In the realm of farming machinery, understanding the intricate elements that ensure optimal performance is crucial. Each component plays a vital role in enhancing efficiency and productivity on the field. This exploration aims to clarify these elements, highlighting their significance and functionality.

Visualizing the assembly of these implements can provide valuable insights for maintenance and repair tasks. A detailed breakdown of the various elements reveals how they interact to achieve seamless operation. This knowledge is essential for both enthusiasts and professionals alike.

As we delve deeper into this topic, we will uncover the ultimate guide to recognizing each segment’s purpose. By familiarizing ourselves with these components, we equip ourselves with the tools needed for effective management of agricultural tasks.

Understanding the John Deere Sickle Mower

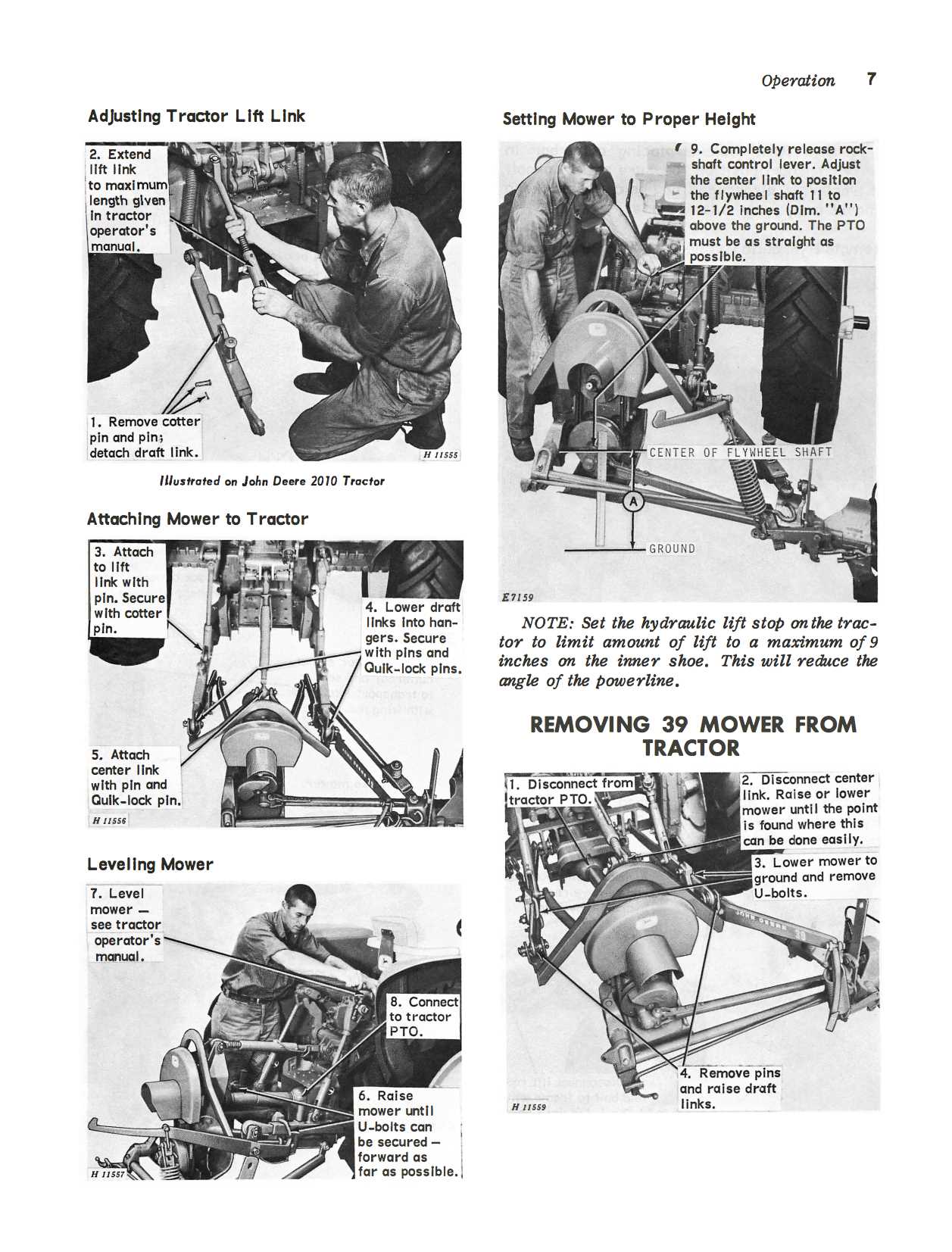

This section aims to provide insight into a specific type of agricultural implement designed for cutting and harvesting. These machines are essential tools for maintaining fields and ensuring efficient crop management. By examining their components and functionality, users can gain a better understanding of how to optimize their use for various farming tasks.

The implement typically consists of a series of sharp blades that work in a coordinated motion to slice through vegetation. This design allows for a clean cut, promoting healthier regrowth and easier harvesting processes. The mechanism operates through a series of linkages and levers, which translate the operator’s movements into precise actions, enhancing efficiency in the field.

Familiarity with the various elements of this equipment is crucial for maintenance and troubleshooting. Each component plays a significant role in overall performance, and understanding how they interact can prevent common issues. Regular inspections and timely replacements of worn parts ensure that the machine remains in optimal condition, thus extending its lifespan and improving productivity.

Furthermore, knowledge of adjustments and settings can significantly impact the quality of the work performed. Different crops and field conditions may require specific configurations, highlighting the importance of adaptability in using this type of equipment. Overall, mastering the intricacies of this implement empowers users to achieve better results and maximize their operational efficiency.

Importance of Proper Maintenance

