When it comes to navigating the waters, having a reliable propulsion mechanism is essential. Various components work together seamlessly to ensure smooth operation and maneuverability. Understanding the intricate relationships among these elements can significantly enhance your boating experience.

In this section, we will explore the essential components of these systems, delving into their functions and interactions. By gaining insight into the specific features and layouts, you can make informed decisions regarding maintenance and upgrades.

Equipped with knowledge about the arrangement and role of each element, you’ll be better prepared to tackle any issues that may arise. This ultimate guide aims to empower you with the necessary understanding to optimize your aquatic adventures.

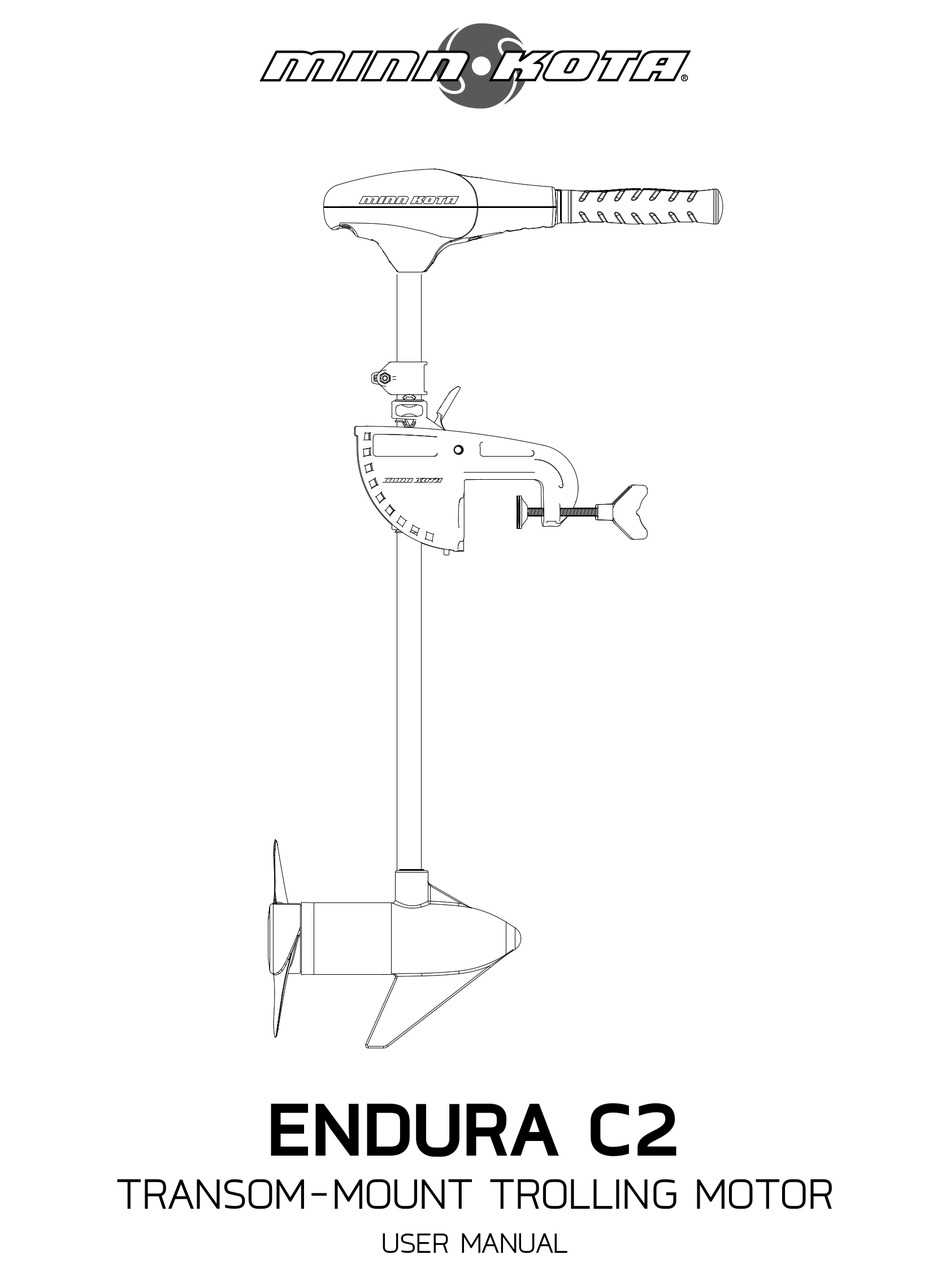

Minn Kota Trolling Motor Overview

This section provides an insight into the essential components and functionalities of propulsion devices designed for aquatic environments. These mechanisms enhance navigation and allow for precise maneuvering, making them indispensable for fishing and leisure activities on the water.

