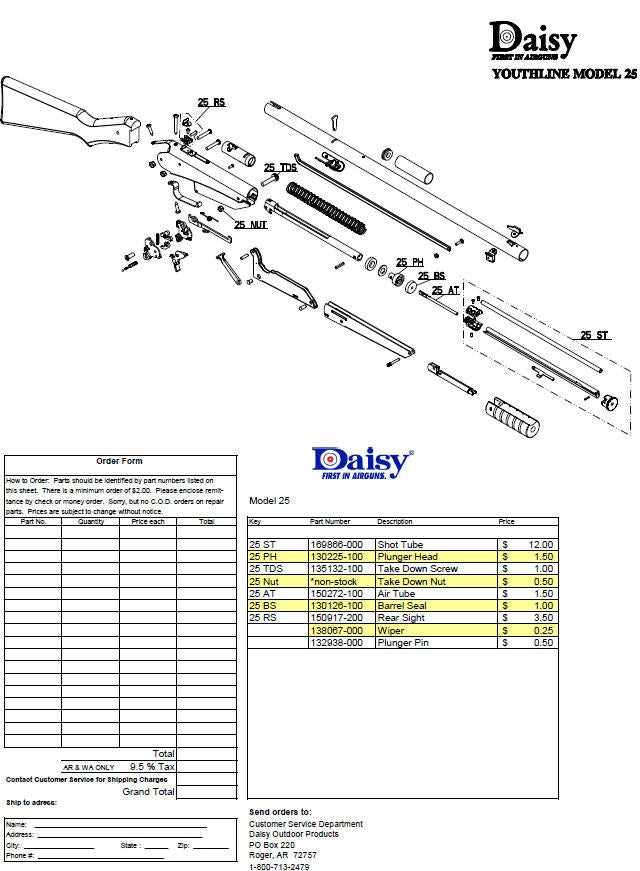

Daisy Model 25 Parts Overview

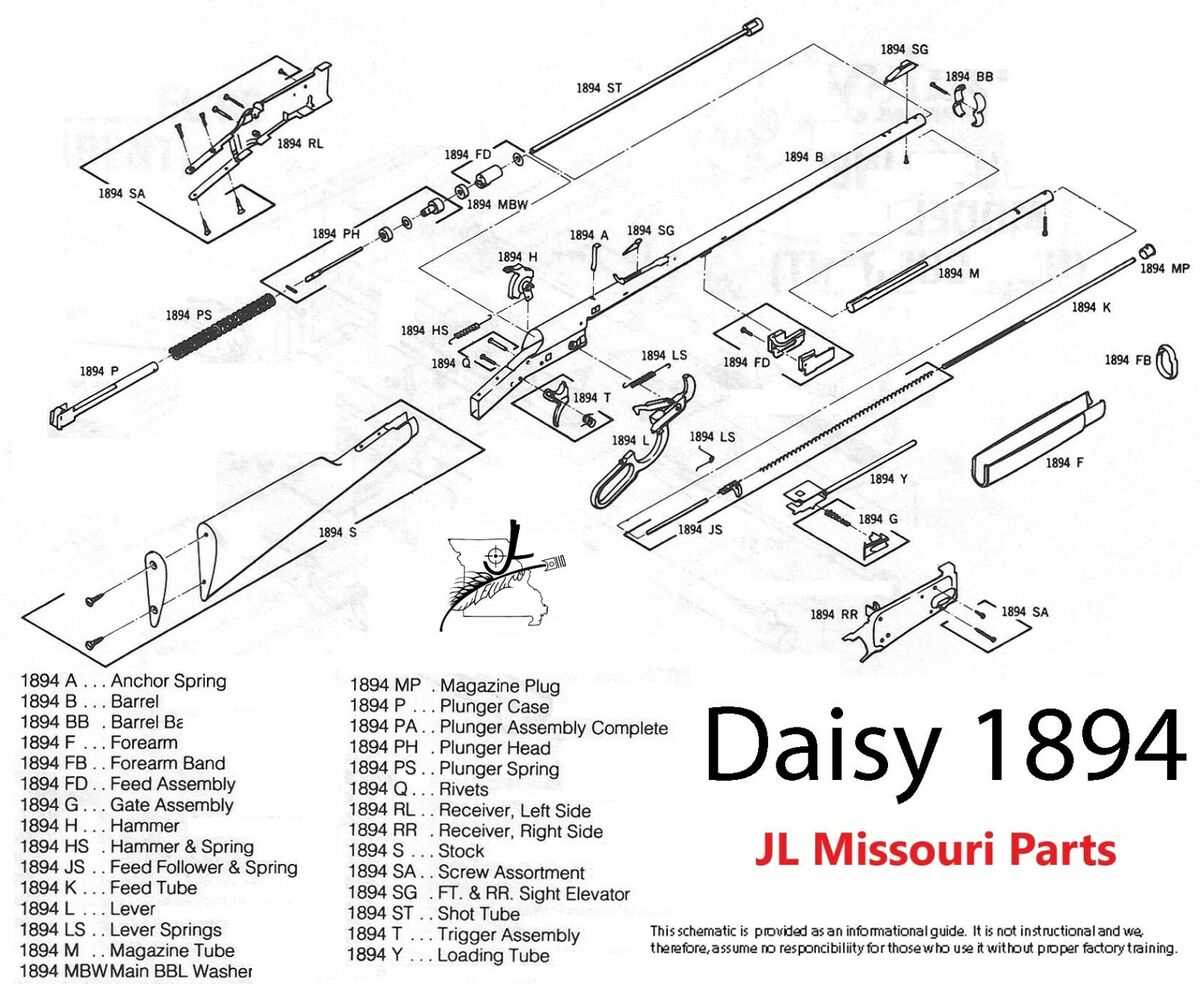

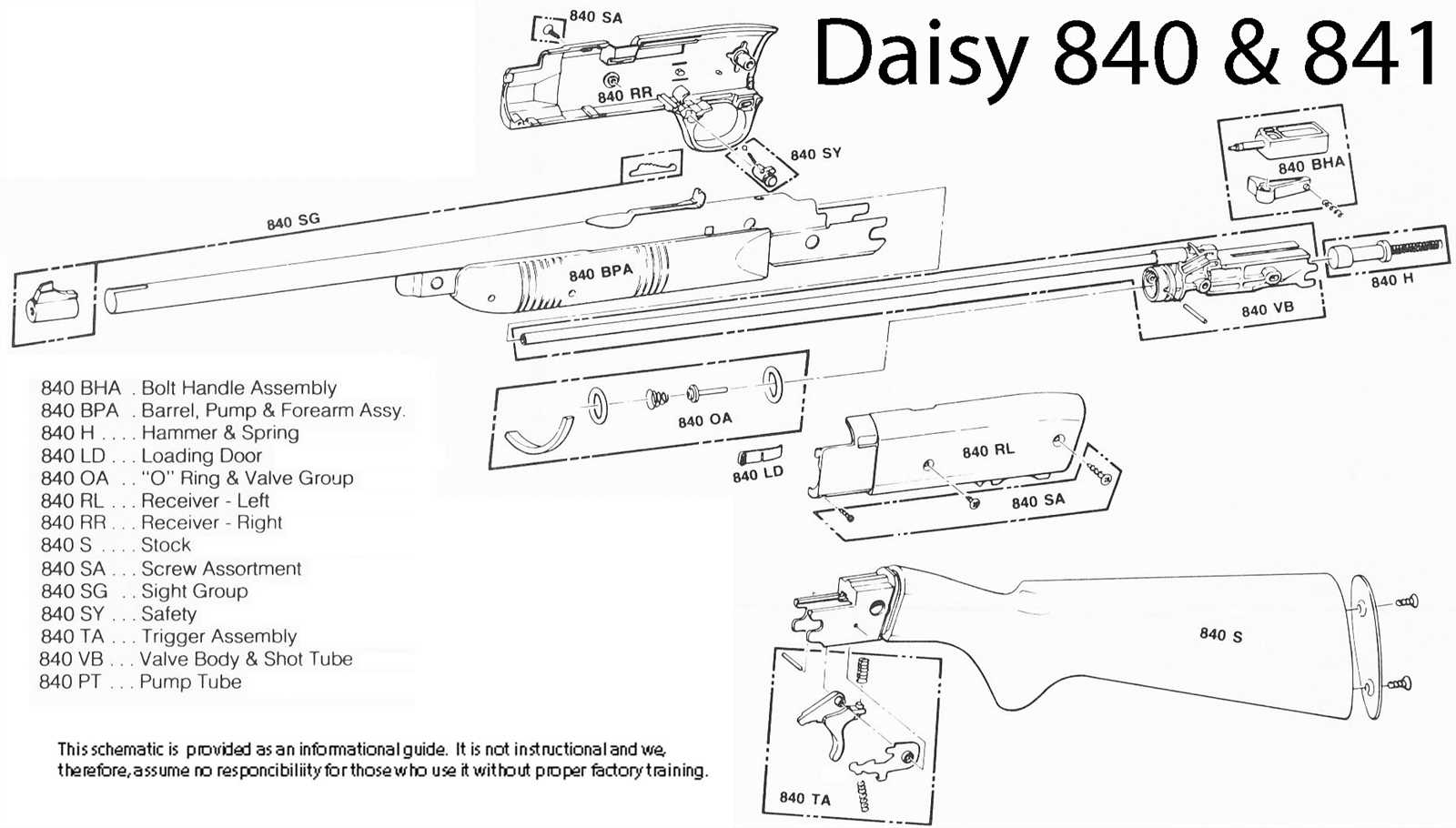

The classic air rifle under discussion is composed of various integral components that work together to ensure precision and reliability. Understanding the structure and function of each element can enhance the user’s experience and improve maintenance practices. This overview will break down the key features and mechanisms involved in its operation.

Main Assemblies

- Barrel assembly – responsible for directing projectiles with accuracy.

- Trigger mechanism – controls the firing sequence and safety features.

- Stock and grip – provides stability and comfort during usage.

Internal Mechanisms

- Spring system – powers the firing mechanism, delivering force to propel shots.

- Loading chamber – holds ammunition in preparation for firing.