Ensuring the longevity and efficiency of agricultural equipment relies heavily on regular upkeep and attention. By implementing a comprehensive maintenance strategy, operators can avoid costly repairs and enhance the performance of their machinery. This proactive approach not only prolongs the lifespan of the equipment but also promotes safety during its operation.

Regular inspection and servicing help identify potential issues before they escalate into significant problems. Neglecting maintenance can lead to diminished performance, increased fuel consumption, and unexpected breakdowns. Operators should prioritize routine checks and adhere to manufacturer recommendations to achieve optimal functioning.

| Maintenance Task | Frequency | Benefits |

|---|---|---|

| Inspect Blades | Monthly | Ensures effective cutting and prevents damage to crops |

| Lubricate Moving Parts | Weekly | Reduces wear and tear, improving efficiency |

| Check Fluid Levels | Before Use | Prevents overheating and maintains optimal performance |

| Tighten Fasteners | Monthly | Enhances safety and reliability during operation |

| Clean Equipment | After Each Use | Prevents rust and buildup, ensuring longevity |

Investing time and effort into proper maintenance not only safeguards the investment in machinery but also boosts overall productivity. By staying vigilant and committed to regular upkeep, operators can ensure their equipment remains in peak condition, ready to tackle any task effectively.

Common Issues with Sickle Mowers

Equipment designed for cutting grass and similar vegetation can experience a variety of challenges during operation. Understanding these common issues can help operators maintain efficiency and prolong the lifespan of their machines. Identifying problems early can lead to quicker resolutions, ensuring smooth performance.

- Uneven Cutting: This can result from dull blades or improper adjustment. Regularly sharpening blades and checking height settings can prevent this issue.

- Jamming: Debris such as tall grass or rocks can cause blockages. Clearing the cutting area and performing routine maintenance can reduce the likelihood of jamming.

- Excessive Vibration: This may occur due to loose components or imbalance. Regular inspections and tightening of hardware can help minimize vibrations during use.

- Wear and Tear: Components such as belts and bearings can degrade over time. Scheduled replacements and lubrication can extend the life of these parts.

- Hydraulic Issues: Low fluid levels or leaks can affect the performance of hydraulic systems. Regular checks and maintenance of hydraulic fluid can prevent malfunctions.

By being aware of these potential issues, operators can take proactive steps to ensure that their cutting machinery operates effectively and efficiently.

