In the realm of machinery and equipment, comprehending the intricate relationships between various elements is crucial for optimal performance and maintenance. This exploration delves into the intricate network of components that work in unison, ensuring functionality and reliability. Recognizing how each piece contributes to the overall system enhances not only troubleshooting skills but also the ability to implement effective upgrades.

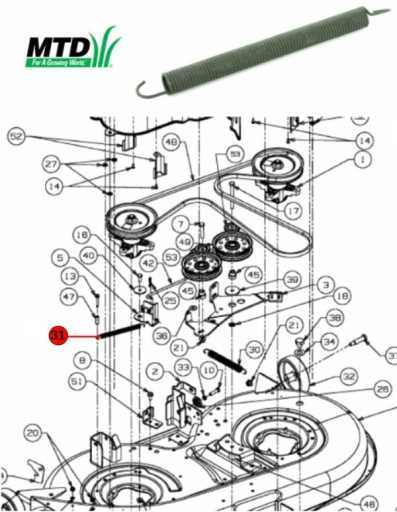

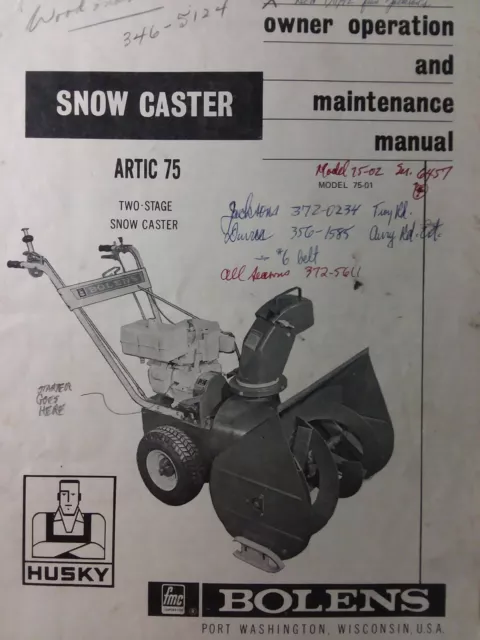

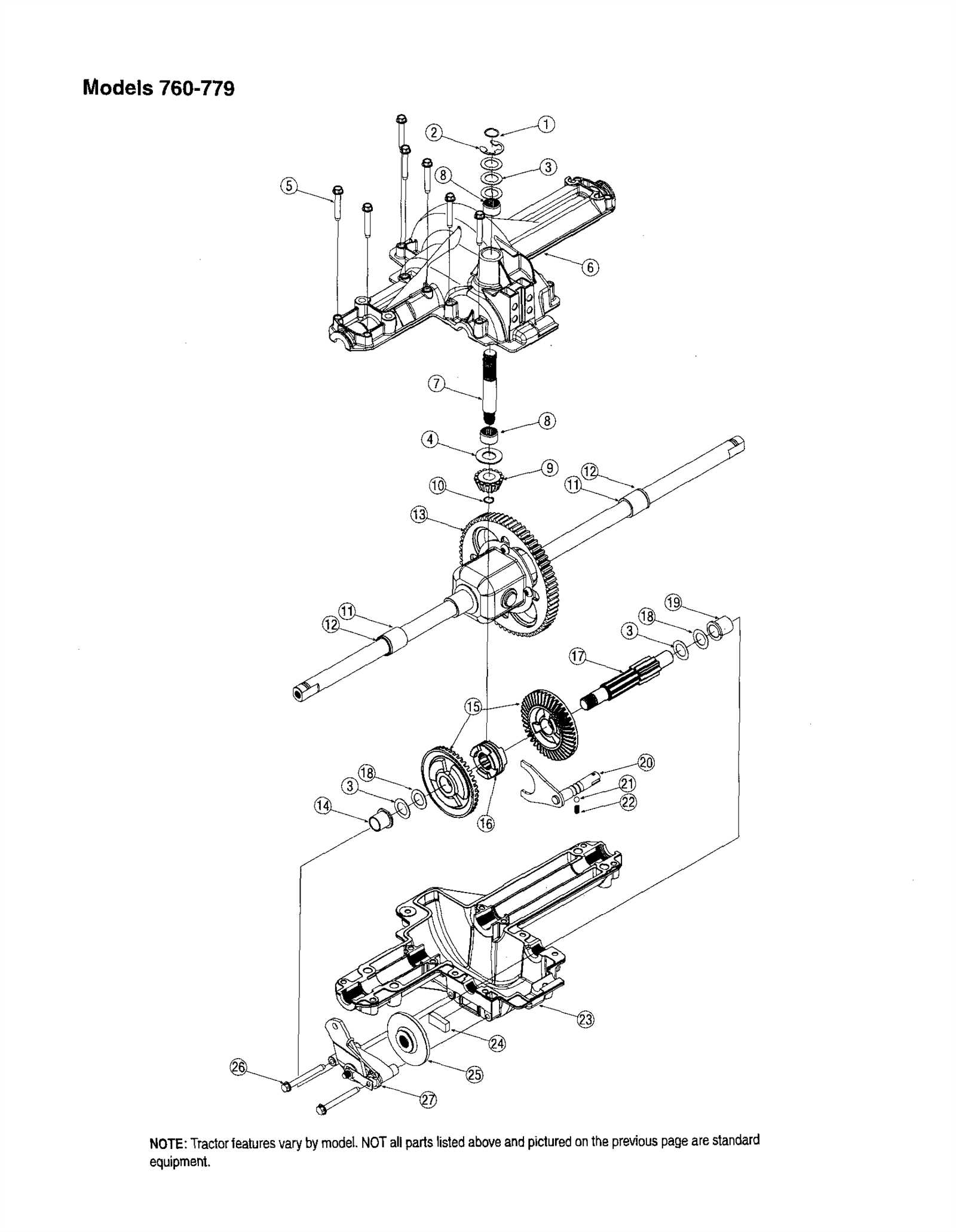

Detailed representations of these elements can illuminate their specific roles and interactions. Such illustrations serve as invaluable resources for technicians and enthusiasts alike, providing insights into assembly and disassembly processes. By gaining a thorough understanding of these individual segments, users can enhance their operational efficiency and ensure the longevity of their devices.

Moreover, this knowledge empowers users to make informed decisions when sourcing replacements or upgrades, ultimately leading to improved performance. By familiarizing oneself with the structure and organization of these integral parts, one can navigate the complexities of machinery with confidence and precision.

Understanding the 13am762f765 Components

To effectively maintain and repair machinery, it’s crucial to comprehend the various elements that contribute to its functionality. Each component plays a specific role, working in harmony with others to ensure optimal performance. By familiarizing oneself with these parts, one can diagnose issues more accurately and implement solutions efficiently.

Core Elements: The foundational units of any equipment are designed to withstand stress and provide reliable operation. These components often include structural frames, drive systems, and control mechanisms that are essential for proper functionality. Understanding their construction and interaction is key to enhancing overall performance.

Interconnectivity: It’s important to recognize how these units connect and communicate. Many rely on a network of fasteners, levers, and pulleys that allow them to work together seamlessly. This interdependence means that a malfunction in one area can affect the entire system, highlighting the need for thorough knowledge of each part’s role.

Maintenance Considerations: Regular inspections and maintenance of these elements can prevent costly breakdowns. Knowing which components are prone to wear and how to access them for servicing is vital for anyone involved in machinery upkeep. Developing a routine that includes checking these parts will extend the lifespan of the equipment.

By understanding the intricacies of these essential components, operators and technicians can ensure that their machinery remains efficient and reliable, ultimately enhancing productivity and reducing downtime.