Key Features

Advanced propulsion systems come equipped with several notable features that improve user experience. Durability is a primary characteristic, ensuring reliable performance even in challenging conditions. Additionally, many models offer variable speed settings, allowing operators to adjust their pace according to specific needs.

Maintenance and Care

Proper maintenance is crucial for the longevity of these devices. Regular inspections of electrical components and propulsion units can prevent malfunctions. Cleaning and protecting the exterior from corrosion also contribute significantly to sustaining optimal performance over time.

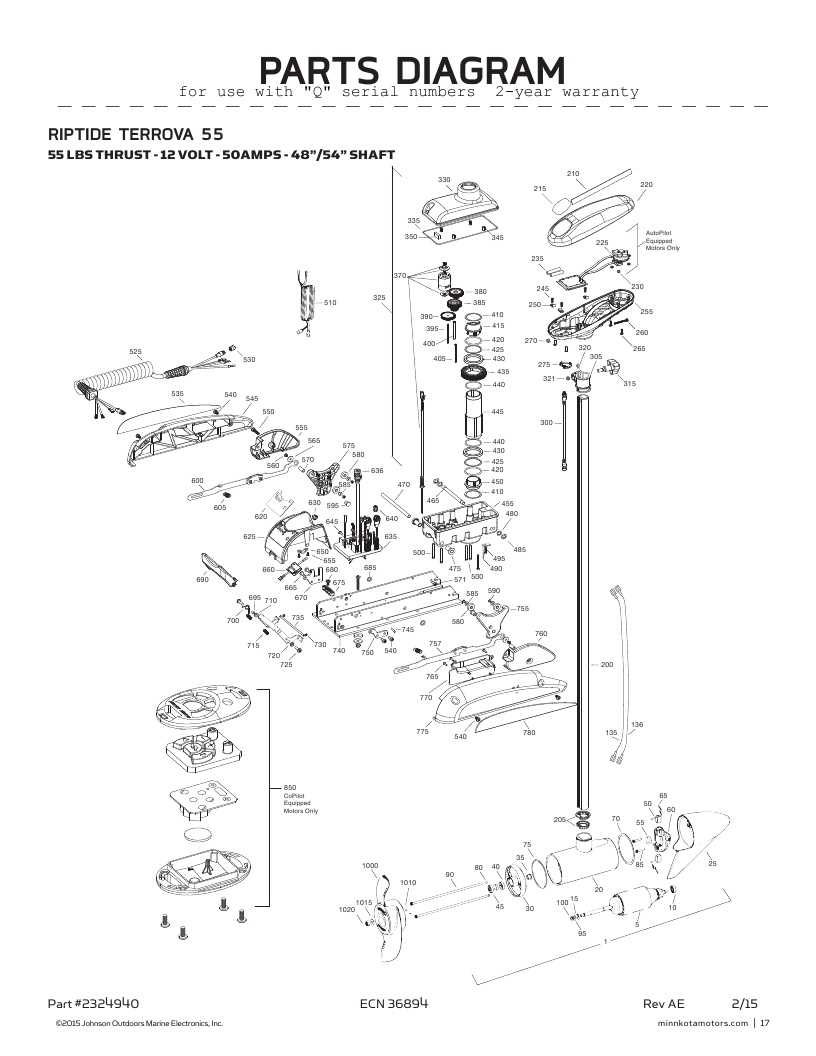

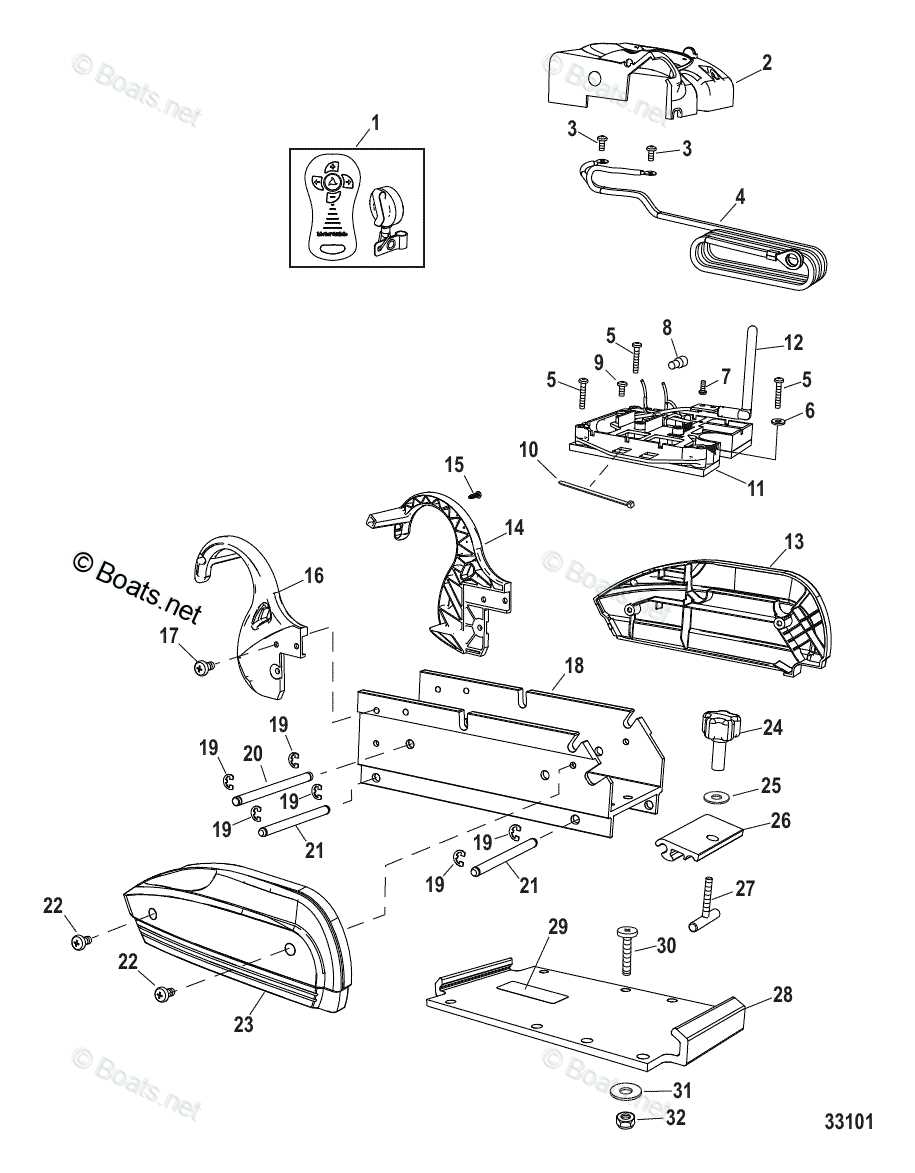

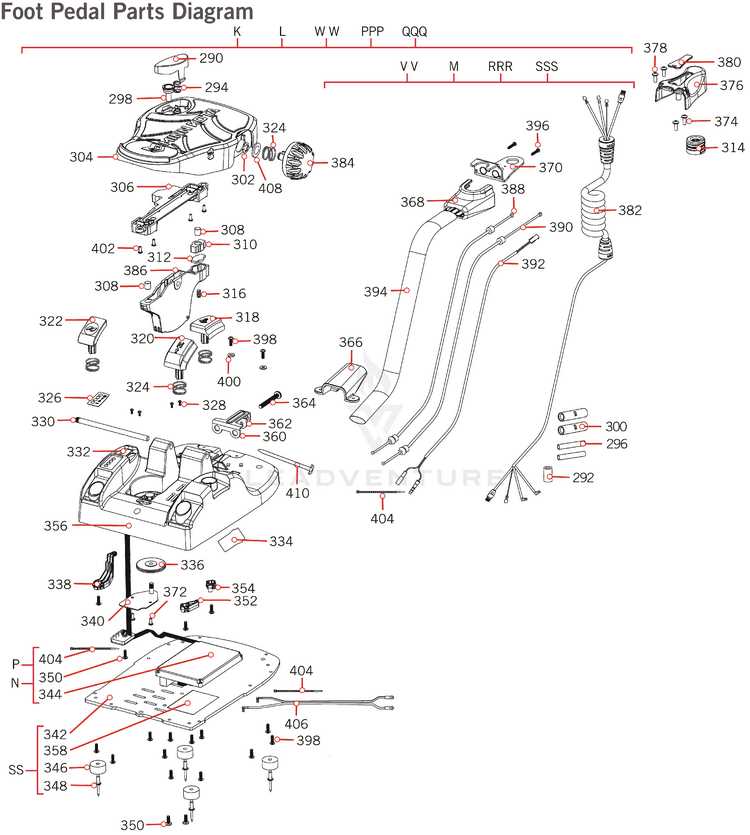

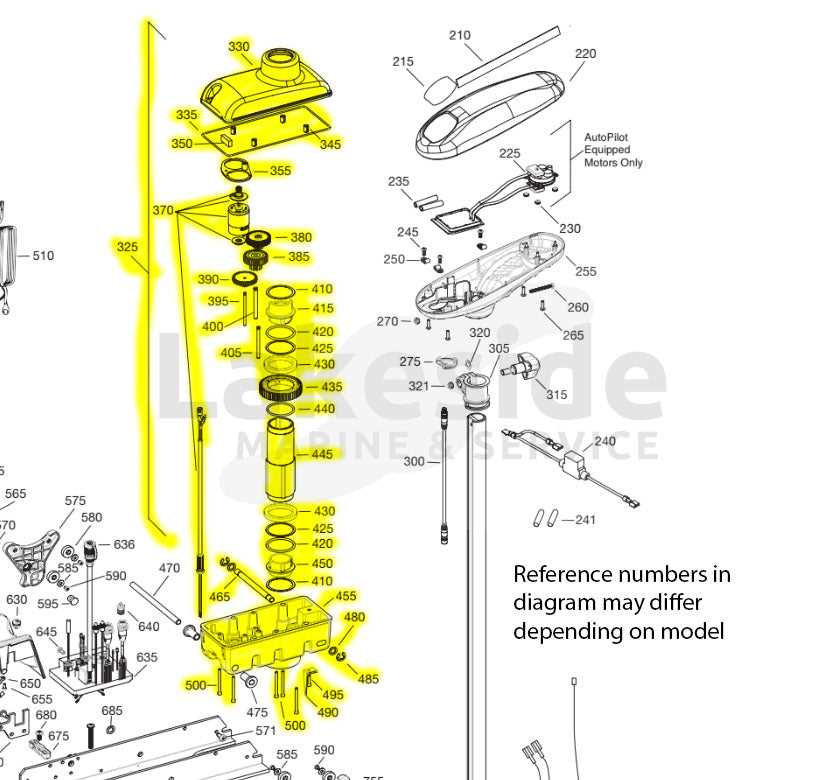

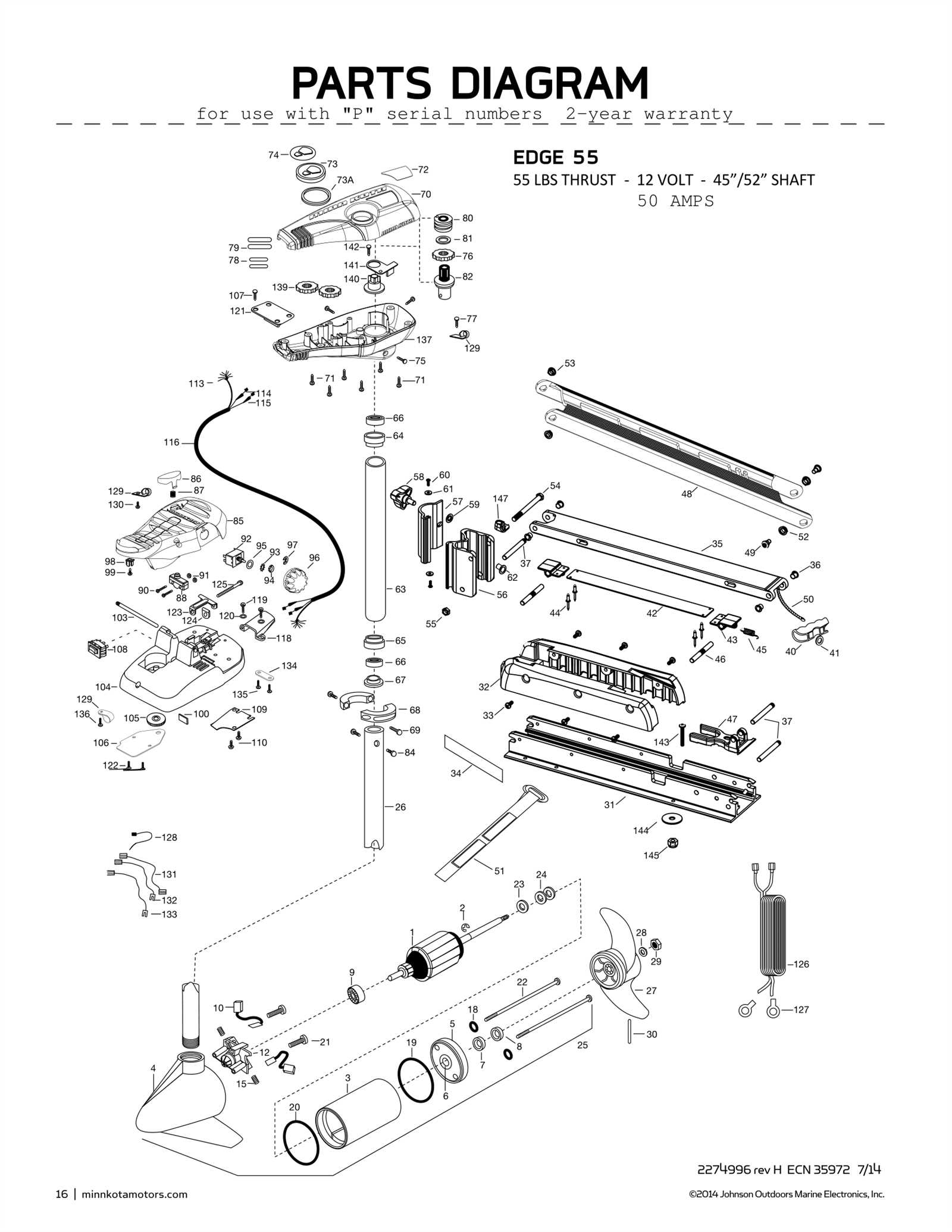

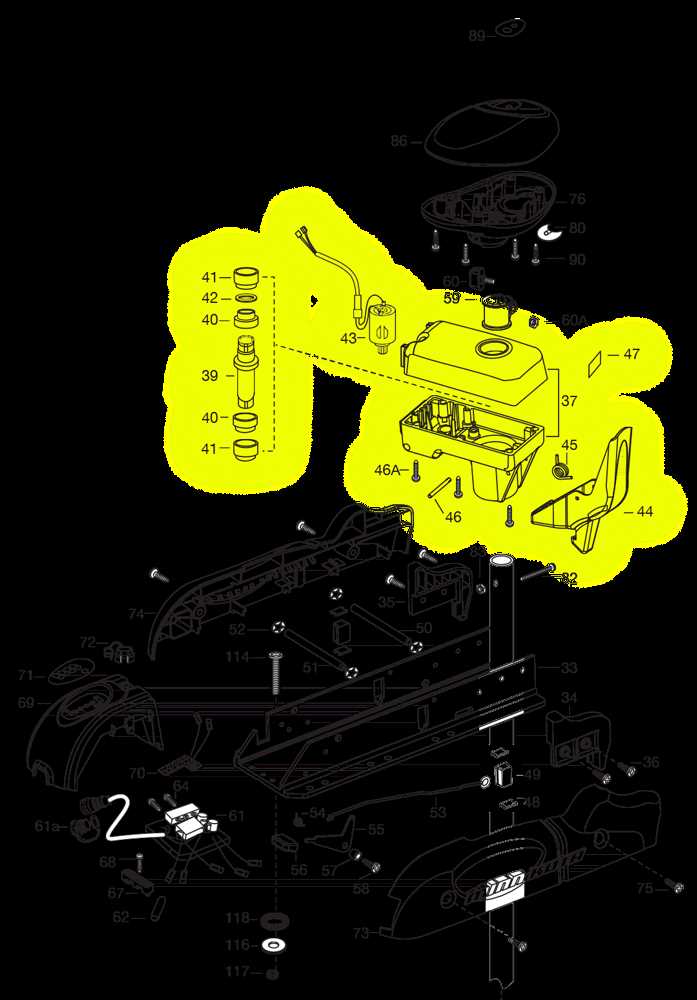

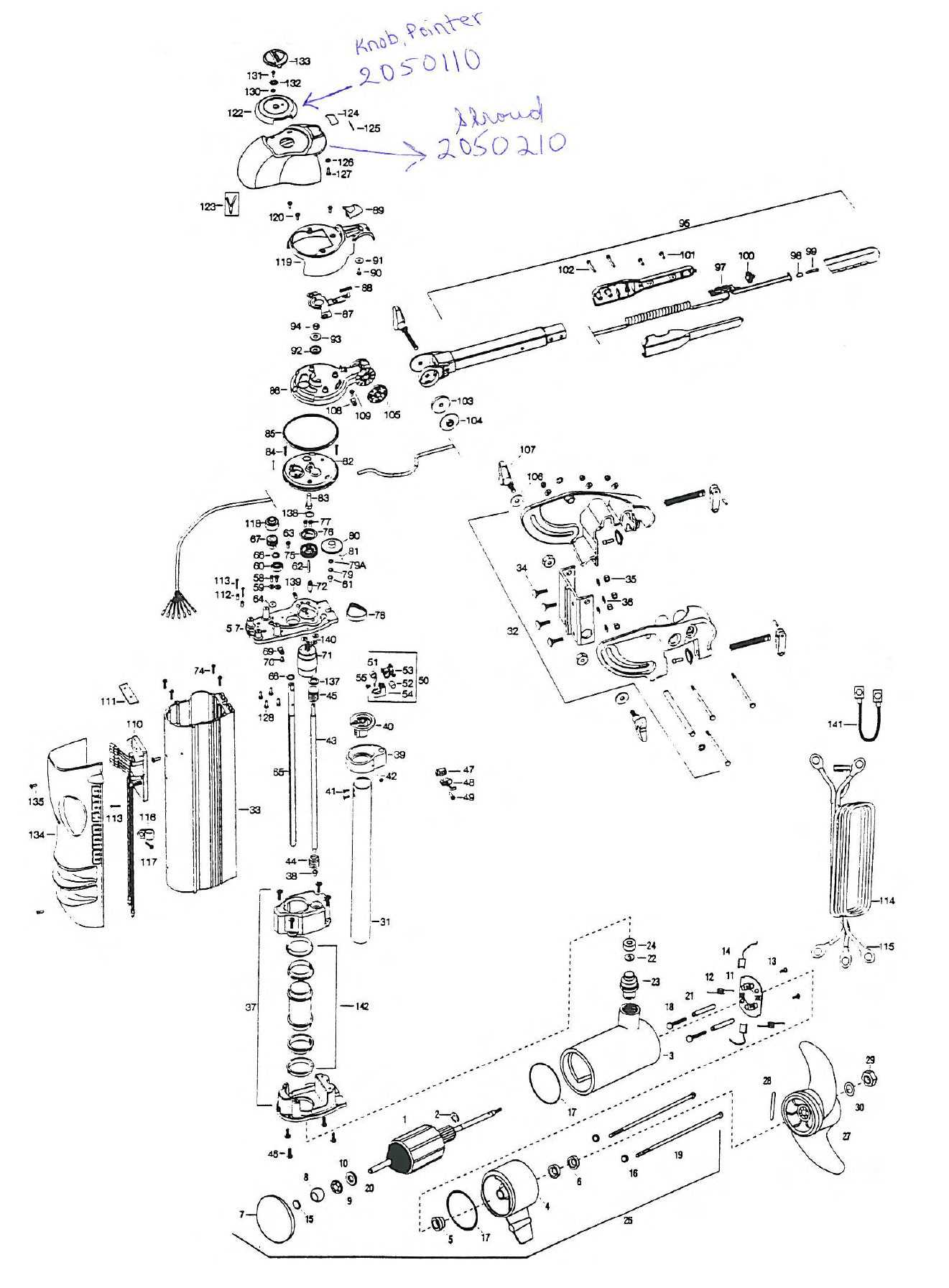

Essential Components Explained

Understanding the key elements of a propulsion system is crucial for effective maintenance and optimal performance. Each component plays a vital role, contributing to the overall functionality and efficiency of the unit. Familiarity with these elements can enhance user experience and ensure longevity.

| Component | Description |

|---|---|

| Propeller | Designed to convert rotational motion into thrust, enhancing maneuverability on the water. |

| Power Supply | Provides the necessary energy to the system, typically sourced from batteries. |

| Control System | Facilitates user interaction, allowing for speed adjustment and directional control. |

| Mounting Bracket | Secures the unit to the vessel, ensuring stability and proper alignment during operation. |

| Steering Mechanism | Enables precise navigation, allowing for easy directional changes while underway. |

Understanding Wiring Diagrams

Wiring schematics serve as essential guides in the world of electrical systems. They provide a visual representation of connections and components, helping users grasp the layout and functionality of the entire setup. By decoding these illustrations, one can better understand how different elements interact within the circuitry.

These diagrams typically include various symbols and lines that indicate connections, making it easier to troubleshoot and maintain electrical systems. Familiarizing oneself with these symbols is crucial for effective interpretation.

- Components: Representations of items such as switches, connectors, and power sources.

- Connections: Lines that show how components are linked, indicating the flow of electricity.