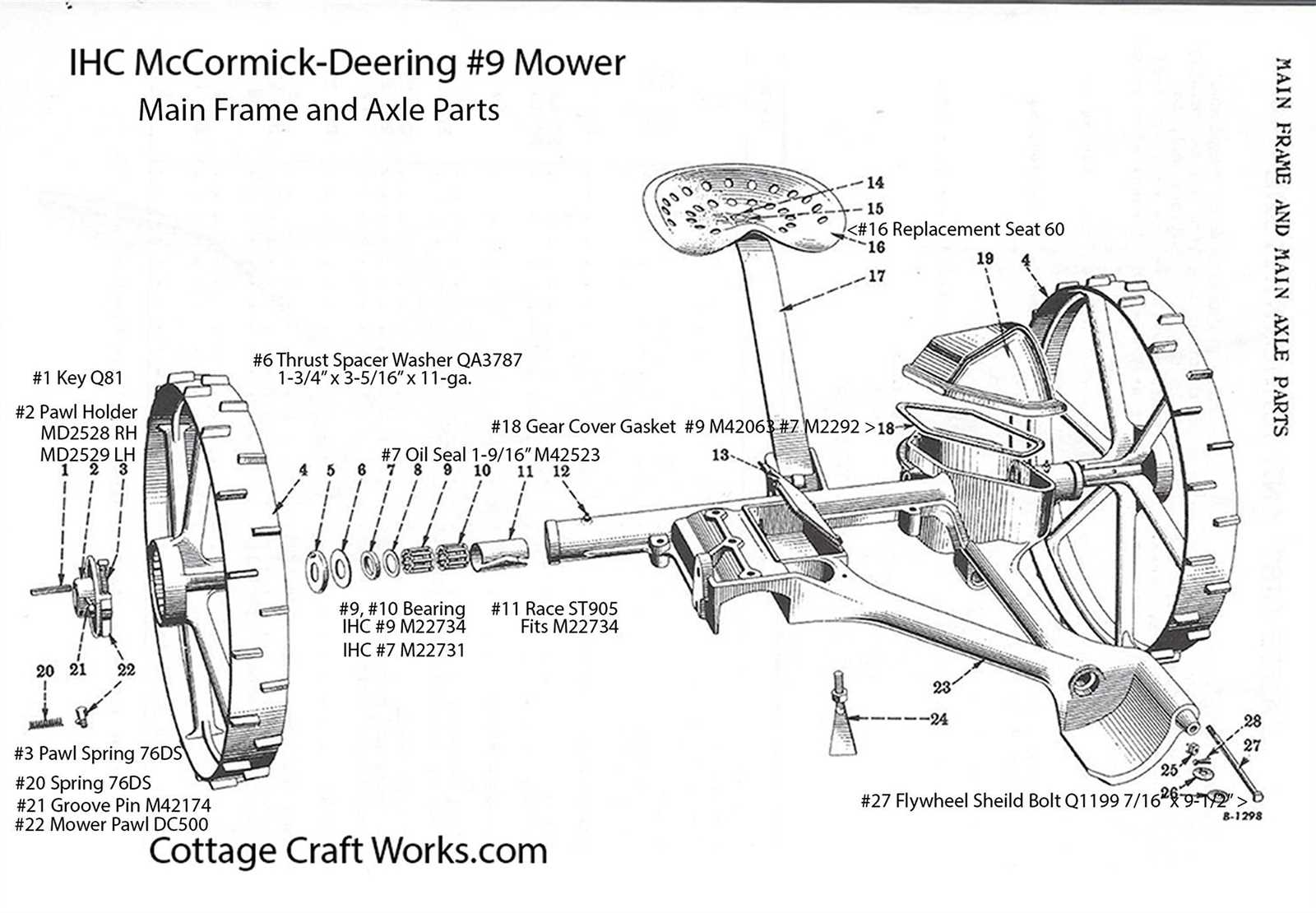

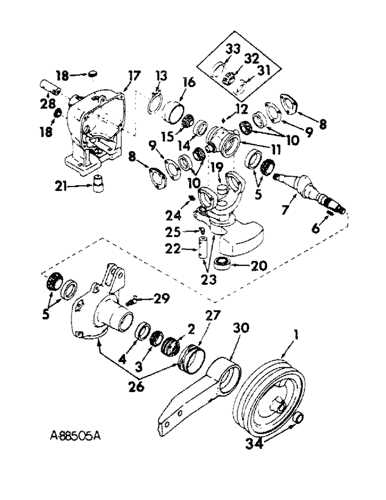

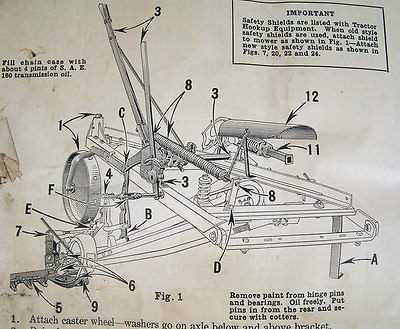

Identifying Key Components in Diagrams

Understanding the essential elements within mechanical illustrations is crucial for effective maintenance and repair. Recognizing each component’s role enhances comprehension and ensures accurate assembly and disassembly. This knowledge is particularly beneficial for those working with agricultural machinery, as it fosters confidence in handling various tasks.

Common Elements to Look For

When analyzing an illustration, focus on identifying the primary components. Each part usually has a designated label or number, aiding in quick reference and ordering replacements if necessary. Familiarizing oneself with these symbols can significantly streamline the troubleshooting process.

Interpreting the Layout

Understanding the spatial arrangement of parts is equally important. The layout often reveals how components interact with one another, offering insight into the overall functionality. Pay attention to connections, as they indicate how power or motion is transferred through the system.

| Component | Description |

|---|---|

| Drive System | Transmits power from the engine to various attachments. |

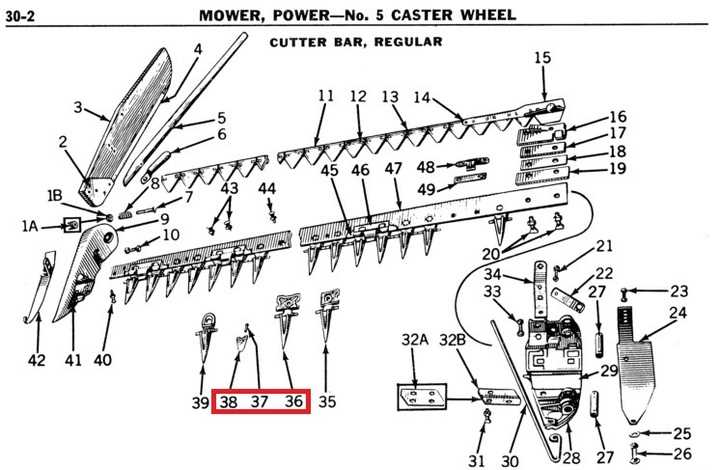

| Cutter Bar | Main element responsible for cutting; often features multiple blades. |

| Frame | Provides structural integrity and support for other components. |

| Adjustments | Mechanisms allowing for height and angle modifications. |

Replacement Parts for Model Number 5

