When working with outdoor equipment, it’s essential to have a clear understanding of how various elements come together to ensure smooth operation. Each component plays a vital role in maintaining performance and ensuring longevity. By exploring the structure and layout of key elements, users can more effectively manage repairs and maintenance.

For those looking to extend the lifespan of their equipment, familiarizing themselves with the internal mechanisms is crucial. Knowing where each component is located and how it interacts with others allows for quick troubleshooting and more efficient upkeep.

With a focus on practical guidance, this guide aims to provide a clear overview of the essential elements and their placement. It serves as a useful reference for anyone looking to enhance their knowledge and improve the reliability of their gardening tools.

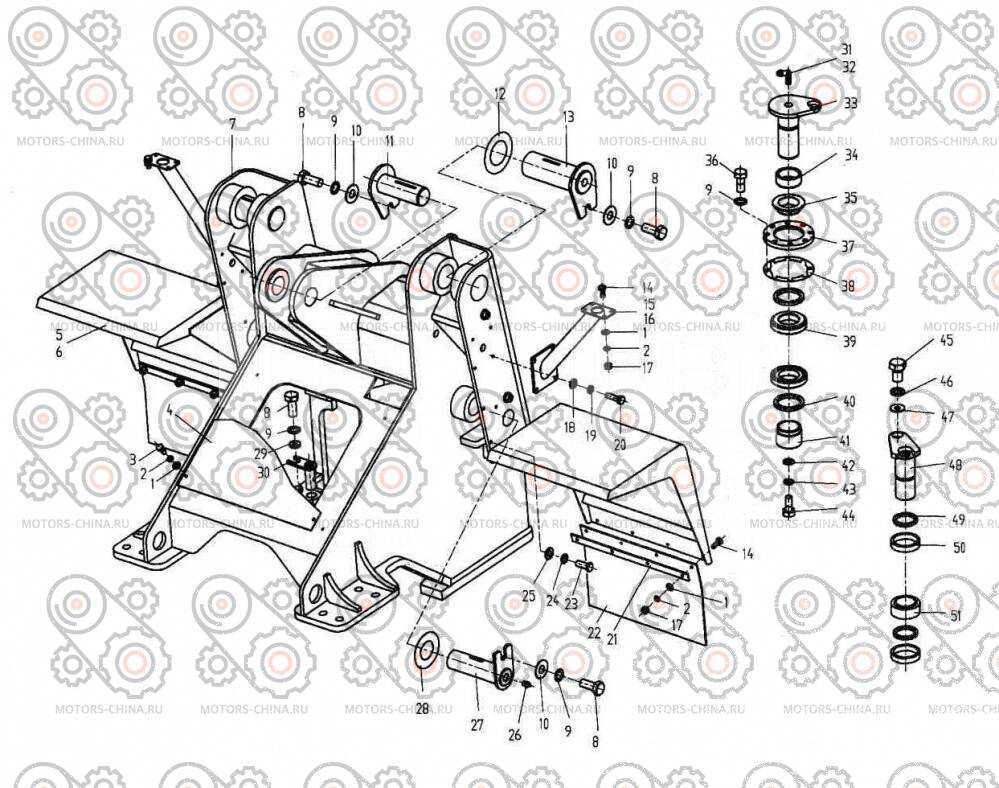

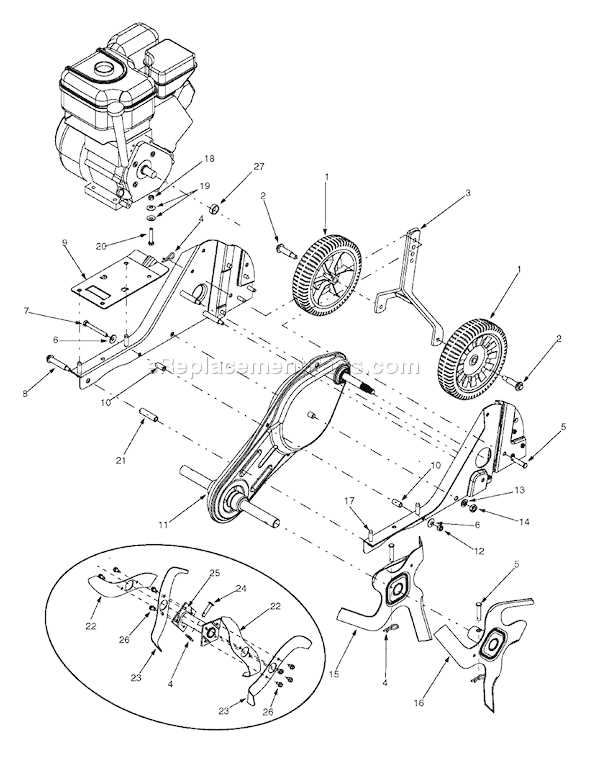

Huskee Tiller Parts Overview

The components of this gardening tool work together to ensure efficient soil preparation and maintenance. Each element plays a crucial role in the overall functionality, contributing to both durability and performance. Understanding how these pieces interact can help in maintaining and repairing the equipment, ensuring longevity and optimal results during use.

