Exploring the inner workings of a vehicle reveals a complex system of interconnected elements that work in harmony to provide a smooth driving experience. Each component plays a crucial role in ensuring optimal performance, from the mechanisms that manage airflow to those responsible for regulating power. Delving into these details can help enthusiasts and drivers alike better appreciate the intricacies involved in automotive design and maintenance.

When aiming to maintain or enhance the functionality of your vehicle, it’s essential to recognize how various elements interact. Whether it’s fine-tuning specific sections, ensuring proper lubrication, or addressing issues related to overheating, understanding the layout of these systems is key. This knowledge can be invaluable for identifying potential issues early on and taking appropriate measures to extend the lifespan of your vehicle.

By familiarizing yourself with the arrangement of essential components, you can make more informed decisions about repairs, upgrades, or routine maintenance. Such insights empower you to troubleshoot effectively, reduce the likelihood of unexpected problems, and optimize the overall driving experience.

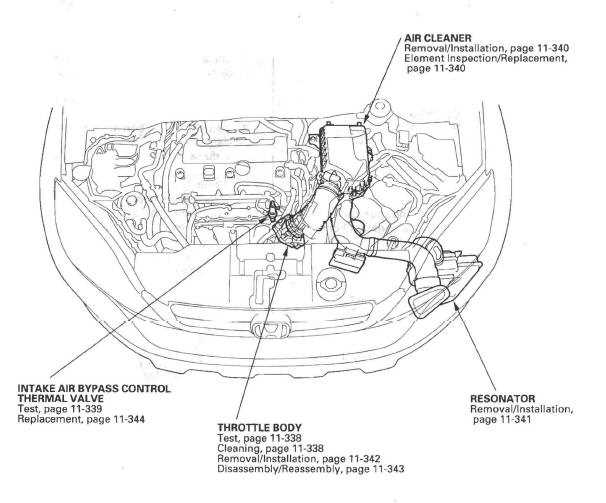

2004 Honda CRV Engine Parts Diagram

Understanding the layout and components of a vehicle’s power unit can significantly aid in maintenance and repair tasks. Familiarity with the various elements that make up the power source allows for quicker identification of potential issues and more efficient replacement of components. This guide provides a clear overview of key sections and elements, helping to simplify complex mechanisms.

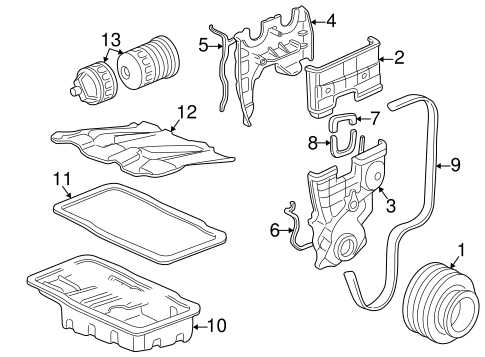

Main Components Overview

The power source is composed of multiple interconnected sections, each serving a specific function. Knowing these elements helps ensure smooth operation and can assist in diagnosing common problems. Below is a breakdown of essential parts commonly found within the system:

- Cooling system: Ensures optimal temperature, preventing overheating.

- Lubrication channels: Distribute oil to reduce friction between moving sections.

- Ignition system: Initiates the combustion process for propulsion.

- Air intake assembly: Manages airflow to enhance efficiency.

- Fuel delivery setup: Regulates the supply of fuel for combustion.

Additional Key Elements

Aside from the main sections, several smaller yet crucial parts contribute to overall performance. These include mechanisms that control timing, filters that keep fluids clean, and seals that prevent leaks. Recognizing these components and their roles ensures comprehensive upkeep and improves longevity.

- Timing mechanism: Coordinates the movement of internal parts.

- Filtration units: Clean the air and fluids entering the system.

- Gaskets and seals: Prevent leaks and maintain pressure levels.