Importance of Parts Diagrams

Visual representations of components play a crucial role in understanding complex machinery. They serve as essential tools for both assembly and maintenance, allowing users to grasp the relationships between various elements effectively. Such illustrations enhance clarity and facilitate accurate repairs, ultimately reducing downtime and improving efficiency.

Enhancing Communication

Clear visual guides foster better communication among technicians, engineers, and operators. They provide a common language, making it easier to convey instructions and troubleshoot issues. This shared understanding is vital for collaboration and successful project completion.

Streamlining Maintenance

Access to comprehensive visual references simplifies the maintenance process. Technicians can quickly identify required components, ensuring timely interventions. This not only saves time but also minimizes the risk of errors, contributing to the longevity and reliability of the equipment.

Common Issues with 13am762f765

When dealing with specific machinery components, users often encounter various challenges that can affect performance and reliability. Understanding these frequent problems is crucial for maintaining functionality and extending the lifespan of the equipment. This section highlights some prevalent issues that may arise during usage.

Mechanical Failures

One of the primary concerns involves mechanical breakdowns, which can occur due to wear and tear over time. These failures can manifest as unusual noises or decreased efficiency. Regular inspections and timely replacements of worn elements can mitigate such risks.

Electrical Problems

Another common issue relates to electrical components that may malfunction. This can lead to inconsistent operation or complete failure to start. Users should pay attention to signs such as flickering lights or erratic performance, which may indicate underlying electrical faults. Regular maintenance checks and proper troubleshooting are essential to ensure optimal performance.

How to Read Parts Diagrams

Understanding the visual representations of components can significantly enhance your ability to assemble or repair various equipment. These illustrations serve as a roadmap, guiding you through the intricate details of each element, making it easier to identify, locate, and replace them when necessary. Mastering this skill can save you time and reduce frustration in any project involving machinery or devices.

Identifying Components

The first step in interpreting these visuals is to familiarize yourself with the symbols and labels used. Each element is typically accompanied by a reference number or letter that corresponds to a list detailing its specifications. Paying attention to the layout is crucial, as it often reflects the order of assembly or the relationship between different elements.

