In the realm of construction and craftsmanship, various implements serve crucial roles in shaping materials and facilitating projects. A specific tool stands out for its versatility and efficiency, playing an essential part in both professional and DIY endeavors. By dissecting its structure, one can appreciate the intricate interplay of its elements and how they contribute to its functionality.

Each element of this implement has a unique role, designed to optimize performance while ensuring safety and ease of use. From the striking surface to the supportive handle, every feature is crafted with purpose. Understanding these individual characteristics enhances not only practical skills but also deepens the appreciation for the craftsmanship involved in tool design.

As we explore the different segments, we will uncover how each contributes to the overall effectiveness of this indispensable device. This exploration provides valuable insights for users looking to improve their techniques and achieve superior results in their projects.

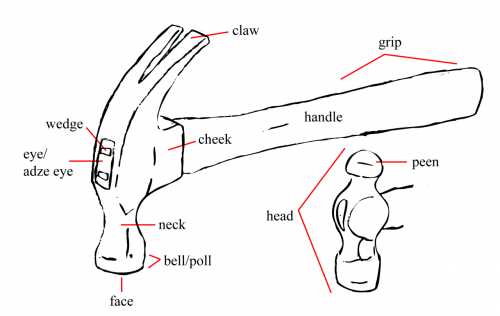

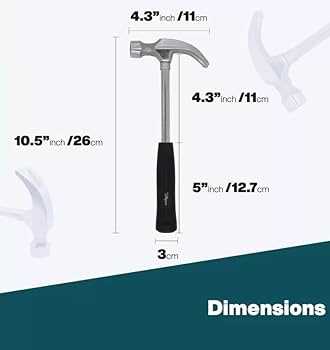

Understanding Hammer Anatomy

Gaining insight into the structure of this essential tool allows users to maximize its functionality and efficiency. Each component plays a specific role, contributing to its overall effectiveness in various tasks, whether in construction, crafting, or repair work.

Main Components

- Striking Surface: The area designed for impact, crafted to endure repeated blows.

- Handle: The part that provides grip and control, often made from wood or composite materials.

- Head: The entire upper portion, which can vary in shape depending on its intended use.

- Claw: A feature found on specific designs, useful for pulling nails or prying objects apart.

Material Considerations

- Durability: Selecting robust materials ensures longevity and performance under stress.

- Weight: Heavier models can deliver more force, while lighter options enhance maneuverability.

- Comfort: Ergonomic designs reduce fatigue during extended use, promoting efficiency.

By understanding these elements, users can choose the right tool for their needs and improve their overall effectiveness in various projects.

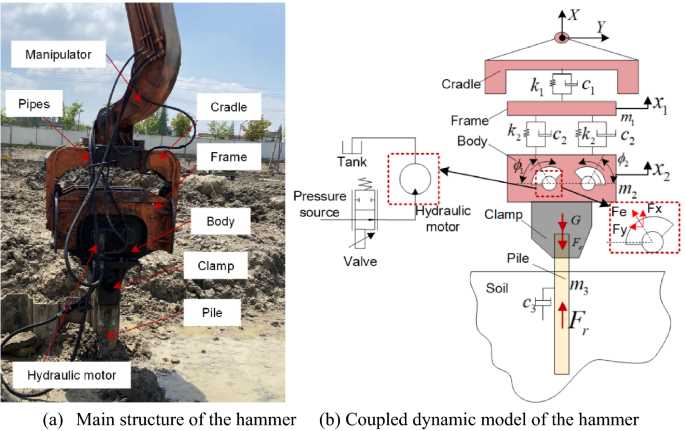

Types of Hammers and Their Uses

Various tools designed for striking serve distinct purposes across a range of tasks. Understanding the differences can enhance efficiency and effectiveness in both professional and DIY projects. Each variant is tailored to specific materials and applications, making them invaluable in different contexts.

Common Variants

Claw Tool is primarily used for driving nails and removing them. Its dual functionality makes it a staple in woodworking and general construction. Another popular choice is the sledge tool, ideal for heavy-duty tasks requiring substantial force, such as breaking concrete or driving stakes into the ground.

Specialized Tools

For delicate work, an awning tool provides precision without damaging the surface, perfect for upholstery or light carpentry. In contrast, a ball-peen variant is often utilized in metalworking, suitable for shaping and peening metal joints. Each type plays a crucial role in its respective field, ensuring tasks are completed effectively.