From the engine to the tines, every part is designed with precision to handle the demands of heavy-duty tasks. By keeping each component in good condition, users can ensure smooth operation and prevent potential issues that could disrupt gardening activities.

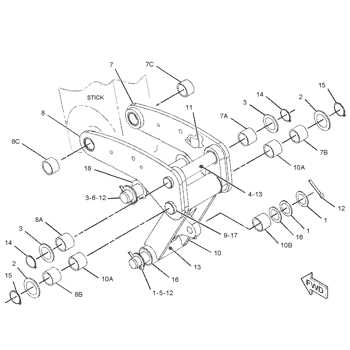

Identifying Key Components of a Tiller

The overall design of soil cultivation machines includes several critical elements, each contributing to its efficient operation. Understanding these main parts is essential for proper maintenance and usage. By recognizing the functions of each segment, users can ensure the equipment runs smoothly and addresses different terrain and soil conditions effectively.

Engine and Drive System

The engine serves as the heart of the machine, powering all movements and actions. Connected to this is the drive system, which transmits power from the motor to the working elements. Ensuring both the engine and transmission components are functioning optimally is key to achieving reliable performance.

Blades and Depth Adjustments

The cutting blades, positioned at the front or bottom, are responsible for breaking up and turning the soil. Their sharpness and angle determine the effectiveness of the task. Depth control mechanisms, often adjustable, allow for customization depending on soil type and the desired depth of penetration, offering flexibility in various gardening or farming tasks.

Engine Parts Essential for Operation

The functioning of any motorized equipment relies heavily on key components that work together to ensure smooth performance and longevity. Each of these elements plays a critical role in powering the machine and maintaining its efficiency. Below is an overview of the most important engine elements necessary for proper operation.

- Cylinder: The heart of the engine, where fuel combustion occurs, generating the power that drives the machine.

- Crankshaft: Converts the linear motion of the pistons into rotational movement, transferring energy to other mechanisms.

- Pistons: Move up and down within the cylinder, compressing fuel and air for ignition, which powers the engine.

- Spark Plug: Provides the necessary spark to ignite the fuel-air mixture within the cylinder, initiating the combustion process.

- Carburetor: Mixes air and fuel in the correct proportions, ensuring the engine runs smoothly and efficiently.

- Fuel Filter: Ensures that clean fuel reaches the engine by filtering out contaminants that could cause damage or reduce performance.

- Air Filter: Prevents dust and debris from entering the engine, ensuring optimal combustion and reducing wear on