- Symbols: Standardized icons that denote specific functions or types of connections.

Understanding these key elements allows for better planning and execution of repairs or upgrades. When tackling any electrical project, referring to a schematic can save time and prevent costly mistakes.

- Identify each component based on its symbol.

- Trace the connections to understand the flow of electricity.

- Use the diagram as a roadmap for installation or troubleshooting.

Mastering wiring schematics not only enhances one’s technical skills but also instills confidence in managing electrical systems effectively.

Maintenance Tips for Longevity

Ensuring the durability and optimal performance of your equipment requires regular upkeep and attention to detail. By following specific care routines, you can significantly extend the lifespan of your gear and enhance its functionality. Here are some essential maintenance tips to consider.

- Regular Cleaning: After each use, clean the unit to remove debris and saltwater, which can lead to corrosion.

- Check Connections: Periodically inspect electrical connections for signs of wear or corrosion. Secure any loose connections.

- Battery Care: Maintain batteries by keeping them charged and clean. Store them in a cool, dry place when not in use.

- Lubrication: Apply appropriate lubricants to moving parts to reduce friction and prevent wear.

- Inspection: Regularly examine all components for cracks or damage. Address any issues immediately to avoid further problems.

Implementing these maintenance practices can lead to enhanced reliability and efficiency, ensuring your equipment serves you well for years to come.

Common Replacement Parts

When maintaining a boat’s propulsion system, certain components may require replacement over time due to wear and tear. Understanding which elements are frequently substituted can help ensure optimal performance and longevity of the equipment.

- Propellers: These are essential for movement and may become damaged or corroded, necessitating replacement.

- Battery Cables: Over time, cables can fray or corrode, impacting efficiency and power delivery.

- Brushes: Often found in electric systems, worn brushes can reduce performance and should be checked regularly.

- Control Cables: These facilitate operation and can wear out, leading to responsiveness issues.

- Fuse Kits: Fuses protect against electrical overloads and may need replacement if blown.

Regularly inspecting and replacing these components can significantly enhance the functionality and reliability of your vessel’s propulsion system. Familiarity with these common elements helps in planning for maintenance and avoiding unexpected failures.

How to Identify Issues

Recognizing problems in your equipment is crucial for maintaining optimal performance. Various symptoms can indicate underlying issues that require attention. By understanding these signs, you can ensure that your gear remains in top condition and operates efficiently.

Common Symptoms to Watch For

- Unusual noises during operation

- Inconsistent power output

- Physical damage to components

- Unresponsive controls

- Overheating after short use

Steps to Diagnose Problems

- Conduct a visual inspection of all components.

- Listen for any irregular sounds while in operation.

- Check connections and wiring for wear or corrosion.

- Test the functionality of controls and settings.

- Monitor performance metrics to identify discrepancies.

By following these guidelines, you can effectively pinpoint potential issues and take appropriate corrective measures to enhance the longevity and efficiency of your equipment.