Components of a Hammer Explained

This section explores the essential elements that contribute to the functionality and effectiveness of a striking tool. Each component plays a vital role, ensuring that the implement serves its purpose efficiently.

Key Elements

- Head: The striking surface designed for impact.

- Claw: Often found on one side, useful for pulling out nails.

- Handle: Provides grip and control during use.

Material Choices

- Steel: Commonly used for durability in the head.

- Wood: Traditional choice for handles, offering natural grip.

- Fiberglass: Modern alternative, providing strength and shock absorption.

Materials Used in Hammer Construction

The choice of materials in crafting tools significantly influences their durability and effectiveness. A combination of robust substances is typically employed to ensure optimal performance and longevity during various applications.

Common Materials

Steel is frequently utilized for the striking surface due to its hardness and resistance to wear. The handle may be crafted from wood or fiberglass, each providing unique benefits such as shock absorption and ease of handling.

Innovative Alternatives

Modern innovations have introduced composite materials, offering enhanced strength-to-weight ratios. These alternatives can improve user experience by reducing fatigue and increasing precision during use.

Functionality of the Hammer Head

The head of this tool serves as the primary component responsible for delivering force and precision during various tasks. Its design is essential for maximizing effectiveness in driving or removing materials, showcasing the importance of weight distribution and shape.

Impact Efficiency: The head is crafted to focus kinetic energy at the point of contact, ensuring that each strike yields optimal results. This allows for effective penetration into surfaces, whether it be nails or other materials.

Versatility: Different shapes and sizes of the head enable it to tackle a variety of applications, from construction to woodworking. Each variation is tailored to meet specific needs, enhancing functionality.

Durability: The materials used in the head’s construction are selected for their strength and resilience, enabling it to withstand repeated use and resist deformation, ultimately prolonging its lifespan.

In summary, the head’s design and functionality are crucial for achieving the desired outcomes in manual tasks, emphasizing the tool’s role in both precision and power.

Importance of the Hammer Handle

The element that serves as the gripping point plays a crucial role in the effectiveness and usability of striking tools. Its design and construction significantly influence the overall performance, comfort, and control during tasks. An optimal gripping surface not only enhances user experience but also improves safety by reducing the risk of slippage.

Comfort and Ergonomics: A well-designed grip accommodates the natural contours of the hand, allowing for prolonged use without discomfort. This ergonomic approach minimizes strain and fatigue, enabling users to complete tasks efficiently.

Control and Precision: The connection between the hand and the striking component is vital for accurate movements. A secure hold ensures that force is directed precisely where needed, enhancing the effectiveness of each strike and improving overall results.

Material and Durability: The composition of the gripping element affects its longevity and resistance to wear. High-quality materials not only provide a better grip but also withstand the rigors of frequent use, ensuring reliability over time.

In summary, the significance of the gripping portion cannot be overstated. Its impact on comfort, control, and durability is essential for achieving optimal performance in various tasks.

Weight Distribution in Hammers

The balance of mass within a striking tool significantly influences its performance and usability. Understanding how weight is allocated across its structure can enhance effectiveness in various applications.

Optimal weight distribution allows for better control and reduces fatigue during extended use. For instance, a tool with more mass concentrated at the striking end can deliver stronger impacts, while a more balanced design facilitates precision and reduces the effort required for each swing.

Designers often experiment with different materials and shapes to achieve the ideal combination of strength and maneuverability. This careful consideration ensures that users can achieve their ultimate goals, whether in construction or crafting.

Choosing the Right Hammer for Tasks

Selecting the appropriate tool for various activities can significantly enhance efficiency and precision. Each task often requires a specific design and weight distribution to achieve optimal results. Understanding the unique features of different instruments will ensure that you are well-equipped to handle any project that comes your way.

Understanding Your Needs

Before making a choice, assess the requirements of your project. Consider the materials you will be working with, the type of impact needed, and the scale of your tasks. Some projects may demand a heavier model for driving in nails or breaking apart materials, while others might call for a lighter option for delicate work.

Evaluating Options

There are numerous types available, each tailored for specific functions. For general construction, a versatile variant may suffice, while specialized versions can improve performance in niche applications. Additionally, handle design and grip comfort are crucial factors that influence effectiveness and safety during use.