- Air compression unit – generates the required pressure for projectile discharge.

Each part contributes to the overall

Main Components of the Iconic Airgun

This section covers the essential elements that make up the design and functionality of the classic air rifle. Each component plays a vital role in ensuring reliable operation, precision, and durability, contributing to its long-standing reputation among enthusiasts. The main elements provide both structural integrity and seamless mechanical performance, forming a cohesive system that enhances the overall shooting experience.

Mechanical Structure

The airgun’s core is composed of a robust frame that houses all moving parts. The trigger mechanism, spring-powered firing system, and loading lever are all interconnected to facilitate smooth operation. This solid foundation ensures that the rifle remains sturdy and efficient during repeated use, while also maintaining balance and comfort in handling.

Barrel and Sights

The precision-crafted barrel ensures accurate shot placement by guiding the projectile with minimal deviation. It is paired with front and rear sights, allowing the user to align their aim precisely. These components work together to enhance accuracy, making it easier for shooters to hit their intended targets consistently.

Internal Mechanisms of the Air Rifle

The internal workings of an air rifle rely on a combination of mechanical elements designed to provide accuracy, power, and reliability. These components work together to ensure smooth operation and consistent performance when the trigger is pulled. Understanding these mechanisms can offer insight into how the system converts compressed air into kinetic energy, propelling the projectile with precision.