When maintaining or restoring agricultural equipment, sourcing the correct components is crucial for optimal performance. Understanding the various elements that comprise this specific model can enhance its longevity and functionality. In this section, we will explore essential substitutes and accessories that can help you keep your machinery in top shape.

Common Components and Their Functions

- Blades: Vital for cutting efficiency, blades must be sharp and in good condition to ensure precise operation.

- Belts: These ensure proper power transmission between different parts, facilitating smooth functioning.

- Bearings: Integral for reducing friction, bearings allow for smoother movement of moving parts.

- Knives: Designed for cutting, they should be regularly inspected and replaced as necessary to maintain performance.

Where to Find Quality Replacements

Quality components can be obtained from a variety of sources. Here are some reliable options:

- Authorized Dealers: They offer genuine components that ensure compatibility and reliability.

- Online Retailers: Numerous platforms provide a wide range of substitutes, often with customer reviews for reference.

- Local Farm Supply Stores: These establishments may stock common items and can offer expert advice.

Investing in quality replacements not only improves functionality but also prolongs the lifespan of your equipment.

Tools Required for Repairs

When undertaking maintenance or repairs on agricultural equipment, having the right tools is crucial for ensuring efficiency and effectiveness. A well-equipped toolkit not only simplifies the process but also enhances safety, reducing the likelihood of accidents and injuries. The selection of tools can vary depending on the specific tasks at hand, but there are fundamental items that are essential for any repair job.