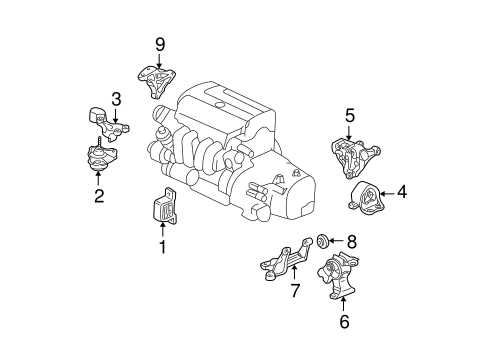

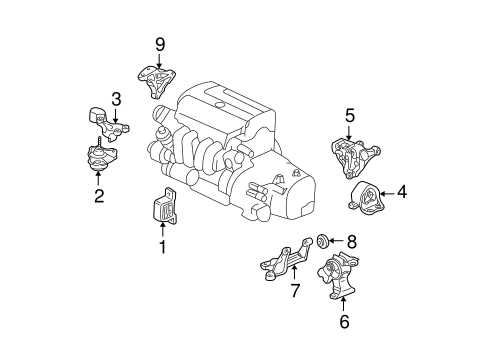

Identifying Key Engine Components

Understanding the main elements under the hood is essential for maintaining and troubleshooting a vehicle’s performance. Each component plays a crucial role in the overall functioning of the power system, working together to ensure smooth operation and optimal efficiency. Recognizing these parts and their purposes can help in diagnosing issues and performing basic upkeep.

Cylinder Block serves as the foundation, housing various moving elements that convert energy into motion. Its structure accommodates other components, creating a secure environment for the internal processes to occur.

The cylinder head sits atop the block, providing passageways for air, fuel, and exhaust gases. It also supports vital mechanisms such as valves and spark devices, which regulate the flow and ignition of the air-fuel mixture.

The crankshaft converts linear force into rotational motion, powering various systems within the vehicle. Its position and movement are central to the engine’s functionality, influencing how smoothly the vehicle operates.

Additionally, the camshaft is responsible for controlling the timing of the opening and closing of valves, ensuring the precise delivery of air and fuel for combustion. This synchronization is critical for optimal performance.

Understanding the Engine Layout

The arrangement under the hood is crucial for anyone who wants to perform maintenance or understand how their vehicle operates. The layout provides insights into how different systems work together, affecting both functionality and performance. Recognizing the locations of various components helps with identifying potential issues, performing repairs, and enhancing the longevity of the vehicle.

Main Components and Their Functions

The configuration typically consists of various key elements, each with specific tasks that contribute to the vehicle’s operation. Understanding these components and their roles ensures better maintenance practices and can help with troubleshooting. Below is an overview of some main areas and their associated tasks.

| Component |

Function |

| Cooling System |

Maintains optimal temperature by circulating coolant throughout the structure. |

| Fuel Delivery System |

Supplies the necessary amount of fuel to the combustion chambers, ensuring efficient operation. |

| Ignition System |

Generates the spark needed to ignite the fuel-air mixture, leading to power generation. |

| Exhaust System |

Directs harmful gases away from the interior and minimizes emissions. |

Location of Major Engine Parts

The layout of essential components within the power unit is crucial for understanding maintenance and repair tasks. Knowing where each element is situated can help identify potential issues and ensure efficient upkeep. The placement varies based on the vehicle’s design, but key areas remain relatively consistent across most models.

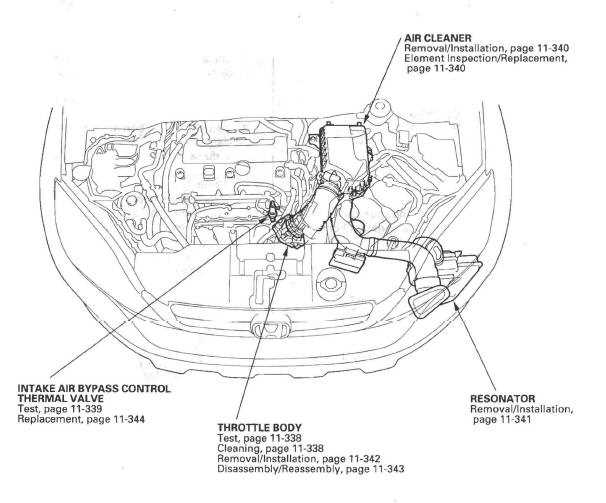

The upper section houses the mechanisms responsible for air and fuel intake, which work together to deliver the correct mixture needed for combustion. This includes items related to the air pathway and systems that regulate the fuel supply.

The central area typically accommodates the power-generating chambers. Here, combustion occurs, creating the energy necessary to drive the vehicle forward. It also includes components that manage temperature and help dissipate excess heat during operation.