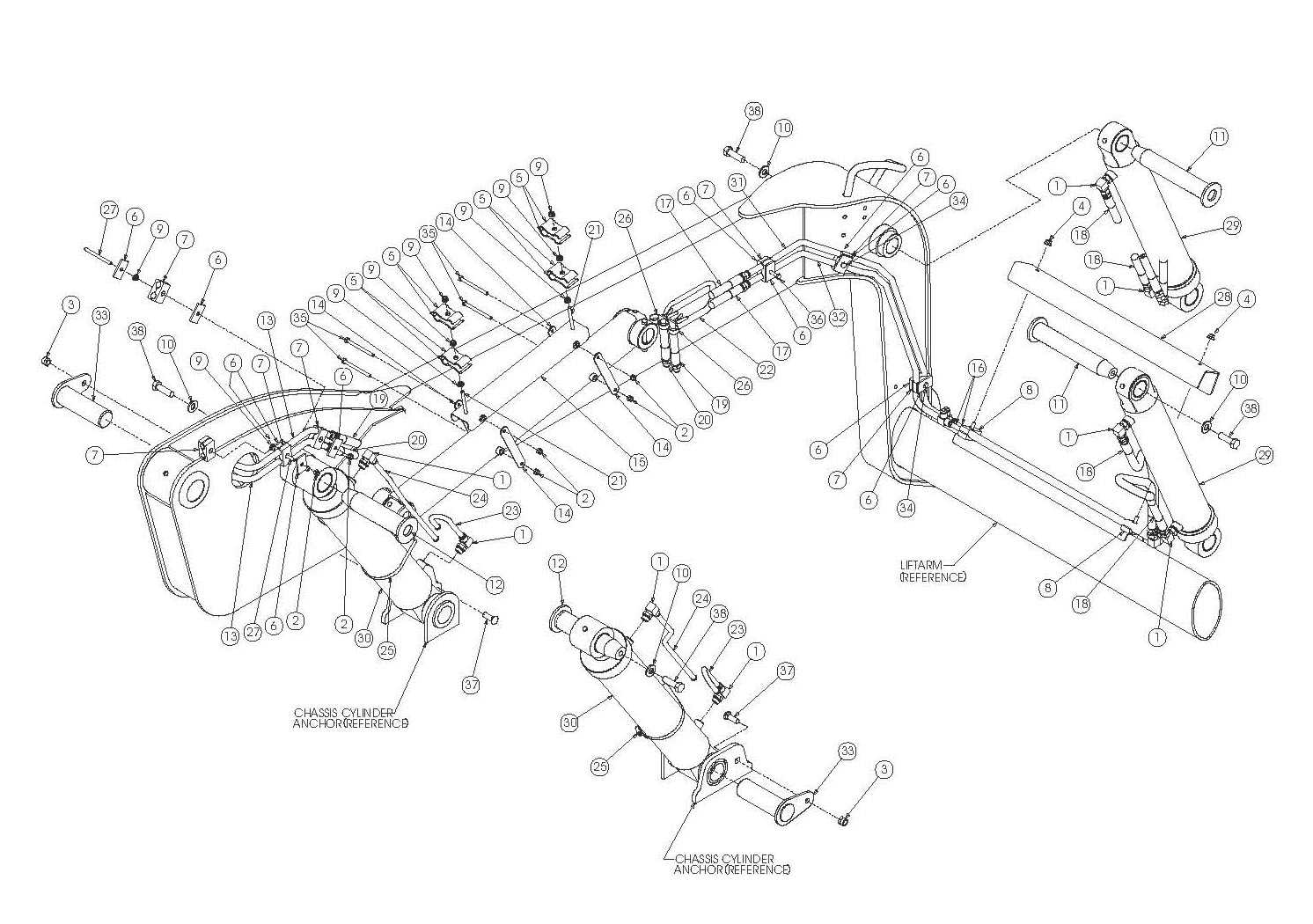

How the Transmission System Functions

The transmission system plays a crucial role in transferring power from the engine to the machine’s wheels or blades, allowing it to operate effectively across different terrains and under various conditions. This mechanism ensures that the energy produced by the engine is directed and regulated, offering smooth transitions between speeds and maximizing efficiency.

Key Components of the transmission system include gears, belts, and shafts, all working together to distribute the engine’s power evenly. Each of these elements is designed to handle specific tasks within the system, ensuring that the right amount of force is applied where needed.

The functionality of this system depends on the seamless interaction between these components, with gears controlling the speed and belts or chains delivering the force to the operating parts of the equipment. Regular maintenance is essential to keep this system running smoothly, preventing wear and tear from affecting overall performance.

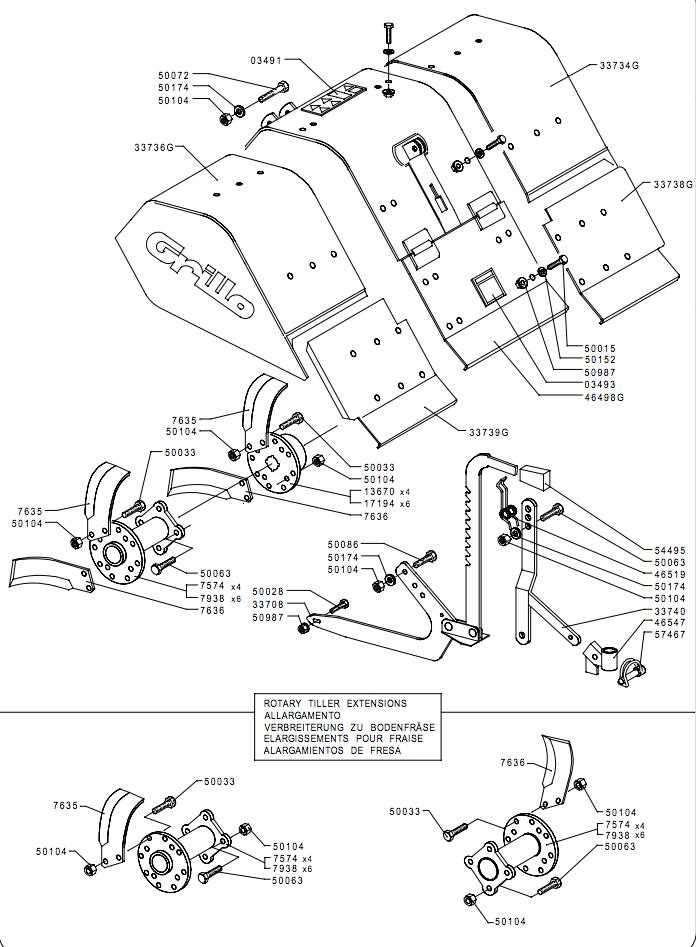

Maintaining Blades for Optimal Performance

Ensuring the efficiency of cutting instruments is crucial for achieving outstanding results in soil preparation. Regular upkeep not only enhances performance but also prolongs the lifespan of the equipment. By focusing on essential maintenance practices, users can significantly improve the functionality of their machinery.