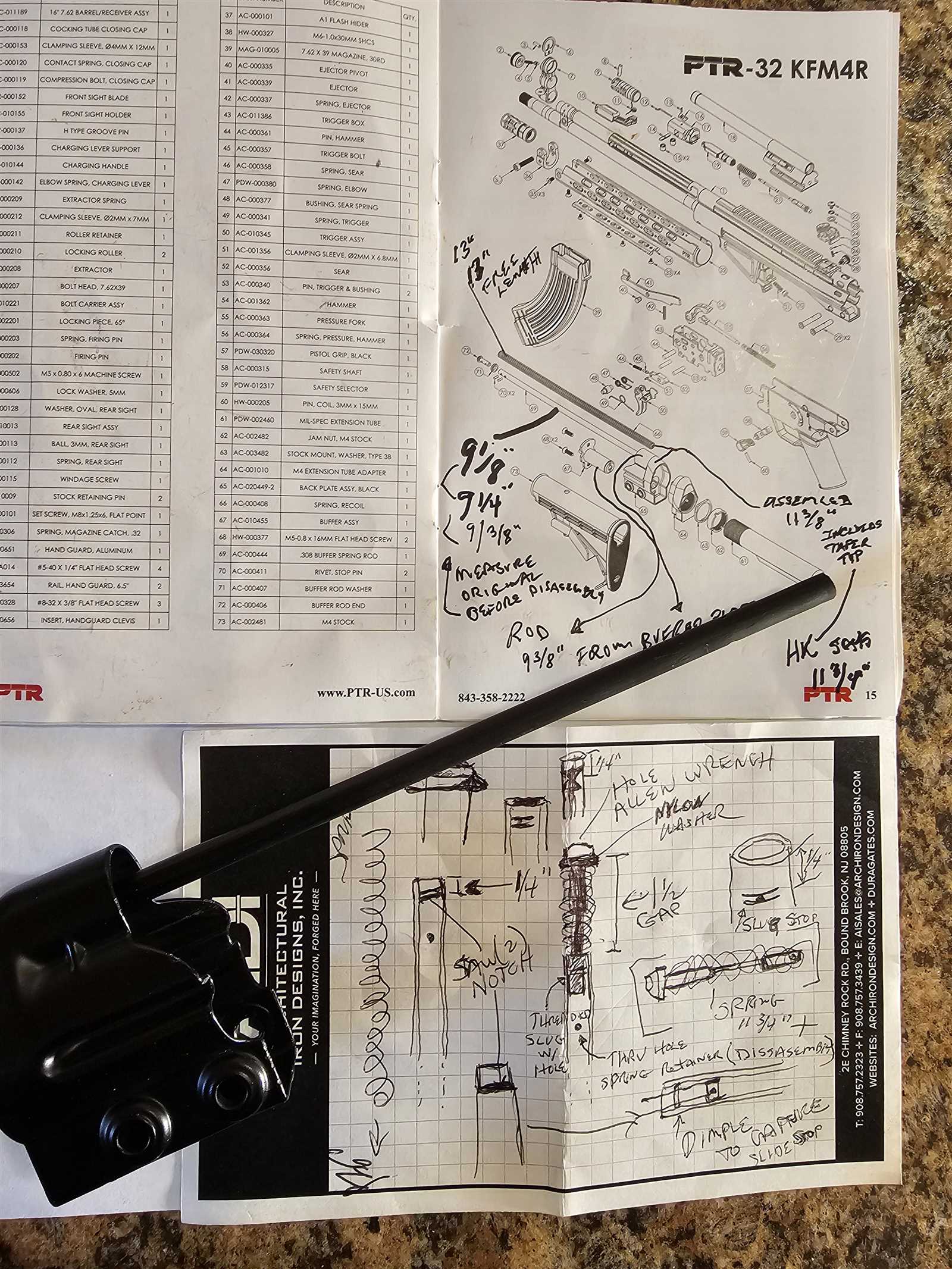

Trigger Assembly: The trigger assembly plays a critical role in initiating the firing sequence. By engaging with other internal elements, it releases the stored energy, allowing the compressed air to power the shot. This interaction between parts is carefully calibrated to ensure optimal timing and control over the shot.

Compression Chamber: The heart of the air rifle’s power lies in the compression chamber. When the rifle is cocked, air is compressed within this chamber, creating the force necessary to propel the ammunition. The chamber’s design is key to maintaining the balance between power and efficiency.

Spring and Piston System:

Trigger Assembly and Functionality

The trigger system is a vital component responsible for the firing mechanism, ensuring the smooth operation of the device. It plays a critical role in translating user input into the discharge of the projectile, integrating various mechanical parts to achieve a seamless action. Understanding how the trigger functions is essential for both maintenance and performance optimization.