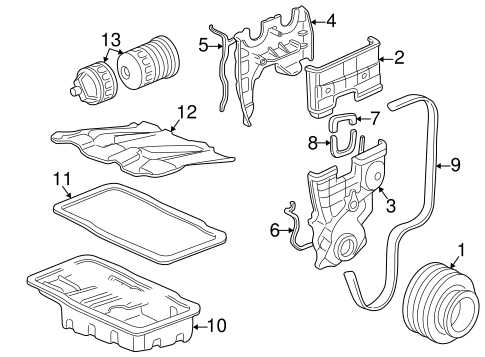

The lower region is where lubrication systems are located, ensuring that all moving elements remain properly oiled. This area may also contain components involved in transferring energy to other mechanical parts, keeping the vehicle in motion.

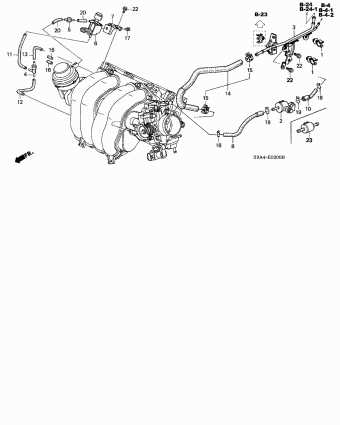

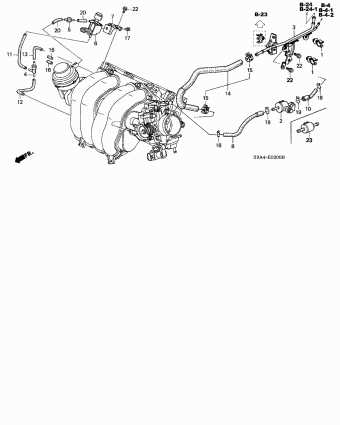

Exploring the Cooling System

The cooling system plays a crucial role in maintaining optimal operating temperatures within a vehicle’s mechanical components. Its primary function is to dissipate heat generated during operation, ensuring that the various elements remain within a safe thermal range. A well-functioning cooling system enhances performance, prolongs the lifespan of components, and contributes to overall efficiency.

Key Components of the Cooling System

- Radiator: Acts as a heat exchanger, transferring heat from the coolant to the air.

- Water Pump: Circulates the coolant throughout the system, facilitating effective heat transfer.

- Thermostat: Regulates the flow of coolant based on the engine’s temperature, ensuring optimal warmth.

- Cooling Fans: Assist in drawing air through the radiator, enhancing the cooling process, especially at low speeds.

- Coolant Reservoir: Stores excess coolant and maintains proper levels within the system.

Importance of Maintenance

Regular upkeep of the cooling system is vital to prevent overheating and subsequent damage. Neglecting this aspect can lead to severe issues such as engine failure. Key maintenance practices include:

- Checking coolant levels and quality periodically.

- Inspecting hoses and connections for wear and leaks.

- Flushing the system to remove contaminants and ensure efficiency.

- Replacing the thermostat and water pump as necessary.

Fuel System Components Overview

The fuel system is a crucial element in any vehicle’s operation, responsible for delivering the necessary fuel to the combustion chamber for efficient performance. Understanding the various components that make up this system can help in diagnosing issues and ensuring optimal functionality. This overview highlights key elements and their roles in maintaining the system’s efficiency.

Key Elements of the Fuel System

- Fuel Tank: The reservoir that stores fuel until it is needed for combustion.

- Fuel Pump: A device that transfers fuel from the tank to the engine, ensuring adequate pressure and flow.

- Fuel Filter: A component that removes impurities from the fuel, protecting the engine from potential damage.

- Fuel Injectors: Nozzles that atomize fuel into the intake manifold or combustion chamber, promoting efficient mixing with air.

- Fuel Lines: Hoses or tubes that transport fuel between the tank, pump, filter, and injectors.

Understanding Component Functions

- Fuel Tank: Serves as a storage unit, preventing fuel evaporation and ensuring a constant supply.

- Fuel Pump: Electrically or mechanically operated, it generates the necessary pressure to push fuel through the lines.

- Fuel Filter: Vital for maintaining engine health by trapping dirt and contaminants, thereby prolonging component lifespan.

- Fuel Injectors: Precision devices that enhance combustion efficiency by delivering the correct amount of fuel at the right time.

- Fuel Lines: Designed to withstand high pressure, these lines ensure a safe and reliable fuel delivery system.

Common Issues with Engine Parts

When it comes to automotive machinery, various components can experience challenges that affect overall performance. Understanding these common concerns can assist in timely maintenance and repairs, ultimately enhancing the longevity and efficiency of the vehicle.

- Wear and Tear: Continuous usage can lead to the degradation of certain components, impacting their functionality.