Understanding Connections

Another important aspect is recognizing how the parts fit together. Look for lines or arrows that indicate connections, pathways, or the flow of operation. These cues help you visualize how each component interacts within the larger system, ensuring a more efficient approach to any task at hand.

Where to Find Replacement Parts

Locating suitable components for machinery can be a straightforward process if you know where to look. Various resources are available that cater to different needs, ensuring that you can maintain and repair your equipment effectively.

Online Resources

The internet offers a wealth of options for sourcing components. Here are some key places to explore:

- Manufacturer Websites: Start with the official site of the manufacturer for authentic items and specifications.

- Specialty Retailers: Many online stores specialize in specific types of equipment, providing a range of options.

- Marketplaces: Platforms like eBay and Amazon often have listings from various sellers, allowing for price comparisons.

Local Options

If you prefer to shop in person, consider these local avenues:

- Authorized Dealers: These retailers typically carry genuine items and can offer expert advice.

- Repair Shops: Local technicians may have spare components or can guide you on where to find what you need.

- Salvage Yards: For older models, these places can be treasure troves for hard-to-find parts at a lower cost.

Maintenance Tips for Longevity

Proper care and regular upkeep are essential for ensuring the extended life of any mechanical device. By following a few straightforward practices, you can enhance performance and reduce the likelihood of unexpected failures. This guide provides essential tips to maintain your equipment effectively, keeping it in optimal condition for years to come.

Regular Inspection

Conducting routine checks can help identify potential issues before they escalate. Look for signs of wear, such as fraying cables or corrosion. Regular assessments allow for timely repairs, ensuring that all components function smoothly and efficiently.

Lubrication and Cleaning

Maintaining cleanliness is crucial for operational efficiency. Regularly remove dirt and debris that can impede functionality. Additionally, applying appropriate lubricants to moving parts minimizes friction, reducing wear and tear. This simple step can significantly extend the lifespan of your machinery.

Assembly Instructions for 13am762f765

Proper assembly is crucial for ensuring the optimal performance of your equipment. This guide outlines the necessary steps to successfully combine various components into a cohesive unit. By following these instructions carefully, you can achieve a reliable and efficient setup.

Step 1: Prepare Your Workspace

Begin by organizing your workspace to ensure you have ample room to work. Gather all required items and tools beforehand to avoid interruptions during the assembly process.

Step 2: Review the Components

Familiarize yourself with each element involved in the construction. Understanding the function and placement of each part will facilitate a smoother assembly process.

Step 3: Start the Assembly

Begin by attaching the foundational components. Ensure that each piece fits snugly and securely. Pay attention to any alignment indicators that guide proper positioning.

Step 4: Secure Connections

Once the base is in place, proceed to connect additional sections. Utilize the appropriate fasteners and tools to ensure a tight fit. Double-check that each connection is stable and reliable.

Step 5: Final Adjustments

After assembling all parts, inspect the complete structure for any discrepancies. Make necessary adjustments to ensure everything is aligned correctly. Tighten any loose connections to enhance durability.

Step 6: Testing

Before putting the assembled unit into regular use, conduct thorough testing. Check for any unusual noises or movements, and confirm that all functions operate as intended.

By adhering to these assembly steps, you can ensure a successful build, leading to enhanced performance and longevity of your equipment.

Comparative Analysis of Similar Models

This section aims to explore the similarities and differences among various models within the same category, highlighting their unique features and performance characteristics. By examining these aspects, we can better understand the options available and make informed decisions based on specific needs and preferences.

Key Features Comparison

- Design: Evaluate the structural layout and ergonomics.

- Performance: Compare engine capabilities, speed, and efficiency.

- Durability: Assess materials used and overall longevity.

- Technology: Analyze the incorporation of advanced features and user interfaces.

Market Positioning

- Target Audience: Identify the primary users for each model.

- Price Range: Compare the cost structures and perceived value.

- Brand Reputation: Examine consumer feedback and brand loyalty.

- Availability: Look into distribution channels and accessibility.

Understanding these elements will provide a clearer picture of how these models stand in relation to one another, assisting consumers in making the best choice tailored to their requirements.

Expert Recommendations for Users

For individuals navigating the complexities of mechanical assemblies, understanding the intricacies involved is crucial. Expert insights can significantly enhance user experience and ensure optimal functionality. This section provides valuable tips to maximize the efficiency and longevity of your equipment.

Key Tips for Maintenance

Regular upkeep is essential for sustaining performance. Implementing a systematic maintenance routine can prevent potential issues and extend the lifespan of your machinery.

| Action | Frequency | Benefits |

|---|---|---|

| Inspection | Monthly | Identifies wear and tear early |

| Lubrication | Bi-weekly | Reduces friction and overheating |

| Cleaning | Weekly | Prevents buildup of debris |

Choosing Quality Components

Selecting high-grade elements is vital for achieving optimal performance. Always consider reliability and compatibility when sourcing replacements to ensure seamless operation.