Key Components of the Trigger Mechanism

The trigger mechanism is composed of several interacting elements. The trigger lever initiates the firing process when pulled. This movement causes the sear to release the firing pin, allowing it to strike the projectile chamber. Each component works in unison to ensure precise and controlled action.

Operational Efficiency and Safety

A well-maintained trigger system ensures consistent operation, improving overall firing accuracy. Additionally, safety mechanisms, such as a trigger lock or safety catch, are typically integrated to prevent accidental discharge, highlighting the importance of regular inspections and adjustments.

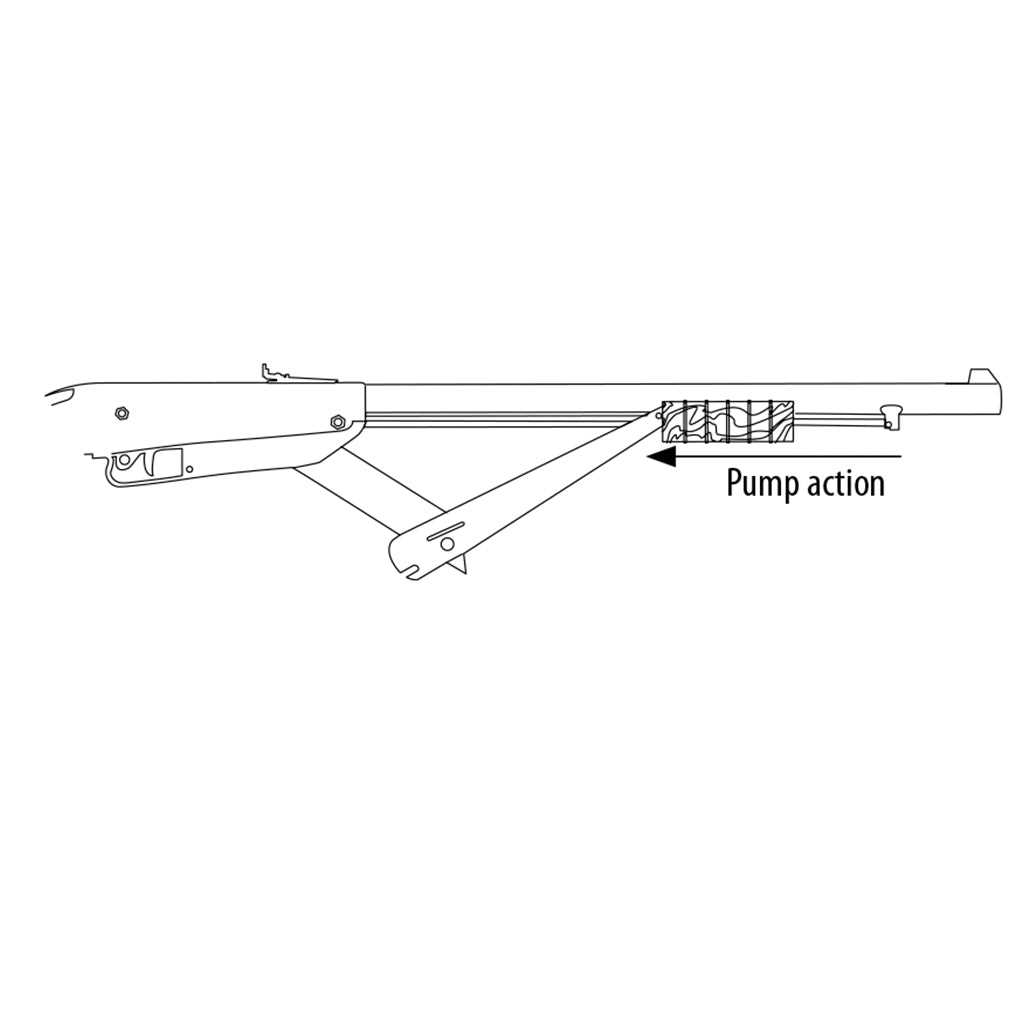

Loading Mechanism and Ammunition Details

The functioning of the loading system is a crucial aspect of ensuring smooth operation. It involves a careful arrangement that allows for the efficient introduction of projectiles into the chamber. This process is designed to optimize the performance and ensure reliable discharge with every use.