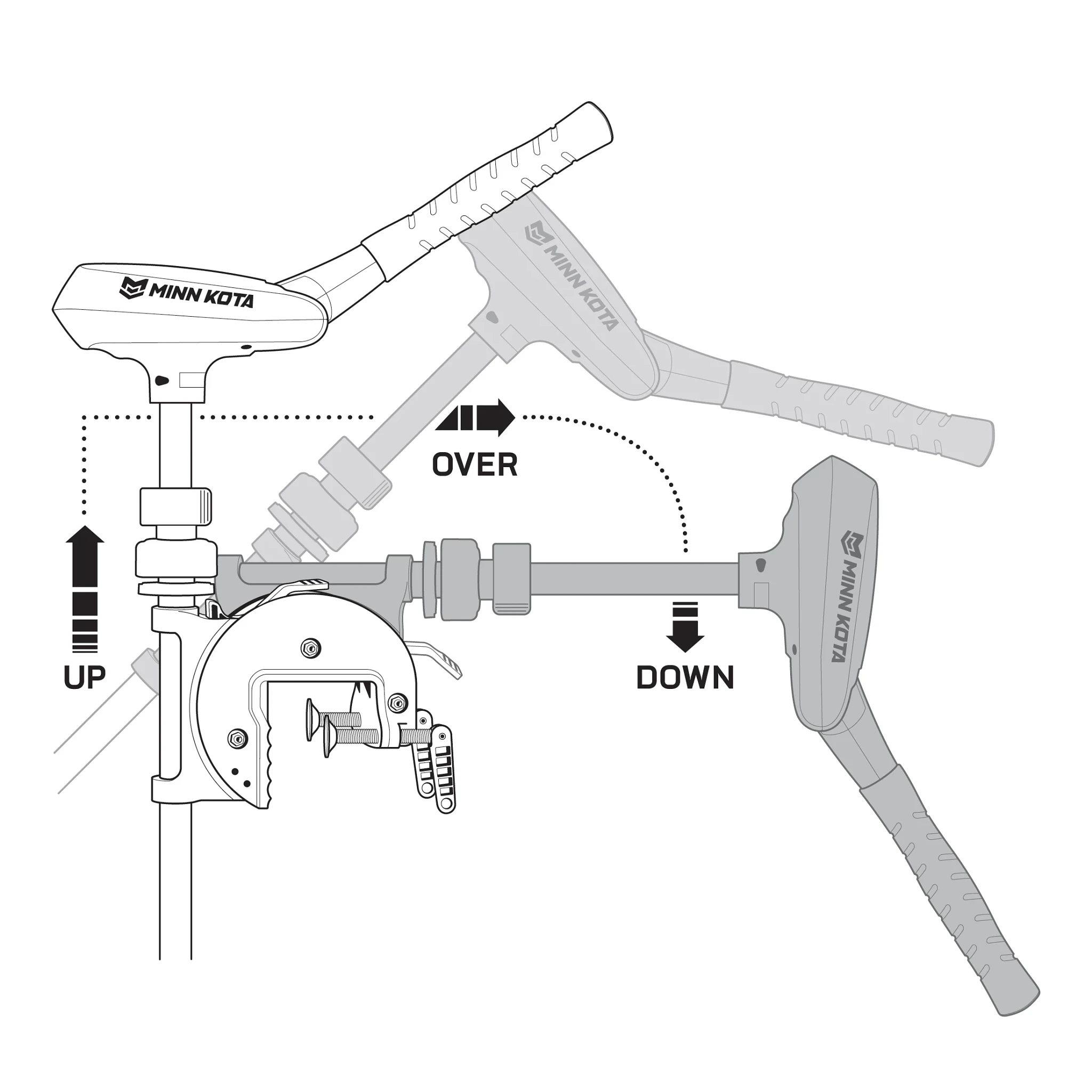

Assembly and Disassembly Guide

This section provides a comprehensive overview of the procedures involved in assembling and disassembling your equipment. Understanding these steps is crucial for maintenance, repairs, and ensuring optimal performance. Proper handling during these processes can significantly extend the lifespan of your apparatus.

Before starting, ensure you have all necessary tools at hand. Here’s a checklist of items you may need:

- Screwdrivers (flathead and Phillips)

- Wrenches

- Pliers

- Lubricant

- Cleaning cloth

Follow these steps for disassembly:

- Begin by disconnecting the power source to prevent any accidental activation.

- Carefully remove any coverings or protective shields.

- Loosen and remove fasteners that secure various components.

- Take out individual parts in a logical order to avoid confusion during reassembly.

- Keep track of all removed items, possibly using labeled containers.

For assembly, adhere to the following guidelines:

- Start with the main unit and ensure it is clean and free from debris.

- Reattach components in the reverse order of disassembly, ensuring each part fits securely.

- Use appropriate fasteners and tighten them to the manufacturer’s specifications.

- Reinstall any coverings or shields that were previously removed.

- Finally, reconnect the power source and perform a function test to ensure everything operates correctly.

Following these detailed instructions will help maintain the functionality and reliability of your equipment. Regular checks and servicing can prevent unexpected issues and enhance overall performance.

Upgrades for Enhanced Performance

Improving the functionality of your propulsion system can significantly enhance your overall experience on the water. Various upgrades can provide better efficiency, increased speed, and extended battery life, allowing you to enjoy longer outings with less hassle. Whether you are a casual angler or an avid adventurer, investing in these enhancements will optimize your setup for superior performance.

Battery Optimization

One of the most impactful upgrades is selecting a high-capacity battery. Lithium-ion options, for instance, offer a lighter weight and longer lifespan compared to traditional lead-acid batteries. Additionally, incorporating smart charging systems can ensure your power source is always ready for action, providing consistent performance throughout your trips.

Propeller Enhancements

Upgrading your propeller can lead to noticeable improvements in efficiency and speed. Choosing a propeller designed for specific water conditions can optimize thrust and minimize drag. Stainless steel models, for example, tend to offer better durability and performance compared to plastic variants, making them a worthwhile investment for serious enthusiasts.