- Leaks: Fluids may escape from seals or gaskets, resulting in decreased performance and potential damage to surrounding parts.

- Overheating: Insufficient cooling can cause components to operate at high temperatures, leading to malfunctions.

- Noises: Unusual sounds can indicate loose or damaged components that require immediate attention.

- Corrosion: Environmental factors can lead to rust and deterioration, particularly in metal parts, affecting their integrity.

Addressing these common issues promptly can prevent more significant problems down the line. Regular inspections and maintenance can ensure that the vehicle remains in optimal condition.

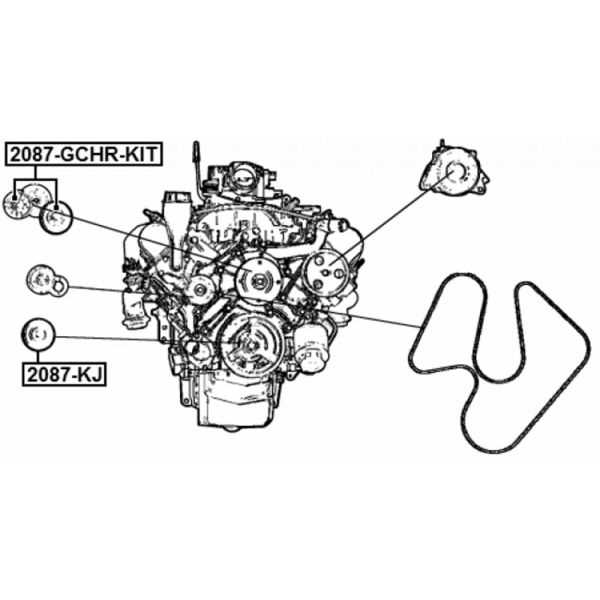

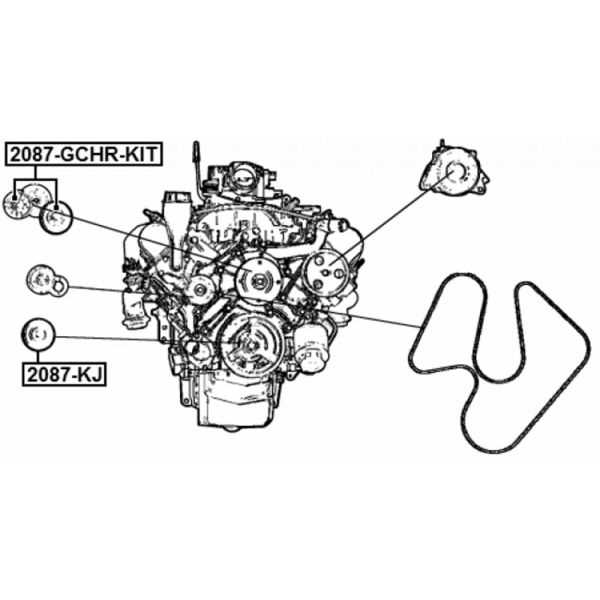

Maintenance Tips for Engine Parts

Regular upkeep of vital components is essential for ensuring optimal performance and longevity of your vehicle. By adopting proactive measures, you can prevent potential issues and enhance the efficiency of your transportation system.

- Routine Inspections: Conduct frequent checks of key components to identify wear and tear early. Look for signs of corrosion, cracks, or leaks.

- Fluid Changes: Regularly replace essential fluids such as oil and coolant to maintain proper lubrication and temperature control.

- Filter Replacements: Ensure that air and fuel filters are replaced periodically to maintain optimal airflow and fuel efficiency.

- Belts and Hoses: Examine belts and hoses for any signs of fraying or deterioration. Replace them as needed to avoid breakdowns.

- Keep It Clean: Maintain cleanliness around critical components to prevent dirt and debris from causing damage.

- Monitor Performance: Pay attention to any changes in your vehicle’s performance, such as unusual noises or reduced efficiency, and address them promptly.

By following these guidelines, you can ensure the longevity and reliability of essential components, ultimately leading to a smoother driving experience.