Efficient Feeding System: The mechanism incorporates a spring-driven feeder, which facilitates the steady flow of ammunition into the chamber. This ensures that each round is properly positioned for firing, minimizing any chances of misfire or jamming.

Ammunition Compatibility: The system is calibrated to work with specific types of projectiles, offering versatility in the type of ammunition that can be used. The user should ensure proper alignment and insertion of each round to maintain optimal performance.

Overall, the balance between the loading mechanism and ammunition compatibility ensures the system remains efficient and reliable during prolonged use.

Barrel Structure and Maintenance

The barrel plays a crucial role in ensuring both the accuracy and longevity of any air-powered mechanism. Understanding its composition and how to maintain it effectively can prevent common issues, enhance performance, and extend the lifespan of the equipment.

Material and Design: The barrel is typically crafted from durable metals that resist wear and offer smooth internal surfaces. The precision of its internal diameter directly influences the trajectory of the projectile, making regular checks essential.

Cleaning and Care: Proper cleaning methods are vital to maintaining the internal structure. Dust, moisture, and residue from projectiles can accumulate, leading to performance degradation. A simple yet consistent cleaning routine can prevent blockages and preserve the smoothness of the interior surface.

Lubrication: Applying a light, appropriate lubricant periodically helps in reducing friction and maintaining the condition of the barrel. However, over-lubrication can attract unwanted

Sights and Aiming System Explained

The sighting and aiming mechanisms are crucial for achieving precision during shooting. These components allow the user to align the target with the point of impact, providing consistency and accuracy. Understanding how these systems work enhances performance and helps shooters adjust their techniques for various distances and conditions.

Front and Rear Sights

The front sight, usually a small bead or post, is located at the muzzle and serves as the first point of alignment. The rear sight, positioned closer to the shooter, often features a notch or aperture. Properly aligning the front sight within the rear sight ensures that the shot is on target. Both must be used in harmony for effective aiming.

Aiming Techniques

There are different approaches to aiming, depending on the distance and the environment. Target focus involves concentrating on the object being aimed at, while keeping the sights slightly

Stock Design and Material Options

This section explores the various design choices and material alternatives available for firearms, focusing on their impact on aesthetics and functionality. Understanding these options is essential for enthusiasts looking to customize or enhance their shooting experience.

Design Features

- Sleek contours and ergonomic shapes contribute to user comfort.

- Textured grips improve handling and control, especially in adverse conditions.

- Adjustable components allow for personalized fit and performance.

Material Choices

- Metal: Durable and often provides a classic appearance.

- Polymer: Lightweight and resistant to environmental factors.

- Wood: Offers a traditional look and feel, often preferred for its aesthetic appeal.

When selecting a design and material, it is crucial to consider the intended use and personal preferences. Each option presents unique advantages, contributing to the overall effectiveness and enjoyment of the firearm.

Common Wear and Replacement Parts

Every mechanical device is subject to wear over time, necessitating certain components to be replaced periodically. Understanding which elements are prone to degradation can enhance the longevity and efficiency of your equipment. Below are some common components that may require attention or replacement during maintenance.

- Seals and O-rings: These elements are essential for preventing leaks and maintaining pressure. Regular inspection is advisable as they can wear out, leading to diminished performance.

- Springs: Springs provide the necessary tension in various mechanisms. Over time, they can lose their elasticity and may need to be swapped out to ensure proper functionality.

- Barrels: The barrel can experience wear from repeated usage, affecting accuracy. If signs of wear are noticeable, replacing it may improve performance.

- Trigger Mechanism: This assembly can suffer from wear, impacting the responsiveness of the device. Routine checks and replacements can enhance user experience.

- Firing Pin: A crucial component for ignition, the firing pin can become damaged or worn. Regular replacement can prevent misfires and ensure reliability.

Monitoring these critical components can greatly influence the overall performance and safety of your equipment. Regular maintenance and timely replacements help maintain optimal operation and extend the lifespan of the device.