Basic Hand Tools: A set of quality hand tools should include wrenches, pliers, and screwdrivers. These items are necessary for loosening and tightening fasteners, as well as making minor adjustments. Ensure that the tools are comfortable to use and suitable for the various sizes of bolts and screws typically found on the equipment.

Specialized Tools: In addition to standard hand tools, some repairs may require specialized instruments. These can include torque wrenches for applying precise force, alignment tools for ensuring components are correctly positioned, and gauges for measuring wear and tear on parts.

Safety Equipment: Safety should always be a top priority when performing repairs. Protective gear such as gloves, goggles, and ear protection will help safeguard against injuries from sharp edges, flying debris, and loud noises. Investing in high-quality safety equipment is just as important as the tools themselves.

Cleaning Supplies: Keeping the workspace organized and clean is vital. Having cleaning supplies such as rags, degreasers, and brushes will help maintain equipment and facilitate thorough inspections, ensuring all parts are in optimal condition before reassembly.

By assembling a comprehensive toolkit with both standard and specialized tools, individuals can confidently tackle repairs, leading to more reliable operation and longevity of the machinery.

Where to Buy Replacement Parts

Finding suitable components for agricultural machinery is essential for maintaining efficiency and performance. Fortunately, there are various avenues available for sourcing high-quality alternatives that can keep your equipment running smoothly.

Online Retailers: The internet offers a vast array of platforms specializing in machinery components. Websites dedicated to agricultural equipment often provide comprehensive catalogs, allowing users to search for specific items easily. These platforms frequently include user reviews and detailed product descriptions, aiding in informed purchasing decisions.

Local Dealers: Many equipment dealerships carry an inventory of necessary items for farm machinery. Visiting a local dealer can provide not only immediate access to the required components but also the opportunity to consult with knowledgeable staff who can offer advice on installation and compatibility.

Salvage Yards: Salvage yards can be a treasure trove for those looking for specific pieces at a lower cost. Many of these establishments dismantle old equipment, making it possible to find rare or discontinued items that might otherwise be difficult to source.

Manufacturer’s Website: Directly accessing the manufacturer’s official website can yield valuable information regarding availability and compatibility. Many manufacturers provide online ordering options, ensuring that customers receive original equipment with reliable quality.

Trade Shows and Expos: Attending agricultural trade shows or expos presents a unique opportunity to connect with suppliers and manufacturers. These events often showcase new products and innovations, allowing attendees to discuss their needs with industry professionals.

By exploring these options, you can ensure that your agricultural machinery remains in optimal condition and continues to serve you well in the field.

Tips for Efficient Operation

Maximizing productivity while maintaining equipment longevity is essential for any operator. By adopting best practices and ensuring proper maintenance, one can significantly enhance the performance of their machinery.

Routine Maintenance

Regular check-ups and servicing are crucial. This includes cleaning components, checking fluid levels, and inspecting belts for wear. Keeping everything in optimal condition reduces downtime and improves efficiency.

Operating Techniques

Employing the right techniques can make a notable difference in effectiveness. Adjusting speed based on conditions and maintaining a steady pace can lead to a smoother operation and better results.

| Tip | Description |

|---|---|

| Regular Lubrication | Ensure all moving parts are adequately lubricated to prevent friction and wear. |

| Proper Settings | Adjust settings according to the terrain and crop type for optimal results. |

| Pre-Operation Checks | Conduct thorough checks before use to identify any potential issues early. |

FAQs about Sickle Mower Maintenance

Proper upkeep of your cutting equipment is essential for optimal performance and longevity. Addressing common questions can help ensure that your machinery remains in peak condition, ultimately enhancing efficiency and reducing downtime.

What are the signs that my equipment needs maintenance?

Look for unusual noises, decreased cutting efficiency, and visible wear on components. Regularly checking for loose bolts and ensuring lubrication can prevent more significant issues.

How often should I service my machinery?

It is recommended to perform maintenance checks at the start of each season and after heavy use. Keeping a routine schedule will help catch problems early and extend the life of your equipment.