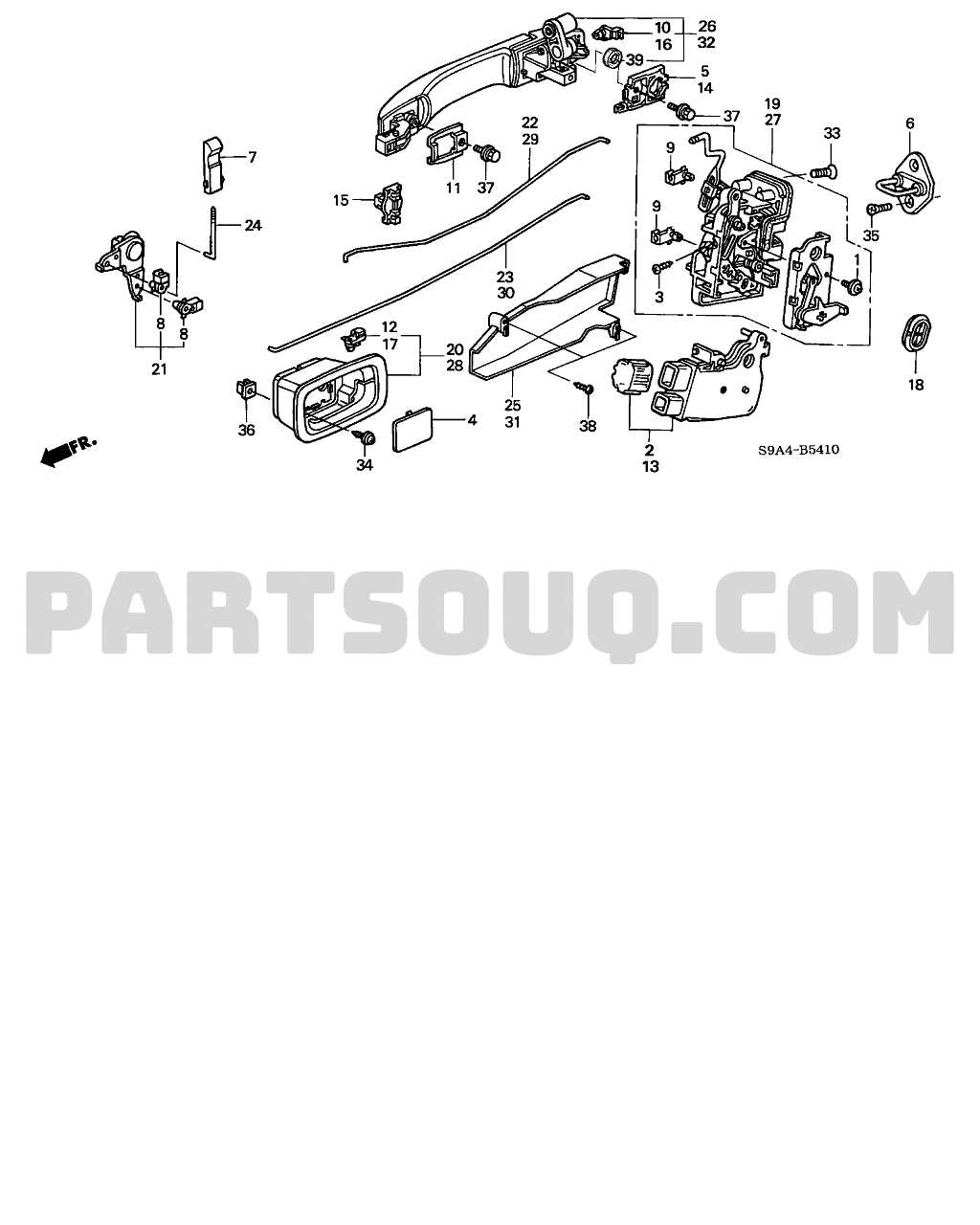

How to Replace Engine Components

Replacing various components within a mechanical system can significantly enhance performance and extend the lifespan of the vehicle. Understanding the process is crucial for maintaining the overall efficiency and reliability. This section will guide you through the essential steps and considerations involved in the replacement of key elements.

Preparation Before Replacement

Before commencing any replacement work, ensure that you have the necessary tools and materials ready. Here are some important steps to follow:

- Gather the required tools such as wrenches, screwdrivers, and pliers.

- Acquire high-quality replacement components suitable for your specific system.

- Consult the relevant manuals or resources for guidance on the process.

- Ensure the vehicle is parked on a flat surface and the engine is cool.

Steps for Component Replacement

Follow these steps to effectively replace the required components:

- Disconnect the battery to prevent any electrical issues.

- Remove any necessary covers or shields to access the components.

- Carefully detach the old parts using the appropriate tools.

- Install the new components, ensuring they are securely fastened.

- Reconnect any removed connectors and restore any covers or shields.

- Reconnect the battery and perform a test to verify proper operation.