Regular Inspection and Sharpening

Frequent checks for wear and tear are vital. Dull blades can lead to inefficient operation and potential damage to the surrounding equipment. Keeping blades sharp ensures a clean cut, which is beneficial for soil health and overall garden productivity. Sharpening should be done using appropriate tools and techniques, allowing for precise angles and effective cutting surfaces.

Cleaning and Lubrication

Post-use cleaning helps prevent the buildup of dirt and debris, which can hinder performance. Lubricating moving parts reduces friction and wear, facilitating smoother operation. Regularly applying a suitable lubricant keeps components functioning optimally, contributing to the overall efficiency of the machinery.

Maintenance Task Frequency Purpose Inspection After each use Identify wear and damage Sharpening As needed Maintain cutting efficiency Cleaning After each use Prevent buildup of debris Lubrication Monthly Reduce friction Clutch Assembly and Its Role

The clutch assembly is a vital component in the operation of various gardening machines, providing the necessary connection between the engine and the cutting mechanism. Its primary function is to engage and disengage the drive, allowing the user to control the power transmitted to the implement.

This assembly typically consists of several parts, including the clutch plate, springs, and housing. When engaged, the clutch plate connects the engine’s power to the blades or tines, enabling effective operation. Conversely, disengaging the clutch interrupts this connection, ensuring safety and preventing damage when adjustments or maintenance are needed.

Understanding the clutch assembly’s role can significantly enhance the user’s ability to operate the machine efficiently. Regular maintenance and timely replacement of worn components are essential to ensure optimal performance and prolong the lifespan of the equipment.

Replacing the Drive Belt Effectively

Replacing the drive belt is a crucial maintenance task that ensures optimal performance of your equipment. A worn or damaged belt can lead to inefficiency and potential breakdowns, making timely replacement essential for smooth operation.

Before starting the replacement process, gather the necessary tools, including a wrench, screwdriver, and a new drive belt. Ensure that the equipment is powered off and completely cool to prevent any injuries. Removing the old belt typically involves loosening the tensioner and detaching the belt from the pulleys.

Once the old belt is removed, compare it with the new one to confirm compatibility. Install the new drive belt by threading it through the appropriate pulleys, ensuring it fits snugly in place. Adjust the tension to the manufacturer’s specifications to prevent slippage during operation.

After installation, double-check all components and ensure everything is secure. Running a test cycle will help verify that the belt functions correctly, allowing for efficient performance of your machinery.

Understanding the Gear Mechanism

The gear mechanism plays a crucial role in the efficient functioning of various machinery. It is responsible for transferring power and motion between different components, allowing for smooth operation. By utilizing interlocking gears, this system enhances torque and speed, making it essential for achieving optimal performance.

At its core, the gear assembly consists of several rotating elements that engage with one another. Each gear is designed with specific tooth configurations that dictate how it meshes with neighboring gears. This meshing is vital for converting input motion into desired output, effectively increasing or decreasing rotational speed as required.

Understanding the intricacies of this mechanism can help users troubleshoot and maintain their equipment effectively. Regular inspections of the gear system can prevent wear and tear, ensuring longevity and reliability. Knowledge of gear ratios and their impact on performance is also important for maximizing the efficiency of machinery.

Tips for Long-lasting Tiller Maintenance

Ensuring the durability of gardening equipment requires consistent care and attention. By following a few essential practices, you can enhance the performance and lifespan of your machinery. Regular maintenance not only improves efficiency but also saves on potential repair costs in the long run.

Regular Inspections

- Check for any visible wear and tear before each use.

- Inspect belts and cables for signs of fraying or damage.

- Look for loose screws or bolts that may need tightening.

Routine Cleaning

- Remove dirt and debris after each session to prevent buildup.

- Clean the engine and exterior with a damp cloth and mild detergent.

- Ensure that air filters are free of dust for optimal airflow.

Proper Storage

- Store equipment in a dry, sheltered area to protect it from the elements.

- Use covers to shield against dust and moisture.

- Remove fuel from the tank if storing for an extended period to prevent gumming.